In-Situ Resource Utilization

Contents

Introduction

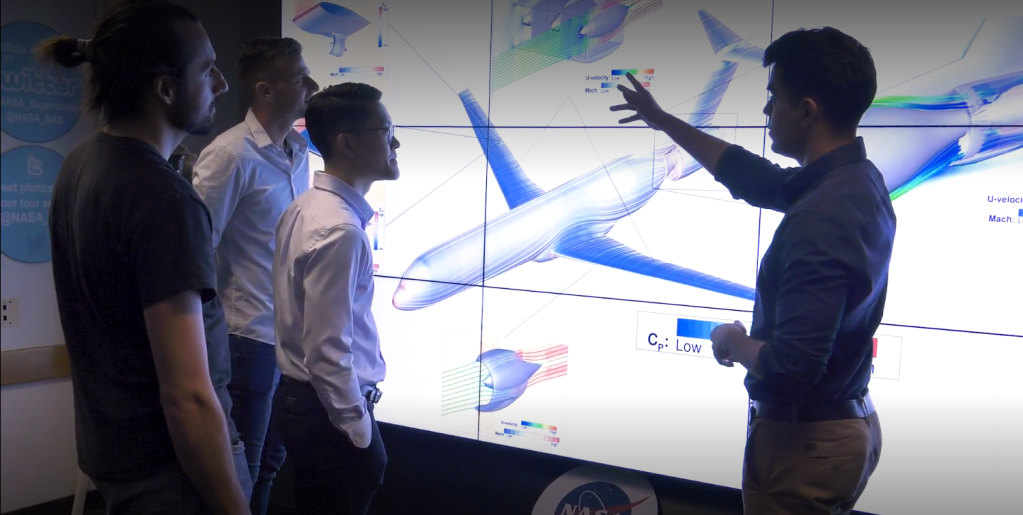

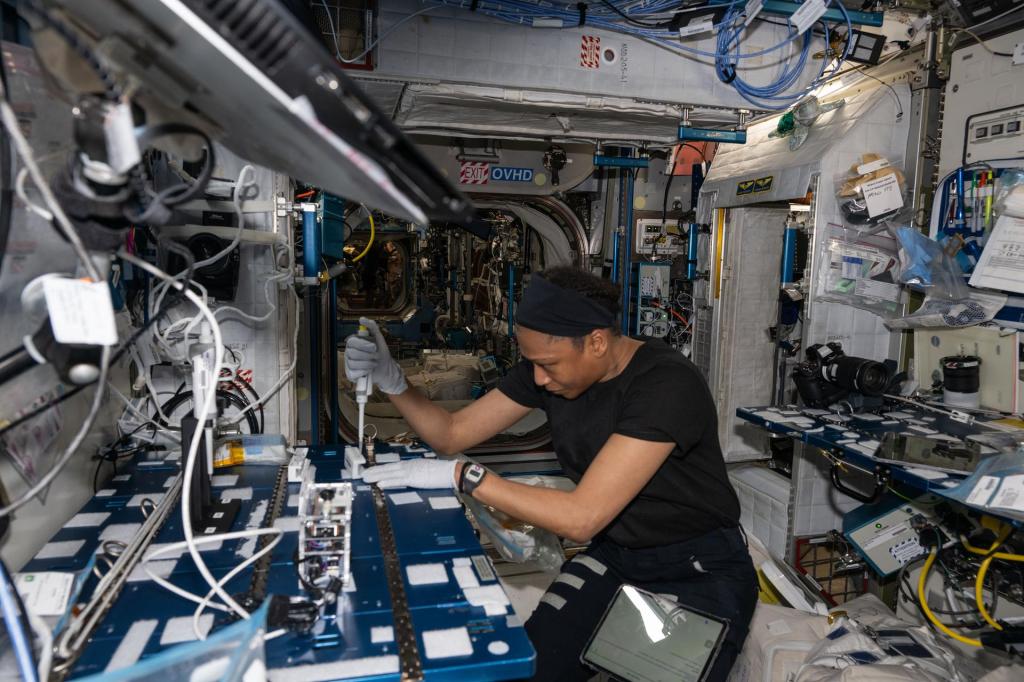

Johnson Space Center (JSC) specializes in system engineering and integration of In-Situ Resource Utilization (ISRU) systems and modeling of complex chemical processes, regolith excavation and transfer systems, and thermal conversion systems while focusing on the interactions between them. JSC is actively involved in further research and development of these technologies that enable the extraction and utilization of resources such as water, oxygen, and other elements available in extraterrestrial environments. This approach aims to reduce the need for Earth-based resources, enhance sustainability, and enable longer-duration space missions by leveraging the available resources on other celestial bodies. Our capabilities include the design, development and testing of these complex systems. JSC’s contributions to ISRU play a crucial role in advancing the capabilities and feasibility of future space exploration missions. We invite our collaborators to leverage our capabilities in in-situ resource utilization and expand humankind’s presence across the solar system. Join us in pioneering the future of human spaceflight.

Capabilities

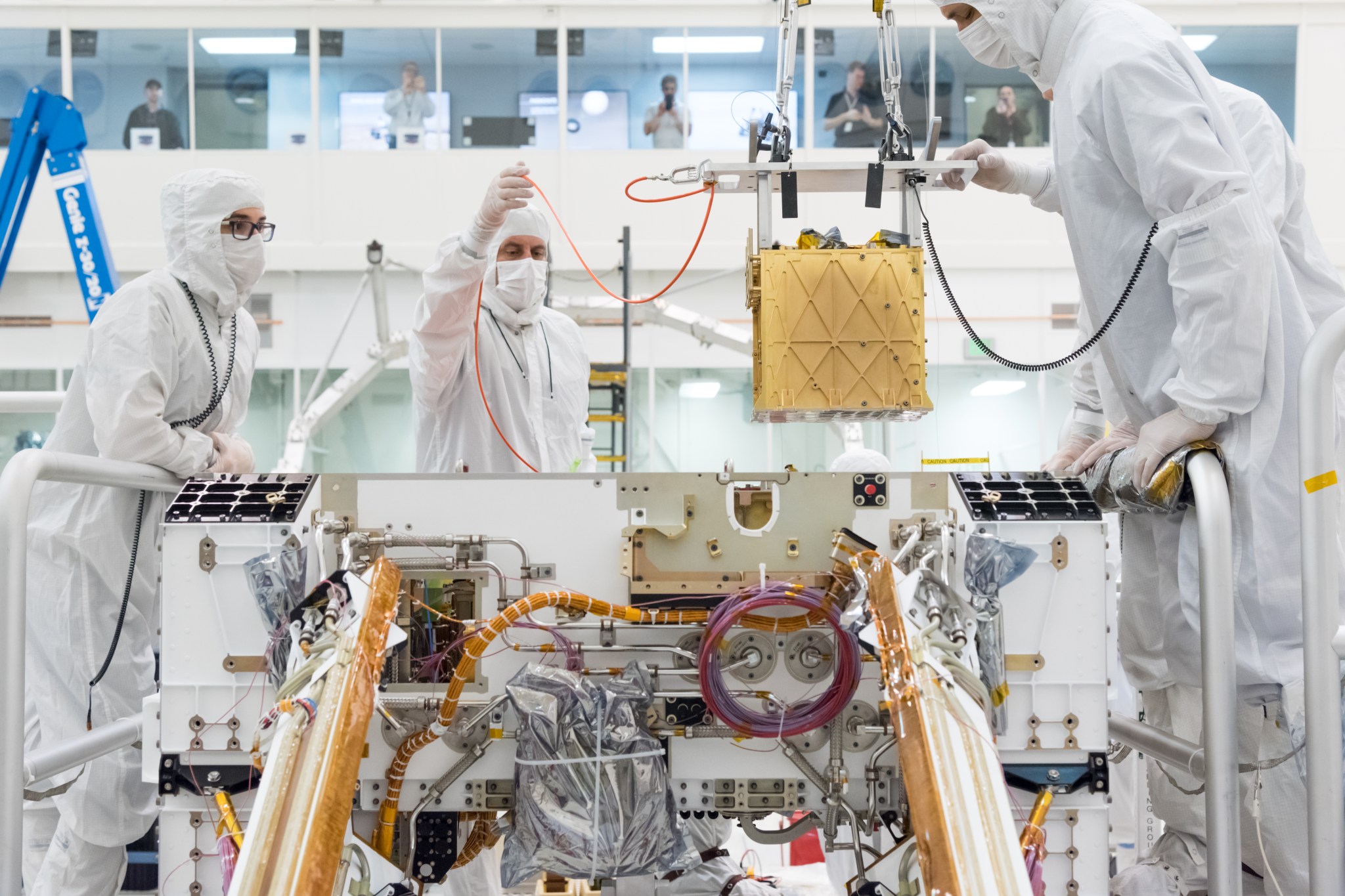

In-situ Resource Utilization (ISRU) Development and Testing

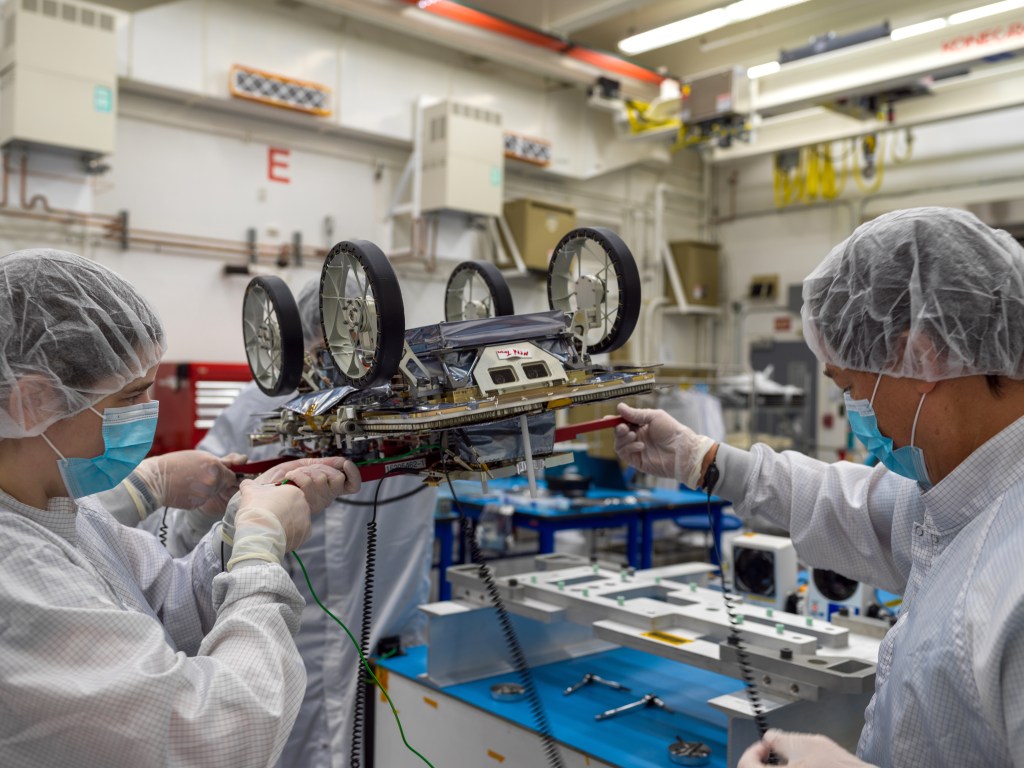

Overview | JSC has a long history of technology development of In-Situ Resource Utilization (ISRU) hardware and systems for use on the Moon and Mars.

Details |

JSC’s In-Situ Resource Utilization (ISRU) area of expertise:

- Various chemical conversion processes: Hydrogen Reduction of Lunar Regolith, Carbothermal Reduction of Lunar Regolith, Solid Oxide Electrolysis of Mars atmosphere

- Water evolution and capture from Lunar polar and Mars soils

- Product stream capture and purification including mixed gas separation, condensation and regenerative gas drying

- Water electrolysis and regenerative fuel cells

- Regolith sample transfer including weighing, manipulation and heating

JSC specializes in System Engineering and integration of ISRU systems:

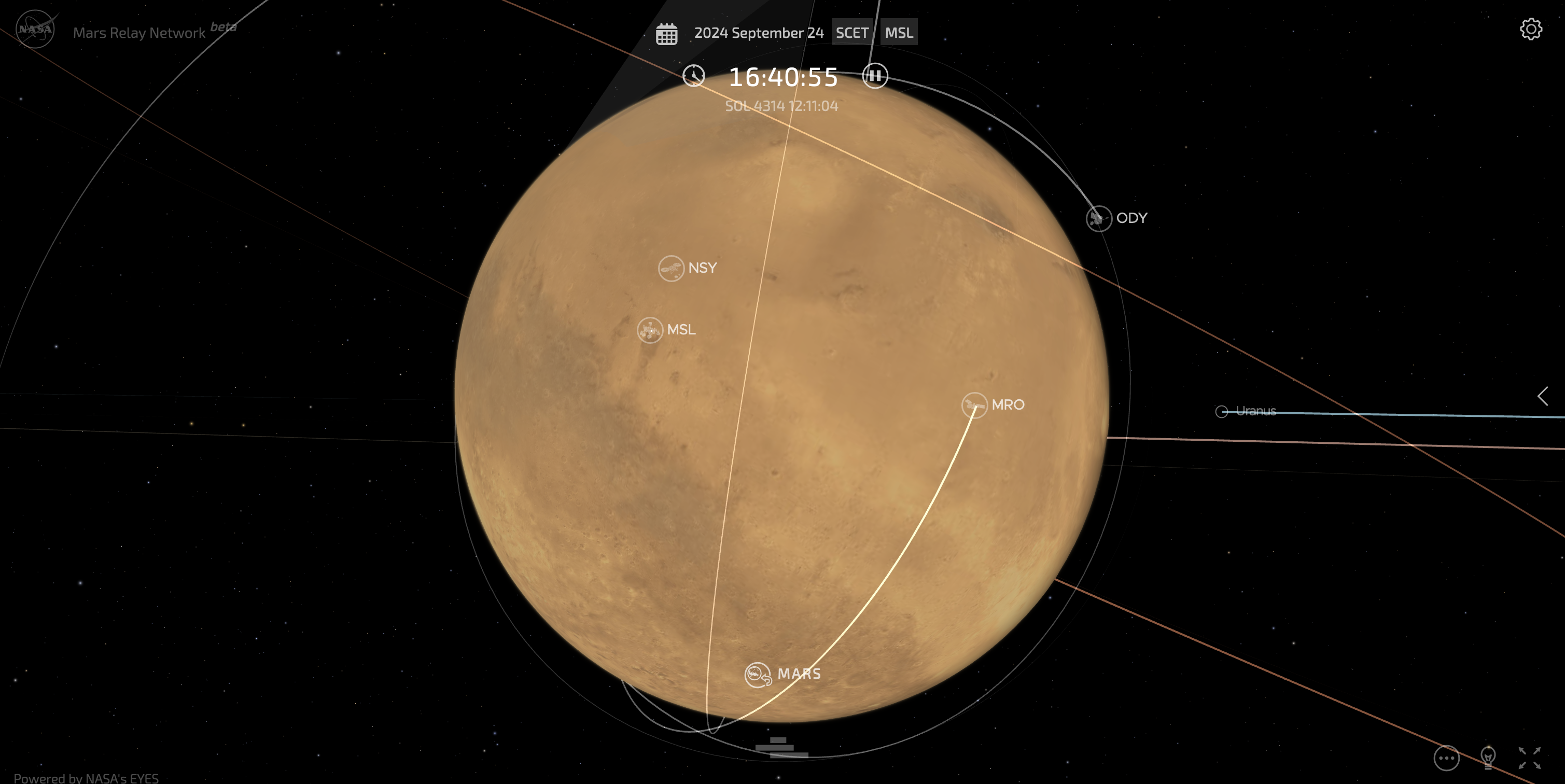

- Modeling of complex chemical processes, regolith excavation and transfer systems, ISRU system sizing and scaling, architectural evaluations, and thermal conversion systems and the interactions between them

- Integration and evaluation of ISRU subsystems and systems

- Integration and execution of end-to-end system field test campaigns

JSC Test Facilities and services for ISRU hardware from concept development through flight:

- Vibration

- Pyro Shock

- Thermal Vacuum

- Dust Exposure

- Oxygen and Hydrogen Testing

- Solid Oxide Electrolysis Performance

- Water Electrolyzer Performance

15-foot Dirty Thermal Vacuum Chamber

Overview | NASA JSC 15-foot dirty thermal vacuum chamber (TVAC) provides unique testing capabilities for dust and planetary surface environments. The 15-foot chamber is a spherical chamber designed to test advanced concepts, especially for battery power systems, space vehicle actuators and auxiliary power units.

Details |

- 12.5-foot internal diameter spherical chamber with ~78-inch diameter clear entry for easy access

- Vacuum conditions: 1×10^-6 torr to 760 torr

- Thermal conditions: -186°C to +120°C

- Air, GN2 pressurization

- Feed-throughs for high-power electrical connections and high-channel count data

- Control automation enabling low-cost operations

- Ambient dust containment room for regolith control and testing

- Hardware exposure testing to dust / regolith

- Regolith bin for design and test of excavation, processing, or construction technology

3-foot Dirty Thermal Vacuum Chamber

Overview | NASA JSC’s 3-foot dirty thermal vacuum chamber (TVAC) provides unique testing capabilities for dust and planetary surface environments. The 3-foot chamber is a 3ft x 3ft x 3ft cube designed to test component level concepts in a lunar simulated environment.

Details |

- Thermal Vacuum capability with dust mitigation for pumping system

- 36”x36”x36” (0.9m x 0.9m x 0.9m) cube shape

- Rough or High vacuum (10^-5 torr range quickly, 10^-7 torr demonstrated)

- Shroud temperature range of -300°F to +300°F (-185°C to +148°C)

- Shroud walls independently controlled for zone temperature conditioning if needed

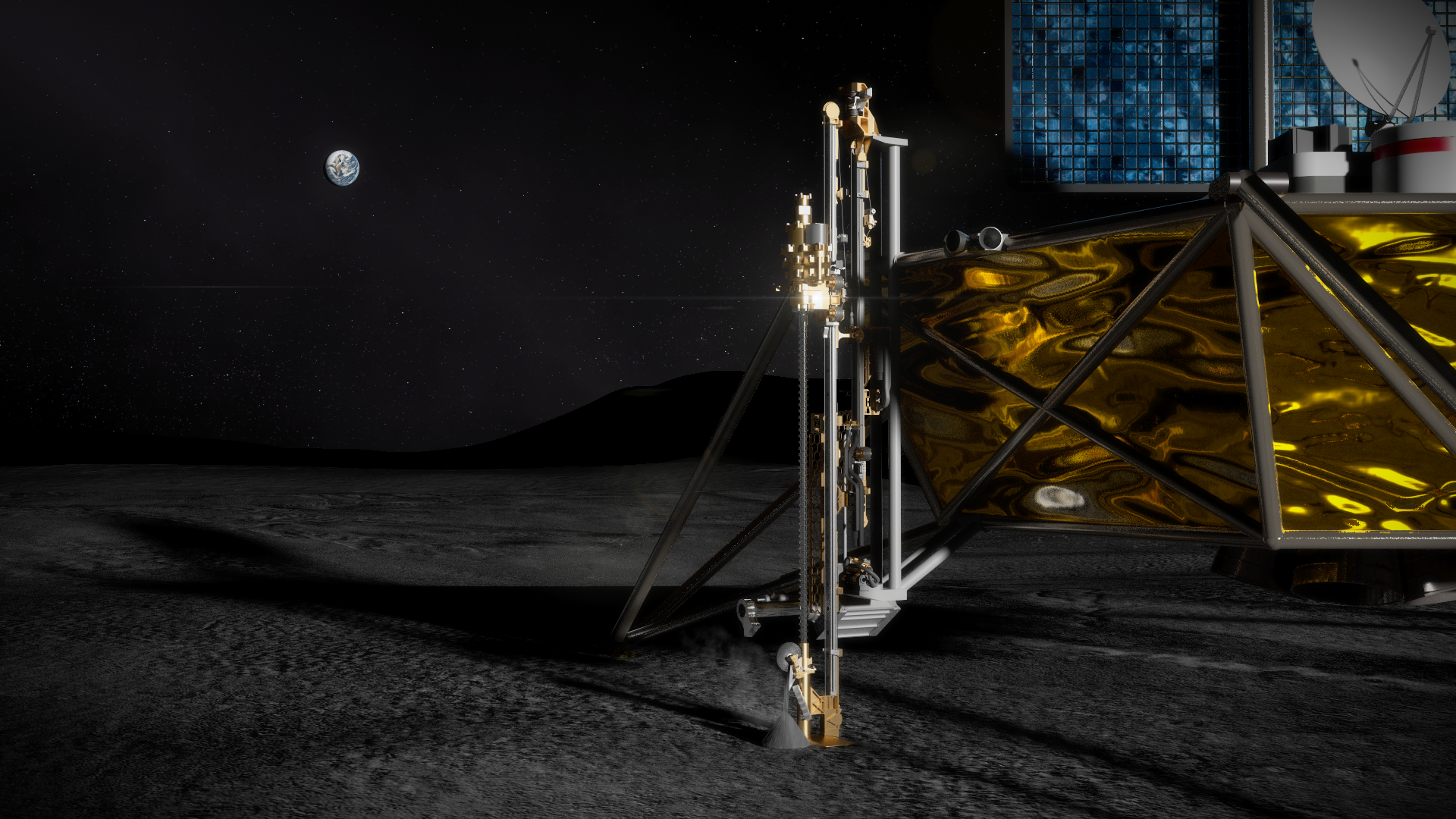

Regolith Simulant Drill Tube

Overview | The regolith simulant drill tube offers a 3 meter deep cylindrical enclosure that can be actively chilled with LN2 to create a frozen simulant for drilling or water capture testing.

Details |

- Tube jacket to be flooded with LN2 for cooling and heated GN2 for return to ambient temperature

- 13.5” (.342 m) ID and 42” (1.06 m) drill depth with 4” clearance above soil height

- Designed to be filled with compacted lunar regolith simulant with a target water content of 5% water by weight

- Holds ~370 lbs (168 kg) of simulant for a combined weight of ~984 lbs (446 kg)