Life Support Subsystems

Introduction

As a world leader in life support for human spaceflight, Johnson Space Center (JSC) offers a comprehensive range of capabilities in Environmental Control and Life Support Systems (ECLSS) and Crew Survival, Space Suits, and Habitability Systems. Reliable life support systems are critical in human spaceflight to provide astronauts with the necessary environmental conditions, such as oxygen, temperature regulation, and waste management, essential for sustaining life during extended missions in the inhospitable environment of space. Toxicological and other environmental risks are assessed and managed within the context of isolation, continuous exposures, reuse of air and water, limited rescue options, and the need to use highly toxic/biohazardous compounds in payloads, for propulsion, and other purposes. JSC personnel provide research, analysis, development and testing of open and closed-loop technologies needed to sustain long-duration human presence in space. JSC also provides expertise in on-orbit operations, the design of future space vehicle ECLSS systems, and the development, certification and maintenance of ECLSS flight hardware.

JSC excels in testing and evaluation, integration, prototype development, flight hardware certification and consultation for critical elements such as carbon dioxide removal, oxygen generation, water recovery, and urine stabilization. JSC is a global leader in the design, testing, and implementation of launch and entry suits, ensuring crew survival during critical mission phases. Additionally, our unparalleled experience in space suit technology covers the entire life cycle, from design to operational support. JSC leads in addressing challenges related to crew comfort, waste management, hygiene, galley hardware, and logistics reduction. The Center’s capabilities span problem definition, research, design, prototyping, testing, and operational support, offering unique solutions for space hardware engineering. Join us in pushing the boundaries of space, through innovation in life support systems. We invite our partners to utilize our life support capabilities to ensure their mission success.

Life Support System Design and Development

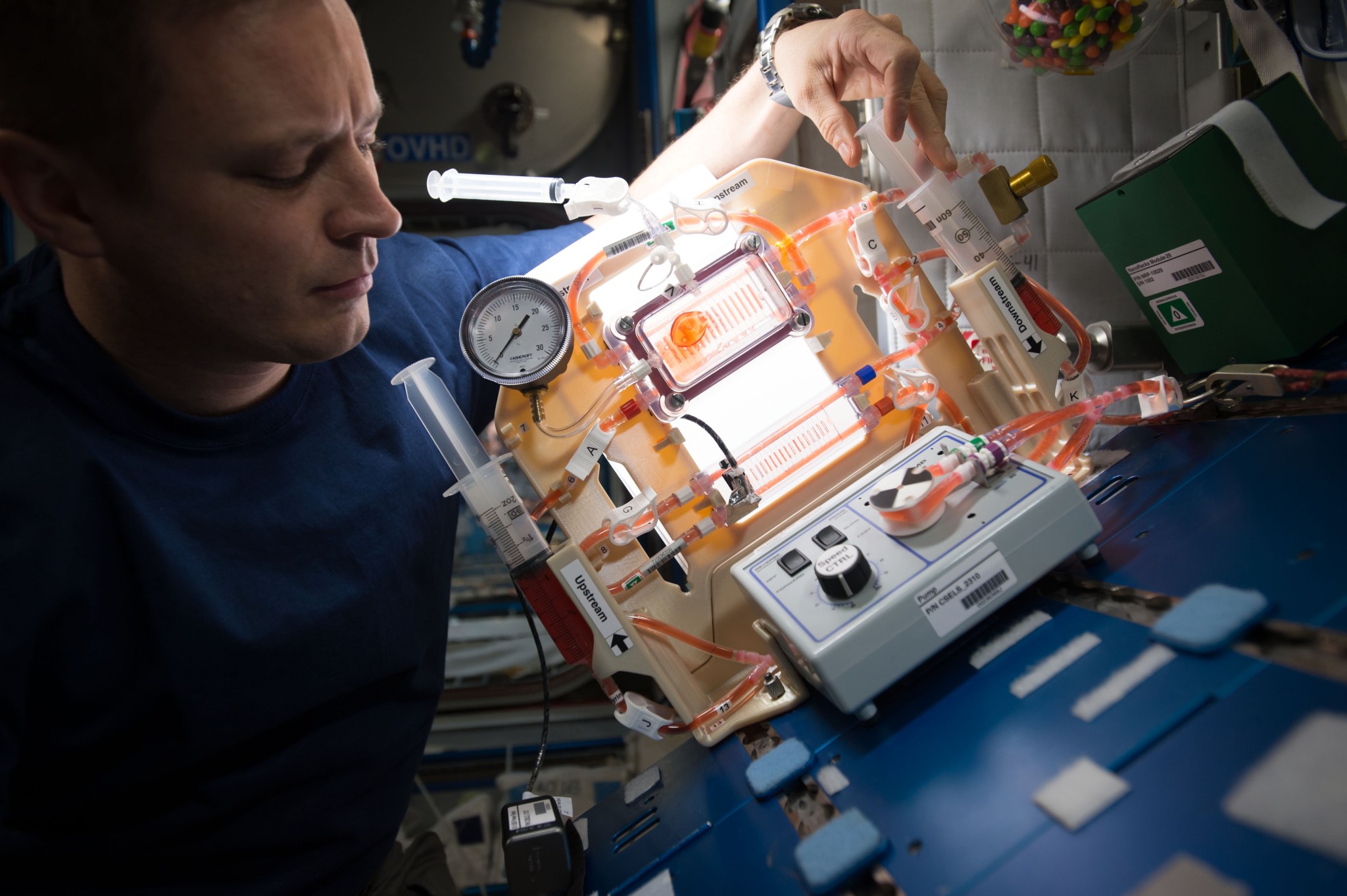

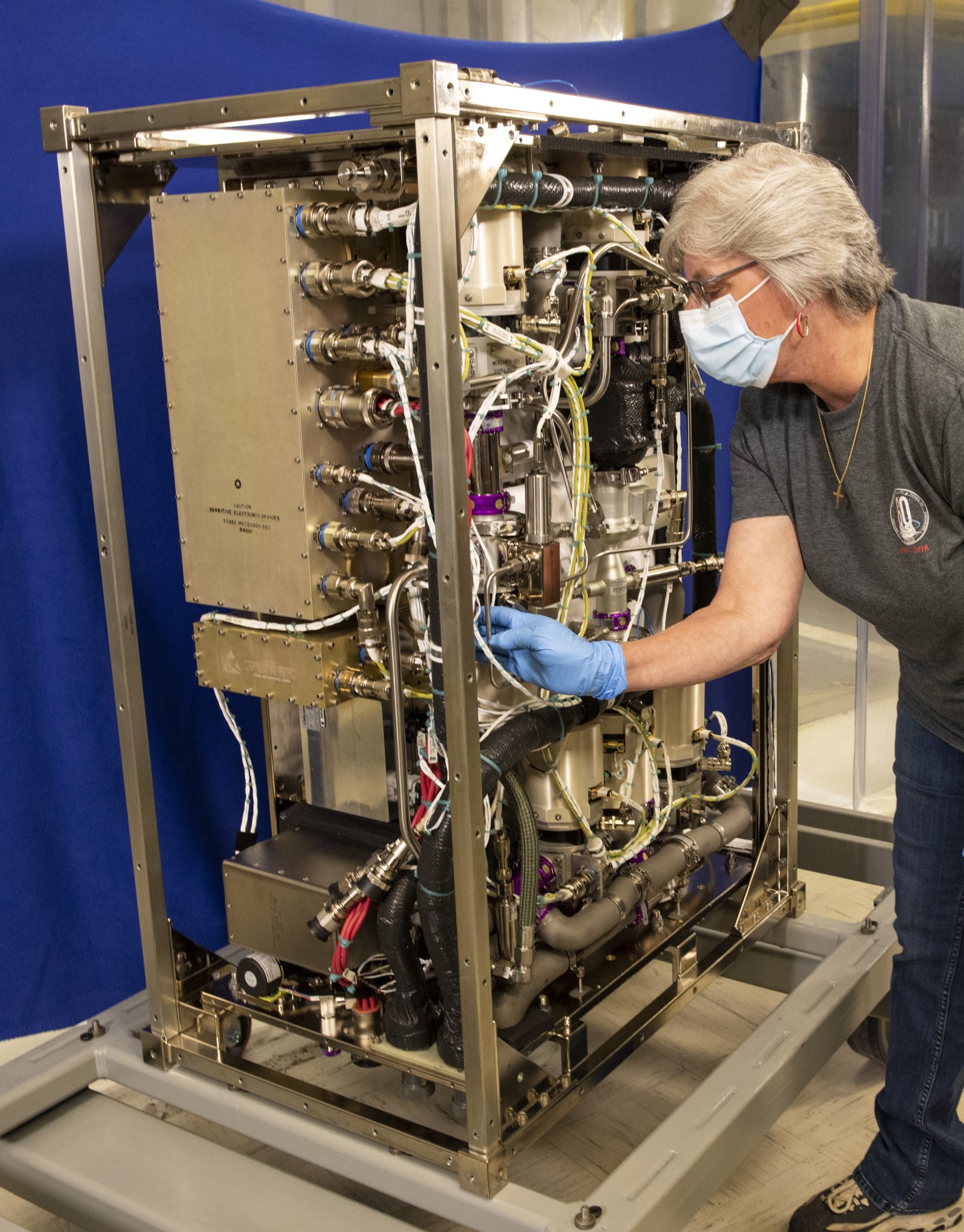

Environmental Control and Life Support Systems (ECLSS)

Overview | NASA JSC Environmental Control and Life Support Systems (ECLSS) team provides research, analysis, development, and testing of open and closed loop technologies needed to sustain a long duration human presence in space. The team provides expertise in on-orbit operations, the design of future space vehicle ECLSS systems, and the development, certification, and maintenance of ECLSS flight hardware.

Details |

- JSC Environmental Control and Life Support Systems (ECLSS) flight hardware design, development, testing and evaluation

- Carbon dioxide removal, reduction, storage, monitoring and transfer

- Oxygen generation and separation

- Trace contaminant control, monitoring and detection

- Environment simulation

- Water recovery, monitoring, distribution and storage

- Water filter packing, testing and analysis

- Formulation, production and analysis of ECLSS fluids

- Urine collection and stabilization

- Prototype development

- Technology demonstrations

- Performance requirements and concept of operations development

- Fabrication, assembly and testing

- Certification and integration support

- Pre-flight inspections, checkouts, packing and delivery for launch

- General and specialized consultation

Crew Survival Suit and Equipment

Overview | The launch and entry suit provides a survivable environment for the crewmember during launch and landing mission phases and emergency survival and escape hardware to aid in emergency events from bailout to search and rescue anywhere on the planet.

Details |

- Crew survival suits and equipment design, development, testing, analysis, certification, and failure investigation

- Launch and entry pressure suits

- Vehicle seats

- Occupant protection systems

- Survival radios

- Life rafts

- Emergency breathing systems

- Automatic inflation life preservers

- Metabolic load physiological limitation studies to determine crewmember heat stress under multiple suit configurations

- Carbon Dioxide (CO2) buildup and washout testing and analysis to disperse helmet CO2 and prevent hypercapnia

- Occupant protection impact testing

- Suit material outgas investigation at vacuum

- Oxygen flammability assessment for emergency breathing hardware

- Multiple crewmember life raft stability studies

Space Suit Systems

Overview | JSC personnel have a vast knowledge of the technical challenges associated with space suit technology, including mobility, sizing, life support, ventilation, hydration, and waste management. JSC experience covers the full life cycle, starting from basic design through development, testing, and operational support.

Details | Space suits are unique in that they are miniature, customized spacecraft. They must provide environmental protection, mobility, and life support to the crewmember during spacewalks.

- Space suit design and development

- Pressure garment and glove design

- Mobility and sizing

- Helmet and visor design

- Life support umbilical design

- Suit maintenance and operations

- Portable life support technologies

- Thermal control

- Ventilation

- Oxygen systems

- Contaminant control

- Hydration

- Waste control

- Space suit testing, verification, and training

- Suit checkout

- Altitude testing

- Thermal vacuum testing

- Flight crew training

- System-level engineering insight into the Extravehicular Mobility Unit (EMU) hardware operational performance and detailed leadership into anomaly resolution

- Real-time mission support for on-orbit activities

- Ground training simulations for training and crew extraction from the Neutral Buoyancy Laboratory and vacuum chamber facilities

- Engineering risk-based guidance for management, sustaining and changes of the EMU hardware and forecast for long-term hardware lifecycle usage

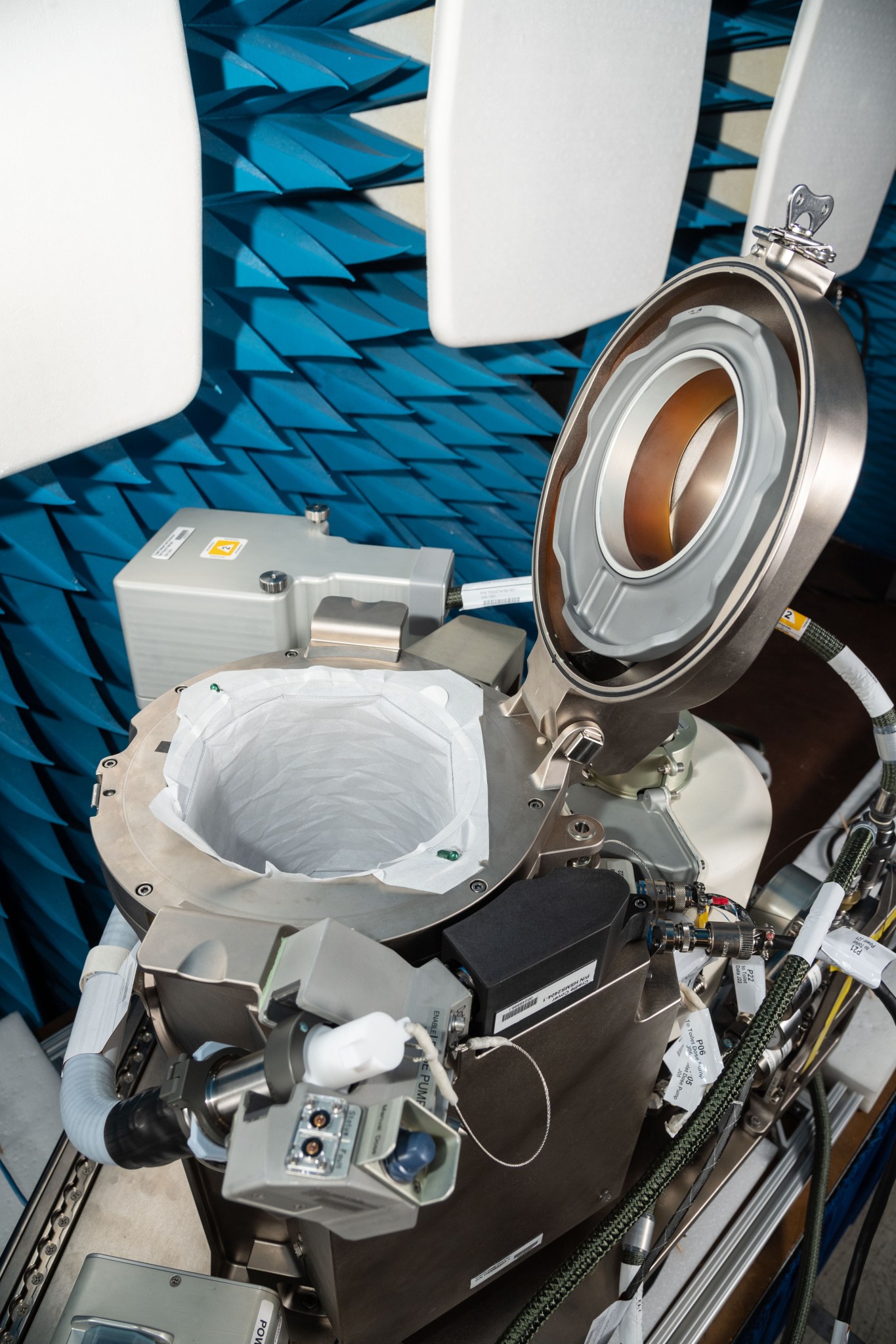

Habitability Systems and Flight Crew Equipment

Overview | JSC personnel have the unique experience and vast knowledge of the technical challenges associated with metabolic waste management, personal hygiene, crew accommodations, galley hardware, trash management and odor control, logistics reduction and tracking, advanced clothing, housekeeping, tools and diagnostic equipment, restraints and mobility aids and unique stowage solutions.

Details |

- Habitability systems and flight crew equipment hardware development

- Performance requirements and concept of operations development

- Prototype development including use of rapid manufacturing and 3D printing

- Fabrication, assembly, and testing

- Technology demonstrations

- Certification and integration support

- Pre-flight inspections, checkouts, packing and delivery for launch

Valve Repair and Refurbishment

Overview | White Sands Test Facility (WSTF) provides fluid component support to its customers through valve refurbishment, repair, and maintenance. Services provided follow the American National Standards Institute (ANSI) National Board Inspection Code (NBIC)/NB-23.

Details |

- Component Services workforce: disassembly, cleaning, maintenance, reassembly, refurbishment, and testing of pressure relief and pressure safety valves in compliance with the American National Standards Institute (ANSI) National Board Inspection Code (NBIC)/NB-23

- Operations: hardware precision cleaning, component assembly, and component calibration. With a full-service clean room and an American Society of Mechanical Engineers/ National Board Inspection Code (ASME/NBIC) certified Valve Repair (VR) Facility, this organization has extensive cleaning and refurbishing experience with numerous valve configurations, metal types, and elastomerics

- Unique VR facility: relief valve repairs and flow tests are performed in an oxygen-clean environment to service ASME code relief devices for use in oxygen systems

- The Fluid Components Laboratory: services on fluid components and systems, including manual valves, chemical pumps, compressors, vacuum pumps, and flight compressors on the ISS

- Refurbish and repair valves for oil, gas, chemical, propellant, and fuel use, as well as for components in liquid oxygen systems

- Reassembly and functional testing, cleanliness is maintained using a clean, Class 10,000 environment

Composite Overwrapped Pressure Vessels

Overview | White Sands Test Facility (WSTF) tests and evaluates composite overwrap pressure vessels (COPVs) and components through studying damage tolerance and stress rupture. It also offers leading expertise in both destructive and nondestructive evaluation, training, analysis, and development of life extension protocols for composite structures.

Details | White Sands Test Facility (WSTF) offers leading expertise in the testing, nondestructive evaluation, training, and analysis of composite structures. WSTF engages in the test and evaluation of structures by performing mechanical damage tests, sustained load testing, material compatibility, and hydraulic and pneumatic burst tests to understand and evaluate environmental effects on pressurized systems.

Damage Detection Course

A two-day damage detection course is offered to qualify aerospace visual inspectors of flight composite pressure vessels and provides comprehensive working knowledge of composite overwrap pressure vessel (COPV) technology. The course focuses specifically on mechanical damage, safe life, sustained load, and propellant/fuel exposure effects on pressure vessels built using graphite/epoxy composite filament wound onto metallic liners.

Related Patents

Corkscrew Filter Extracts Liquid From Air Charge

Filtering Molecules with Nanotube Technology

Freeze-Resistant Hydration System

Liquid Sorbent Carbon Dioxide Removal System