SLS (Space Launch System) Core Stage

NASA’s SLS (Space Launch System) core stage is the tallest stage NASA has ever built. Towering 212 feet with a diameter of 27.6 feet, it stores cryogenic liquid hydrogen and liquid oxygen and all the systems that will feed the stage’s four RS-25 engines.

It also houses the flight computers and much of the avionics needed to control the rocket’s flight. The core stage is designed to operate for

approximately 500 seconds before reaching low Earth orbit and separating from the upper stage and NASA’s Orion spacecraft.

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under its Artemis campaign. SLS is an advanced, super heavy-lift rocket that provides an entirely new capability for science and human exploration beyond Earth’s orbit. With unmatched payload mass and volume capability, SLS is the only rocket that can send the Orion spacecraft, astronauts, and supplies to the Moon in a single launch. This reduces the number and complexity of in-space operations and increases the opportunities for mission success.

The core stage serves as the backbone of the rocket, supporting the weight of the payload, upper stage, and Orion spacecraft, as well as structurally supporting and carrying the thrust of its four

RS-25 engines and two five-segment solid rocket boosters attached to the engine and intertank sections.

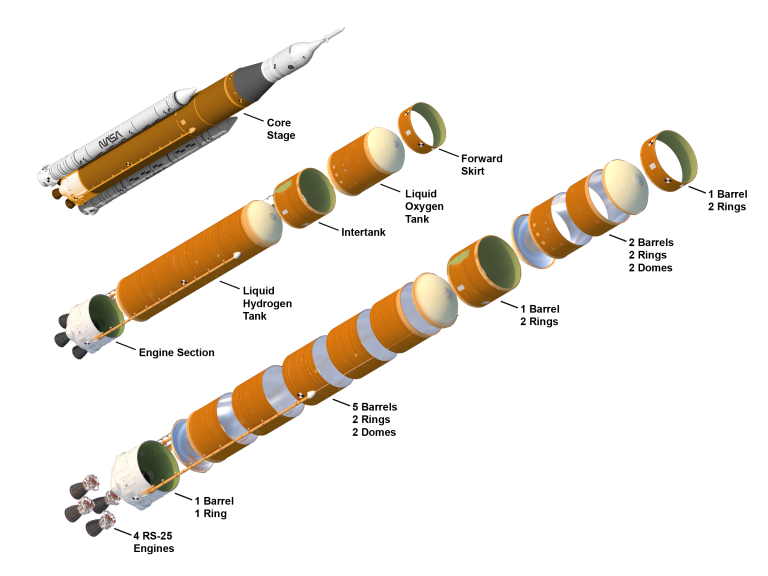

The core stage is the same diameter as the space shuttle external tank and is covered with an orange spray-on foam to insulate the cryogenic propellants. The stage is made up of 10 major barrel sections, four dome sections, and nine rings. Each cylindrical barrel section consists of eight aluminum panels that vary in length and height. Those components are welded to form five major components: the liquid hydrogen and liquid oxygen tanks, engine section, intertank, and forward skirt. Those five major components are joined to form the completed core stage.

As part of the core stage test program, structurally similar versions of the core stage’s intertank, engine section, and liquid oxygen and liquid hydrogen tanks were built and tested at NASA’s Marshall Space Flight Center in Huntsville, Alabama, to ensure the stage could withstand the SLS flight environment. The completed Artemis I flight stage was put through functional testing at NASA’s Stennis Space Center in Bay St. Louis, Mississippi.

Boeing, the prime contractor for the SLS core stage, uses state-of-the-art manufacturing equipment to build the stage at NASA’s Michoud Assembly Facility in New Orleans. Michoud is a unique advanced manufacturing facility where NASA has built spacecraft components for decades, including the space shuttle’s external tanks and Saturn launch vehicle stages for Apollo.

NASA Marshall, where SLS is managed, and NASA’s Kennedy Space Center in Florida, the SLS launch site, along with Boeing, signed an agreement in 2022 to use available facility space at Kennedy for final outfitting, assembly, and integration beginning with Artemis III hardware. Production of all the major core stage structures and manufacturing activities will remain at Michoud. The agency will use space in the Space Station Processing Facility and available space in High Bay II in the Vehicle Assembly Building at Kennedy to perform final vertical assembly of the core stage, outfit the engine section of the core stage, and integrate the engines into the engine section. With production of the new SLS exploration upper stage (EUS) gearing up at Michoud alongside core stage, the action enhances production efficiencies, manufacturing capabilities, and cost- effectiveness of both stages.

NASA and Boeing are building the core stages for the Artemis III, IV, and V missions. Every SLS configuration uses the core stage with four RS-25 engines. The first SLS vehicle, called Block 1, can send more than 27 metric tons or 59,500 pounds to orbits beyond the Moon. As the SLS rocket evolves, it will send even heavier and larger payloads to the Moon and other deep space destinations.

| Core Stage Facts | |

| Length | Approximately 212 ft. (64.6 m) |

| Diameter | 27.6 ft. (8.4 m) |

| Empty Weight | Approximately 188,000 lbs. (85,275 kg) |

| Capacities | Liquid Hydrogen (317,000 lbs.) 537,000 gallons (2 million liters) Liquid Oxygen (1.86 million lbs.) |

| Material | Aluminum 2219 |

For more information about SLS, visit:

http://www.nasa.gov/artemis

http://www.nasa.gov/sls

http://www.twitter.com/NASA_SLS

http://www.facebook.com/NASASLS

http://www.instagram.com/nasaartemis

National Aeronautics and Space Administration

George C. Marshall Space Flight Center

Huntsville, AL 35812

www.nasa.gov/marshall

MSFS-06-2024-SLS-4837