Marshall Moon/Mars Surface Technologies and Systems

Marshall Space Flight Center builds innovative solutions through technology development demonstrations and risk reduction activities to enable humans to live and work on the Moon and Mars.

Contents

Overview

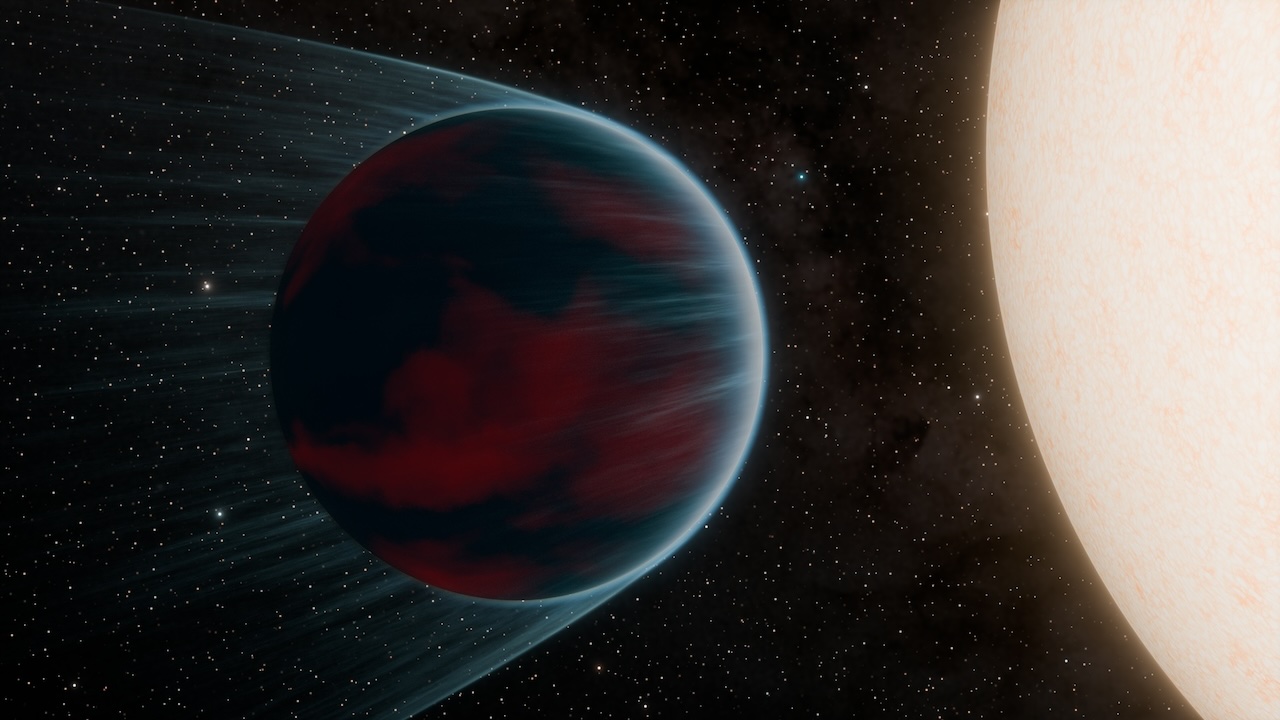

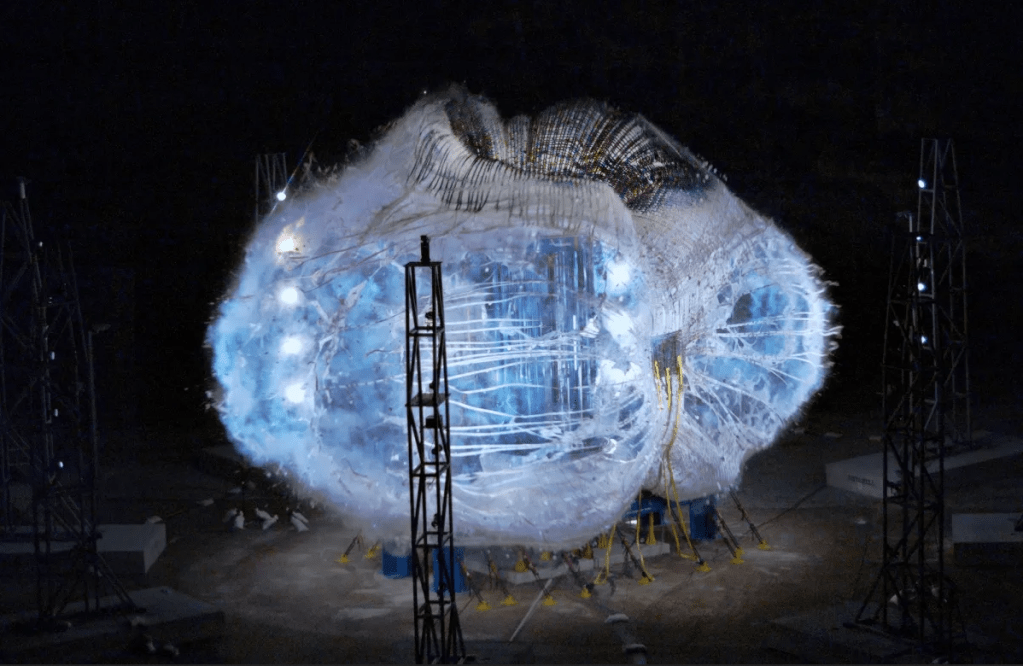

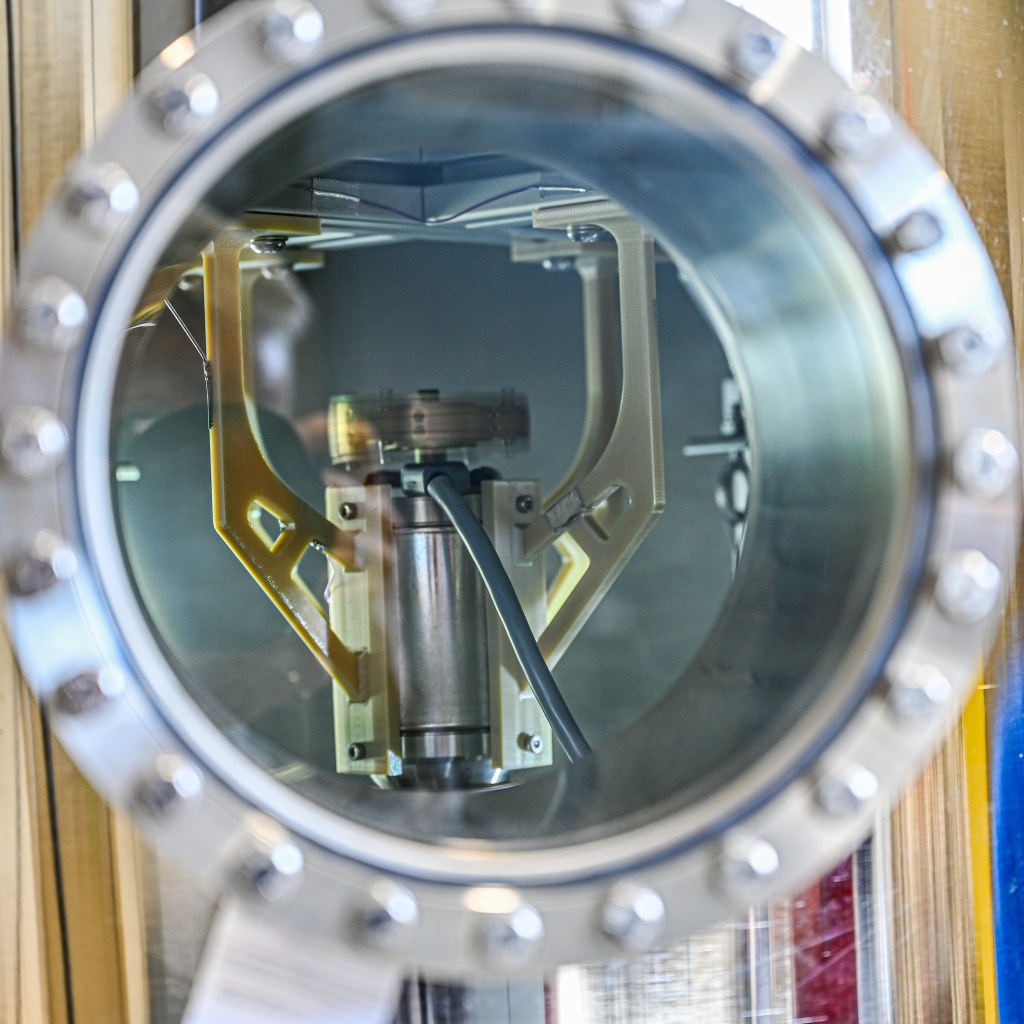

Space Environmental Effects Testing

Test capabilities to characterize the effects of the space environment on materials and systems, from low Earth orbit to deep space – simulated elements include charged particle radiation, plasma, high vacuum, solar ultraviolet (VUV, NUV), atomic oxygen, impact, thermal extremes, Lunar/Martian surface environments (including regolith simulants), all either individually or in combination.

Space Systems Integration & Test Capabilities

Unique multipurpose facilities that enable the design and development of space systems from proof-of-concept studies, prototype and development hardware checkout, integration and assembly of flight systems, and qualification and acceptance testing of components, subsystems, and integrated systems through real-time operations of on-orbit payloads.

Advanced Manufacturing

Unique expertise in applying state-of-the-art advanced manufacturing methods to support development and production of advanced Moon/Mars Surface Technology Systems

Leading efforts to demonstrate 3D printing technology in orbit and on planetary surfaces.

Human Factors Modelling/Simulation

Using cutting-edge augmented reality/virtual reality tools, Marshall engineers model exploration system designs for human factors constraints, identifying potential operational issues before the design is finalized.

Simulated environments allow for detailed concept of operations development in parallel with systems engineering design.

Hardware- and Software-In-the-Loop Testing Capability

State-of-the-art facilities for developing, testing, and verifying flight software.

Real-time hardware-in-the-loop capabilities enable spacecraft integrated software and avionics hardware systems to be modeled, simulated, and tested early, before finalizing designs.

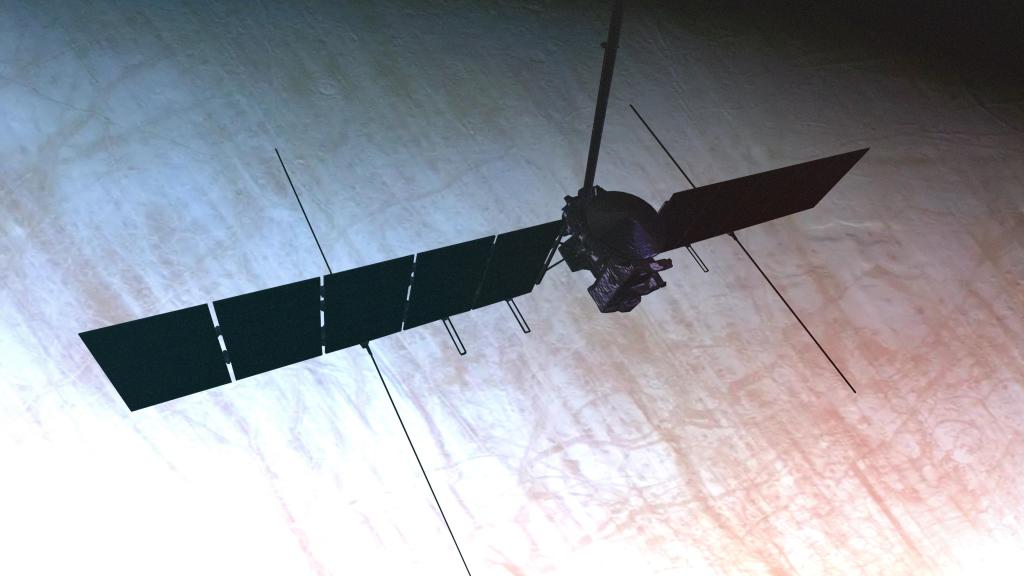

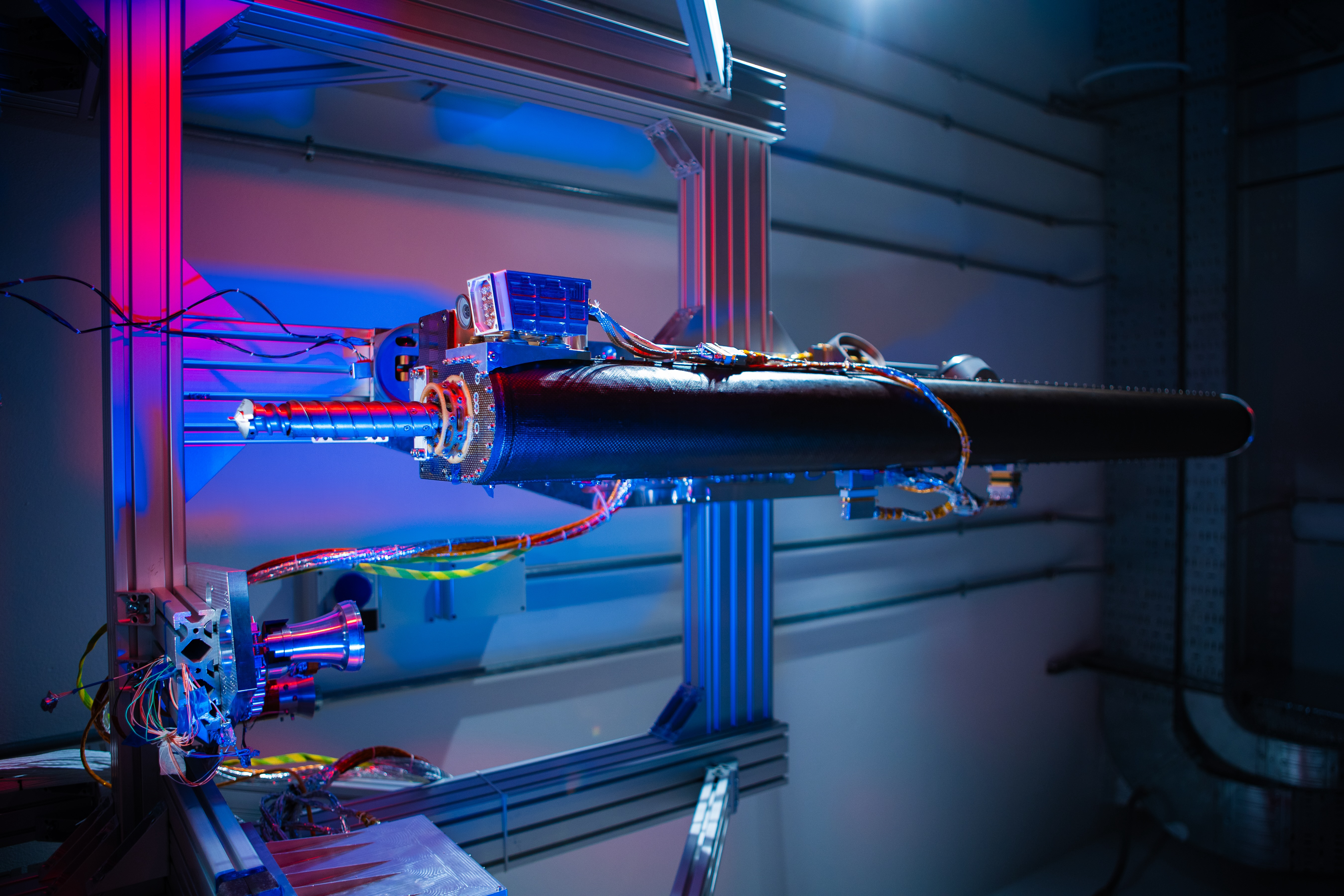

Scientific Instrument Development Capability

Five decades of expertise in instrument design, development, and testing across the entire electromagnetic spectrum, from the Apollo Telescope Mount to James Webb and Chandra to IXPE.

World-class grazing incidence optics manufacturing facility, unique in the nation, for high-energy astrophysics observations.

Lunar Surface Environments and Operations

Simulated lunar terrain field enables high-fidelity testing of automated descent and landing technologies, as well as surface operations of rovers, sample return spacecraft, and more.

World-class simulant regolith allows for the design of robust systems that will function under the unique characteristics of lunar dust/soil composition.

Exploration of processes for and properties of construction materials via 3D printing made from in-situ resources.

Guidance, Navigation & Control (GN&C) Hardware Development and Test Capability

Providing complete end-to-end GN&C development and test for launch vehicles and/or spacecraft systems — from initial concept through detailed mission analysis and design, hardware development and test, verification and validation, and mission operations.

World-class developer of Earth-to-orbit and in-space stages for GN&C. Marshall is a key developer of in-space transportation, spacecraft control, automated rendezvous and capture techniques, and testing.

Do Business with Us

MSFC Partnerships Office

Nick Case

nicholas.l.case@nasa.gov

256.544.8789