Let’s be honest — geysers are really cool. You’ve got an eruption of water and vapor that can burst to heights of 185 feet. What’s not to like about that?

When building propellant tanks for the world’s most powerful rocket, NASA engineers want to make sure Old Faithful stays in Yellowstone. So beginning Aug. 5, anti-geyser testing is underway at NASA’s Marshall Space Flight Center in Huntsville, Alabama, for the agency’s Space Launch System (SLS) — the rocket that will make deep space missions possible, including to an asteroid and ultimately to Mars.

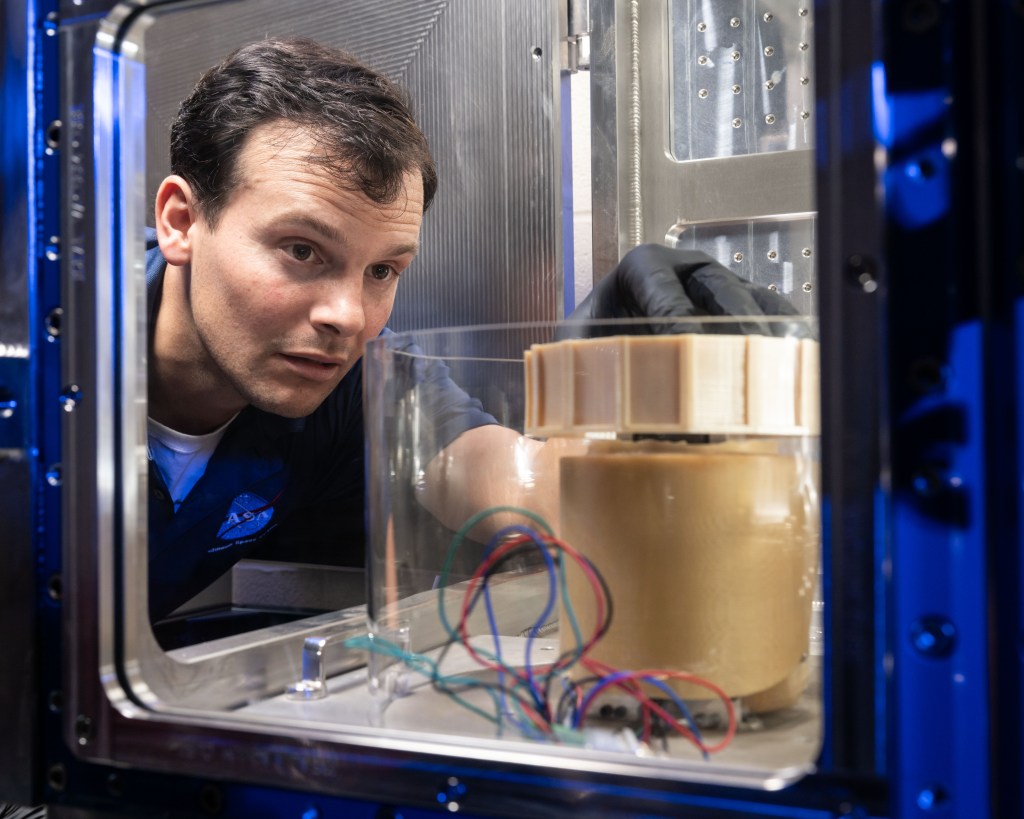

A full-scale replica of the SLS liquid oxygen tank feed system — which will be housed in the rocket’s core stage — is set up on one of Marshall’s test stands to show that proven procedures will keep the tank’s thousands of gallons of oxidizer from geysering. Oxidizer is a type of chemical that fuels require to burn.

“Geysering occurs when heat enters the system and forms gas bubbles,” said Chad Bryant, propulsion manager in the Stages Office at Marshall, where the SLS Program is managed for the agency. “Those bubbles displace the liquid and allow it to come crashing down, which can cause hardware damage. In order to prevent geysering the first time the actual vehicle is loaded, we are going through different scenarios using the test article. We want to manage the quality of the liquid oxygen that’s in the system to prevent heat buildup, which would cause these gas bubbles to form.”

As propellant is poured into the system from the bottom, helium is injected into different points along two feed lines that deliver the propellant all the way up to the tank. “The helium really acts as a spoon — it induces circulation almost like stirring and keeps the propellant uniform and at the right temperature,” said Jacob Parton, anti-geyser test conductor. “This is the largest testing effort I’ve been a part of at Marshall. It took about 12 trailers carrying approximately 6,000 gallons of propellant each to fill the test article tank.

“The majority of the test hardware is geometrically comparable to actual flight hardware for the SLS and was built here at the center, except for the tank itself,” Parton added.

Watch a video of the anti-geyser testing:

The tank, about 40 feet tall, was provided by The Boeing Co., prime contractor for the SLS core stage and its avionics. Testing is scheduled to be completed in November.

The first flight test of the SLS will feature a configuration for a 70-metric-ton (77-ton) lift capacity and carry an uncrewed Orion spacecraft beyond low-Earth orbit to test the performance of the integrated system. As the SLS evolves, it will provide an unprecedented lift capability of 130 metric tons (143 tons) to enable missions even farther into our solar system.

For more information, visit the SLS website.

By Megan Davidson

Marshall Space Flight Center, Huntsville, Ala.

Media Contact:

Kim Henry

Marshall Space Flight Center, Huntsville, Ala.

256-544-0034