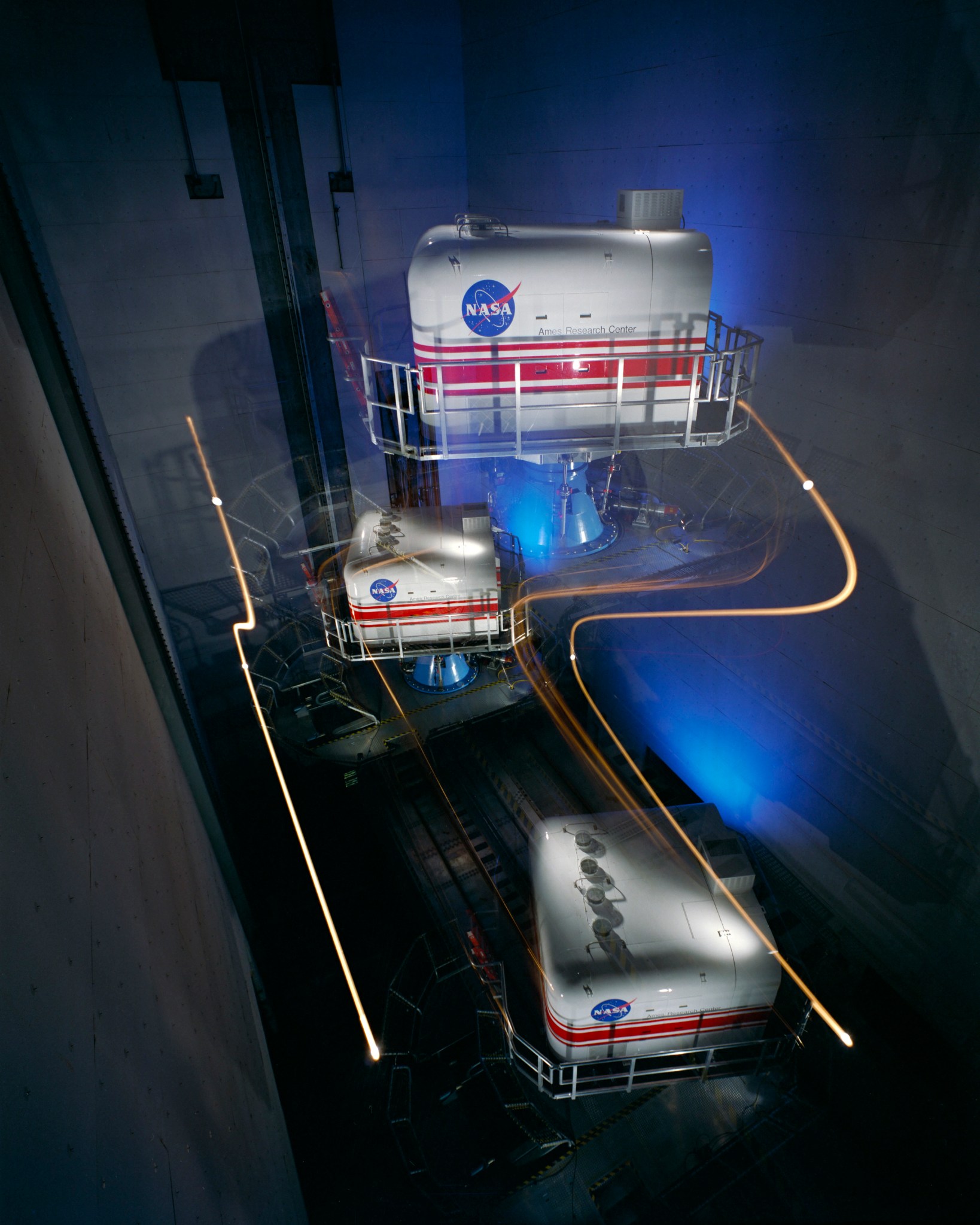

The Vertical Motion Simulator (VMS) complex is an important national resource that supports many of the country’s most sophisticated aerospace research and development programs. Its motion base has the largest vertical displacement of any simulator in the world, allowing the VMS to provide the highest level of motion fidelity available in the simulation community.

Housed in a ten-story tower, the large amplitude motion system allows the simulator to travel up to 60 feet vertically and 40 feet laterally. The simulator operates with three translational degrees of freedom (vertical, lateral, and longitudinal) and three rotational degrees of freedom (pitch, roll, and yaw), and it can perform at maximum capability in all axes simultaneously.

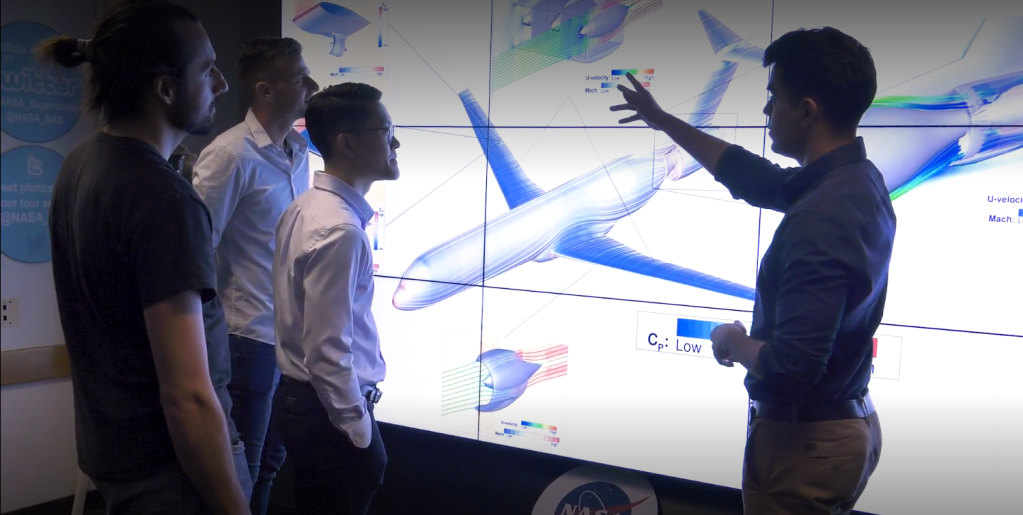

The operational efficiency of the laboratory is enhanced by the Interchangeable Cab (ICAB) system, which consists of five different interchangeable and completely customizable cabs. The flexibility of the ICAB system allows the VMS to simulate any type of vehicle, whether it is already in existence or merely in the conceptual phase. Each ICAB is customized, configured, and tested at a fixed-base development station, after which it is either used in-place for a simulation at one of the VMS’s fixed-base labs or moved onto the motion platform.

While the VMS offers much that is unique, two capabilities stand out. First, engineers can customize the system to simulate any aerospace vehicle, whether existing or in the design stage. Existing vehicles that have been simulated include an airship, helicopters, fighter jets, and the Space Shuttle Orbiter.

Second, simulations occur with high fidelity; that is, the simulator reproduces the flight characteristics of an aircraft with a high degree of accuracy. This entails delivering realistic cues to the pilot in real time, so that the pilot perceives that the simulated aircraft responds just as quickly as a real aircraft.

At the VMS, flexibility in both hardware and software allow the simulation of any aerospace vehicle. Powerful computers and custom-designed systems enable high-fidelity, real-time simulation. By providing flexible, accurate tools and the support of experts, the facility offers researchers quick and cost-effective solutions in aeronautical design.

| VMS Motion System Performance Limits | ||||||

| Degree of Freedom | Displacement | Velocity | Acceleration | |||

| System Limits | Operational Limits | System Limits | Operational Limits | System Limits | Operational Limits | |

| Longitudinal | ± 4 ft | ± 3 ft | ± 5 ft/sec | ± 4 ft/sec | ± 16 ft/sec/sec | ± 10 ft/sec/sec |

| Lateral | ± 20 ft | ± 15 ft | ± 8 ft/sec | ±8 ft/sec | ± 13 ft/sec/sec | ± 13 ft/sec/sec |

| Vertical | ± 30 ft | ± 22 ft | ± 16 ft/sec | ±15 ft/sec | ± 22 ft/sec/sec | ± 22 ft/sec/sec |

| Roll | ± 0.31 rad | ± 0.24 rad | ± 0.9 rad/sec | ± 0.7 rad/sec | ± 4 rad/sec/sec | ± 2 rad/sec/sec |

| Pitch | ± 0.31 rad | ± 0.24 rad | ± 0.9 rad/sec | ± 0.7 rad/sec | ± 4 rad/sec/sec | ± 2 rad/sec/sec |

| Yaw | ± 0.42 rad | ± 0.34 rad | ± 0.9 rad/sec | ± 0.8 rad/sec | ± 4 rad/sec/sec | ± 2 rad/sec/sec |