Overview

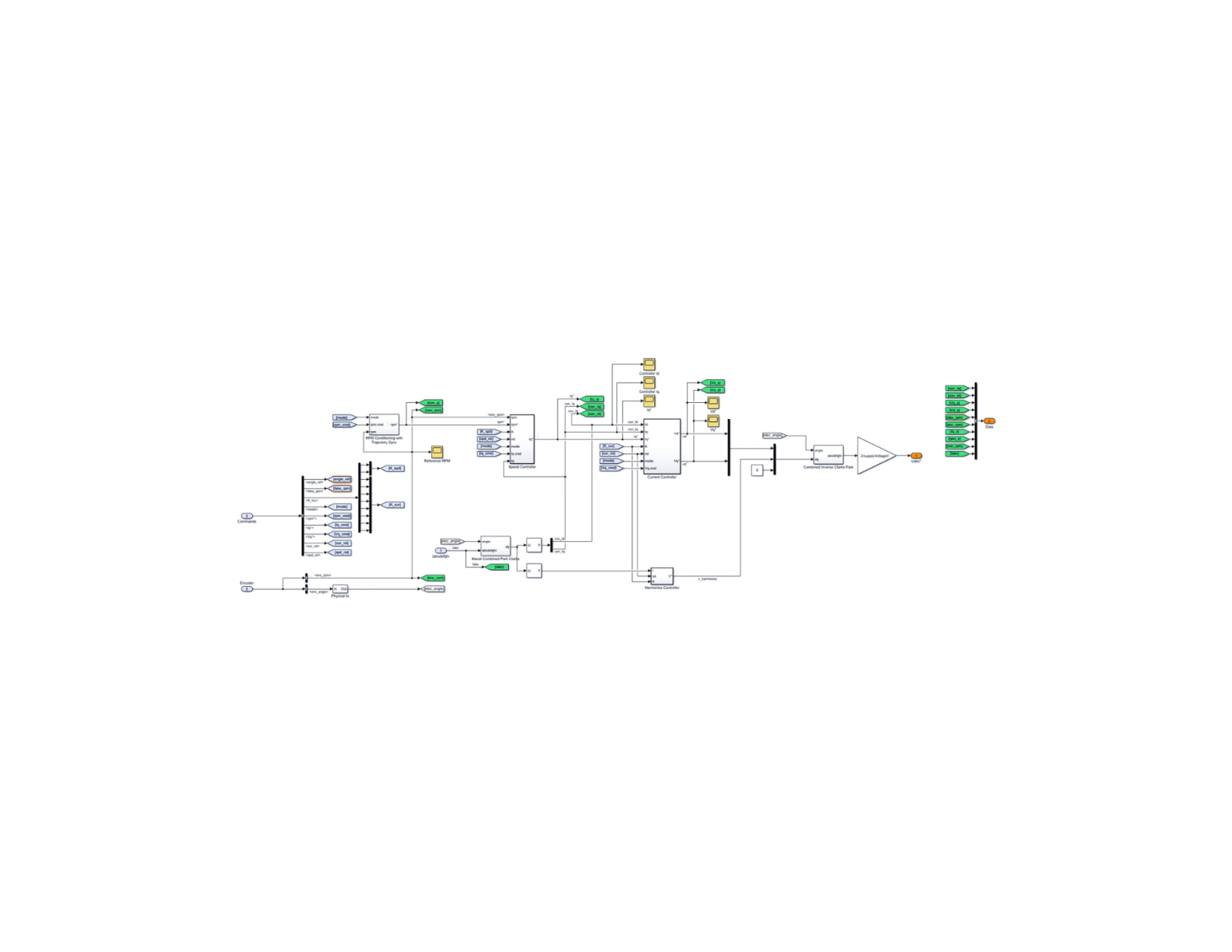

A big challenge when designing propulsion system components for electrified aircraft is managing weight and energy loss during operation. When dealing with megawatt-levels of power, lightweight systems with minimal energy loss are crucial in ensuring high efficiency.

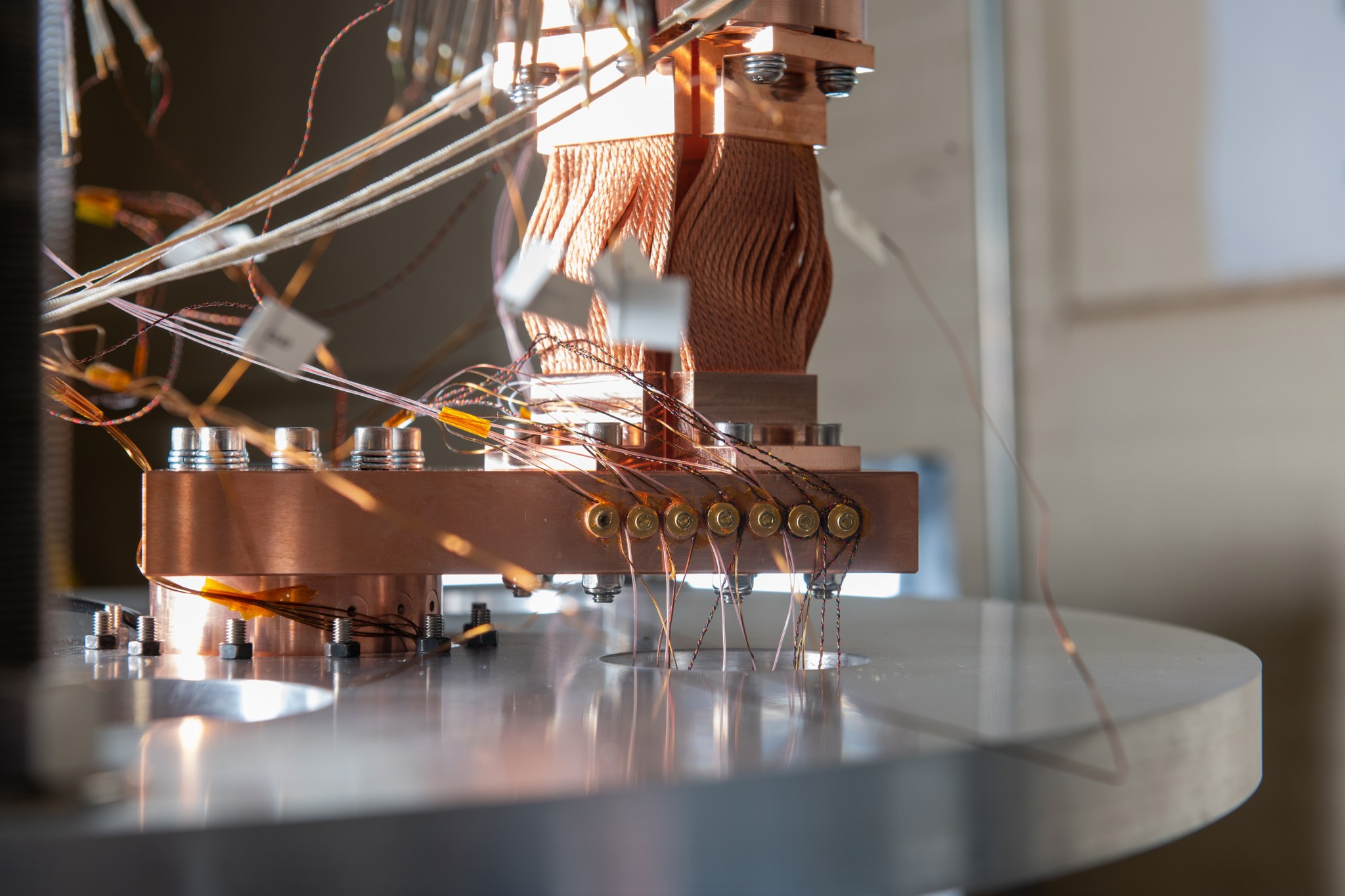

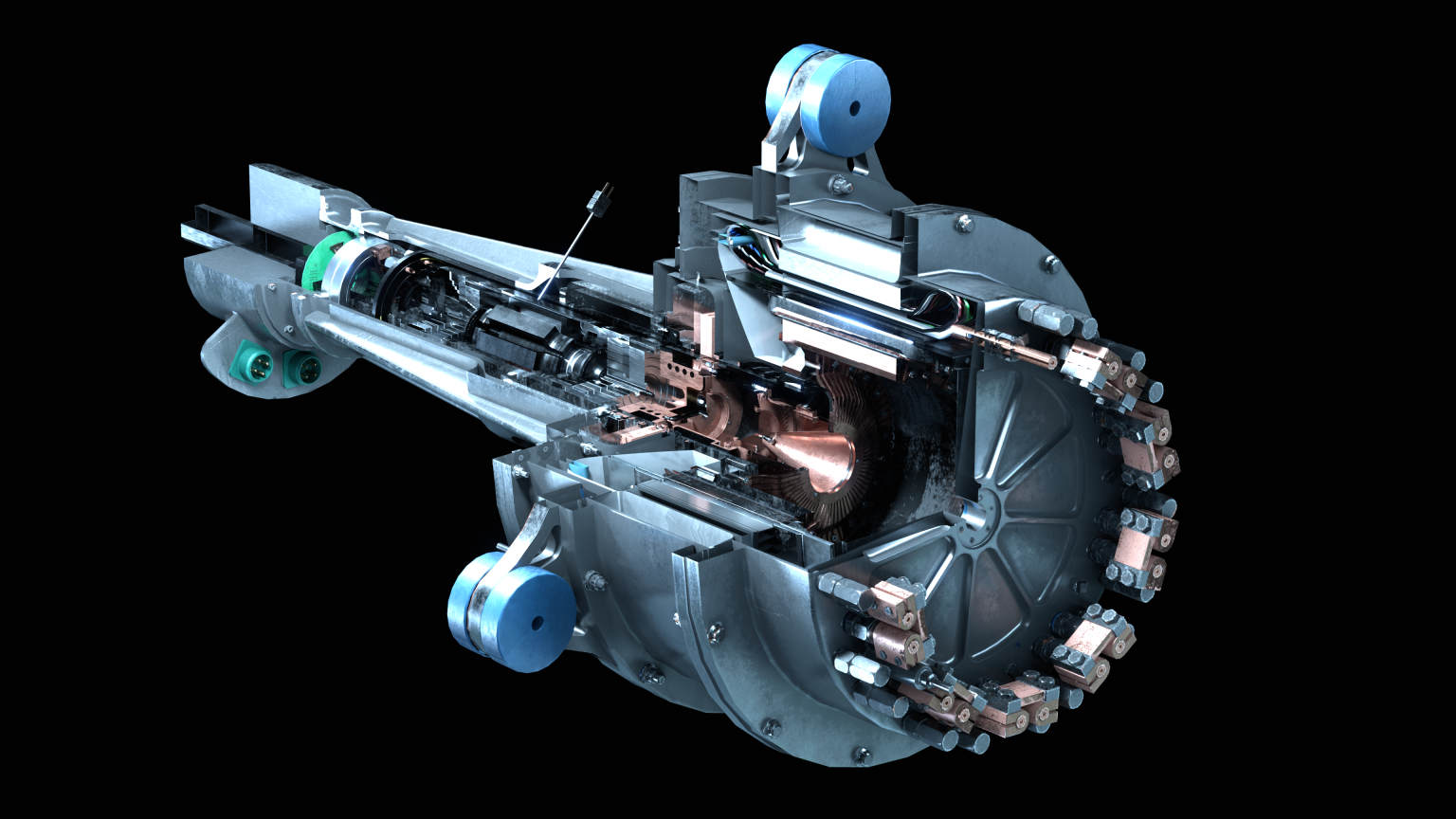

NASA is collaborating with industry to advance research and development of superconducting wires for use in motors and generators on aircraft with turboelectric propulsion system configurations. The materials used in superconducting wires eliminate electrical resistance when cooled below a critical temperature, which helps support higher current loads with minimal energy loss.

Technology Development

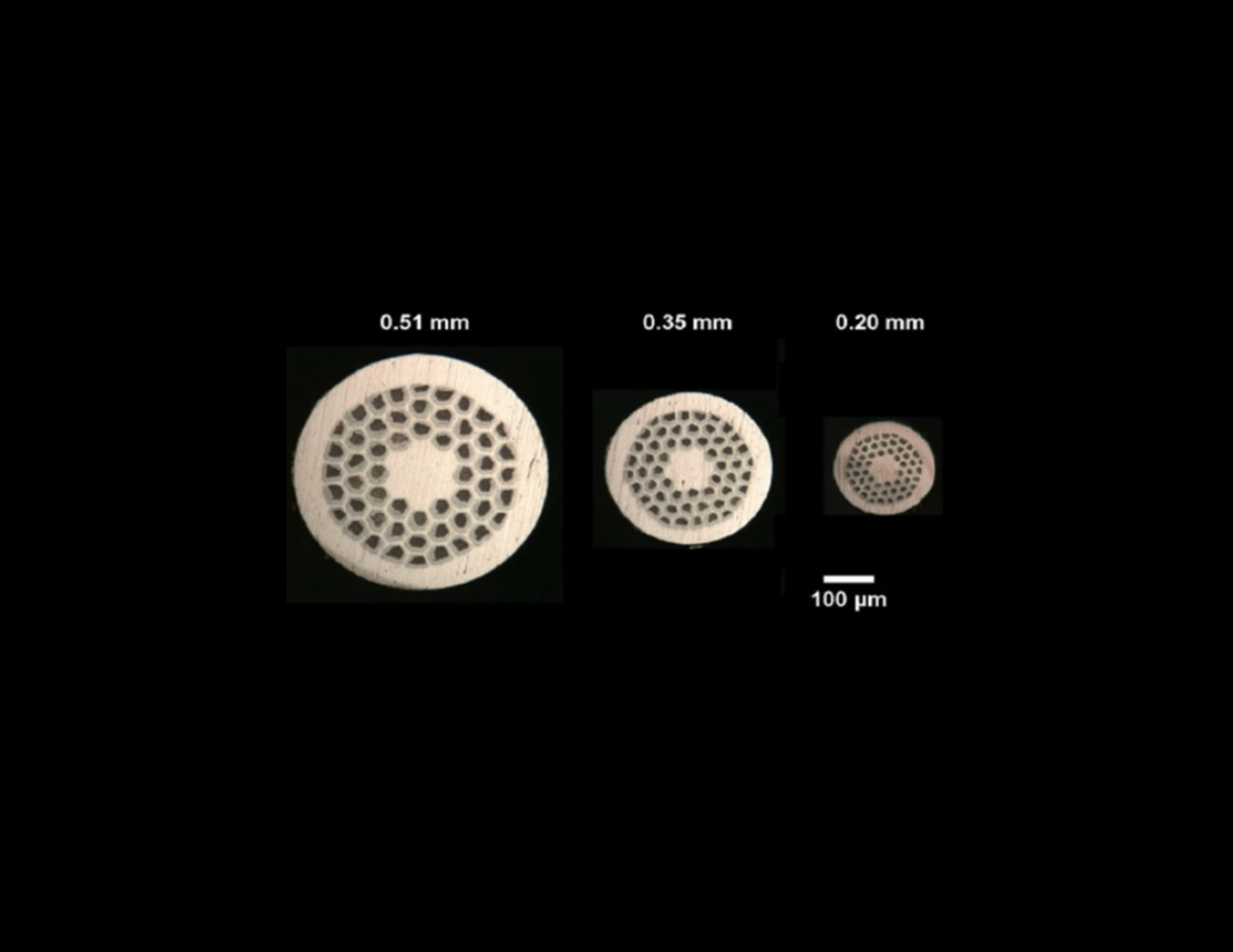

Through a series of NASA Small Business Innovation Research (SBIR) contracts, engineers at Hyper Tech Research developed new superconducting wires using fine-filament magnesium diboride (MgB2). Wires designed with this material showed a reduction in alternating current (AC) losses while enabling higher frequencies and reduced weight at a lower cost.

The company also demonstrated a new wire manufacturing process that uses magnesium-infiltration instead of magnesium boron powder mixtures typically used in the traditional method. This switch helped improve the wire’s current density and overall efficiency.

Testing and Analysis

NASA’s Glenn Research Center in Cleveland is home to a superconducting laboratory that provides unique resources to test electrified aircraft components at cryogenic temperatures as low as 12 Kelvin (K) without the need to handle hazardous fluids. The environment also allows for measuring AC and direct current (DC) losses in superconductors.

Learn More