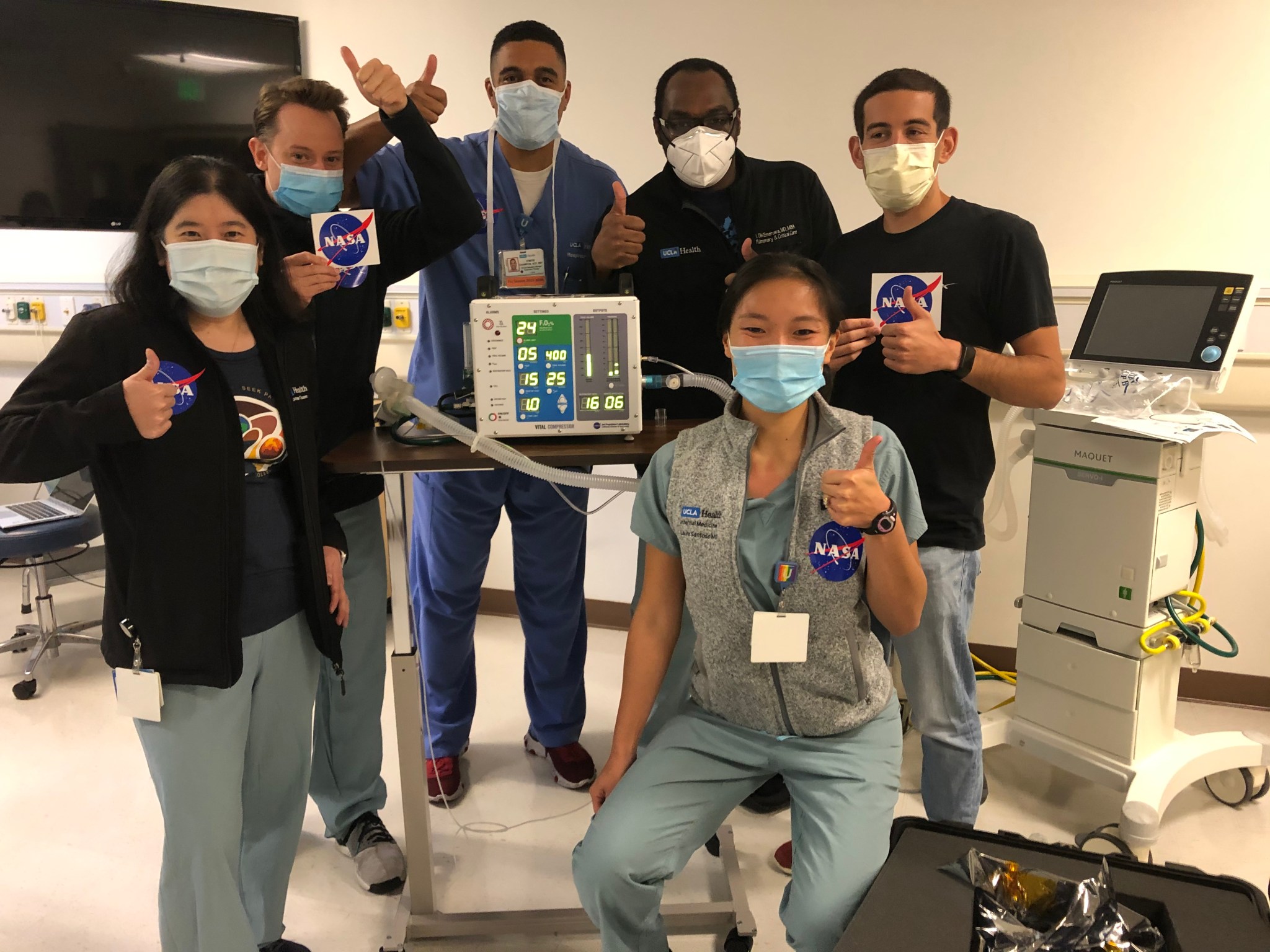

UPDATE: The FDA has awarded a second ventilator emergency use authorization for a modified design of VITAL that uses a compressor to generate pressurized air. This makes it ideal for a wider range of medical locations, including field hospitals. A separate version of VITAL received a ventilator emergency use authorization on April 30; this version, which relies on a pneumatic design, is better suited to traditional hospitals, where pressurized air is more readily available. (June 3)

After receiving more than 100 applications, NASA’s Jet Propulsion Laboratory (JPL) in Southern California has selected eight U.S. manufacturers to make a new ventilator tailored for coronavirus (COVID-19) patients.

The prototype, which was created by JPL engineers in just 37 days, received an emergency use authorization from the Food and Drug Administration on April 30.

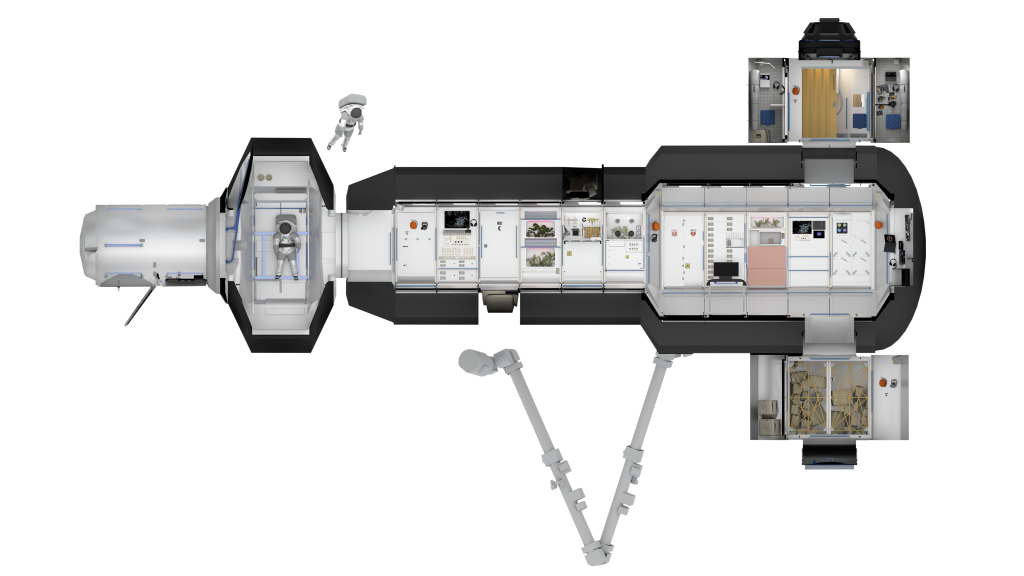

Called VITAL (Ventilator Intervention Technology Accessible Locally), the high-pressure ventilator was designed to use one-seventh the parts of a traditional ventilator, relying on parts already available in supply chains. It offers a simpler, more affordable option for treating critical patients while freeing up traditional ventilators for those with the most severe COVID-19 symptoms. Its flexible design means it also can be modified for use in field hospitals.

The Office of Technology Transfer and Corporate Partnerships at Caltech, which owns the patents and software for VITAL, is offering a free license for the device. Caltech manages JPL for NASA.

The U.S. companies selected for licenses are:

- Vacumed, a division of Vacumetrics, Inc. in Ventura, California

- Stark Industries, LLC in Columbus, Ohio

- MVent, LLC, a division of Minnetronix Medical, in St. Paul, Minnesota

- iButtonLink, LLC in Whitewater, Wisconsin

- Evo Design, LLC in Watertown, Connecticut

- DesignPlex Biomedical, LLC in Fort Worth, Texas

- ATRON Group, LLC in Dallas

- Pro-Dex, Inc. in Irvine, California

“The VITAL team is very excited to see their technology licensed,” said Leon Alkalai, manager of the JPL Office of Strategic Partnerships and a member of the VITAL leadership team. “Our hope is to have this technology reach across the world and provide an additional source of solutions to deal with the on-going COVID-19 crisis.”

JPL now is evaluating international manufacturers from countries as diverse as Brazil, Mexico, India and Malaysia. A full list of approved manufacturers is available here.

VITAL was developed with input from doctors and medical device manufacturers. A prototype of the JPL device was successfully tested by the Human Simulation Lab in the Department of Anesthesiology, Perioperative and Pain Medicine at Mount Sinai on April 23.

A modified design, which uses compressed air and can be deployed by a greater range of hospitals, was recently tested at the UCLA Simulation Center in Los Angeles. A high-fidelity lung simulator tested almost 20 different ventilator settings, representing a number of scenarios that could be seen in critically ill patients in an intensive care unit.

“VITAL performed well in simulation testing with both precise and reproducible results,” said Dr. Tisha Wang, clinical chief of the UCLA Division of Pulmonary and Critical Care Medicine. “In addition, the setup and operation of the ventilator was quick and user-friendly. The UCLA team commends JPL for actively contributing to the COVID-19 response and successfully addressing one of the key medical needs in the sickest group of patients.”

The compressed-air design also has been submitted to the FDA for a ventilator emergency use authorization and is currently under review.

For more information about NASA’s work in fighting COVID-19, visit:

-end-

Bettina Inclán / Matthew Rydin / Karen Northon

Headquarters, Washington

202-358-1600 / 202-603-7522 / 202-358-1540

bettina.inclan@nasa.gov / matthew.m.rydin@nasa.gov / karen.northon@nasa.gov

Andrew Good

Jet Propulsion Laboratory, Pasadena, Calif.

818-393-2433

andrew.c.good@jpl.nasa.gov