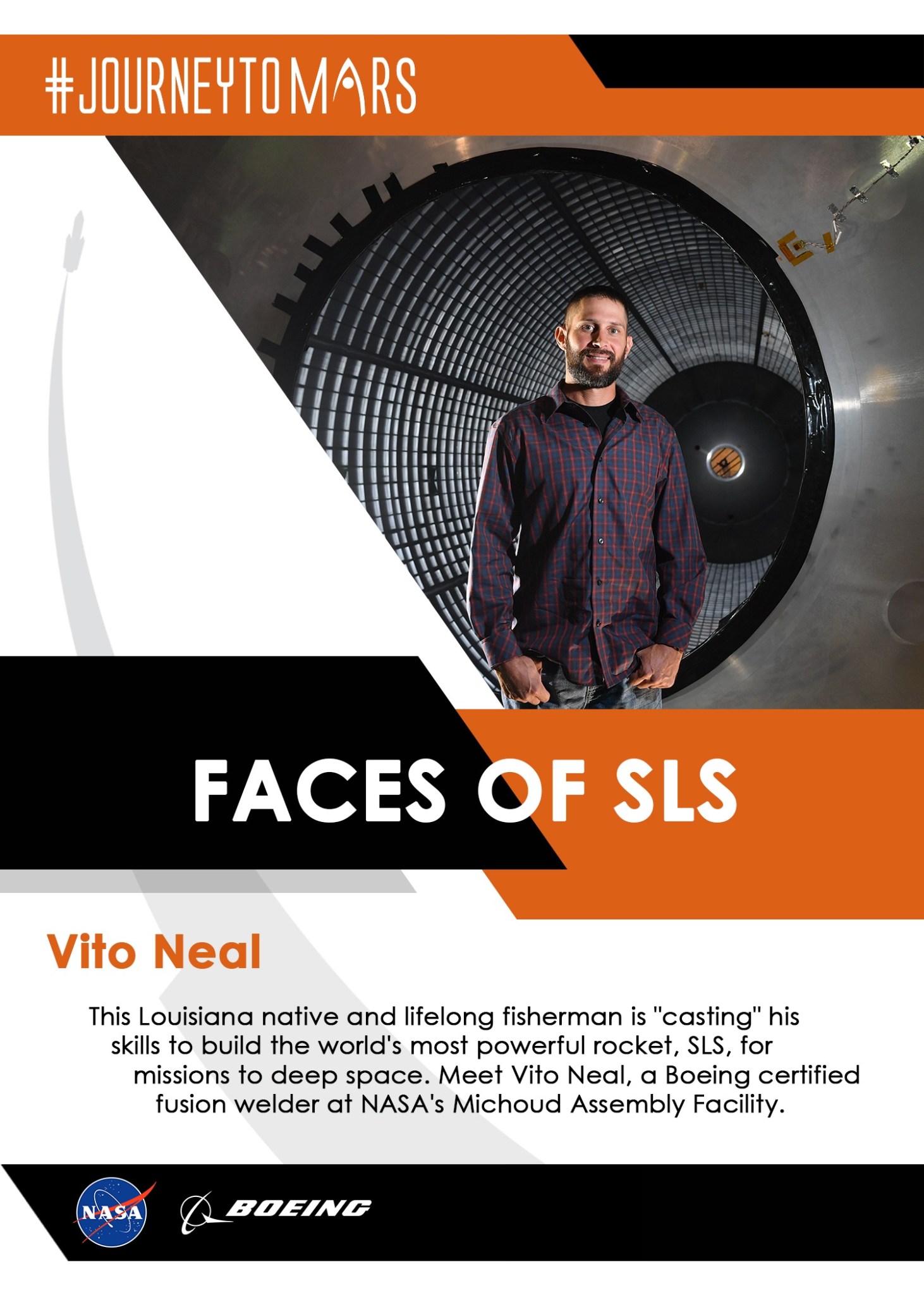

Faces of SLS: Vito Neal

I’m an enthusiastic, lifelong fisherman in just about every good water hole in Louisiana, but my favorite stories to share are about my role building the giant rocket for the journey to Mars.

Born and raised right here in Slidell, Louisiana, it’s a tremendous opportunity to work at NASA’s Michoud Assembly Facility in New Orleans and help build America’s rocket, the Space Launch System. I’ve always liked building things, and after spending a few years in the Army and working with Multiple Launch Rocket System rockets, it gave me even more of an appreciation for the work being done for SLS at Michoud. Those past experiences, as well as on-the-job training, helped strengthen my welding expertise. I was ready when the chance to work on SLS came up.

The work here is important, and I take it very seriously as the only certified fusion welder at Michoud. I also do other types of welding, including friction-stir-weld plug welding. Once a tank or dome is completed on the world’s largest welding tool, the Vertical Assembly Center, there are holes left from the weld head. My job is to fill those holes, and maintain the integrity and strength of the overall weld.

It’s an art form that relies on precision. When you’re building rockets for human spaceflight, your work has to be flawless. Astronauts in NASA’s Orion spacecraft will ride on the rocket, and we’re doing everything right to ensure a perfect launch. It’s a lot of responsibility, and I’m proud to tell my son and daughter what I do every day.