NASA’s Marshall Space Flight Center in Huntsville, Alabama, has started a series of structural and pressure tests on one of the largest composite cryogenic fuel tanks ever manufactured. The center also has just completed testing and certification for an additive manufacturing, or “3-D,” printer that will head to the International Space Station later this year. These are two of the advanced space technologies NASA is developing to enable future deep space exploration.

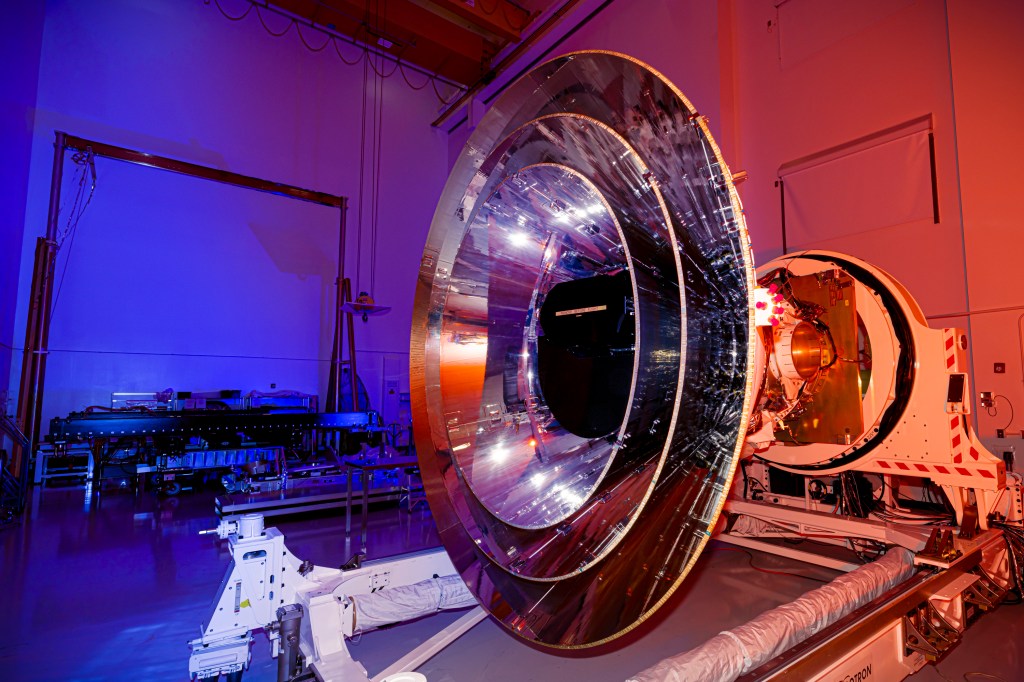

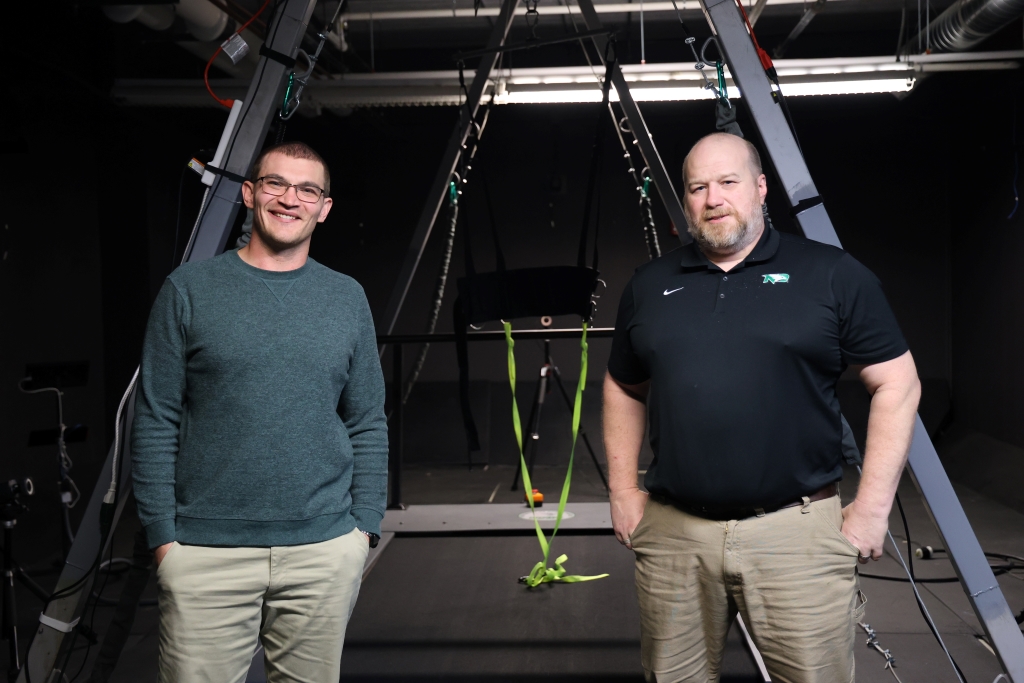

On Tuesday, June 24, at 2:45 p.m. CDT, media will be able to see a 3-D printer identical to the one headed to the space station and visit the test area control room to experience how engineers control testing for the 18-foot-diameter (5.5-meter) diameter composite cryotank. During a visit to Marshall’s test area, media will be able to interview Michael Gazarik, NASA’s associate administrator for Space Technology, as well as other experts about these advanced technologies.

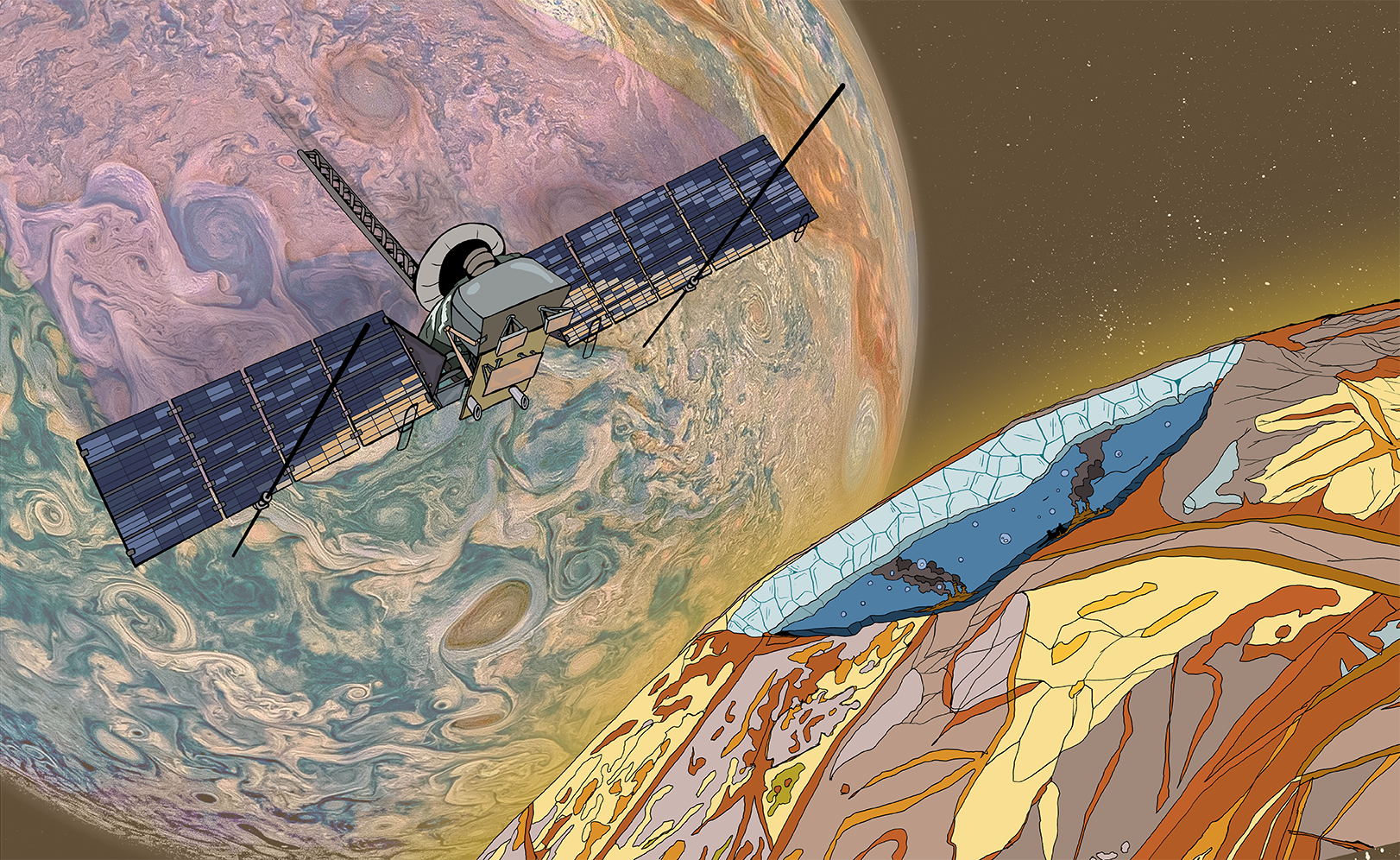

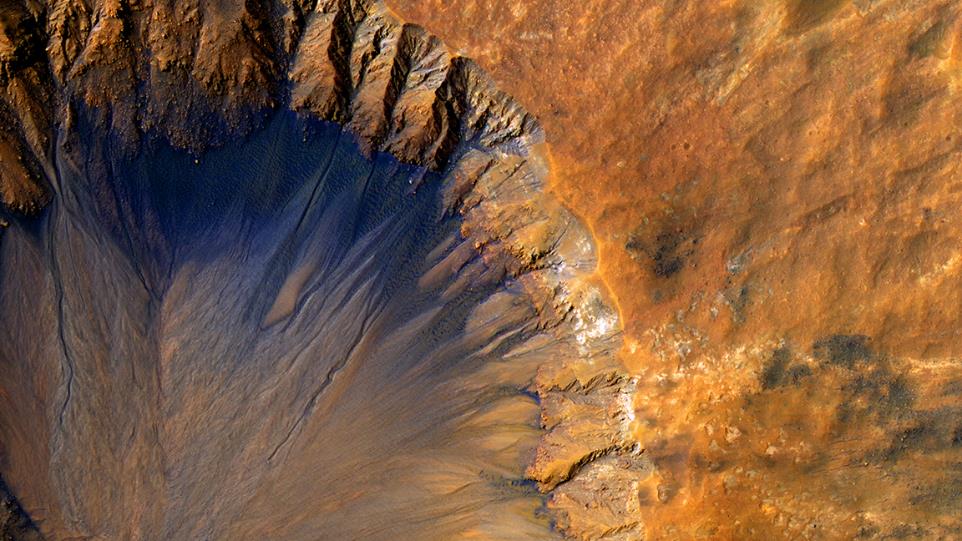

The composite rocket fuel tank built by the Boeing Company near Seattle arrived at Marshall on March 26 on NASA’s Super Guppy airplane. The tank has just completed its first round of testing. NASA is pursuing composite cryogenic fuel tanks, a potentially game changing technology, because the tanks could yield significant cost and weight reductions on future launch vehicles.

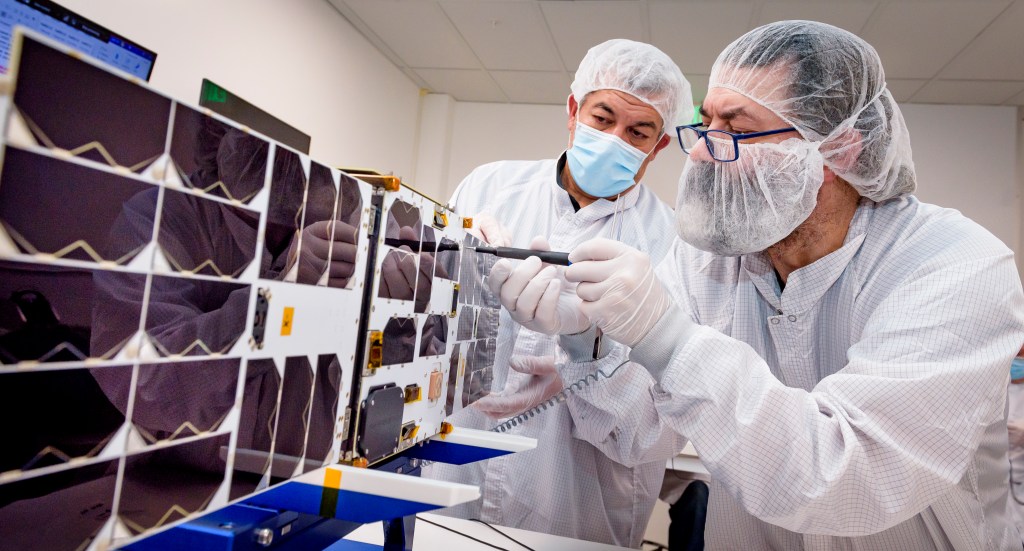

The 3-D printer provided by Made In Space of Mountain View, California, will head to the International Space Station aboard the upcoming SpaceX-4 mission. The printer will demonstrate 3-D printing in space. This technology has the potential to enable explorers to print tools wherever they are in the universe.

Reporters interested in covering this media tour with Gazarik should contact Janet Anderson (janet.l.anderson@nasa.gov) of the Marshall Public & Employee Communications Office at 256-544-0034.

Journalists must report to the Redstone Visitor Center at Gate 9, Interstate 565 interchange at Rideout Road/Research Park Boulevard no later than 2 p.m. CDT, Tuesday, June 24, for escort to the test area. Vehicles are subject to a security search at the gate. Journalists will need a photo identification and proof of car insurance.

For more information about how the Composite Cryotank Technologies and Demonstration project will revolutionize tank design, visit:

To learn more about 3-D printing, visit:

http://www.youtube.com/watch?v=lTxb43yiDUo&list=PLBEXDPatoWBngmgCe62SgrfKc6ai-Rg7V

To support stories about the cryotank and 3-D printer, B-roll video is available at:

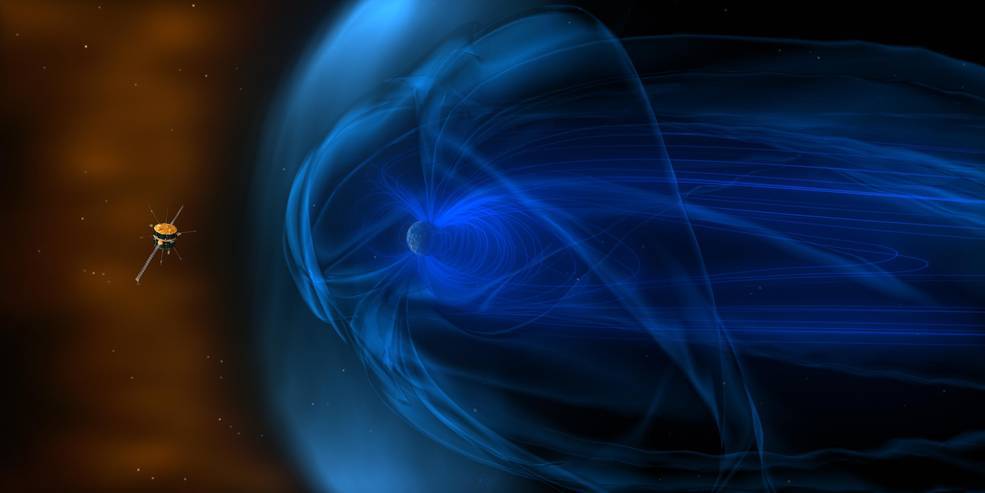

The project is part of NASA’s Space Technology Mission Directorate, which is innovating, developing, testing and flying hardware for use in NASA’s future missions. Over the next 18 months, the directorate will make significant new investments to address several high-priority challenges in achieving safe and affordable deep space exploration. These focused technology thrust areas are tightly aligned with NASA’s Space Technology Roadmaps, the Space Technology Investment Plan, and National Research Council recommendations.

For more information about NASA’s investment in space technology, visit:

https://www.nasa.gov/spacetech

Tracy McMahan/Janet Anderson

Marshall Space Flight Center, Huntsville, Ala.

256-544-0034

tracy.a.mcmahan@nasa.gov / janet.l.anderson@nasa.gov