[178] In the course of its investigation, the Commission became aware of a number of matters that played no part in the mission 51-L accident but nonetheless hold a potential for safety problems in the future.

Some of these matters, those involving operational concerns, were brought directly to the Commission's attention by the NASA astronaut office. They were the subject of a special hearing.

Other areas of concern came to light as the Commission pursued various lines of investigation in its attempt to isolate the cause of the accident. These inquiries examined such aspects as the development and operation of each of the elements of the Space Shuttle-the Orbiter, its main engines and the External Tank; the procedures employed in the processing and assembly of 51-L, and launch damage.

This chapter examines potential risks in two general areas. The first embraces critical aspects of a Shuttle flight; for example, considerations related to a possible premature mission termination during the ascent phase and the risk factors connected with the demanding approach and landing phase. The other focuses on testing, processing and assembling the various elements of the Shuttle.

Ascent: A Critical Phase

The events of flight 51-L dramatically illustrated the dangers of the first stage of a Space Shuttle ascent. The accident also focused attention on the issues of Orbiter abort capabilities and crew escape. Of particular concern to the Commission are the current abort capabilities, options to improve those capabilities, options for crew escape and the performance of the range safety system .

It is not the Commission's intent to second-guess the Space Shuttle design or try to depict escape provisions that might have saved the 51-L crew. In fact, the events that led to destruction of the Challenger progressed very rapidly and without warning. Under those circumstances, the Commission believes it is highly unlikely that any of the systems discussed below, or any combination of those systems, would have saved the flight 51-L crew.

Abort Capabilities

Various unexpected conditions during ascent can require premature termination of a Shuttle mission. The method of termination, or abort, depends upon the nature of the unexpected condition and when it occurs.

The Space Shuttle is lifted to orbit by thrust from its two solid rockets and three main engines. The design criteria for the Shuttle specify that, if a single main engine is lost at any time between lift off and normal main engine cut off, the Shuttle must be able to continue to orbit or to execute an intact abort, that is, make a survivable landing on a runway. That design requirement has been met. If a single main engine is lost early in ascent, the Shuttle can return to make an emergency landing at Kennedy (a return-to-launch-site abort). If the failure occurs later, the Shuttle can make an emergency landing in Africa or Europe (a transatlantic abort landing). If the failure occurs during the last part of the ascent, the Shuttle can proceed around the Earth to a [179] landing in the continental United States (abort once around), or can continue to a lower-than-planned orbit (abort to orbit). Indeed, if the failure occurs late enough, the Shuttle will achieve the intended orbital conditions.

Return-to-Launch-Site Abort. If the termination is necessary because of loss of a main engine during the first four minutes of flight, the Shuttle has the capability to fly back to the launch site. It continues downrange to burn excess propellant, and at the proper point it turns back toward Florida. The computers shutdown the remaining two engines and separate the Orbiter from the External Tank, which falls into the Atlantic Ocean. The Orbiter then glides to a landing on the runway at the Shuttle Landing Facility at Kennedy.

Transatlantic Abort. During ascent there comes a time when the Shuttle is too far downrange to fly back to Kennedy. If it suffers an engine failure after that point, but has not yet achieved enough energy to continue toward orbit, it will have to land on the other side of the Atlantic. It will continue on a special flight path until it achieves the energy necessary to glide to the landing site. At that point the Shuttle computers will cut off the two remaining engines and separate the Orbiter from the External Tank. The...

[180] ....Shuttle will then re-enter the lower atmosphere much like a normal entry. The landing, however, will be at a pre-selected site in Africa or Europe.

Design. The Shuttle design specifications do not require that the Orbiter be able to manage an intact abort (i.e., make it to a runway) if a second main engine should fail. If two (or all three) main engines fail within the first five to six minutes of the flight, the Space Shuttle will land in water. This maneuver is called a "contingency abort" and is not believed to be survivable because of damage incurred at water impact.

The Shuttle design requirements did not specify that the Shuttle should be able to survive a Solid Rocket Booster failure. The system has no way to identify when a booster is about to fail, and no way to get the Orbiter or the crew away from a failing Solid Rocket Booster.

Crew survival during ascent rests on the following assumptions:

1. The Solid Rocket Boosters will work from ignition to planned separation.

2. If more than one main engine fails, the crew must be able to survive a water landing.

Shuttle Abort Enhancements

Between 1973 and 1983, first stage abort provisions were assessed many times by all levels of NASA management. Many methods of saving the Orbiter and/or crew from emergencies during first stage were considered.

Ejection seats (which afforded only limited protection during first stage) were provided for the two-man crews of the Orbital Flight Test program (the first four Shuttle flights). Other options for "operational" flights carrying crews of five or more astronauts were considered, but were not implemented because of limited utility, technical complexity and excessive cost in dollars, weight or schedule delays.

Because of these factors, NASA adopted the philosophy that the reliability of first stage ascent must be assured, and that design and testing must preclude time critical failures that would require emergency action before normal Solid Rocket Booster burnout. That philosophy has been reviewed many times during the Space Shuttle program and is appropriately being reevaluated, as are all first stage abort options, in light of the 51-L accident.

Early Orbiter Separation

If a problem arose that required the Orbiter to get away from failing Solid Rocket Boosters, the separation would have to be performed extremely quickly. Time would be of the essence for two reasons. First, as 51-L demonstrated, if a problem develops in a Solid Rocket Booster, it can escalate very rapidly. Second, the ascent trajectory is carefully designed to control the aerodynamic loads on the vehicle; very small deviation from the normal path will produce excessive loads, so if the vehicle begins to diverge from its path there is very little time (seconds) before structural breakup will occur.

The normal separation sequence to free the Shuttle from the rest of the system takes 18 seconds, far too long to be of use during a firststage contingency. "Fast-separation" was formally established by Review Item Discrepancy 03.00.151, which stated the requirement to separate the Orbiter from the External Tank at any time. The sequence was referred to as fast-separation because delays required during normal separation were bypassed or drastically shortened in order to achieve separation in approximately three seconds. Some risk was accepted to obtain this contingency capability. Fast-separation was incorporated into the flight software, so that technically this capability does exist. Unfortunately, analysis has shown that, if it is attempted while the Solid Rocket Boosters are still thrusting, the Orbiter will "hang up" on its aft attach points and pitch violently, with probable loss of the Orbiter and crew.

In summary, as long as the Solid Rocket Boosters are still thrusting, fast-separation does not provide a way to escape. It would be useful during first stage only if Solid Rocket Booster thrust could first be terminated.

The current concept of fast-separation does, however, have some use. Contingency aborts resulting from loss of two or three main engines early in ascent are time-critical, and every fraction of a second that can be trimmed from the separation sequence helps. These abort procedures are executed after the Solid Rocket Boosters are expended, and fast-separation is used to reduce the time required for separation as the Shuttle must attain entry attitude very quickly. Unfortunately, all contingency aborts culminate in water impact.

[181] Thrust Termination

Thrust termination (or thrust neutralization) as originally proposed for the Space Shuttle was a concept conceived for the Titan 3-M booster intended for use in the Manned Orbiting Laboratory Program. The objective of thrust termination is to either extinguish or reduce the thrust of the Solid Rocket Booster in an emergency situation. With this thrust terminated, emergency options such as crew ejection or fast-separation might become feasible during the first two minutes of flight.

The principal drawback is that thrust termination itself introduces high dynamic loads that could cause Shuttle structural components to fail. Early design reviews suggested that to strengthen the Orbiter to withstand the stresses caused by rapid thrust termination would require an additional, prohibitive 19,600 pounds. Thrust termination was deleted from design consideration on April 27, 1973, by Space Shuttle Directive SS00040. Key factors in the decision were that (l) proper design would be stressed to prevent Solid Rocket Booster failure and (2) other firststage ascent systems provided enough redundancy to allow delaying an abort until after the Solid Rocket Boosters burned out.

The subject arose again in 1979 when Space Shuttle Directive S13141 required the system contractor to determine the time over which thrust reduction must be spread so that the deceleration loads would not destroy the Orbiter. Marshall analyzed the thrust decay curves submitted by the contractor and concluded that achieving the required thrust decay rates was impractical.

On July 12, 1982, the Associate Administrator for Space Transportation Systems requested reconsideration of thrust termination. Gerald Griffin, director of Johnson, responded to the request in a letter dated September 9, 1982, as follows:

"In our opinion, further study of a thrust termination system for the SRB [Solid Rocket Booster] would not be productive. The potential failure modes which could result in a set of conditions requiring SRB thrust termination are either very remote or a result of primary structural failure. The structural failure risk would normally be accepted as a part of the factor of safety verification by analysis or test. In addition, any thrust termination system is going to be extremely heavy, very costly and, at best, present some risk to the Orbiter and ET [External Tank]. Venting of' trot gases and the shock load or pressure spike, have the potential for being as great a hazard as the problem to be corrected. It does not appear that a practical approach exists for achieving the desired pressure decay rate without a major redesign of the motor."1

In retrospect, the possibility of Solid Rocket Booster failures was neither very remote nor limited to primary structural failure.

Although it would not have helped on mission 51-L, thrust termination is the key to any successful first-stage abort, and new ideas and technologies should be examined. If a thrust termination system is eventually deemed feasible (that is, the Orbiter/External Tank will still be intact after the rapid deceleration), it cannot have failure modes that would cause an uncommanded neutralization of the thrust of one or both of the Solid Rocket Boosters. If thrust termination were to be implemented, reliable detection mechanisms and reliable decision criteria would be mandatory.

Ditching

As previously discussed, most contingency aborts (those resulting from failure of two or three main engines during the first five to six minutes of flight) result in a water landing, or ditching. In addition, if the Space Shuttle did have a thrust termination capability to use with fast-separation to allow it to separate from failing solid rockets, the Orbiter would have to ditch in the water unless the failure occurred during a small window 50-70 seconds after launch. Accordingly, whether the crew can survive a water impact is a critical question.

In 1974 and 1975, ditching studies were conducted at Langley Research Center. Although test limitations precluded definitive conclusions, the studies suggested that the loads at water impact would be high. The deceleration would most probably cause structural failure of the crew cabin support ties to the fuselage, which would impede crew egress and possibly flood the cabin. Furthermore, payloads in the cargo bay are not designed to withstand decelerations as high as those expected, 2 and would very possibly break free and travel forward to the crew cabin. The Langley report does state that the Orbiter shape and mass [182] properties are good for ditching, but given the structural problems and deceleration loads, that is little consolation.

Orbiter ditching was discussed by the Crew Safety Panel and at Orbiter flight techniques meetings before the first Shuttle flight. The consensus of these groups was that (1) ditching is more hazardous than suggested by the early Langley tests, and (2) ditching is probably not survivable.

This view was reiterated in the September 9, 1982, letter from Griffin to Abrahamson:

"We also suggest no further effort be expended to study bailout or ditching. There is considerable doubt that either case is technically feasible with the present Orbiter design. Even if a technical solution can be found, the impact of providing either capability is so severe in terms of cost and schedule as to make them impractical."

There is no evidence that a Shuttle crew would survive a water impact. Since all contingency aborts and all first stage abort capabilities that are being studied culminate in a water impact, an additional provision for crew escape before impact should also be considered.

Astronaut Paul Weitz expressed this before the Commission on April 3, 1986:

"My feeling is so strong that the Orbiter will not survive a ditching, and that includes land, water or any unprepared surface....

"I think if we put the crew in a position where they're going to be asked to do a contingency abort, then they need some means to get out of the vehicle before it contacts earth, the surface of the earth."3

Crew Escape Options

In a study conducted before the Orbiter contract was awarded, Rockwell International evaluated a range of ejection systems (Rockwell International, Incorporated, Phase B Study, 1971). The table shows the results comparing three systems: ejection seats, encapsulated ejection seats and a separable crew compartment. The development costs are in 1971 dollars, and the costs and weights cited were those required to incorporate these systems into the developing Orbiter design, not to modify an existing Orbiter.

The only system that could provide protection for more than the two-man experimental flight crew was the separable crew compartment, which would add substantial weight and development cost. All of these systems had limitations in their ability to provide successful escape, and all would require advance warning of an impending hazard from reliable data sources.

The Request for Proposal, written in April, 1971 (reference paragraph 1.3.6.2.1), states: "Provisions shall be made for rapid emergency egress of the crew during development test flights." Ejection seats were selected as the emergency escape system. The objective was to offer the crew some protection, though limited, from risks of the test flights. The philosophy was that after the test flights, all unknowns would be resolved, and the vehicle would be certified for "operational" flights.

Conventional ejection seats similar to those installed in the Lockheed F-12/SR-71 were selected shortly after the Orbiter contract was awarded. They were subsequently incorporated into Columbia and were available for the first four flights. The ejection could be initiated by either crew member and would be used in the event of.....

1971 Rockwell Data on Ejection

Systems

.

Type

.

Open Ejection Seat

B-70 Encapsulated Seat

Separable Crew Compartment

[183] .....uncontrolled flight, on-board fire or pending landings on unprepared surfaces. The escape sequence required approximately 15 seconds for the crew to recognize pending disaster, initiate the sequence and get a safe distance away from the vehicle.

Although the seats were originally intended for use during first-stage ascent or during gliding flight below 100,000 feet, analysis showed that the crew would be exposed to the Solid Rocket Booster and main engine exhaust plumes if they ejected during ascent. During descent, the seats provided good protection from about 100,000 feet to landing.

After the Space Shuttle completed the four test flights it was certified for"operational" flights. But missions for the "operational" flights required more crew members, and there were no known ejection systems, other than an entire cabin escape module, that could remove the entire crew within the necessary time. The Orbiter configuration allowed room for only two ejection seats on the flight deck. With alternative ejection concepts and redesign of the flight deck, this number might have been increased slightly, but not to the full crew size. Thus, because of' limited utility during first- stage ascent and inability to accommodate a full crew, the ejection seats were eliminated for operational flights.

The present Shuttle has no means for crew escape, either during first-stage ascent or during gliding flight. Conventional ejection seats do not appear to be viable Space Shuttle options because they severely limit the crew size and, therefore, prevent the Space Shuttle from accomplishing its mission objectives. The remaining options fall into three categories:

1. Escape Module. The entire crew compartment would be separated from the Orbiter and descend by parachute.

2. Rocket-assisted Extraction. Many military aircraft employ a system using a variety of small rocket-assisted devices to boost occupants from the plane. Such a system could be used in the Orbiter.

3. Bail-Out System. The crew can exit unassisted through a hatch during controlled, gliding flight.

Only one of these, the escape module, offers the possibility of escape during first-stage ascent.

Its use would probably be practical only after thrust termination. It should be noted that in all cases of crew escape, the Orbiter would be lost, but in cases of Solid Rocket Booster failure or Orbiter ditching the vehicle would be lost anyway. The utility and feasibility of each method are described below.

An escape module can offer an opportunity for crew escape at all altitudes during a first-stage time-critical emergency if the escape system itself is not damaged to the point that it cannot function. The module must be sufficiently far from the vehicle at the time of catastrophe that neither it nor its descent system is destroyed. Incorporation of an escape module would require significant redesign of the Orbiter: some structural reinforcement, pyrotechnic devices to sever the escape module from the rest of the Orbiter, modifications to sever connections that supply power and fluids, separation rockets and a parachute system. An additional weight penalty would result from the requirement to add mass in the rear of the Orbiter to compensate for the forward shift in the c enter of gravity. Recent estimates indicate this could add as much as 30,000 pounds to the weight of' the Orbiter.4 This increase in weight would reduce payload capacity considerably, perhaps unacceptably. There is no current estimate of the attendant cost.

An escape module does theoretically offer the widest range of' crew escape options. The other two options, rocket extraction and bail-out, arc only practical during gliding flight. Both methods would be useful when the Orbiter could not reach a prepared runway, for they would allow the crew to escape before a very hazardous landing or a water ditching. Aerodynamic model tests showed that a crew member bailing out through either the side or overhead hatch would subsequently contact the wing, tail or orbital maneuvering system pod unless he or she could exit with sufficient velocity (> 5 to 10 feet per second) to avoid these obstacles. Slides and pendant rocket systems were evaluated as means of' providing this velocity, but all concepts of bail-out and rocket extraction that were studied require many minutes to get the entire crew out and would be practical only during controlled gliding flight. The results of these studies were presented at the Program Requirements Change Board session held on May 12, 1983, and subsequently to the NASA administrator, but none of the alternatives was [184] implemented because of limited capability and resulting program impacts.

There is much discussion and disagreement over which escape systems are feasible, or whether any provide protection against a significant number of failure modes.

The astronauts testifying before the Commission on April 3, 1986, agreed that it does not appear practical to modify the Orbiter to incorporate an escape module. The astronauts disagreed, however, about which of the other two systems would be preferable. As Astronaut Weitz testified:

"John [Astronaut John Young] likes the rocket extraction system because it does cover a wider flight regime and allows you to get out perhaps with the vehicle only under partial control as opposed to complete control; however, any system that adds more parts like rockets gets more complex.... The only kind of a system that I think is even somehow feasible would be maybe some kind of a bail-out system that could be used subsonic."5

In its 1982 Annual Report, the Aerospace Safety Advisory Panel listed "crew escape . . . at launch and prior to potential ditching" 6 as a priority item that warranted further study. The Commission fully supports such studies. In particular, the Commission believes that the crew should have a means of escaping the Orbiter in controlled, gliding flight. The Commission thinks it crucial that the vehicle that will carry astronauts into orbit through this decade and the next incorporate systems that provide some chance for crew survival in emergencies. It nonetheless accepts the following point made by Astronaut Robert Crippen:

"I don't know of an escape system that would have saved the crew from the particular incident that we just went through [the Challenger accident] . " 7

Range Safety

Television coverage of the Challenger accident vividly showed the Solid Rocket Boosters emerging from the ball of fire and smoke. The erratic and uncontrolled powered flight of such large components could have posed a potential danger to populated areas. The responsible official accordingly destroyed the Solid Rocket Boosters.

To understand how the booster rockets were destroyed, one must understand the purpose of a range safety system, its functions, and the special considerations that apply to Shuttle launches.

The Eastern Space and Missile Center operates a range safety system for all Department of Defense and NASA launch activities in the Cape Canaveral area. The primary responsibility of the range safety system, run by the U.S. Air Force, is to protect people and property from abnormal vehicle flights during first stage ascent.

To fulfill its range safety responsibilities, the Eastern Space and Missile Center staff supervises on-site launch preparations and tracks rockets and vehicles until they are far enough away from populated areas to remove any danger. When such a danger arises during the ascent stage of a launch, the vehicle may have to be destroyed to minimize harm to persons and property on the ground. Every major vehicle flown from the Cape Canaveral area has carried an explosive destruct system that could be armed and fired by the range safety officer.

Range safety procedures in launch activities from Kennedy are governed by Department of Defense and NASA documents. The primary regulatory publication is DOD Document 3200.11, Use, Management, and Operation of DOD Major Ranges and Test Facilities.

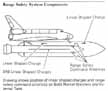

Space Shuttle Range Safety System

Both Space Shuttle Solid Rocket Boosters and the External Tank are fitted with explosive charges. These can be detonated on the command of the range safety officer if the vehicle crosses the limits established by flight analysis before launch and the vehicle is no longer in controlled flight. The determination of controllability is made by the flight director in Mission Control, Houston, who is in communication with the range safety officer. Following an encoded"arm" command, the existing package on the Shuttle System is detonated by a subsequent encoded "fire" command.

The range safety officer who sends the commands is the key decision maker who is finally responsible for preventing loss of life and property that could result if the vehicle or components should fall in populated areas. The destruct criteria are agreed to by NASA and the Eastern Space and Missile Center.

[185] A range safety system for the Shuttle launches was approved in concept in 1974. Under that concept, the capability to destroy the system in flight....

....from the ground was to be installed in the form of radio detonated explosive charges triggered by encoded signals. Such a range safety package appeared necessary for a variety of reasons based upon the initial Shuttle design that included ejection seats. If the crew were to eject, the unmanned vehicle would be uncontrollable and thus a much greater danger than a manned system.

After the first four test flights, however, the ejection seats were deactivated. Retaining the range safety package when the crew could no longer escape was an emotional and controversial decision. In retrospect, however, the Challenger accident has demonstrated the need for some type of range safety measure. Since the current range safety system does not allow for selective destruction of components, the Commission believes that NASA and the Air Force should critically re-examine whether the destruct package on the External Tank might be removed.

Range Safety Activities, January 28, 1986

The range safety officer for the Challenger flight on January 28 was Maj. Gerald F. Bieringer, U.S. Air Force. He reported that the mission was normal until about 76 seconds after launch. The following description is from Maj. Bieringer's written statement prepared approximately two hours after the accident:

"Watching the IP [impact point] displays and optics I observed the primary and alternate sources diverge significantly at about T + 76 [76 seconds into the flight]. At about the same time I heard . . [through monitored communications] the vehicle had exploded. Concurrently, I saw the explosion on the video monitor on my right. A white cloud seemed to envelop the vehicle, small pieces exploded out of it. The IP displays PRI and ALT indications were jumping around wildly I was about to recommend we do nothing as it appeared the entire vehicle had exploded when I observed what appeared to be an SRB [Solid Rocket Booster] stabilized and flying toward the upper left corner of the display. As it appeared stabilized I felt it might endanger land or shipping and as the ET [External Tank] had apparently exploded I recommended to the SRSO [senior range safety officer] we send functions. I sent ARM, waited about 10 seconds, and sent FIRE.... FIRE was sent at about 110 [seconds].''8

During the flight and prior to the accident, tracking and control functions performed normally. There were no communications problems throughout the range or with the NASA flight dynamics officer in Mission Control Houston.

Range safety data displays did not provide useful information immediately after the accident. The range safety officer depended upon the video displays for evidence concerning the performance of the Solid Rocket Boosters. Without that information, the range safety officer would not have sent the destruct signals. Detailed studies from Marshall had indicated that Solid Rocket Boosters would tumble if prematurely separated. That assumption made possible the prediction of impact points. When the Challenger Solid Rocket Boosters separated after the explosion, however, they continued powered, stabilized flight and did not tumble, contrary to the expectations upon which range safety rules had been based Without the live television pictures, the range safety officer would not have known about the unexpected performance of' the boosters

The Eastern Space and Missile Center and NASA have appropriately initiated a comprehensive [186] review of the Shuttle range safety requirements and their implementation. The events of' the Challenger accident demonstrate the need for a range safety package of some type on the Solid Rocket Boosters. However, the review should examine whether technology exists that would allow combining the range safety function for the Solid Rocket Boosters with a thrust termination system, and whether, if technically feasible, it would be desirable.

Postflight Analysis

The Mission Control Center in Houston had no more warning of' the impending disaster than the range safety officer had. All information that might be useful in recognizing problems that the crew or the mission control flight team could do something about is available to flight controllers during the launch, but that information constitutes only a fraction of the electronic data being telemetered from the Shuttle. To ensure that nothing was overlooked during the launch, Johnson flight controllers conducted a thorough analysis of the telemetry data on January 29 and 30, 1986.

Their review of the recorded events revealed that the chamber pressure inside the right Solid Rocket Booster began to differ from that of the left booster approximately 60 seconds after lift off. A sampling of that information is available to a flight controller during ascent, but the internal pressures of the boosters are normally not monitored during the first stage. The readings are used only to indicate whether the crew can expect an on-time or slightly delayed separation of the boosters from the Orbiter and External Tank. The difference in pressure during the brief ascent of Challenger was small, and pressures were within acceptable limits.

The replay of the data also indicated that the vehicle flight control system was responding properly to external forces and continued to control the Shuttle until the accident. No unusual motion responses occurred, and inside the cockpit there were no alarms. There are no indications that the crew had any warning of a problem before the fire and the disintegration of the Space Shuttle.

Findings

1. The Space Shuttle System was not designed to survive a failure of the Solid Rocket Boosters. There are no corrective actions that can be taken if the boosters do not operate properly after ignition, i.e., there is no ability to separate an Orbiter safely from thrusting boosters and no ability for the crew to escape the vehicle during first-stage ascent.

Landing: Another Critical Phase

The consequences of faulty performance in any dynamic and demanding flight environment can be catastrophic. The Commission was concerned that an insufficient safety margin may have existed in areas other than Shuttle ascent. Entry and landing of the Shuttle are dynamic and demanding with all the risks and complications inherent in flying a heavyweight glider with a very steep glide path. Since the Shuttle crew cannot divert to any alternate landing site after entry, the landing decision must be both timely and accurate. In addition, the landing gear, which includes wheels, tires and brakes, must function properly. These considerations will be discussed for both normal and abort landings.

Abort Site Weather

The acceptability of the weather at abort landing sites, both inside and outside the continental United States, is a critical factor in the launch decision process. The local weather minima for the actual launch are necessarily restrictive. The minima for acceptably safe abort landings are even more restrictive. Of course, the wider the range of acceptable weather conditions, the greater the possibility of launch on any given day. As a result of past efforts to increase the likelihood of launch, abort landing weather criteria are currently less restrictive than the criteria for planned landings.

The program also allows consideration of launching with a light rain shower over the Kennedy runway. Although engineering assessments [187] indicate that the tile damage that would result would not affect Shuttle controllability, it would be a serious setback to the program in terms of budget and schedule. This rule is designed to allow the program to weigh the probability of a return-to-launch-site abort and decide whether it is worthwhile to launch and accept the risk of a setback because of tile damage should a return-to-launch-site abort be required. This risk appears to be unnecessary.

The programmatic decision to accept worse weather for an abort landing, in a situation where other conditions are also less than optimal, is not consistent with a conservative approach to flight safety. The desire to launch is understandable, and abort landings are indeed improbable. However, if an abort is required, it is irrelevant that it was unlikely. An emergency, the loss of a Space Shuttle Main Engine, has already occurred to produce the necessity. Abort situations will require landing under emergency conditions on limited runways with Orbiter weights higher than normal. The difficulties should not be compounded by high crosswinds or reduced visibility. The Commission recommended that this subject be reviewed, and those reviews are currently underway.

Orbiter Tires and Brakes

The Aerospace Safety Advisory Panel has shared NASA's concern over the Orbiter wheels, tires and brakes since the beginning of the Shuttle program. This is summarized in its 1982 Annual Report.

"The landing gear including wheels, tires, and brakes is vital for safe completion of any mission. With the future flights going to higher weights and lower margins, possibly even negative margins, it is imperative that existing capabilities be fully explored, documented and improved where necessary." 9

Orbiter Tires

Orbiter tires are manufactured by B. F. Goodrich and are designed to support a Space Shuttle landing up to 240,000 pounds at 225 knots with 20 knots of crosswind. The tires have a 34-ply rating using 16 cords. Though they have successfully passed testing programs, they have shown excessive wear during landings at Kennedy, especially when crosswinds were involved.

The tires are rated as Criticality 1 because loss of a single tire could cause loss of control and subsequent loss of vehicle and crew.

Based upon approach and landing test experience, crosswind testing was added to the Space Shuttle tire certification testing. To date, Orbiters have landed with a maximum of 8 knots of crosswind at the Kennedy runway resulting in heavy tire wear: both spinup wear that occurs initially at touchdown and crosswind wear induced by side forces and differential braking. While dynamometer tests indicated that these tires should withstand conditions well above the design specification, the tests have not been able to simulate runway surface effects accurately. A Langley Research Center test track has been used to give a partial simulation of the strains caused by a landing at Kennedy. This test apparatus will be upgraded for further testing in the summer of 1986 in an attempt to include all the representative flight loads and conditions.

The tires have undergone extensive testing to examine effects of vacuum exposure, temperature extremes, and cuts. They also have undergone leakage, side force, load, storage, and durability tests. The tires have qualified in all these areas.

To date, tests using the simulated Kennedy runway at Langley indicate that spinup wear by itself will not lead to tire failure. Tests using the Kennedy test surface do indicate that spinup wear is worse if the tire is subjected to crosswind. For this reason, the crosswind allowable for normal landings is limited to 10 knots. This restriction also permits a safe stop if the nosewheel steering system fails. The limitation is being reviewed to see if it is too high for abort landings involving nosewheel steering failure. Testing has not been conducted to ensure that excessive crosswind wear will not be a hazard when landing on the various hard surface runways with maximum crosswinds and failed nosewheel steering.

Main tire loads are increased substantially after nosewheel touchdown because of the large downward wing force at its negative angle of attack. The total force on each side can be nearly 200,000 pounds, which exceeds the capability of a single tire. In fact, the touchdown loads alone can exceed the load bearing ability of a single tire. The obvious result is that if a single tire fails before nosegear touchdown, the vehicle will have serious if not catastrophic directional control problems following the expected failure of the [188] adjacent tire. This failure case has led to a Criticality 1 rating on the tires. Before nosegear touchdown, control is maintained through the rudder. However, it loses effectiveness as the speedbrake is opened and the vehicle decelerates. After nosegear touchdown, simulations have shown that directional control is possible using the nosewheel steering system for most subsequent failures, but not for some cases in which crosswinds exceed the current flight rule limits. Because of the consequences of this failure, crew members strongly recommend that the nosewheel steering system be modified to achieve full redundancy.

Tire side loads have been difficult to measure and subsequently model because of test facility limitations. Two mathematical models were developed from early dynamometer tests and extrapolation from nosewheel tire tests. New dynamic tests of main gear tires show a more flexible side response, which has been incorporated into the latest mathematical model. A reasonably accurate model is required both for nosewheel steering engineering studies and for crew training simulators.

The Orbiter tire in use meets specifications and has been certified through testing. However, testing has not reproduced results observed on Kennedy runways. To date, the only blown tire has been caused by a brake lockup and the resulting skid wear.

Several improvements have been considered to increase protection against the high-speed blowntire case. One would add a skid at the bottom of the main gear strut to take the peak load during nosegear touchdown; another would add a roll-on-rim capability to the main gear wheel. None of the possible improvements has been funded, however, nor has any been seriously studied.

In summary, two blown tires before nosegear touchdown would likely be catastrophic, and the potential for that occurrence should be minimized. NASA has directed testing in the fall of 1986 to examine actual tire, wheel, and strut failures to better understand this failure case.

Orbiter Brakes

The Orbiter brake design chosen in 1973 was based on the Orbiter's design weight. It used beryllium rotors and stators with carbon lining. However, as the actual Orbiter weight grew, the response from the Shuttle program management was not a redesign of the brakes, but an extension of required runway length from 10,000 to 12,500 feet. Thus, the brakes for many years have been known to have little or no margin, even if they performed as originally designed.

There are four brake assemblies, one for each main landing gear wheel. Each assembly uses four rotors and three stators, the stators being attached to a torque tube. Carbon pads are attached to provide the friction surface. The Orbiter brakes were designed to absorb 36.5 million foot-pounds of energy for normal stops and 55.5 million footpounds of energy for one emergency stop. The brakes were tested and qualified using standard dynamometer tests.

Actual flight experience has shown brake damage on most flights. The damage is classified by cause as either dynamic or thermal. The dynamic damage is usually characterized by damage to rotors and carbon lining chipping, plus beryllium and pad retainer cracks. On the other hand, the thermal damage has been due to heating of the stator caused by energy absorption during braking. The beryllium becomes ductile and has a much reduced yield strength at temperatures possible during braking. Both types of damage are typical of early brake development problems experienced in the aviation industry.

Brake damage has required that special crew procedures be developed to assure successful braking. To minimize dynamic damage and to keep any loose parts together, the crews are told to hold the brakes on constantly from the time of first application until their speed slows to about 40 knots. For a normal landing, braking is initiated at about 130 knots. For abort landings, braking would be initiated at about 150 knots. Braking speeds are established to avoid exceeding the temperature limits of the stator. The earlier the brakes are applied, the higher the heat rate. The longer the brakes are applied, the higher the temperature will be, no matter what the heat rate. To minimize problems, the commander must get the brake energy into the brakes at just the right rate and just the right time-before the beryllium yields and causes a low-speed wheel lockup.

At a Commission hearing on April 3, 1986, Astronaut John Young described the problem the Shuttle commander has with the system:

"It is very difficult to use precisely right now. In fact, we're finding out we don't really [189] have a good technique for applying the brakes.... We don't believe that astronauts or pilots should be able to break the brakes." 10

Missions 5, 51-D and 61-C had forms of thermal stator damage. The mission 51 -D case resulted in a low-speed wheel lockup and a subsequent blown tire at Kennedy. The mission 61-C case did not progress to a lockup but came very close. The amount of brake energy that can be obtained using normal braking procedures is about 40 million foot-pounds before the first stator fails. The mission 61-C damage occurred at 34 million foot-pounds but had not progressed to the lockup condition. Inspection of failed stators clearly shows the ductile failure response of the beryllium, and, hence, it appears that this failure mechanism cannot contribute to a high-speed lockup and subsequent tire failure. It should be noted that the brake specification called for a maximum energy of 55 million foot-pounds. Qualification testing of the abort braking profile showed that 55 million foot-pounds was the point of first stator failure. During qualification tests, the brakes continued to operate until all stators failed, providing about another 5 million footpounds of energy. Based upon the thermal response of beryllium under load, it appears that the early heavy braking required for transatlantic abort landings produces more than the 40 million foot-pounds that have resulted in thermal failure of the brakes during the normal braking profile. No numbers are certain, however, and clearly the qualification testing did not point out the current thermal problems.

The assumed normal and abort brake energy limits for the current design should be reinvestigated. The 61-C damage resulted from only 34 million foot-pounds of energy. If this same brake design is to continue to fly, the mission 61-C damage should be fully understood, and destructive testing should be accomplished to establish the short runway (transatlantic abort landing) brake limit and appropriate abort landing planning factors.

NASA is considering stator improvements, including steel or thicker beryllium stators, and has undertaken a carbon brake program that would provide a major margin improvement and less dynamic damage because of fewer parts. Additional testing is currently underway, and more is planned, to evaluate these brake modifications and to perform destructive testing. The testing results are expected to conform more closely to flight conditions because landing gear dynamics have been included. Early tests have confirmed the energy levels for the abort braking profile with a modified brake, and future tests may provide confidence in the normal braking profile.

The Aerospace Safety Advisory Panel recognized NASA's efforts in its 1985 Annual Report:

"A carbon brake review was conducted by NASA in early December, 1985, and re-sulted in agreement to procure a carbon brake system for the Orbiter.... There is concern by the STS [Space Transportation System] management about the availability of resources to support the development of the carbon brakes given the many com-peting requirements and the projected con-strained budget during the 1986 period. The program management considers the development of the carbon brake system to be of the highest priority . . . and the Panel sup-ports this position as it has in the past." 11

Because of the brake problems encountered in the program, two reviews have been conducted by NASA. The third review will take place during the summer of 1986. The review board members have studied all of the Orbiter brake data and have compared Orbiter problems to industry problems. Improvements suggested have been implemented. It is the consensus of NASA and industry experts that high priority should be placed on correcting Orbiter brake problems, and that brake redesign should proceed with emphasis on developing higher energy and torque capacity.

Concern within the program about the entire deceleration system (landing gear, wheels, tires, brakes and nosewheel steering) has been the subject of numerous reviews, meetings and design efforts. These concerns continued to be expressed by the Aerospace Safety Advisory Panel in 1982:

"Studies of Shuttle landings to date show that tire, wheel and brake stresses are approaching limits."12

"Short runways, with inadequate overruns, are cause for concern, for instance, a transatlantic abort to Dakar." 13

The issues are difficult, and the required technology is challenging, but most agree that it is appropriate and important that NASA resolve [190] each of these problems. A conservative approach to the landing phase of flight demands reliable performance by all critical systems.

Kennedy Space Center Landings

The original Space Shuttle plan called for routine landings at Kennedy to minimize turnaround time and cost per flight and to provide an efficient operation for both the Shuttle system and the cargo elements. While those considerations remain important, other concerns, such as the performance of the Orbiter tires and brakes, and the difficulty of accurate weather prediction in Florida, have called the plan into question.

When the Shuttle lands at Edwards Air Force Base, California, approximately six days are added to the turnaround time compared with a landing at Kennedy. That is the time required to load the Orbiter atop the Shuttle carrier aircraft, a specially modified Boeing 747, and to ferry it back to Florida for processing.

Returning the Orbiter to Kennedy from Edwards costs not only time but also money: nearly $1,000,000, not including the cost of additional ground support equipment, extra security and other support requirements. Further, the people necessary to accomplish the turnaround tasks must be drawn from the staffs at Kennedy and Vandenberg Air Force Base, California. They are the same people needed for the preparation for subsequent flights.

Returning the Orbiter also imposes an additional handling risk to the vehicle in both the loading operation and the ferry flight itself. Encountering light precipitation during the ferry flight has caused substantial damage to the Orbiter thermal protection system. These costs and risks, however, are minimal when compared with those of a Space Shuttle mission.

The Kennedy runway was built to Space Shuttle design requirements that exceeded all Federal Aviation Administration requirements and was coordinated extensively with the Air Force, Dryden Flight Research Center, NASA Headquarters, Johnson, Kennedy, Marshall and the Army Corps of Engineers. The result is a single concrete runway, 15,000 feet long and 300 feet wide. The grooved and coarse brushed surface and the high coefficient of friction provide an all-weather landing facility.

The Kennedy runway easily meets the intent of most of the Air Force, Federal Aviation Administration and International Civil Aviation Organization specification requirements. According to NASA, it was the best runway that the world knew how to build when the final design was determined in 1973.

In the past several years, questions about weather predictability and Shuttle systems performance have influenced the Kennedy landing issue. Experience gained in the 24 Shuttle landings has raised concerns about the adequacy of the Shuttle landing and rollout systems: tires, brakes and nosewheel steering. Tires and brakes have been discussed earlier. The tires have shown excessive wear after Kennedy landings, where the rough runway is particularly hard on tires. Tire wear became a serious concern after the landing of mission 51-D at Kennedy. Spinup wear was three cords deep, crosswind wear (in only an 8-knot crosswind) was significant and one tire eventually failed as a result of brake lock-up and skid.

This excessive wear, coupled with brake failure, led NASA to schedule subsequent landings at Edwards while attempting to solve these problems. At the Commission hearing on April 3, 1986, Clifford Charlesworth, director of Space Operations at Johnson, stated his reaction to the blown-tire incident:

"Let me say that following 51-D . . . one of the first things I did was go talk to then program manager, Mr. Lunney, and say we don't want to try that again until we understand that, which he completely agreed with, and we launched into this nosewheel steering development." 14

There followed minor improvements to the braking system. The nosewheel steering system was also improved, so that it, rather than differential braking, could be used for directional control to reduce tire wear.

These improvements were made before mission 61-C, and it was deemed safe for that mission and subsequent missions to land at Kennedy. Bad weather in Florida required that 61-C land at Edwards. There were again problems with the brakes, indicating that the Shuttle braking system was still suspect. Mr. Charlesworth provided this assessment to the Commission:

"Given the problem that has come up now with the brakes, I think that whole question still needs some more work before I would [191] be satisfied that yes, we should go back and try to land at the Cape." 15

The nosewheel steering, regarded as fail-safe, might better be described as fail-passive: at worst, a single failure will cause the nosewheel to castor. Thus, a single failure in nosewheel steering, coupled with failure conditions that require its use, could result in departure from the runway. There is a long-range program to improve the nosewheel steering so that a single failure will leave the system operational.

Eight flights have been launched with plans to land in Florida. Of those, three have been diverted to California because of bad weather. Moreover, it is indicative of the dynamic weather environment in Florida that twice in the program's history flights have been waved off for one orbit to allow for weather conditions to improve enough to be acceptable for landing. Thus, even if NASA eventually were to resume routine operations at Kennedy, experience indicates the Orbiter will divert into Edwards more than 30 percent of the time. NASA must therefore plan to use Edwards routinely. This requires reserving six days in the post-landing processing schedule for the Orbiter's ferry trip back to Florida. It also requires redundancy in the ferry aircraft. The single Shuttle carrier aircraft, with some one-of-a-kind support items, is presently the only way to get the Orbiter from California back to its launch site in Florida.

Landing Site Changes

.

Mission

.

STS-3

STS-7

STS 41-C

STS 61-C

The most serious concern is not that the weather in Florida is bad, but that the atmospheric conditions are frequently unpredictable. Captain Robert Crippen testified before the Commission on April 3, 1986:

"I don't think the astronaut office would disagree with the premise that you are much safer landing at Edwards. There are some things you could do, as was indicated, to make Kennedy better, but you're never going to overcome the weather unpredictability." 16

Once the Shuttle performs the deorbit burn, it is going to land approximately 60 minutes later; there is no way to return to orbit, and there is no option to select another landing site. This means that the weather forecaster must analyze the landing site weather nearly one and one-half hours in advance of landing, and that the forecast must be accurate. Unfortunately, the Florida weather is particularly difficult to forecast at certain times of the year. In the spring and summer, thunderstorms build and dissipate quickly and unpredictably. Early morning fog also is very difficult to predict if the forecast must be made in the hour before sunrise.

In contrast, the stable weather patterns at Edwards make the forecaster's job much easier.

Although NASA has a conservative philosophy, and applies conservative flight rules in evaluating end-of-mission weather, the decision always comes down to evaluating a weather forecast. There is a risk associated with that. If the program requirements put forecasters in the position of predicting weather when weather is unpredictable, it is only a matter of time before the crew is allowed to leave orbit and arrive in Florida to find thunderstorms or rapidly forming ground fog. Either could be disastrous.

The weather at Edwards, of course, is not always acceptable for landing either. In fact, only days prior to the launch of STS-3, NASA was forced to shift the normal landing site from Edwards to Northrup Strip, New Mexico, because of flooding of the Edwards lakebed. This points out the need to support fully both Kennedy and Edwards as potential end-of-mission landing sites.

In summary, although there are valid programmatic reasons to land routinely at Kennedy, there are concerns that suggest that this is not wise under the present circumstances. While planned landings at Edwards carry a cost in dollars and days, the realities of weather cannot be ignored. Shuttle program officials must recognize that Edwards is a permanent, essential part of the program. The cost associated with regular, scheduled landing and turnaround operations at Edwards is thus a necessary program cost.

Decisions governing Space Shuttle operations must be consistent with the philosophy that unnecessary risks have to be eliminated. Such [192] decisions cannot be made without a clear understanding of margins of safety in each part of the system.

Unfortunately, margins of safety cannot be assured if' performance characteristics are not thoroughly understood, nor can they be deduced from a previous flight's "success."

The Shuttle Program cannot afford to operate outside its experience in the areas of tires, brakes, and weather, with the capabilities of the system today. Pending a clear understanding of all landing and deceleration systems, and a resolution of the problems encountered to date in Shuttle landings, the most conservative course must be followed in order to minimize risk during this dynamic phase of flight.

Shuttle Elements

The Space Shuttle Main Engine teams at Marshall and Rocketdyne have developed engines that have achieved their performance goals and have performed extremely well. Nevertheless the main engines continue to be highly complex and critical components of the Shuttle that involve an element of risk principally because important components of the engines degrade more rapidly with flight use than anticipated. Both NASA and Rocketdyne have taken steps to contain that risk. An important aspect of the main engine program has been the extensive "hot fire" ground tests. Unfortunately, the vitality of the test program has been reduced because of budgetary constraints.

The ability of the engine to achieve its programed design life is verified by two test engines. These "fleet leader" engines are test fired with sufficient frequency that they have twice as much operational experience as any flight engine. Fleet leader tests have demonstrated that most engine components have an equivalent 40-flight service life. As part of the engine test program, mayor components are inspected periodic ally and replaced if wear or damage warrants. Fleet leader tests have established that the low-pressure fuel turbopump and the low-pressure oxidizer pump have lives limited to the equivalent of 28 and 22 flights, respectively. The high-pressure fuel turbopump is limited to six flights before overhaul; the high-pressure oxidizer pump is limited to less than six flights.17 An active program of flight engine inspection and component replacement has been effectively implemented by Rocketdyne, based on the results of' the fleet leader engine test program.

The life-limiting items on the high-pressure pumps are the turbine blades, impellers, seals and bearings. Rocketdyne has identified cracked turbine blades in the high - pressure pumps as a primary concern. The contractor has been working to improve the pumps' reliability by increasing bearing and turbine blade life and improving dynamic stability. While considerable progress has been made, the desired level of turbine blade life has not yet been achieved. A number of' improvements achieved as a result of the fleet leader program are now ready for incorporation in the Space Shuttle Main Engines used in future flights, but have not been implemented due to fiscal constraints.18 Immediate implementation of these improvements would allow incorporation before the next Shuttle flight.

The number of engine test firings per month has decreased over the past two years. Yet this test program has not yet demonstrated the limits of engine operation parameters or included tests over the full operating envelope to show full engine capability. In addition, tests have not yet been deliberately conducted to the point of failure to determine actual engine operating margins.

The Orbiter has also performed well. There is, however, one serious potential failure mode related to the disconnect valves between the Orbiter and the External Tank. The present design includes two 17-inch diameter valves, one controlling the oxygen flow, and the other the hydrogen flow from the tank to the Orbiter's three engines. Each of the disconnect valves has two flappers that close off the flow of the liquid hydrogen and oxygen when the External Tank separates from the Orbiter. An inadvertent closure by any of the four flappers during normal engine operation would cause a catastrophe due to rupture of the supply line and/or tank. New designs are under study, incorporating modifications to prevent inadvertent valve closures. Redesigned valves could be qualified, certified and available for use on the Shuttle's next flight.

While the External Tank has performed flawlessly during all Shuttle flights, one area of concern pertains to the indicators for the two valves which vent the liquid hydrogen and liquid oxygen. These valves can indicate they are closed when they might be partially open. This condition [193] is potentially hazardous, since leaks of either gaseous oxygen or hydrogen prior to launch, or in flight, could lead to fires. This could, in turn, lead to catastrophic failure of the External Tank. NASA is currently studying design modifications to the valve position indicators. This effort could be expedited and the redesigned indicators installed before the next flight of the Shuttle.

Processing and Assembly

During the processing and assembly of the elements of flight 51-L, various problems were seen in the Commission's review which could bear on the safety of future flights.

Structural Inspections

During the 51-L processing, waivers were granted on 60 of 146 required Orbiter structural inspections. Seven of these waivers were second-time waivers of inspections.

A formal structural inspection plan for the Shuttle fleet had not been fully developed, and not all of the 146 inspections had been scheduled for the 51-L processing. In order to minimize the flight delay until the implementation plan could be fully developed, the waivers were documented, requested and granted by Level II at Johnson.

The structural inspection requirements are relatively new and not completely mature. A working group was formed in December 1985, to expedite a structural inspection plan. A plan now exists for future structural inspections. The Commission believes that these inspections should not be waived. The fleet of Orbiters has no counterpart anywhere in the world. There is no data base relative to reusable spacecraft. The Orbiter's operating environment is totally different from that of airliners, and the program must closely track the effects of the Orbiters' age and use.19

Records

Throughout the Commission's review of the accident, a large number of errors were noted in the paperwork for the Space Shuttle Main Engine/Main Propulsion System and for the Orbiter. The review showed, however, that in the vast majority of cases the problem lay in the documentation itself and not in the work that was actually accomplished. The review led the Commission to conclude that the Operations and Maintenance Instructions are in need of an overall review and update, and the performance of Operations and Maintenance Instructions needs to be improved.

Missed Requirements

At the time of launch, all items called for by the Operational Maintenance Requirements and Specifications Document were to have been met, waived or excepted. The 51-L audit review has revealed additional areas where such requirements were not met and were not formally waived or excepted:

1. A formal post-flight inspection of the forward External Tank attach plate was not documented.

2. A forward avionics bay closeout panel was not verified as installed during Orbiter rollover/stacking operations (the area was properly configured prior to flight with installation of a locker).

3. Flight 51-L was launched with only one of two crew hatch microswitches showing the proper indication. This condition was documented by a Problem Report and was deferred; no waiver was obtained, however.

4. Post-flight hydraulic reservoir sampling was not performed prior to connection of ground hydraulic support equipment at Dryden Flight Research Facility, but was performed in the Orbiter Processing Facility.

5. During Auxiliary Power Unit hypergolic loading operations, the Number 2 tank evacuation prior to loading was not maintained above 20 inches of mercury for five minutes as required (19.8 inches maintained for 2 hours). This incident was documented as an acceptable condition by Kennedy, Johnson and Launch Support Service, but no waiver was submitted.

6. Landing gear voids were not replenished and crew module meters were not verified during final vehicle closeouts. The additional requirement to replenish the landing gear voids during launch countdown was performed. 20

Inspection by Proxy

Another aspect of the processing activities that warrants particular attention is the Shuttle Processing Contractor's policy of using "designated [194] verifiers" to supplement the quality assurance force. A designated verifier is a senior technician who is authorized to inspect and approve his own and his fellow technicians' work in specific nonflight areas, instead of NASA quality assurance personnel inspecting the work. The aviation industry follows this practice in performing verifications for the Federal Aviation Administration. The Shuttle Processing Contractor has about 770 designated verifiers (nearly 15 % of the work force).21 The NASA quality assurance inspection program no longer covers 100 percent of the inspection areas. Due to reduced manpower NASA personnel now inspect only areas that are considered more critical. Thus the system of independent checks that NASA maintained through several programs is declining in effectiveness. The effect of this change requires careful evaluation by NASA.

Accidental Damage Reporting

While not specifically related to the Challenger accident, a serious problem was identified during interviews of technicians who work on the Orbiter. It had been their understanding at one time that employees would not be disciplined for accidental damage done to the Orbiter, provided the damage was fully reported when it occurred. It was their opinion that this forgiveness policy was no longer being followed by the Shuttle Processing Contractor. They cited examples of employees being punished after acknowledging they had accidentally caused damage. The technicians said that accidental damage is not consistently reported, when it occurs, because of lack of confidence in management's forgiveness policy and technicians' consequent fear of losing their jobs. This situation has obvious severe implications if left uncorrected.

Launch Pad 39B

All launch damage and launch measurement data from Pad B ground systems anomalies were considered to be normal or minor with three exceptions: the loss of the springs and plungers on the booster hold-down posts; the failure of the gaseous hydrogen vent arm to latch; and the loss of bricks from the flame trench. These three items are treated in Appendix I, the NASA Pre-Launch Activities Team Report (May, 1986). None contributed to the accident.

Loss of bricks from the flame trench was also experienced during the launch of STS-1 (April, 1981) and STS-2 (November, 1981) from Pad A, though at locations closer to the centerline of the vehicle. Since the brick was blown out of the flame trench and away from the vehicle, there is no evidence to indicate that the loose brick might have endangered the 51-L vehicle, but it may be possible for damage to occur if the condition remains uncorrected. The Pad B fire brick is to be replaced by refractory concrete, as was done on Pad A.

Involvement of Development Contractors

The Space Shuttle program, like its predecessors Mercury, Gemini, Apollo, Skylab and Apollo-Soyuz, is clearly a developmental program and must be treated as such by NASA. Indeed, the chief differences between the Shuttle and previous developmental programs are that the Shuttle is principally a transportation system and employs reusable hardware. Reusability implies a new set of functions such as logistics support, maintenance, refurbishment, lifetime concerns and structural inspections that must be addressed by the program.

In order to enhance post-flight "turnaround" schedule and efficiency, NASA is striving to implement processing procedures accepted by the transportation industry. While this effort is useful, there is not an exact industry analogy to the Orbiter vehicles' flight operations, because each successive Shuttle mission expands system and performance requirements. Consequently, the Shuttle configuration is evolving as design changes and improvements are incorporated. The demands of individual payloads can cause significant additional developmental changes.

These developmental aspects make significant demands, which can be met only by the following strategies:

1. Maintain a significant engineering design and development capability among the Shuttle contractors and an ongoing engineering capability within NASA.

2. Maintain an active analytical capability so that the evolving capabilities of the [195] Shuttle can be matched to the demands on the Shuttle.

The Shuttle's developmental status demands that both NASA and all its contractors maintain a high level of in-house experience and technical ability.

All Shuttle contractors and their corresponding NASA project organizations expressed concern about the organization of contractor services. When Shuttle operations were begun, the prime development contractors had total responsibility for all Shuttle activities. The concept of a single Shuttle Processing Prime Contractor was adopted as NASA policy in 1981, and implemented in 1983 when a team led by Lockheed Space Operations was selected. The Lockheed team includes Lockheed Missiles & Space Company, responsible for processing the Orbiter; Grumman Aerospace Corporation, responsible for operation and maintenance of the launch processing system; Pan American World Airways, charged with introducing and maintaining airline methods and techniques in the processing system; Morton Thiokol, Inc., responsible for processing the Solid Rocket Boosters and External Tank; and Rocketdyne, responsible for processing the Shuttle main engines.

Lockheed's performance as Shuttle Processing Contractor is judged on the basis of a NASA grading system using agreed criteria. In September, 1984, the company was marked down for failure to form a coordinated contractor team. As a result of that grading, Lockheed earned for that period an award fee of about one-quarter of one percent of cost, on a maximum fee scale at that time of one percent of cost. Lockheed reviewed the findings of NASA's grading and did not quarrel with its major thrust.

The award fee presently is a composite of incentives to be earned on mission success and cost control. It can vary along a scale of one to 14 percent of cost. The Shuttle Processing Contractor was earning, at the time of the Challenger accident, about six percent of cost, or nearly midpoint on the scale.

Although the performance of' the Shuttle Processing Contractor's team has improved considerably, serious processing problems have occurred, especially with respect to the Orbiter. An example is provided by the handling of the critical 17-inch disconnect valves during the 51-L flight preparations.

During External Tank propellant loading in preparation for launch, the liquid hydrogen 17-inch disconnect valve was opened prior to reducing the pressure in the Orbiter liquid hydrogen manifold, through a procedural error by the console operator. The valve was opened with a six pounds per square inch differential. This was contrary to the critical requirement that the differential be no greater than one pound per square inch. This pressure held the valve closed for approximately 18 seconds before- it finally slammed open abruptly. These valves are extremely critical and have very stringent tolerances to preclude inadvertent closure of the valve during mainstage thrusting. Accidental closing of' a disconnect valve would mean catastrophic loss of' Orbiter and crew. The slamming of this valve (which could have damaged it) was not reported by the operator and was not discovered until the post-accident data review. Although this incident did not contribute to the 51-L incident, this type of error cannot be tolerated in future operations, and a policy of rigorous reporting of anomalies in processing must be strictly enforced.

During the pre-launch processing and postflight refurbishment of the Orbiter, Rockwell- the development contractor-acts largely as an adviser to the Shuttle Processing Contractor. Martin Marietta has a similar role regarding the pre-launch processing of the External Tank. In contrast, NASA directed the Shuttle Processing Contractor to subcontract with Rocketdyne and Thiokol for the processing and refurbishment of the main engines and the Solid Rocket Motors, respectively. If Rockwell and Martin Marietta, as the development contractor, had a similar direct involvement with their elements of the Shuttle system, the likelihood of difficulties caused by improper processing would probably be decreased. Furthermore, all Shuttle elements would benefit from the advantages of beginning-to-end responsibility vested in individual contractors, each responsible for the design, development, manufacturing, operation, and refurbishment of' their respective Shuttle elements.

[196] References