The last thing you need on a trip to the Moon is a flat tire. Luckily, NASA’s water-hunting robot – bound for the lunar surface in 2023 – has no tires! But the all-metal wheels of the Volatiles Investigating Polar Exploration Rover, or VIPER, will have to withstand a whole lot of rocking and rolling as they move across the rugged lunar surface. Before the rover’s design was finalized at its Critical Design Review, the endurance of its wheels had to undergo rigorous testing in the lab. The tests helped solidify plans for the wheels and gave engineers an opportunity to study its movements, in the name of designing even better mobility controls for future rovers.

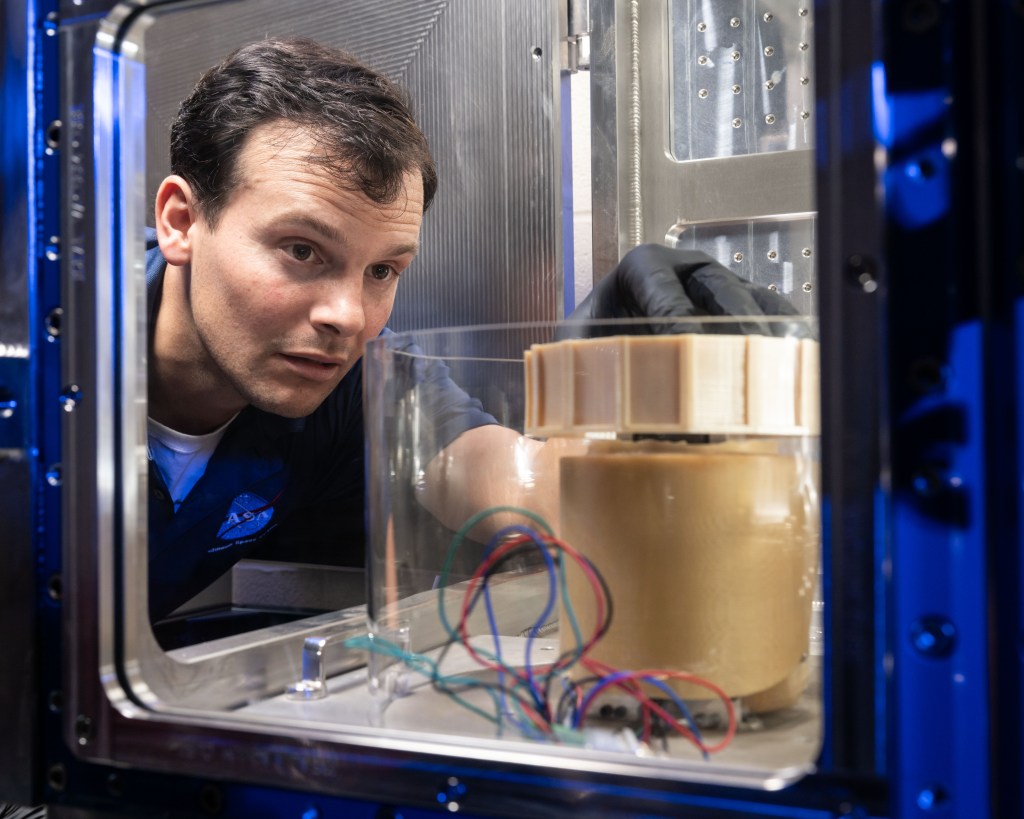

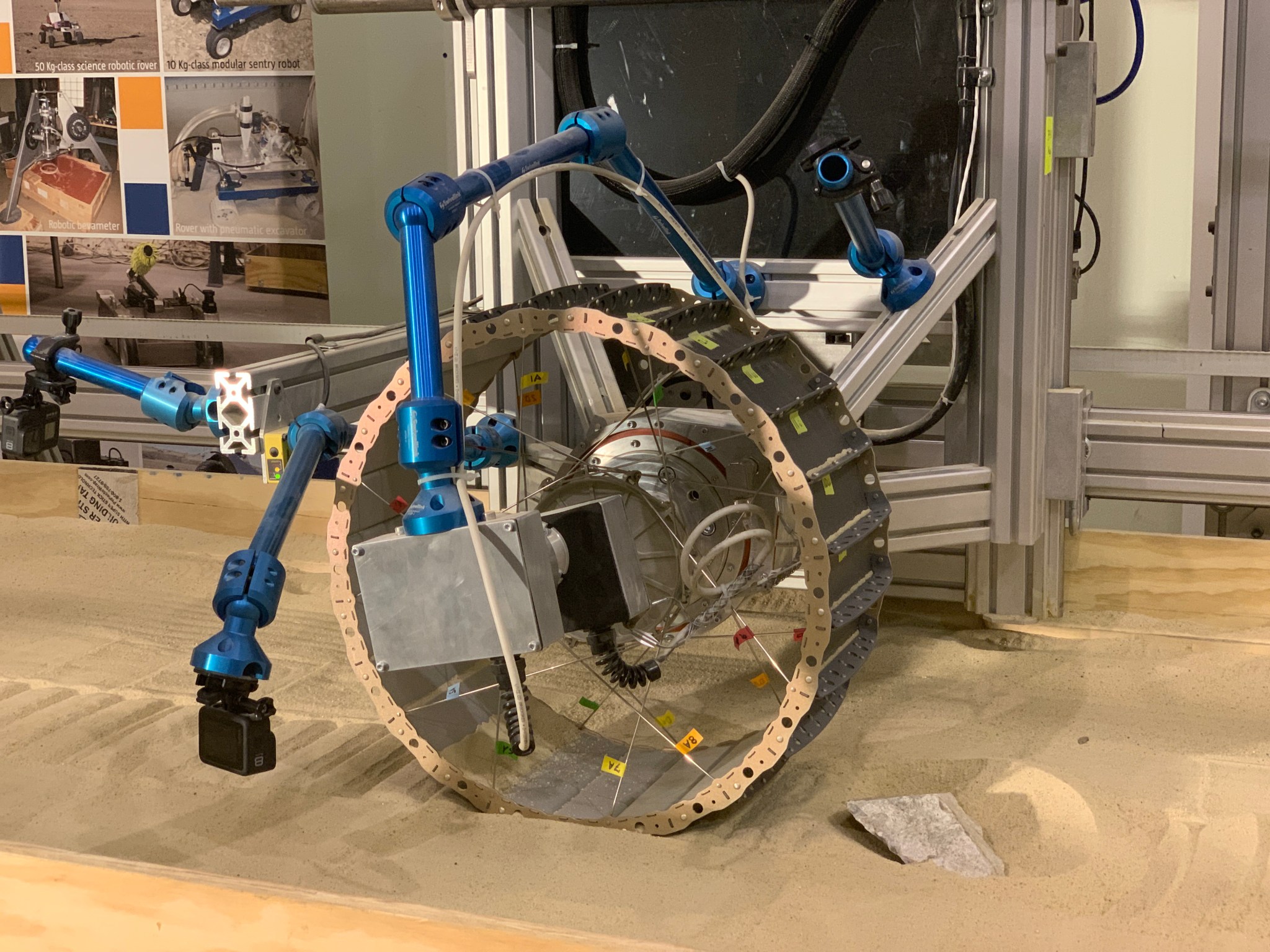

Using a Moon-mimicking set-up in the lab, the VIPER team tested one of the rover’s wheels over a three-week period. It clocked 25 miles of movement in a high-tech sandbox filled with lunar soil simulant, running through a battery of tests. They simulated slopes, wheel slips, and even the size, shape, and distribution of rocks the rover will encounter on the Moon.

While NASA has considerable experience designing Mars rovers, engineers had to invent new technology for controlling VIPER’s wheels in the unexplored environment of the Moon’s South Pole.

“Lunar regolith is fluffy due to the low gravity and lack of most weathering processes, and the particles are sharp like broken glass,” said Arno Rogg, a rover mobility system engineer at NASA’s Ames Research Center in California’s Silicon Valley. “Rocks of various sizes are scattered everywhere on the Moon’s surface. All that presented some real engineering challenges to designing a lightweight, performant, and robust wheel for the half-ton rover.”

To test if their wheel was ready for the Moon, the team worked with ProtoInnovations of Pittsburgh. The robotics company, which also designed software controls for VIPER’s wheels, is working to improve rover driving ability in unknown and highly variable lunar terrain. Their work is supported by NASA’s Small Business Innovation Research and Small Business Technology Transfer program.

At the ProtoInnovations lab, engineers attached one of VIPER’s wheels to the narrow, 20-foot-long lunar sandbox equipped with measuring devices, cameras, and robotic controls for simulating slipping and sliding. The wheel rolled slowly back and forth under conditions that simulated as closely as possible what it will experience on the Moon.

Well-defined slopes were created in the lunar soil simulant, and the wheel’s tracks were studied after any significant slip. Sensors let the team measure how much the wheel sank into the soil, its traction performance, and how it maneuvered over rocks.

“Simulating on Earth the way the rover will move on the Moon required complicated robotic controls – but that’s what we do,” said Dimi Apostolopoulos, CEO of ProtoInnovations. “Our biggest challenge was picking just the right rocks to stand in for Moon rocks in the test bed.”

Goldilocks Moon Rocks

Actual samples of Moon rocks are, of course, too precious to use for a rover test drive, and the terrestrial stand-ins had to be just right. Too hard or too soft and they’d give a false impression of the challenge the rover will face.

The team secured some of the rare Earth rocks that most closely resemble the Moon’s, and, by scaling down real data about the distribution of lunar rocks, learned how many of what size should be used in the test bed. They also learned how to space them so the wheel experienced hitting rocks the way it will during VIPER’s mission.

In all, the wheel was put through 196 scenarios of different rock shapes, heights, and positions the rover is likely to find on the Moon.

“Overall, the wheel’s performance was excellent,” said Rogg. “At the end of the test, both its physical condition and its behavior – looking especially at its traction – were only slightly degraded compared to when we started the test. By driving the wheel more than twice the distance it’s expected to travel on the lunar surface, we reduced the risk of any premature wheel failure occurring on the Moon.”

Minor weaknesses detected in the wheels during testing were addressed by VIPER’s mechanical design team with improvements that went into the rover’s final design. VIPER will be delivered to the surface of the Moon in late 2023 as part of the Commercial Lunar Payload Services initiative.

For news media: Members of the news media interested in covering this topic should reach out to the NASA Ames newsroom.

Author: Abby Tabor, NASA’s Ames Research Center