Rapid Analysis and Manufacturing Propulsion Technology (RAMPT)

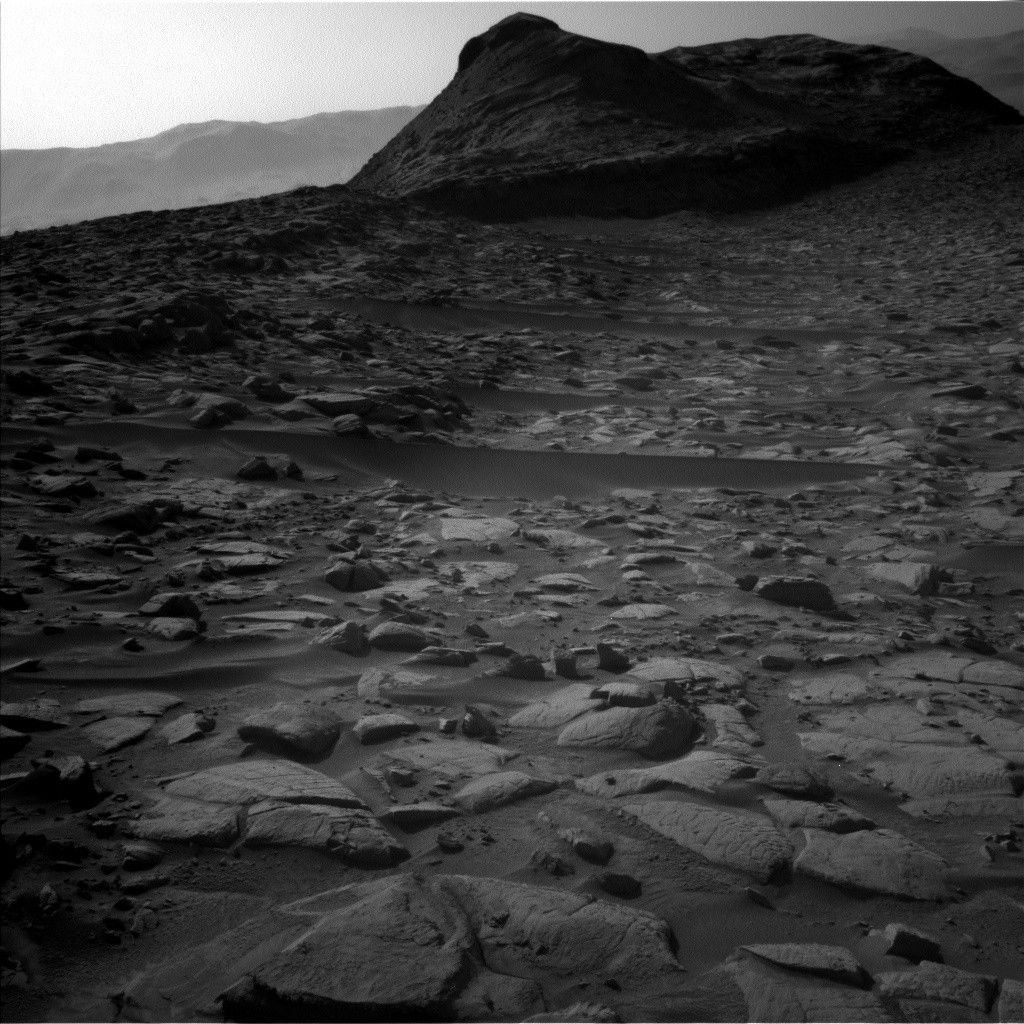

NASA has developed lighter and more efficient liquid rocket engine parts for future missions to the Moon, Mars, and beyond.

Lead Center

Marshall Space Flight Center

Introduced

October 2017

Principal Technologist

John Vickers

Project Manager

John Fikes

RAMPT

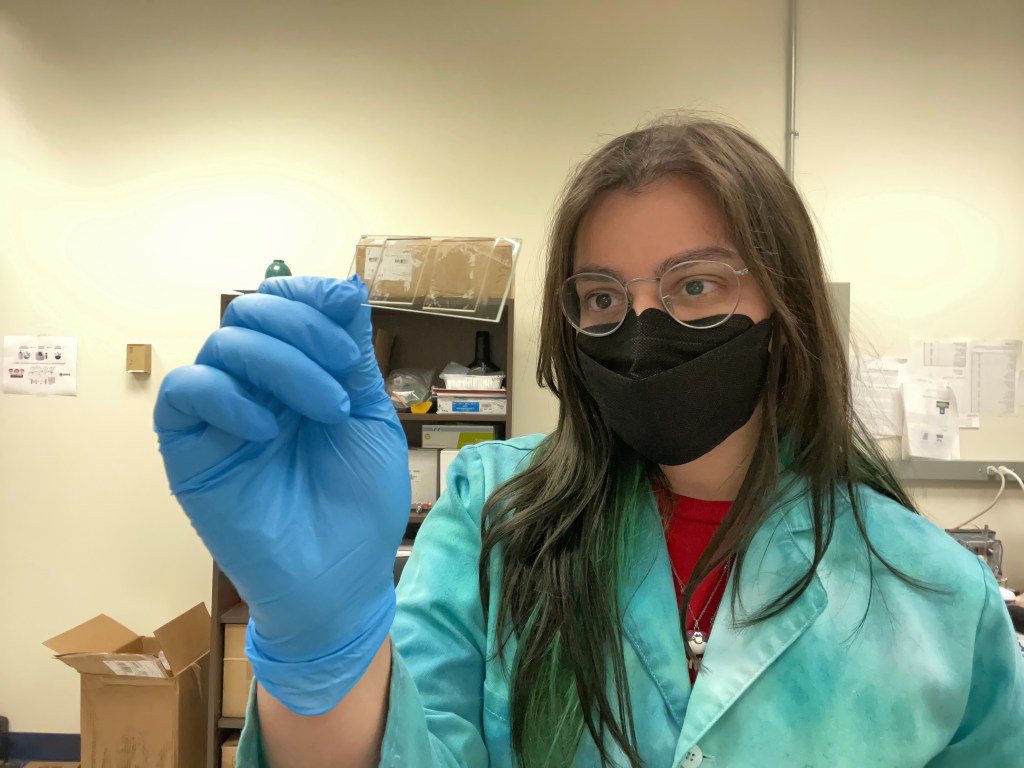

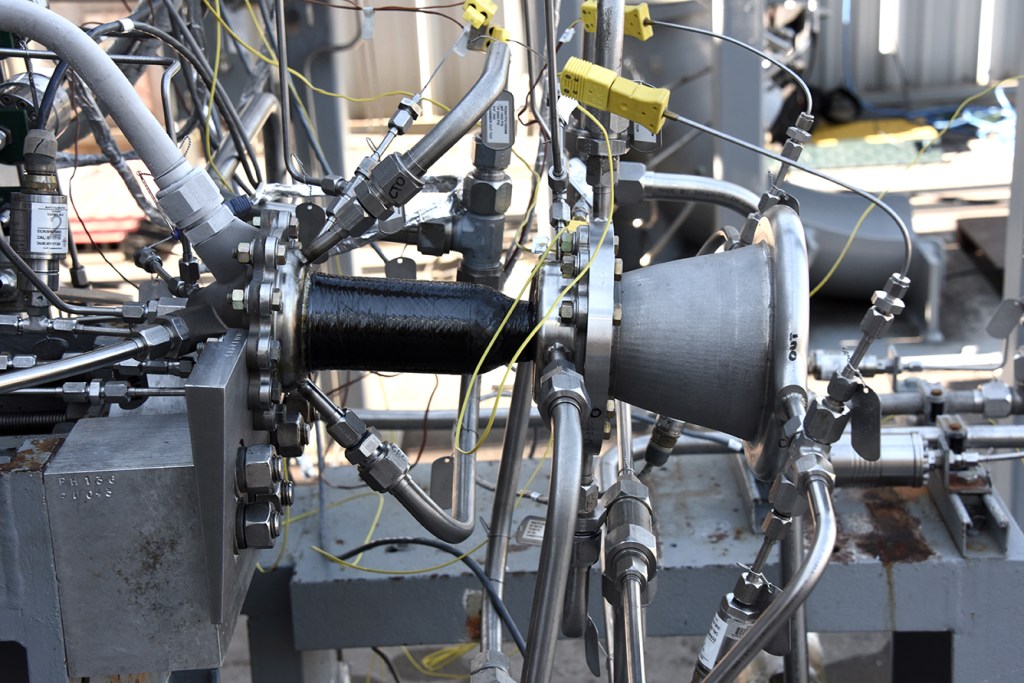

NASA engineers are exploring a new way to 3D print rocket engine parts using metal powder and lasers. The method, called blown powder directed energy deposition, is faster and more affordable than conventional fabrication methods. The development is part of NASA’s Rapid Analysis and Manufacturing Propulsion Technology, or RAMPT, project.

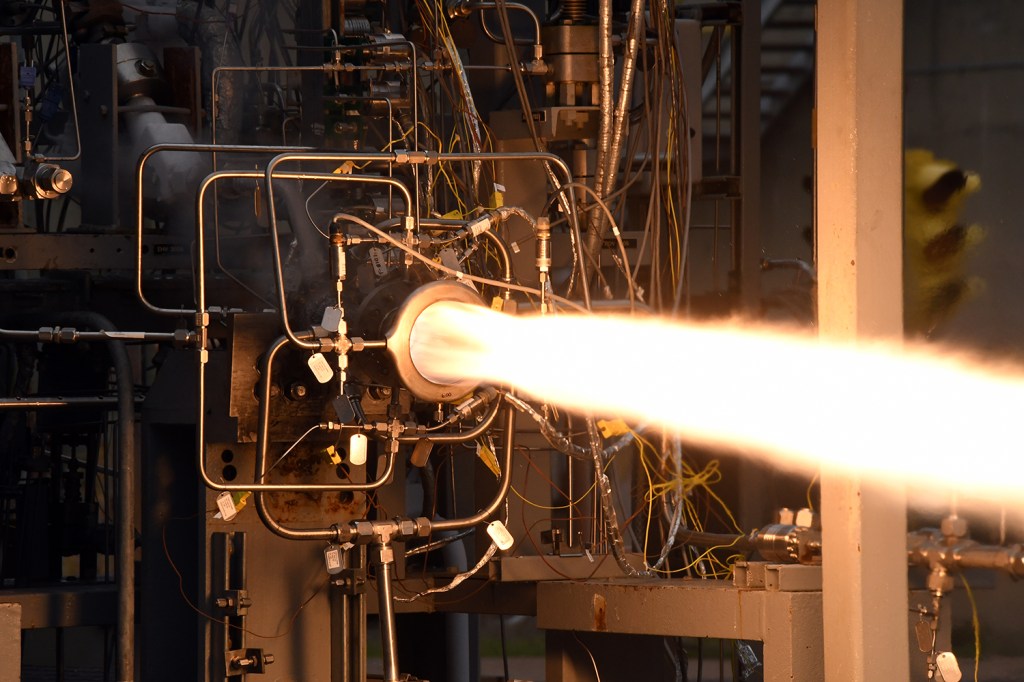

Learn MoreThe Rapid and Analysis Manufacturing Propulsion Technology (RAMPT) project has advanced manufacturing methods that improved the performance and reduced the production costs of rocket thrust chamber “assemblies.” These thrust chamber “assemblies” are made up of a combustion chamber, nozzle and joints. In rocket engines, fuel and an oxidizer are mixed and burned in the combustion chamber. This combustion produces hot exhaust, which is passed through a nozzle to accelerate the flow and produce thrust.

Thrust chamber assemblies are the most expensive parts of rocket engines to develop because they are highly complex and take a long time to manufacture. They are also one of the heaviest components within a rocket engine due to the high pressures and thermal loads, and can significantly drive up the costs of NASA missions.

Novel Manufacturing Methods Will Cut Costs, Production Time for NASA Missions

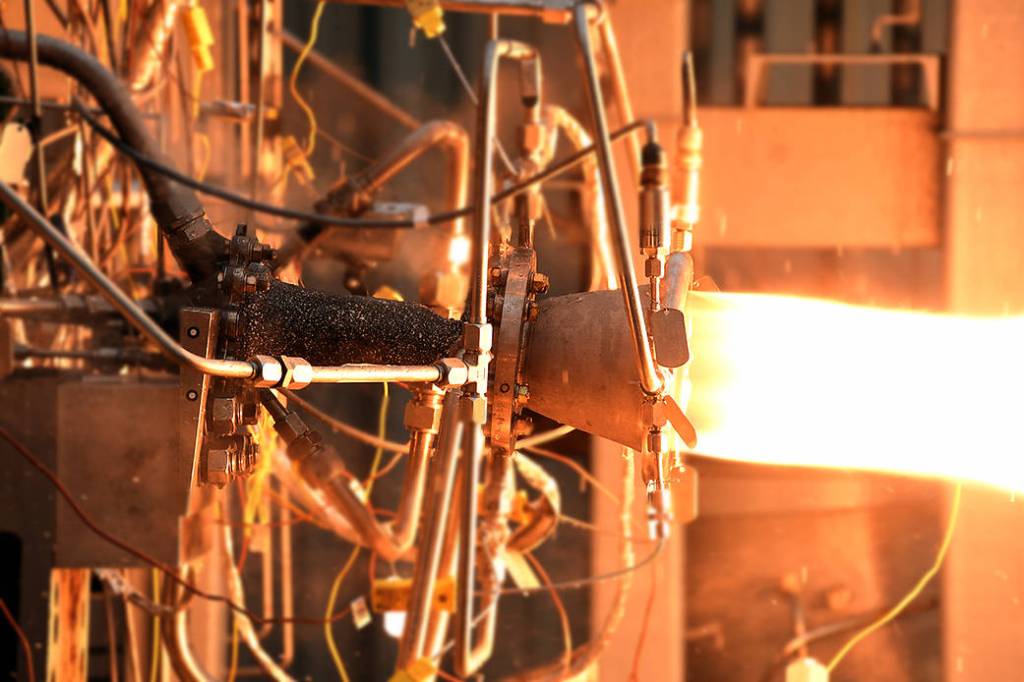

To cut down on these costs, RAMPT replaced some traditionally metal pieces on the thrust chamber with composite material, used advanced 3D printing methods to “print” the combustion chamber and nozzle, and employed innovative mechanical methods to fuse the two instead of using traditional metal joints.

RAMPT’s 3D-printed copper combustion chamber was covered with a composite wrap. This thin wrap – made of carbon fiber – provided structural support for the combustion chamber and replaced the traditional metal jacket, resulting in a weight savings of up to 40% compared to metal counterparts. The RAMPT nozzle was printed using a large-scale additive manufacturing process called directed energy deposition. This method uses lasers to melt and deposit metal powder, which then solidifies the material into a structure. This manufacturing method has reduced the time required for rocket engine nozzle production from years to months/weeks compared to traditional processes. It also significantly reduced the part count since less pieces need to be manufactured individually.

Another manufacturing capability RAMPT has advanced to reduce the weight and cost of the thrust chamber assembly is “bimetallic joints,” a method to fuse the copper combustion chamber directly onto the nozzle of a different alloy without any additional metal joints or bolts.

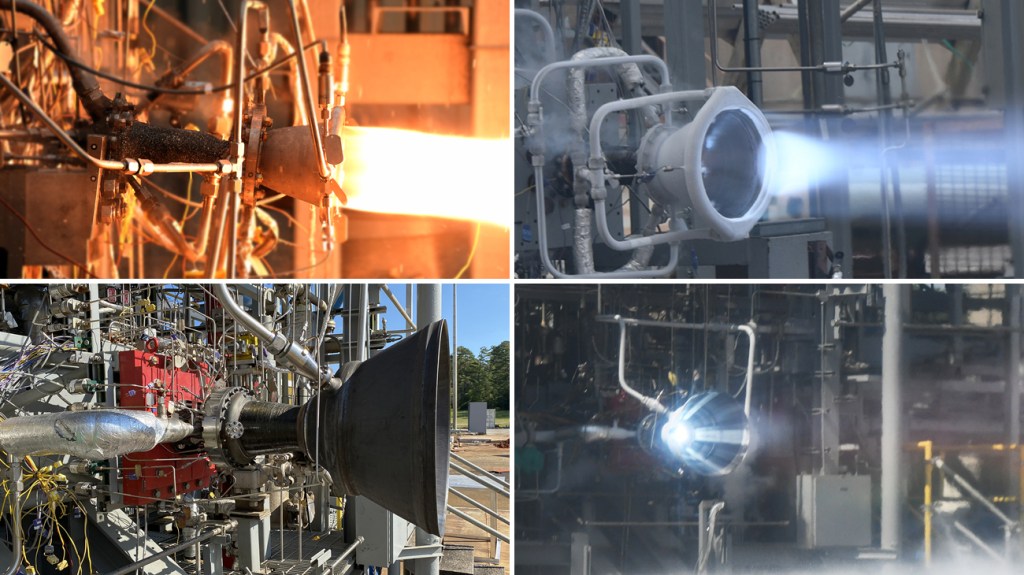

Advancement for NASA, Commercial Aerospace, and Related Industries

RAMPT’s advanced manufacturing methods provide design options not previously possible and replaces the standard manufacturing processes for assembling thrust chambers. The prior methods would manufacture the combustion chamber and nozzle individually and then bolt or weld them together. The RAMPT project combined several additively manufactured and composite overwrap methods to produce a single piece integrated thrust chamber assembly. To date, more than 16,000 seconds of hot-fire testing and nearly 500 starts have been recorded utilizing the integrated RAMPT nozzle and chamber hardware demonstrating capabilities at 2,000, 7,000, 35,000, and 40,000 pounds of thrust.

Major Achievements & Milestones:

- Matured GRCop-42 using Laser Powder Bed Fusion (L-PBF) and flew the alloy successfully on Relativity Space Terran 1.

- Developed and matured large-scale laser powder directed energy deposition (LP-DED) and successfully manufactured a 65% scale RS25 integral channel nozzle.

- Accumulated over 16,000 seconds and ~500 starts on various RAMPT nozzle and chamber hardware.

- Successfully demonstrated the feasibility of composite overwrap for chambers and offers a staggering 35% mass savings.

- Developed new modeling and simulation techniques along with industry and helped advance some commercial codes.

- Advanced NASA HR-1 (hydrogen resistant alloy) for additive, which is actively being tested on commercial space hardware and being considered for power/energy applications.

- Published over 100 conference papers and journal articles to disseminate data.

- Published (through AIAA) an 850-page textbook on additive manufacturing as result of 2+ year effort from 50+ co-authors from around the world. Many of these were RAMPT partners.

In a public private partnership with Auburn University, the RAMPT team has provided NASA and the commercial sector with advanced manufacturing capabilities that have resulted in shorter production times and reduced overall costs for aerospace and related industry projects.

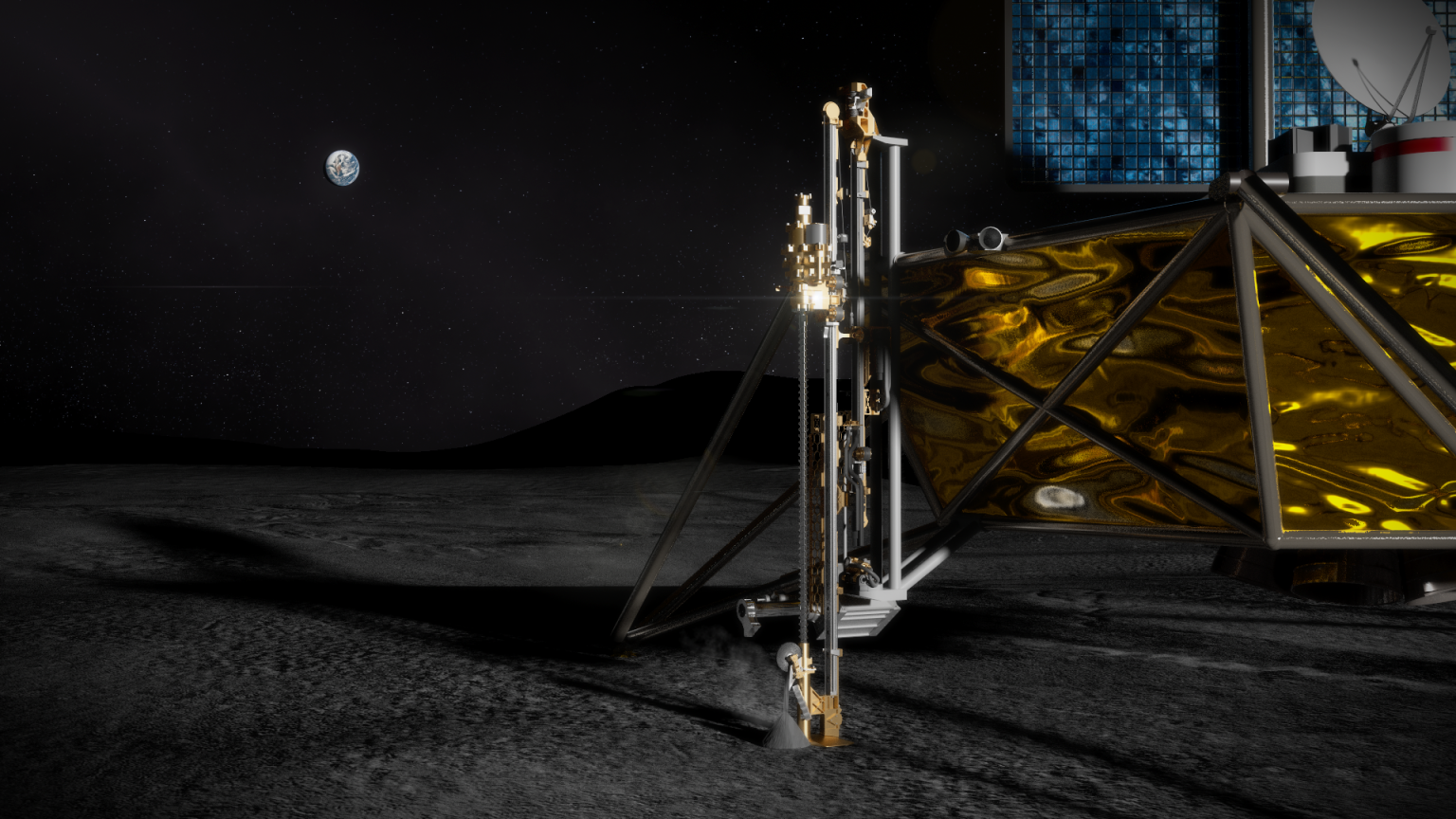

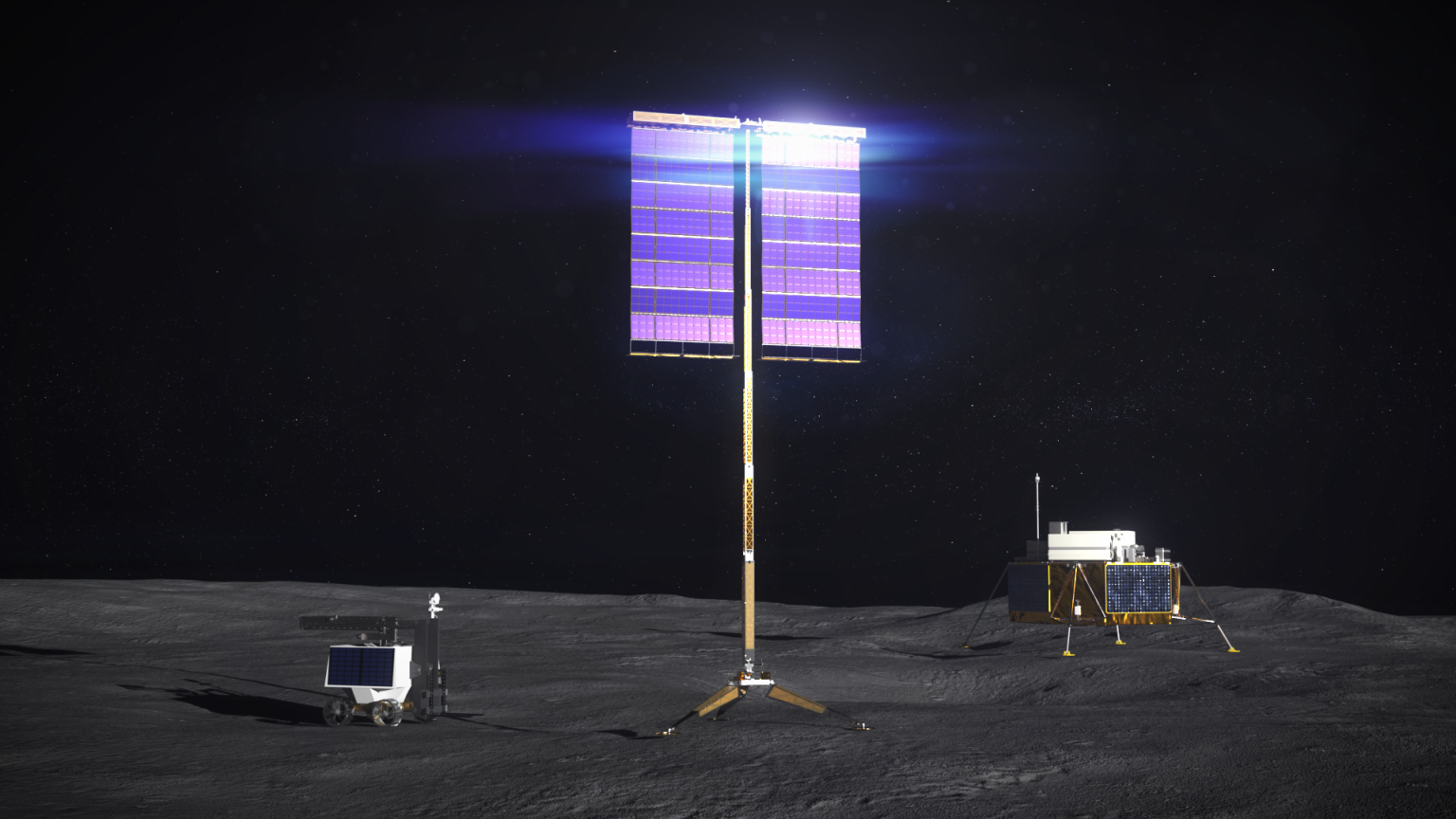

The advancement of this technology has allowed for its infusion within the aerospace industry. Relativity Space recently validated that this technology is capable for infusion by using nine additively manufactured rocket engines created with an alloy called GRCop-42, which was matured during the RAMPT project, on a Terran 1 rocket, which launched in March 2023. Following the RAMPT project, this work continues with the development of enabling alloys for both harsh and extreme environments as well as performance improvements for additive components. Testing these alloys, components and hardware will help qualify the technology for use on future missions; from NASA’s Artemis lunar missions to future deep space exploration of Mars and beyond.

Technical Paper Resources

Additive Manufacturing Subtracts from Rocket Build Time

NASA Spinoff (Jan 2024)

Advancement of extreme environment additively manufactured alloys for next generation space propulsion applications

Acta Astronautica, Volume 211, October 2023, Pages 483-497

Lightweight Thrust Chamber Assemblies using Multi-Alloy Additive Manufacturing and Composite Overwrap

Paul R. Gradl, Chris Protz, John Fikes, David Ellis, Laura Evans, Allison Clark, Sandi Miller and Tyler Hudson

AIAA 2020

Development of Directed Energy Deposited NASA HR-1 to Optimize Properties for Liquid Rocket Engine Applications

NASA/TM–20230006075

Thermophysical properties of additively manufactured (AM) GRCop-42 and GRCop-84

Materials Today Communications, Volume 36, August 2023, 106665

Separation anxiety: Lessons learned at NASA from a developmental rocket engine failure

Metal AM, Vol. 9 No. 1, Spring 2023

3D Printed Rocket Launched Using Innovative NASA Alloy

NASA Press Release, May 2, 2023

Robust Metal Additive Manufacturing Process Selection and Development for Aerospace Components

Journal of Materials Engineering and Performance, Springer, Volume 31, April 2022, pages 6013

Metal Additive Manufacturing for Propulsion Applications

AIAA Textbook, July 2022

In-Situ Alloying of GRCop-42 via Additive Manufacturing: Precipitate Analysis

NASA/TM-20205003857

Segregation Evolution and Diffusion of Titanium in Directed Energy Deposited NASA HR-1

NASA/TM-20210013649