Thermal Management Subsystems

Contents

Introduction

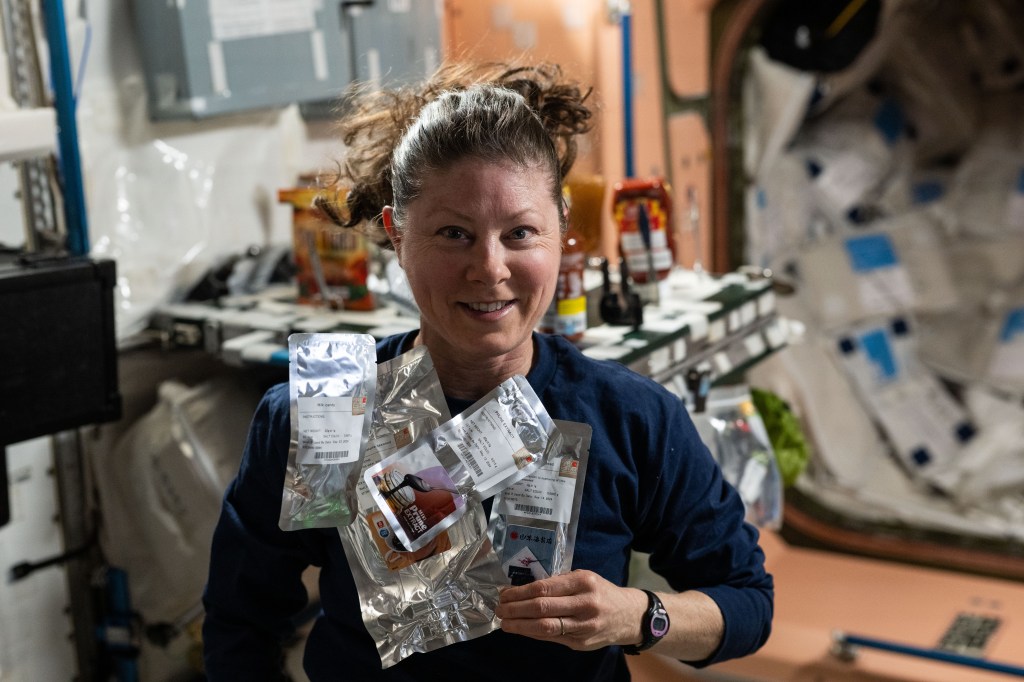

Thermal management systems for human spacecraft are critical to ensure the well-being of astronauts, maintain optimal performance of onboard systems, prevent material degradation, and safeguard the spacecraft’s structural integrity in the extreme temperature variations encountered during space missions. Effective thermal management is a critical aspect of spacecraft design and operation, and Johnson Space Center (JSC) stands at the forefront with its advanced thermal management design, development and testing capabilities. From cold stowage systems, to active and passive thermal control system designs to thermal protection systems, JSC experts provide design, analytical simulation and modeling, standards and specifications development, validation and integrated testing.

Thermal test facilities offer a versatile range of performance capabilities tailored to accommodate the diverse needs of both small and large test articles, components, and subsystems. Key details of the thermal testing capabilities include temperature and humidity cycling, precise determination of design factors, evaluation of operating temperatures, analysis of changes in absorptive or emissive properties of thermal coatings, and accelerated testing of electrical or electronic components. Moreover, the facilities support environmental cycling for materials survivability, battery performance and abuse testing, and thermal analysis, including human thermal modeling. We invite our partners to leverage our advanced thermal management expertise and capabilities, ensuring the safety, comfort, and optimal performance of both astronauts and spacecraft components during the challenging conditions of space exploration.

Capabilities

Active Thermal Control Systems

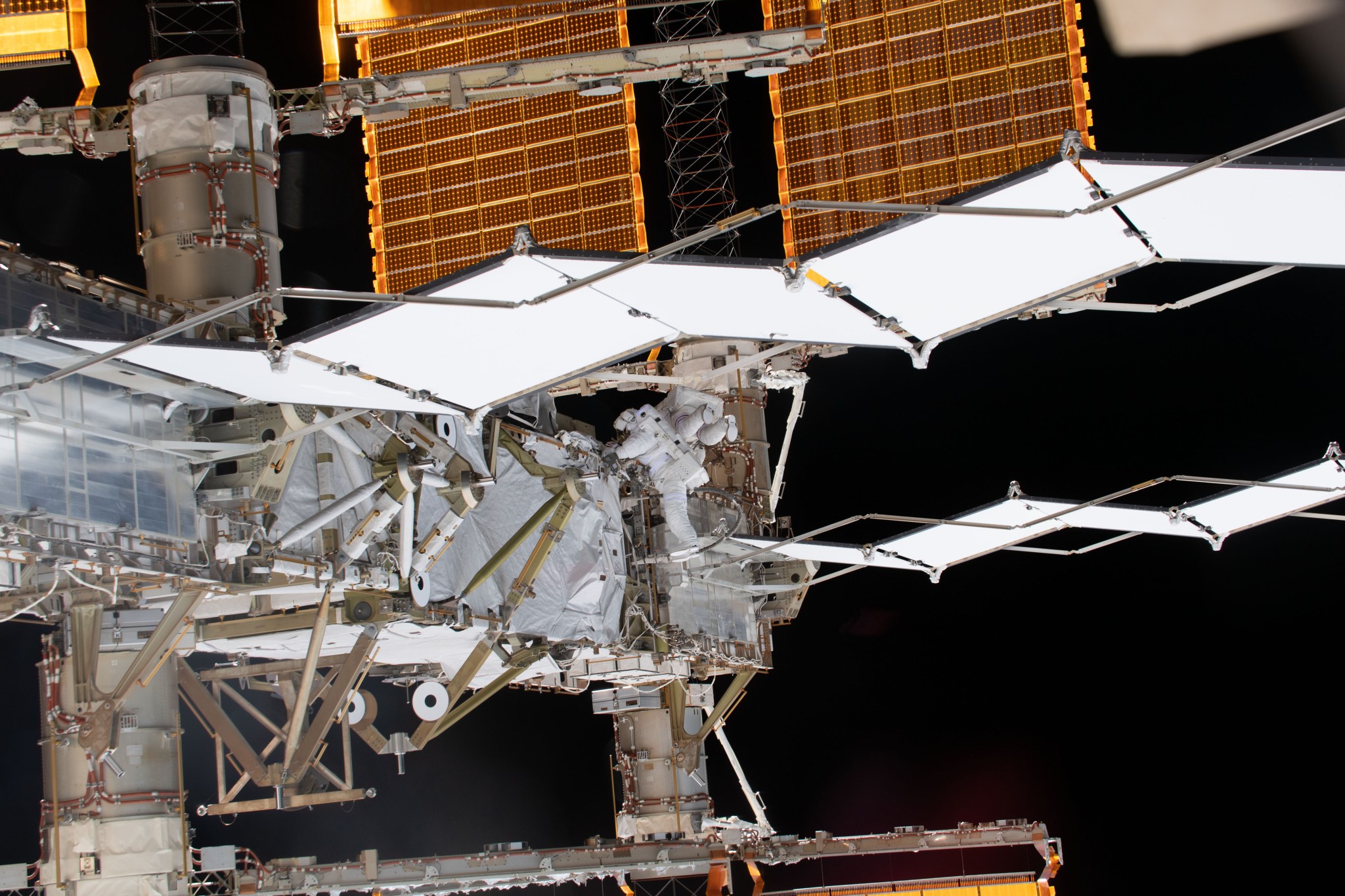

Overview | The NASA JSC Thermal Systems team is the agency focal point for engineering system management of Active Thermal Control Systems (ATCS). The team provides ATCS research, analysis, design, development, testing, and system management to enable human space exploration.

Details |

- Active Thermal Control System (ATCS) System Management for human spaceflight including International Space Station (ISS), Orion, Commercial Crew Program (CCP), Gateway, and Human Landing System (HLS)

- System architecture

- Flight hardware development

- Technology development

- Laboratories for testing for low- to mid-TRL technologies along with flight hardware assembly and evaluation

- Advanced Thermal Lab (ATL)

- Advanced Thermal Platform (ATP)

- Advanced Thermal Technology Integration Center (ATTIC)

- Thermal control fluids

- Gas traps for fluid loops

- Condensing heat exchangers

- Phase change material heat exchangers

- Evaporative cooling

- Thermal analysis

Integrated Thermal Analysis

Overview | At NASA JSC, integrated thermal analysis expertise is available for successful thermal design, modeling, analysis, and testing of integrated vehicles.

Details |

- Thermal design

- Analytical Simulation/Prediction

- Independent Modeling

- Model Validation

- Standards and Specifications Development

- Integrated Testing

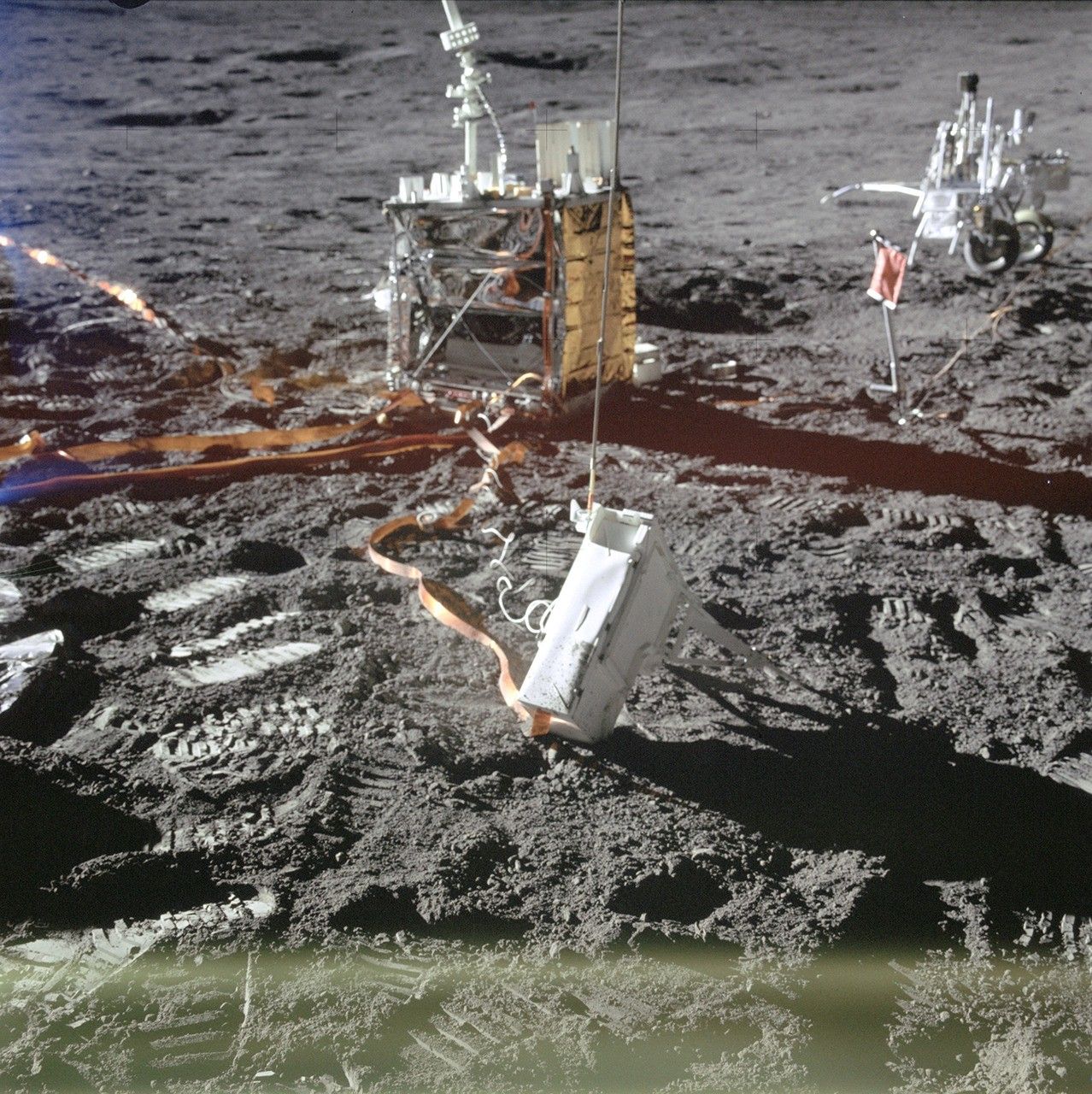

Thermal Testing

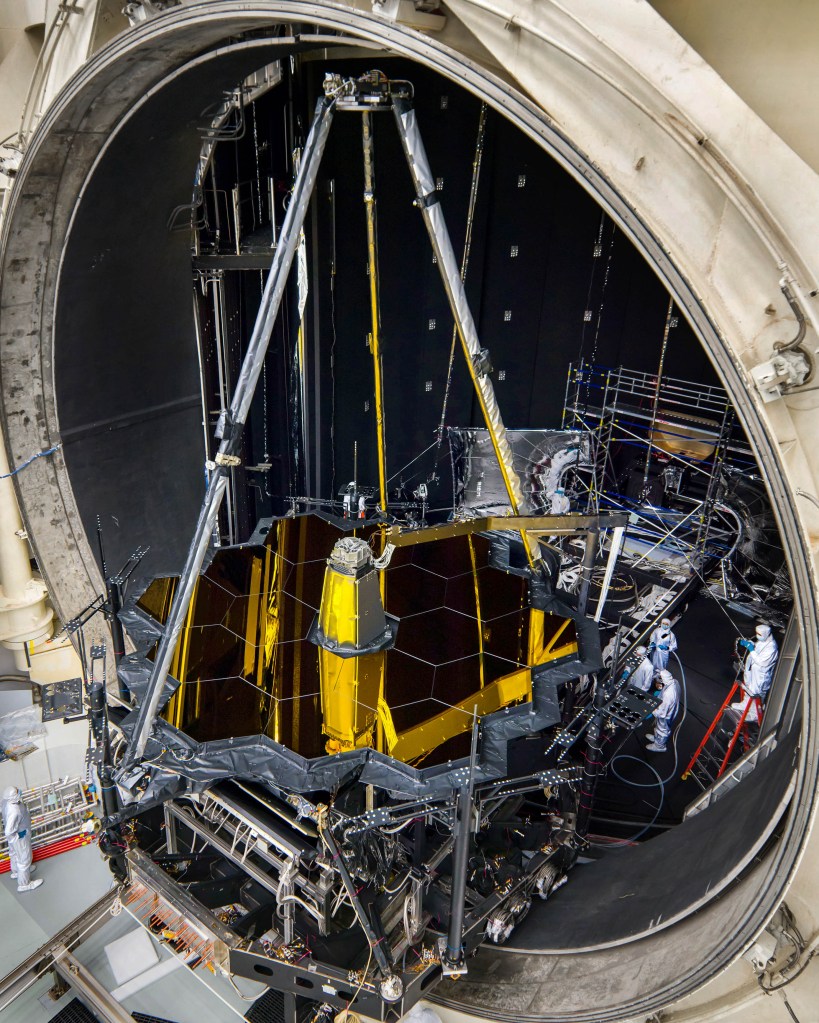

Overview | Johnson Space Center (JSC) thermal test facilities offer a wide range of performance capability, which can be matched to the individual test requirements of smaller test articles or large test article components and subsystems. Typical uses of these chambers have included development, engineering evaluation, and qualification testing of spacecraft components, subassemblies and experiments, and preflight thermal conditioning of flight hardware.

Details |

- Temperature and humidity cycling

- Accurate determination of design factors

- Operating temperatures

- Changes in absorptive or emissive properties of thermal coating

- Changes in electrical or mechanical properties of materials

- Accelerated electrical or electronic components burn-ins and life-cycle testing

- Environmental cycling (thermal and humidity) for materials survivability

- Battery performance and abuse testing

- Thermal analysis, including human thermal modeling

- Subscale evaluation of thermal components