[164] With the 1982 completion of the orbital flight test series, NASA began a planned acceleration of the Space Shuttle launch schedule. One early plan contemplated an eventual rate of a mission a week, but realism forced several downward revisions. In 1985, NASA published a projection calling for an annual rate of 24 flights by 1990. Long before the Challenger accident, however, it was becoming obvious that even the modified goal of two flights a month was overambitious.

In establishing the schedule, NASA had not provided adequate resources for its attainment. As a result, the capabilities of the system were strained by the modest nine-mission rate of 1985, and the evidence suggests that NASA would not have been able to accomplish the 15 flights scheduled for 1986. These are the major conclusions of a Commission examination of the pressures and problems attendant upon the accelerated launch schedule.

On the same day that the initial orbital tests concluded-July 4, 1982-President Reagan announced a national policy to set the direction of the U. S. space program during the following decade. As part of that policy, the President stated that:

"The United States Space Transportation System (STS) is the primary space launch system for both national security and civil government missions."

Additionally, he said:

"The first priority of the STS program is to make the system fully operational and cost-effective in providing routine access to space."

From the inception of the Shuttle, NASA had been advertising a vehicle that would make space operations "routine and economical." The greater the annual number of flights, the greater the degree of routinization and economy, so heavy emphasis was placed on the schedule. However, the attempt to build up to 24 missions a year brought a number of difficulties, among them the compression of training schedules, the lack of spare parts, and the focusing of resources on nearterm problems.

One effect of NASA's accelerated flight rate and the agency's determination to meet it was the dilution of the human and material resources that could be applied to any particular flight.

The part of the system responsible for turning the mission requirements and objectives into flight software, flight trajectory information and crew training materials was struggling to keep up with the flight rate in late 1985, and forecasts showed it would be unable to meet its milestones for 1986. It was falling behind because its resources were strained to the limit, strained by the flight rate itself and by the constant changes it was forced to respond to within that accelerating schedule. Compounding the problem was the fact that NASA had difficulty evolving from its singleflight focus to a system that could efficiently support the projected flight rate. It was slow in developing a hardware maintenance plan for its reusable fleet and slow in developing the capabilities that would allow it to handle the higher volume of work and training associated with the increased flight frequency.

[165] Pressures developed because of the need to meet customer commitments, which translated into a requirement to launch a certain number of flights per year and to launch them on time. Such considerations may occasionally have obscured engineering concerns. Managers may have forgotten-partly because of past success, partly because of their own well-nurtured image of the program-that the Shuttle was still in a research and development phase. In his testimony before a U.S. Senate Appropriations subcommittee on May 5, 1982, following the third flight of the Space Shuttle, James Beggs, then the NASA Administrator, expressed NASA's commitment:

"The highest priority we have set for NASA is to complete development of the Shuttle and turn it into an operational system. Safety and reliability of flight and the control of operational costs are primary objectives as we move forward with the Shuttle program."1

Sixteen months later, arguing in support of the Space Station, Mr. Beggs said, "We can start anytime.... There's no compelling reason [why] it has to be 1985 rather than '86 or '87. The point that we have made is that the Shuttle is now operational." 2 The prevalent attitude in the program appeared to be that the Shuttle should be ready to emerge from the developmental stage, and managers were determined to prove it "operational."

Various aspects of the mission design and development process were directly affected by that determination. The sections that follow will discuss the pressures exerted on the system by the flight rate, the reluctance to relax the optimistic schedule, and the attempt to assume an operational status.

Planning of a Mission

The planning and preparation for a Space Shuttle flight require close coordination among those making the flight manifest, those designing the flight and the customers contracting NASA's services. The goals are to establish the manifest; define the objectives, constraints and capabilities of the mission; and translate those into hardware, software and flight procedures.

There are major program decision points in the development of every Shuttle flight. At each of these points, sometimes called freeze points, decisions are made that form the basis for further engineering and product development. The disciplines affected by these freeze points include integration hardware, engineering, crew timeline, flight design and crew training.

The first major freeze point is at launch minus 15 months. At that time the flight is officially defined: the launch date, Orbiter and major payloads are all specified, and initial design and engineering are begun based on this information.

The second major freeze point is at launch minus 7.7 months, the cargo integration review. During this review, the integration hardware design, Orbiter vehicle configuration, flight design and software requirements are agreed to and specified. Further design and engineering can then proceed.

Another major freeze point is the flight planning and stowage review at launch minus five months. At that time, the crew activity timeline and the crew compartment configuration, which includes middeck payloads and payload specialist assignments, are established. Final design, engineering and training are based on these products.

Development of Flight Products

The "production process" begins by collecting all mission objectives, requirements and constraints specified by the payload and Space Shuttle communities at the milestones described above. That information is interpreted and assimilated as various groups generate products required for a Space Shuttle flight: trajectory data, consumables requirements, Orbiter flight software, Mission Control Center software and the crew activity plan, to name just a few.

Some of these activities can be done in parallel, but many are serial. Once a particular process has started, if a substantial change is made to the flight, not only does that process have to be started again, but the process that preceded it and supplied its data may also need to be repeated. If one group fails to meet its due date, the group that is next in the chain will start late. The delay then cascades through the system.

Were the elements of the system meeting their schedules? Although each group believed it had an adequate amount of time allotted to perform its function, the system as a whole was falling....

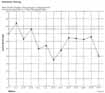

....behind. An assessment of the system's overall performance is best made by studying the process at the end of the production chain: crew training. Analysis of training schedules for previous flights and projected training schedules for flights in the spring and summer of 1986 reveals a clear trend: less and less time was going to be available for crew members to accomplish their required training. (See the Shuttle mission simulator training chart.)

The production system was disrupted by several factors including increased flight rate, lack of efficient production processing and manifest changes.

Changes in the Manifest

Each process in the production cycle is based on information agreed upon at one of the freeze points. If that information is later changed, the process may have to be repeated. The change could be a change in manifest or a change to the Orbiter hardware or software. The hardware and software changes in 1985 usually were mandatory changes; perhaps some of the manifest changes were not.

The changes in the manifest were caused by factors that fall into four general categories: hardware problems, customer requests, operational [167] constraints and external factors. The significant changes made in 1985 are shown in the accompanying table. The following examples illustrate that a single proposed change can have extensive impact, not because the change itself is particularly difficult to accommodate (though it may be), but because each change necessitates four or five other changes. The cumulative effect can be substantial. (See the Impact of Manifest Changes chart.)

When a change occurs, the program must choose a response and accept the consequences of that response. The options are usually either to maximize the benefit to the customer or to minimize the adverse impact on Space Shuttle operations. If the first option is selected, the consequences will include short-term and/or longterm effects.

Hardware problems can cause extensive changes in the payload manifest. The 51-E mission was on the launch pad, only days from launch, with a Tracking and Data Relay Satellite and Telesat satellite in the cargo bay, when a hardware problem in the tracking satellite was discovered. That flight was canceled and the payload reassigned. The cancellation resulted in major changes to several succeeding flights. Mission 51 -D, scheduled to fly two months later, was changed to add the Telesat and delete the retrieval of the Long Duration Exposure Facility. The retrieval mission was then added to mission 61-I, replacing another satellite. A new mission (61-M) was scheduled for July, 1986, to accommodate the Tracking and Data Relay Satellite and the displaced satellite, and all flights scheduled later in 1986 slipped to make room for 61-M.

Customers occasionally have notified NASA Headquarters of a desire to change their scheduled launch date because of development problems, financial difficulties or changing market conditions. NASA generally accedes to these requests and has never imposed the penalties available. An example is the request made to delay the flight of the Westar satellite from mission 61-C (December, 1985) to a flight in March, 1986. Westar was added to flight 61-E, and the Getaway Special bridge assembly was removed to make room for it; the HS-376 satellite slot was deleted from 51-L and added to 61-C; the Spartan-Halley satellite was deleted from 61-D and added to 51 -L. Thus, four flights experienced major payload changes as a result of one customer's request.

1985 Changes in the Manifest

Hardware Problems

Tracking and Data Relay Satellite (canceled 51 -E, added 61 -M).

Synchronous Communication Satellite (added to 61-C).

Synchronous Communication Satellite (removed from 61-C).

OV- 102 late delivery from Palmdale (changed to 51 -G, 51 -I, and 61 -A).

Customer Requests

HS-376 (removed from 51-I). G-Star (removed from 61-C). Satellite Television Corporation-Direct Broadcast Satellite (removed from 61-E).

Westar (removed from 61-C).

Satellite Television Corporation-Direct Broadcast Satellite (removed from 61-H).

Electrophoresis Operations in Space (removed from 61-B).

Electrophoresis Operations in Space (removed from 61-H).

Hubble Space Telescope (swap with Earth Observation Mission).

Operational Constraints

No launch window for Skynet/Indian Satellite Combination (61-H).

Unacceptable structural loads for Tracking and Data Relay Satellite/Indian Satellite (61-H).

Landing weight above allowable limits for each of the following missions: 61-A, 61-E, 71-A, 61 -K.

External Factors

Late addition of SenatorJake Garn (A-Utah) (51 -D)

Late addition of Representative Bill Nelson (D-Florida) (61-C).

Late addition of Physical Vapor Transport Organic Solid experiment (51-I).

Operational constraints (for example, a constraint on the total cargo weight) are imposed to insure that the combination of payloads does not exceed the Orbiter's capabilities. An example involving the Earth Observation Mission Spacelab flight is presented in the NASA Mission Planning and Operations Team Report in Appendix J. That case illustrates that changes resulting from a single instance of a weight constraint violation can cascade through the entire schedule.

External factors have been the cause of a number of changes in the manifest as well. The changes discussed above involve major payloads, but changes to other payloads or to payload specialists can create problems as well. One small change does not come alone; it generates several others. A payload specialist was added to mission 61-C only two months before its scheduled lift off. Because there were already seven crew members assigned to the flight, one had to be removed. The Hughes payload specialist was moved from 61-C to 51-L just three months before 51-L was scheduled to launch. His experiments were also added to 51-L. Two middeck experiments were deleted from 51-L as a result, and the deleted experiments would have reappeared on later flights.

Again, a "single" late change affected at least two flights very late in the planning and preparation cycles.

The effects of such changes in terms of budget, cost and manpower can be significant. In some cases, the allocation of additional resources allows the change to be accommodated with little or no impact to the overall schedule. In those cases, steps that need to be re-done can still be accomplished before their deadlines. The amount of additional resources required depends, of course, on the magnitude of the change and when the change occurs: early changes, those before the cargo integration review, have only a minimal impact; changes at launch minus five months (two months after the cargo integration review) can carry a major impact, increasing the required resources by approximately 30 percent. In the missions from 41-C to 51-L, only 60 percent of the major changes occurred before the cargo integration review. More than 20 percent occurred after launch minus five months and caused disruptive budget and manpower impacts.3

Engineering flight products are generated under a contract that allows for increased expenditures to meet occasional high workloads.

[170] Even with this built-in flexibility, however, the requested changes occasionally saturate facilities and personnel capabilities. The strain on resources can be tremendous. For short periods of two to three months in mid-1985 and early 1986, facilities and personnel were being required to perform at roughly twice the budgeted flight rate.

If a change occurs late enough, it will have an impact on the serial processes. In these cases, additional resources will not alleviate the problem, and the effect of the change is absorbed by all downstream processes, and ultimately by the last element in the chain. In the case of the flight design and software reconfiguration process, that last element is crew training. In January, 1986, the forecasts indicated that crews on flights after 51-I. would have significantly less time than desired to train for their flights.4 (See the Simulation Training chart.)

According to Astronaut Henry Hartsfield:

"Had we not had the accident, we were going to be up against a wall; STS 61-H . . . would have had to average 31 hours in the simulator to accomplish their required training, and STS 61-K would have to average 33 hours. That is ridiculous. For the first time, somebody was going to have to stand up and say we have got to slip the launch because we are not going to have the crew trained." 5

"Operational" Capabilities

For a long time during Shuttle development, the program focused on a single flight, the first Space Shuttle mission. When the program became "operational," flights came more frequently, and the same resources that had been applied to one flight had to be applied to several flights concurrently. Accomplishing the more pressing immediate requirements diverted attention from what was happening to the system as a whole. That appears to be one of the many telling differences between a "research and development" program and an "operational program." Some of the differences are philosophical, some are attitudinal and some are practical.

Elements within the Shuttle program tried to adapt their philosophy, their attitude and their requirements to the "operational era." But that era came suddenly, and in some cases, there had not been enough preparation for what "operational" might entail. For example, routine and regular post-flight maintenance and inspections are critical in an operational program; spare parts arc critical to flight readiness in an operational fleet; and the software tools and training facilities developed during a test program may not be suitable for the high volume of work required in an operational environment. In many respects, the system was not prepared to meet an "operational" schedule.

As the Space Shuttle system matured, with numerous changes and compromises, a comprehensive set of requirements was developed to ensure the success of a mission. What evolved was a system in which the preflight processing, flight planning, flight control and flight training were accomplished with extreme care applied to every detail. This process checked and rechecked everything, and though it was both labor- and time-intensive, it was appropriate and necessary for a system still in the developmental phase. This process, however, was not capable of meeting the flight rate goals.

After the first series of flights, the system developed plans to accomplish what was required to support the flight rate. The challenge was to streamline the processes through automation, standardization, and centralized management, and to convert from the developmental phase to the mature system without a compromise in quality. It required that experts carefully analyze their areas to determine what could be standardized and automated, then take the time to do it.

But the increasing flight rate had priority- quality products had to be ready on time. Further, schedules and budgets for developing the needed facility improvements were not adequate. Only the time and resources left after supporting the flight schedule could be directed toward efforts to streamline and standardize. In 1985, NASA was attempting to develop the capabilities of a production system. But it was forced to do that while responding-with the same personnel-to a higher flight rate.

At the same time the flight rate was increasing, a variety of factors reduced the number of skilled personnel available to deal with it. These included retirements, hiring freezes, transfers to other programs like the Space Station and transitioning to a single contractor for operations support.

[171] The flight rate did not appear to be based on assessment of available resources and capabilities and was not reduced to accommodate the capacity of the work force. For example, on January 1, 1986, a new contract took effect at Johnson that consolidated the entire contractor work force under a single company. This transition was another disturbance at a time when the work force needed to be performing at full capacity to meet the 1986 flight rate. In some important areas, a significant fraction of workers elected not to change contractors. This reduced the work force and its capabilities, and necessitated intensive training programs to qualify the new personnel. According to projections, the work force would not have been back to full capacity until the summer of 1986. This drain on a critical part of the system came just as NASA was beginning the most challenging phase of its flight schedule.6

Similarly, at Kennedy the capabilities of the Shuttle processing and facilities support work force became increasingly strained as the Orbiter turnaround time decreased to accommodate the accelerated launch schedule. This factor has resulted in overtime percentages of almost 28 percent in some directorates. Numerous contract employees have worked 72 hours per week or longer and frequent 12-hour shifts. The potential implications of such overtime for safety were made apparent during the attempted launch of mission 61-C on January 6, 1986, when fatigue and shiftwork were cited as major contributing factors to a serious incident involving a liquid oxygen depletion that occurred less than five minutes before scheduled lift off. The issue of workload at Kennedy is discussed in more detail in Appendix G.

Another example of a system designed during the developmental phase and struggling to keep up with operational requirements is the Shuttle Mission Simulator. There are currently two simulators. They support the bulk of a crew's training for ascent, orbit and entry phases of a Shuttle mission. Studies indicate two simulators can support no more than 12- 15 flights per year. The flight rate at the time of the accident was about to saturate the system's capability to provide trained astronauts for those flights. Furthermore, the two existing simulator s are out-of-date and require constant attention to keep them operating at capacity to meet even the rate of 12-15 flights per year. Although there are plans to improve capability, funds for those improvements are minimal and spread out over a 10-year period. This is another clear demonstration that the system was trying to develop its capabilities to meet an operational schedule but was not given the time, opportunity or resources to do it.7

Responding to Challenges and Changes

Another obstacle in the path toward accommodation of a higher flight rate is NASA's legendary "can-do" attitude. The attitude that enabled the agency to put men on the moon and to build the Space Shuttle will not allow it to pass up an exciting challenge-even though accepting the challenge may drain resources from the more mundane (but necessary) aspects of the program.

A recent example is NASA's decision to perform a spectacular retrieval of two communications satellites whose upper stage motors had failed to raise them to the proper geosynchronous orbit. NASA itself then proposed to the insurance companies who owned the failed satellites that the agency design a mission to rendezvous with them in turn and that an astronaut in a jet backpack fly over to escort the satellites into the Shuttle's payload bay for a return to Earth.

The mission generated considerable excitement within NASA and required a substantial effort to develop the necessary techniques, hardware and procedures. The mission was conceived, created, designed and accomplished within 10 months. The result, mission 51-A (November, 1984), was a resounding success, as both failed satellites were successfully returned to Earth. The retrieval mission vividly demonstrated the service that astronauts and the Space Shuttle can perform .

Ten months after the first retrieval mission, NASA launched a mission to repair another communications satellite that had failed in low-Earth orbit. Again, the mission was developed and executed on relatively short notice and was resoundingly successful for both NASA and the satellite insurance industry.

The satellite retrieval missions were not isolated occurrences. Extraordinary efforts on NASA's part in developing and accomplishing missions will, and should, continue, but such efforts will be a substantial additional drain on resources. NASA cannot both accept the relatively spur-of [172] the-moment missions that its "can-do" attitude tends to generate and also maintain the planning and scheduling discipline required to operate as a "space truck" on a routine and cost-effective basis. As the flight rate increases, the cost in resources and the accompanying impact on future operations must be considered when infrequent but extraordinary efforts are undertaken. The system is still not sufficiently developed as a "production line" process in terms of planning or implementation procedures. It cannot routinely or even periodically accept major disruptions without considerable cost. NASA's attitude historically has reflected the position that "We can do anything," and while that may essentially be true, NASA's optimism must be tempered by the realization that it cannot do everything.

NASA has always taken a positive approach to problem solving and has not evolved to the point where its officials are willing to say they no longer have the resources to respond to proposed changes. Harold Draughon, manager of the Mission Integration Office at Johnson, reinforced this point by describing what would have to happen in 1986 to achieve the flight rate:

"The next time the guy came in and said 'I want to get off this flight and want to move down two' [the system would have had to say,] We can't do that,' and that would have been the decision." 8

Even in the event of a hardware problem, after the problem is fixed there is still a choice about how to respond. Flight 41-D had a main engine shutdown on the launch pad. It had a commercial payload on it, and the NASA Customer Services division wanted to put that commercial payload on the next flight (replacing some NASA payloads) to satisfy more customers. Draughon described the effect of that decision to the Commission: "We did that. We did not have to. And the system went out and put that in work, but it paid a price. The next three or four flights all slipped as a result." 9

NASA was being too bold in shuffling manifests. The total resources available to the Shuttle program for- allocation were fixed. As time went on, the agency had to focus those resources more and more on the near term-worrying about today's problem and not focusing on tomorrow's.

NASA also did not have a way to forecast the effect of a change of a manifest. As already indicated, a change to one flight ripples through the manifest and typically necessitates changes to many other flights, each requiring resources (budget, manpower, facilities) to implement. Some changes are more expensive than others, but all have an impact, and those impacts must be understood.

In fact, Leonard Nicholson, manager of Space Transportation System Integration and Operations at Johnson, in arguing for the development of a forecasting tool, illustrated the fact that the resources were spread thin: "The press of business would have hindered us getting that kind of tool in place, just the fact that all of us were busy . . . . "10

The effect of shuffling major payloads can be significant. In addition, as stated earlier, even apparently "easy" changes put demands on the resources of the system Any middeck or secondary payload has, by itself, a minimal impact compared with major payloads. But when several changes are made, and made late, they put significant stress on the flight preparation process by diverting resources from higher priority problems.

Volume III of JSC 07700, Revision B, specifies that all middeck experiments must be scheduled, and payload specialists assigned, 11 weeks before launch. 11 That rule has not been enforced-in fact, it is more honored in the breach than in the observance. A review of missions 41-G through 61-C revealed that of the 16 payload specialists added to those flights, seven were added after launch minus five months.

Even "secondary" payloads take a lot of time and attention when they are added to a flight late. Harold Draughon:

"I spend more than half of my time working on things that are not very important because they get put in so late. Rather than working on PAM's [Payload Assist Modules] and IUS's [Inertial Upper Stages], I am working on chicken eggs." 12

Those directing the changes in the manifest were not yet sensitive to the problem. Each change nibbles away at the operational resources, and the changes were occurring frequently, even routinely. Much of the capacity of the system was being used up responding to late changes in lower priority experiments. That flexibility toward secondary experiments tied up the resources that would have been better spent building capability to meet the projected flight rate.

[173] Tommy Holloway, chief of the Johnson Flight Director Office, emphasized that, given finite resources, one must decide: "It's flight rate versus [manifest] flexibility.'' l3

The portion of the system forced to respond to the late changes in the manifest tried to bring its concerns to Headquarters. As Mr. Nicholson explained,

"We have done enough complaining about it that I cannot believe there is not a growing awareness, but the political aspects of the decision are so overwhelming that our concerns do not carry much weight.... The general argument we gave about distracting the attention of the team late in the process of implementing the flight is a qualitative argument .... And in the face of that, political advantages of implementing those late changes outweighed our general objections. "14

It is important to determine how many flights can be accommodated, and accommodated safely. NASA must establish a realistic level of expectation, then approach it carefully. Mission schedules should be based on a realistic assessment of what NASA can do safely and well, not on what is possible with maximum effort. The ground rules must be established firmly, and then enforced.

The attitude is important, and the word operational can mislead. "Operational" should not imply any less commitment to quality or safety, nor a dilution of resources. The attitude should be, "We are going to fly high risk flights this year; every one is going to be a challenge, and every one is going to involve some risk, so we had better be careful in our approach to each."15

Effect of Flight Rate on Spare Parts

As the flight rate increases, the demand on resources and the demand for spare parts increases. Since 1981, NASA has had logistics plans for Shuttle flight rates of 12 and 24 flights a year. It was originally forecast (in mid-1983) that the supply of spares required to support 12 flights annually could be accomplished in the spring of 1986. Actual inventory of spare parts had run close to plan until the second quarter of fiscal year 1985. At that time, inventory requirements for spares began to increase faster than deliveries. A year later, when inventory stockage should have been complete, only 32,000 of the required 50,000 items (65 percent) had been delivered. 16

The spare parts plan to support 24 flights per year had called for completing inventory stockage by June, 1987. By mid-1985, that schedule was in jeopardy.

The logistics plan could not be fully implemented because of budget reductions. In October, 1985, the logistics funding requirement for the Orbiter program, as determined by Level III management at Johnson, was $285.3 million. That funding was reduced by $83.3 million-a cut that necessitated major deferrals of spare parts purchases. Purchasing deferrals come at great cost. For example, a reduction due to deferral of $11.2 million in fiscal year 1986 would cost $11.2 million in fiscal year 1987, plus an additional $21.6 million in fiscal year 1988. This three-to-one ratio of future cost to current savings is not uncommon. Indeed, the ratio in many instances is as high as seven to one. This practice cannot make sense by any standard of good financial management.

According to Johnson officials, reductions in spares expenditures provided savings required to meet the revised budgets. As Program Manager Arnold Aldrich reported to the Commission:

"There had been fund contentions in the program for a number of years, at least starting in the mid-seventies and running through into the early to mid-eighties . . . intentional decisions were made to defer the heavy build-up of spare parts procurements in the program so that the funds could be devoted to other more pressing activities. . . . It was a regular occurrence for several annual budget cycles. And once the flight rate really began to rise and it was really clear that spare parts were going to be a problem, significant attention was placed on that problem by all levels of NASA and efforts had been made to catch up. But . . . our parts availability is well behind the flight need . . ." 17

Those actions resulted in a critical shortage of serviceable spare components. To provide parts required to support the flight rate, NASA had to resort to cannibalization. Extensive cannibalization of spares, i.e., the removal of components [174] from one Orbiter for installation in another, became an essential modus operandi in order to maintain flight schedules. Forty-five out of approximately 300 required parts were cannibalized for Challenger before mission 51-L. These parts spanned the spectrum from common bolts to a thrust control actuator for the orbital maneuvering system to a fuel cell. This practice is costly and disruptive, and it introduces opportunities for component damage.

This concern was summarized in testimony before the Commission by Paul Weitz, deputy chief of the Astronaut Office at Johnson:

"It increases the exposure of both Orbiters to intrusion by people. Every time you get people inside and around the Orbiter you stand a chance of' inadvertent damage of whatever type, whether you leave a tool behind or whether you, without knowing it, step on a wire bundle or a tube or something along those lines." 18

Cannibalization is a potential threat to flight safety, as parts are removed from one Orbiter, installed in another Orbiter, and eventually replaced. Each handling introduces another opportunity for imperfections in installation and for damage to the parts and spacecraft.

Cannibalization also drains resources, as one Kennedy official explained to the Commission on March 5, 1986:

"It creates a large expenditure in manpower at KSC. A job that you would have normally used what we will call one unit of' effort to do the job now requires two units of effort because you've got two ships [Orbiters] to do the task with." 19

Prior to the Challenger accident, the shortage of' spare parts had no serious impact on flight schedules, but cannibalization is possible only so long as Orbiters from which to borrow are available. In the spring of 1986, there would have been no Orbiters to use as "spare parts bins." Columbia was to fly in March, Discovery was to be sent to Vandenberg, and Atlantis and Challenger were to fly in May. In a Commission interview, Kennedy director of Shuttle Engineering Horace Lamberth predicted the program would have been unable to continue:

"I think we would have been brought to our knees this spring [1986] by this problem [spare parts] if we had kept trying to fly " 20

NASA's processes for spares provisioning (determining the appropriate spares inventory levels), procurement and inventory control are complicated and could be streamlined and simplified.

As of spring 1986, the Space Shuttle logistics program was approximately one year behind. Further, the replenishment of all spares (even parts that are not currently available in the system) has been stopped. Unless logistics support is improved, the ability to maintain even a three-Orbiter fleet is in jeopardy.

Spare parts provisioning is yet another illustration that the Shuttle program was not prepared for an operational schedule. The policy was shortsighted and led to cannibalization in order to meet the increasing flight rate.

The Importance of Flight Experience

In a developmental program it is important to make use of flight experience, both to understand the system's actual performance and to uncover problems that might not have been discovered in testing. Because Shuttle flights were coming in fairly rapid succession, it was becoming difficult to analyze all the data from one flight before the next was scheduled to launch. In fact, the Flight Readiness Review for 51-L was held while mission 61-C was still in orbit. Obviously, it was impossible to even present, much less analyze and understand, anomalies from that flight.

The point can be emphasized by citing two problems that occurred during mission 61-C but were discovered too late to be considered at the 51-L Flight Readiness Review:

1. The Space Shuttle brakes and tires have long been a source of concern. In particular, after the 51-D Orbiter blew a tire at Kennedy in April, 1985, there was considerable effort (within budgetary constraints) to understand and resolve the problems, and Kennedy landings were suspended until certain improvements were made. (See section "Landing: Another Critical Phase!" page 186.) Mission 51 -L was to be the first flight to land [175] in Florida since 51 -D had experienced brake problems. STS 61-C landed at Edwards Air Force Base in California on January 19, 1986, four days after the 51-L Flight Readiness Review. The 61-C brakes were removed following landing and shipped to the vendor for further inspection and analysis. That inspection revealed major brake damage. The subsystem manager at Johnson in charge of the brakes did not receive the information until January 27, 1986, one day before 51-L was launched, and did not learn the extent of the problem until January 30, 1986.

2. The inspection of the 61 -C Solid Rocket Booster segments was completed on January 19, 1986, four days after the 51-L Level I Flight Readiness Review. The post-recovery inspection of the 61 -C Solid Rocket Booster segments revealed that there was O-ring erosion in one of the left booster field joints and additional O-ring anomalies on both booster nozzles. Although the information was available for Marshall's 51 -L Level III review at launch minus one day, it was clearly not available in time for consideration in the formal launch preparation process.21 These examples underscore the need to establish a list of mandatory post-flight inspections that must precede any subsequent launch.

Effect on Payload Safety

The payload safety process exists to ensure that each Space Shuttle payload is safe to fly and that on a given mission the total integrated cargo does not create a hazard. NASA policy is to minimize its involvement in the payload design process. The payload developer is responsible for producing a safe design, and the developer must verify compliance with NASA safety requirements. The Payload Safety Panel at Johnson conducts a phased series of safety reviews for each payload. At those reviews, the payload developer presents material to enable the panel to assess the payload's compliance with safety requirements.

Problems may be identified late, however, often as a result of late changes in the payload design and late inputs from the payload developer. Obviously, the later a hazard is identified, the more difficult it will be to correct, but the payload safety process has worked well in identifying and resolving safety hazards.

Unfortunately, pressures to maintain the flight schedule may influence decisions on payload safety provisions and hazard acceptance. This influence was evident in circumstances surrounding the development of two high priority scientific payloads and their associated booster, the Centaur.

Centaur is a Space Shuttle-compatible booster that can be used to carry heavy satellites from the Orbiter's cargo bay to deep space. It was scheduled to fly on two Shuttle missions in May, 1986, sending the NASA Galileo spacecraft to Jupiter and the European Space Agency Ulysses spacecraft first to Jupiter and then out of the planets' orbital plane over the poles of the Sun. The pressure to meet the schedule was substantial because missing launch in May or early June meant a year's wait before planetary alignment would again be satisfactory.

Unfortunately, a. number of safety and schedule issues clouded Centaur's use. In particular, Centaur's highly volatile cryogenic propellants created several problems. If a return-to-launch-site abort ever becomes necessary, the propellants will definitely have to be dumped overboard. Continuing safety concerns about the means and feasibility of dumping added pressure to the launch preparation schedule as the program struggled to meet the launch dates.

Of four required payload safety reviews, Centaur had completed three at the time of the Challenger accident, but unresolved issues remained from the last two. In November, 1985, the Payload Safety Panel raised several important safety concerns. The final safety review, though scheduled for late January, 1986, appeared to be slipping to February, only three months before the scheduled launches.

Several safety waivers had been granted, and several others were pending. Late design changes to accommodate possible system failure would probably have required reconsideration of some of the approved waivers. The military version of the Centaur booster, which was not scheduled to fly for some time, was to be modified to provide added safety, but because of the rush to get the 1986 missions launched, these improvements were not approved for the first two Centaur boosters. After the 51-L accident, NASA allotted more than $75 million to incorporate the [176] operational and safety improvements to these two vehicles.22 We will never know whether the payload safety program would have allowed the Centaur missions to fly in 1986. Had they flown, however, they would have done so without the level of protection deemed essential after the accident.

Outside Pressure to Launch

After the accident, rumors appeared in the press to the effect that persons who made the decision to launch mission 51-L might have been subjected to outside pressure to launch. Such rumors concerning unnamed persons, emanating from anonymous sources about events that may never have happened, are difficult to disprove and dispel. Nonetheless, during the Commission's hearings all persons who played key roles in that decision were questioned. Each one attested, under oath, that there had been no outside intervention or pressure of any kind leading up to the launch.

There was a large number of other persons who were involved to a lesser extent in that decision, and they were questioned. All of those persons provided the Commission with sworn statements that they knew of no outside pressure or intervention. 23

The Commission and its staff also questioned a large number of other witnesses during the course of the investigation. No evidence was reported to the Commission which indicated that any attempt was ever made by anyone to apply pressure on those making the decision to launch the Challenger.

Although there was total lack of evidence that any outside pressure was ever exerted on those who made the decision to launch 51-L, a few speculative reports persisted.

One rumor was that plans had been made to have a live communication hookup with the 51-L crew during the State of the Union Message. Commission investigators interviewed all of the persons who would have been involved in a hookup if one had been planned, and all stated unequivocally that there was no such plan. Furthermore, to give the crew time to become oriented, NASA does not schedule a communication for at least 48 hours after the launch and no such communication was scheduled in the case of flight 51-L.

The flight activity officer who was responsible for developing the crew activity plan testified that three live telecasts were planned for the Challenger, but they related in no way to the State of the Union Message: 24

The Commission concluded that the decision to launch the Challenger was made solely by the appropriate NASA officials without any outside intervention or pressure.

Findings

1. The capabilities of the system were stretched to the limit to support the flight rate in winter 1985/1986. Projections into the spring and summer of 1986 showed a clear trend; the system, as it existed, would have been unable to deliver crew training software for scheduled flights by the designated dates. The result would have been an unacceptable compression of the time available for the crews to accomplish their required training.

2. Spare parts are in critically short supply. The Shuttle program made a conscious decision to postpone spare parts procurements in favor of budget items of perceived higher priority. Lack of spare parts would likely have limited flight operations in 1986.

3. Stated manifesting policies are not enforced. Numerous late manifest changes (after the cargo integration review) have been made to both major payloads and minor payloads throughout the Shuttle program.

[177] 4. The scheduled flight rate did not accurately reflect the capabilities and resources.

5. Training simulators may be the limiting factor on the flight rate: the two current simulators cannot train crews for more than 12-15 flights per year.

6. When flights come in rapid succession, current requirements do not ensure that critical anomalies occurring during one flight are identified and addressed appropriately before the next flight.

References