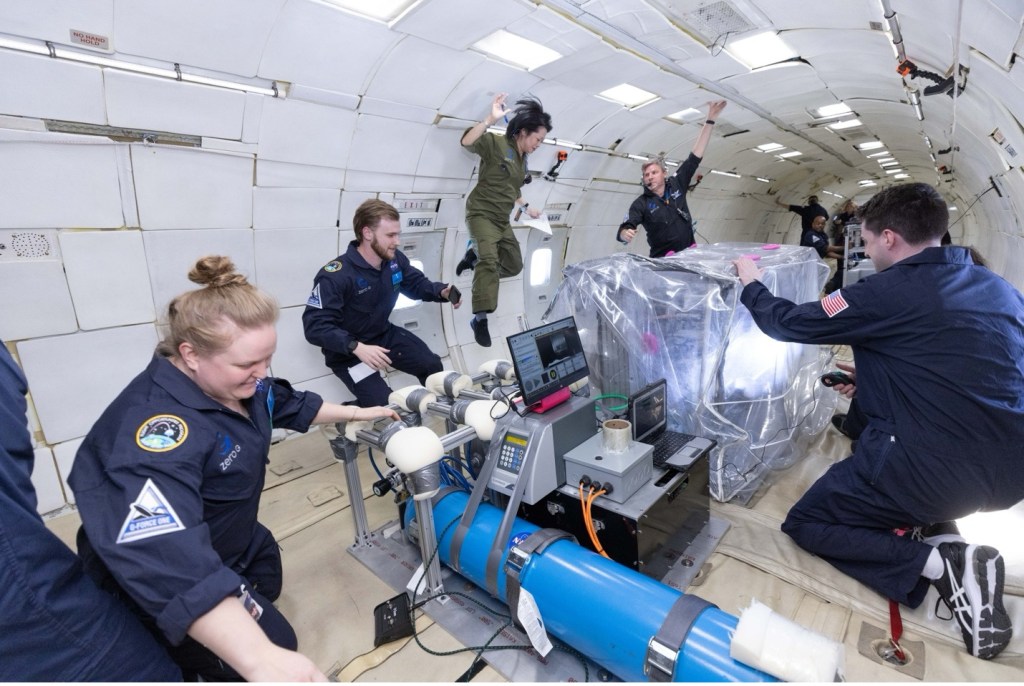

NASA’s Flight Opportunities program supported the testing of 19 technologies in a series of parabolic flights in spring 2024. During brief periods of microgravity as well as lunar gravity, researchers collected data for projects that address several technology shortfalls across the civil space ecosystem. With this data, researchers will prepare for orbital demonstrations aboard the International Space Station, enhance their technologies for further suborbital testing, and share their findings with the scientific and technology community.

Flight Provider

Zero Gravity Corporation

Flight Test Platform

Aircraft flying parabolic profiles

Flight DateS

February–April 2024

Location

Fort Lauderdale, Florida

Advanced Manufacturing | Cryogenic Fluid Management | In-Situ Resource Utilization

Thermal Management Systems | Lunar/Mars Global Access | Advanced Habitation Systems

Large-Scope Bioprinting in Microgravity

Researchers from the Center for Applied Space Technology tested a bioprinter prototype as proof-of-concept for a full-scale, commercial bioprinting facility in low Earth orbit. Bioprinting in microgravity could allow for the large-scale production of cells and tissues more efficiently than on Earth.

On-Demand Manufacturing of Electronics (ODME) Advanced Toolplate

Researchers from NASA’s Marshall Space Flight Center in collaboration with Sciperio and Redwire Space tested a newly developed advanced toolplate with eight miniaturized swappable toolheads for infusion into a low-gravity, on-demand manufacturing system for flexible, hybrid electronic devices currently under development. The technology is supported by the Space Mission Technology Directorate’s (STMD) Game Changing Development program under its ODME project.

Space Enabled Advanced Devices and Semiconductors (SEADS)

Researchers from NASA, industry, and academia took the first step in studying the use of a novel 3D printing technique that leverages electrohydrodynamic inkjet printing (EHD) to manufacture advanced memory devices in microgravity. This work is a continuation of prior parabolic flight tests in 2021 and 2022 to mature the technology. Collaborators included Intel, University of Wisconsin-Madison, Arizona State University, and Iowa State University. This technology is supported by the STMD Game Changing Development program under its ODME project, in conjunction with the Space Operations Mission Directorate’s (SOMD) In Space Productions Applications (InSPA).

Manufacturing of Semiconductors and Thin-Film Integrated Coatings (MSTIC)

A research team from Redwire Space collected microgravity data of the facility known as MSTIC. This autonomous semiconductor manufacturing platform is a collaborative effort with the International Space Station National Laboratory and NASA and is supported by SOMD’s InSPA.

Fluids at Altitude Mixing Experiment (FAME)

Redwire Space tested a variety of liquid-handling processes associated with hardware designed to test multiple crystallization conditions in microgravity and provide samples back to Earth for analysis. The goal of this hardware is to provide services to pharmaceutical and institutional researchers seeking to use target molecules in their crystalline state to reformulate existing products and/or develop formulations for new products. The development of this hardware is supported by SOMD’s InSPA.

Acoustofluidics-Based Multifunctional Manipulation of Micro- and Nanoparticles

Researchers from Mississippi State University examined the acoustic effects on micro- and nanoparticles (or colloids) suspended in liquids under reduced gravity. Colloids have shown potential for additive manufacturing, drug delivery, and more. Researchers aim to develop a novel 3D printing platform that can actively manipulate colloids in reduced gravity, arranging them in resins and fabricating polymer composites containing patterned or aligned particles. This work is supported by NASA’s Established Program to Stimulate Competitive Research (EPScoR).

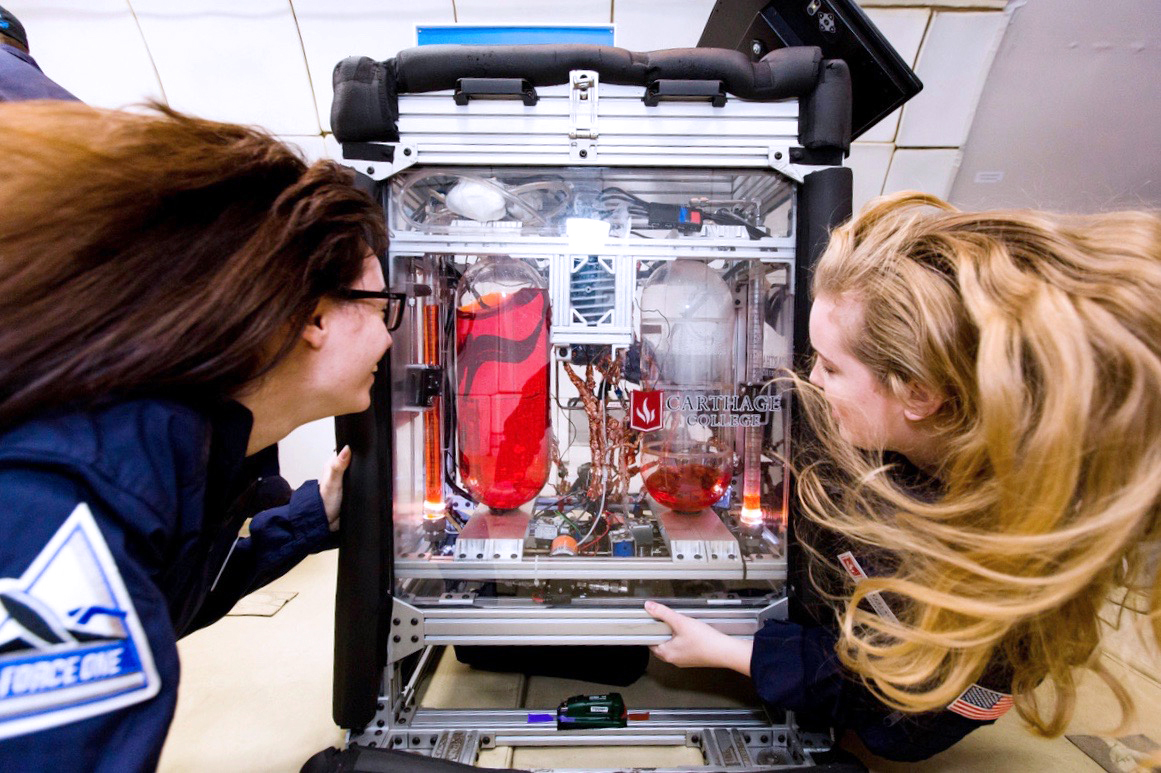

Noninvasive Detection of Liquid Propellant Location

Researchers from Carthage College tested their noninvasive propellant gauging technology designed to facilitate the transfer and storage of cryogenic propellants in microgravity – a key need for refueling of the power and propulsion element for future Gateway lunar station-keeping.

Computational Fluid Dynamics Boiling Models

Massachusetts Institute of Technology researchers collected data to optimize models for cryogenic fluid management through predictive simulations of boiling heat transfer. Accurate modeling of phase change in cryogenic propellants is critical for long-duration crewed missions.

Stability of In-Space Cryogenic Systems

New Jersey Institute of Technology researchers gathered data to understand propellant stability during activities such as refueling, specifically as it relates to temperature and mechanical disturbances. The storage and transfer of cryogenic propellants in microgravity is important for lunar and deep space exploration. Results from the flight test could lead to a strategy to enhance safety and prevent hydraulic shocks.

Measuring Cryogenic Two-Phase Heat Transfer Coefficients for Future In-Space Transfer Systems

Purdue University researchers performed reduced-gravity experiments to gather heat flux data as part of an ongoing effort to develop more precise computational models. These models support the prediction of flow boiling to improve the design of in-space cryogenic fluid management systems and cryogenic propellant transfer systems.

Nucleation of Cryogenic Bubbles in Spacecraft Liquid Acquisition Devices

Another payload from Purdue University sought to understand questions raised during a precursor NASA project on the International Space Station, where vapor bubbles formed during a reduction in test tank pressure. On the parabolic flights, researchers tested a liquid-vapor nitrogen system to explore thermodynamic states and relevant changes, with the goal of helping to advance long-term cryogenic propellant storage in the weightlessness of space.

Development of Cryogenic Propellant Storage Tank Inner Surface Coating

University of Florida researchers tested the effectiveness of several coating candidates to minimize or eliminate propellant boiloff, which can occur on a storage tank’s internal surface from external heat leakage and hotspots. The vapor generation due to boiloff can result in pressure buildup requiring the venting of propellant. Exploring and developing capabilities of the various coating materials and surface finish combinations could lead to substantial propellant savings.

Lightweight, Reliable Cryogenic Screen Channel Acquisition Devices

Creare tested a liquid acquisition device designed to advance cryogenic fluid management in orbit and on the lunar surface. The device optimizes the position of residual liquid in a fuel tank to improve expulsion efficiency and could address the need for vapor-free propellant on long-duration missions. This technology has been developed through NASA’s Small Business Innovation Research/Small Business Technology Transfer (SBIR/STTR) program.

Effects of Extraterrestrial Gravity on Soil Fluidization Imposed by an Ultrasonic Probe

NASA’s Glenn Research Center tested a lunar excavation tool that leverages the use of forced, resonant vibration to fluidize soil around the leading edge of a probe or shovel, requiring less force for the tool to move through the soil. Reduction of excavation forces for a given tool can enable vehicle mass reduction and thereby reduce launch costs. Also supported by STMD’s Game Changing Development program, this technology for extraterrestrial mining or prospecting machinery could enable commodity production on the lunar surface.

Strata-2P: Characterizing Sensor-Regolith Interactions

University of Central Florida tested technologies for investigating the formation and interaction of small particles and layered structures in low-gravity environments to inform robotic and in-situ exploration. Specifically, researchers aim to provide a more detailed understanding of the behavior of dust and regolith on the surfaces of planetary bodies, including how those surfaces respond to disturbances and the subsequent effect on reduced-gravity operations.

Thermal Transport Characterization of Phase Change Material (PCM)

Another payload from Mississippi State University tested a novel PCM design solution that combines the high heat absorption of PCMs with the high thermal conductivity of additively manufactured octet-shaped metal foam meshes. The objective is to enhance the understanding of the phase-change process under microgravity conditions and to address the PCM incorporation challenges. This work is also supported by NASA’s Established Program to Stimulate Competitive Research (EPScoR).

3D Plume-Surface Interaction and Crater Formation Dynamic Measurements

During lunar landings the rocket plume disturbs regolith, which can result in cratering, severe lunar dust blowing, and particle ejecting. Auburn University researchers gathered data on plume-surface interaction in reduced and lunar gravity conditions to better understand the underlying physics and enable safe landings. (Video credit: Auburn University)

Human Waste Ultrasonic Dryer

Ultrasonic Technology Solutions tested a prototype of an ultrasonic drying device for human solid waste in reduced gravity. Water recovery and solid waste stabilization are critical for astronaut health on long-duration space missions. The device had its origins in the Department of Energy’s Oak Ridge National Laboratory. The technology development is supported by the agency’s SBIR program and the Logistics Reduction program under SOMD.

Photo credits: Zero Gravity Corporation unless otherwise noted.