SBIR/STTR

Success Stories

Total

Awarded since 1982

Awards to over 3,500 firms

NASA SBIR/STTR has funded thousands of innovative ideas from small businesses and taken zero equity since 1982

Below find highlights of some of the program’s impressive awardees. Each SBIR/STTR team is introduced alongside a description of their technology and a timeline of the support they have received from the variety of SBIR/STTR opportunities across the Federal Government.

Mango Materials & Colorado School of Mines

Mango Materials, a women-owned small business, has developed a system to transform methane into biopolymers—plastic alternatives made from biodegradable materials.

On Earth, this innovation not only creates a plastic substitute but also recycles methane—a greenhouse gas contributing to climate change. In space, this technology could support sustained presence on Mars by printing tools and providing a binding agent for regolith construction on the planet, reducing the need for shipments from Earth.

Awardee Contact: Molly@MangoMaterials.com

Innovation

Biodegradable plastic alternative made from methane waste gas

Year of first award

2012

Number of Employees

25

Location

San Francisco, California

SBIR from National Science Foundation (2012-2013)

SBIR/STTR funding is granted through different agencies across the federal government, including the National Science Foundation (NSF).

Mango Materials began their journey with support from the National Science Foundation. The company explored how to develop the plastic alternative by feeding methane to naturally occurring bacteria, which create biopolymer granules inside their cell walls. These granules are then harvested into pellets, which can be melted and used to create textiles or plastic alternatives.

Mango Materials CEO, Molly Morse stated in a video for the NSF that “…getting the NSF grant back in the day was huge for us, it gave us control as the entrepreneurs.”

STTR Phase I & II ( 2016-2017)

Phase I: Idea Phase II: Prototype

Mango Materials continued their innovative journey with support form NASA SBIR/STTR. The STTR program incentivizes collaborative innovation between small businesses and research institutions, like universities. In this instance Mango Materials partnered with the Colorado School of Mines.

The team received STTR Phase I and Phase II awards to adapt the bioreactor system to convert methane into bioplastic for low-gravity environments.

STTR Phase II-E (2019)

STTR Phase II-Extended (II-E): Further encourages the advancement of innovations developed under Phase II via a contract.

In 2019, the Phase II was extended through the Phase II-E option to improve the end-to-end system and minimize waste.

Dr.Junko Munakata Marr, Professor and Department Head of Civil and Environmental Engineering at the Colorado School of Mines, said students involved gained insight into small business culture in a real-world setting. Similarly, Dr. Marr shared the school’s space resources program has expanded thanks to the growing relationship with NASA.

STTR Civilian Commercialization Readiness Pilot Program (2020)

Civilian Commercialization Readiness Pilot Program (CCRPP): enables near-term infusion and/or commercialization of SBIR/STTR-developed technologies.

CCRPP appealed to Mango Materials for the program’s emphasis on commercial development and for the STTR dollar-to-dollar match on external investments. Fashion industry investors were interested in exploring how the methane biopolymer could be a more sustainable alternative to existing fibers.

In 2021, Mango Materials received $6 million in total CCRPP funds from STTR and investors to optimize and commercialize the biopolymer product.

Oakwood University & SSS Optical Technologies

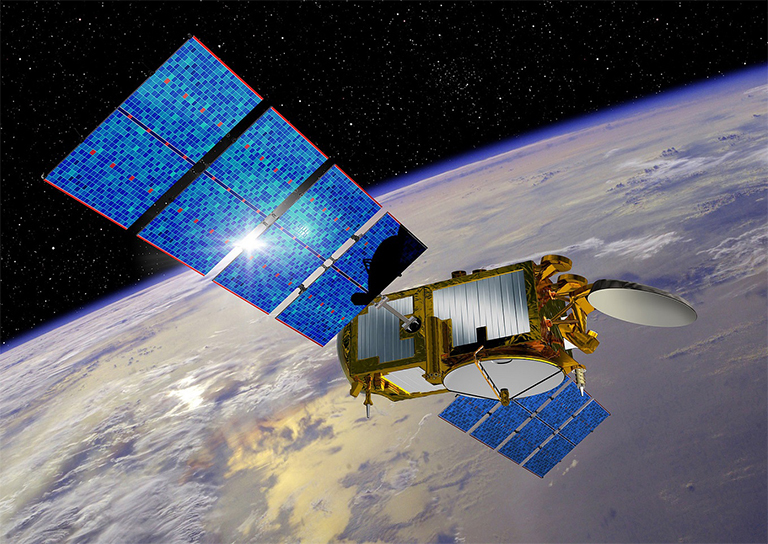

The innovative team composed of Oakwood University, SSS Optical Technologies, and subcontractor Regher Solar, is developing a UV protective coating for photovoltaic solar cells in space. Solar cells convert sunlight into energy but can suffer damage from UV rays.

Oakwood University, a Historically Black College based in Huntsville, Alabama, entered the SBIR/STTR arena after participating in M-STTR, now MPLAN, an initiative enabled by NASA’s Space Technology Mission Directorate (STMD) and NASA’s Office of STEM Engagement’s Minority University Research and Education Project (MUREP).

Awardee Contact: mazillo123@yahoo.com

Innovation

UV protective coating for photovoltaic solar cells in space

Year of first award

2021

Number of employees

3

Location

Huntsville, Alabama

MPLAN (2021)

MPLAN: awards Minority Serving Institutions (MSIs) to further develop ideas and facilitate research and development.

In 2021, Oakwood University and SSS Optical Technologies participated in M-STTR, now MPLAN, an initiative for Minority-Serving Institutions (MSIs) to propose for Small Business Technology Transfer (STTR) research planning grants.

The program allowed the team to generate preliminary data about the solar cell technology which was later used for the 2022 STTR proposal. The program experience unified the team and set them up for an effective partnership for innovation.

STTR Phase I & II (2022-2023)

Phase I: Idea Phase II: Prototype

NASA granted Oakwood University and SSS Optical Technologies with a Phase I contract in 2022 which allowed the team to investigate how the Polymer Anti-damage Nanocomposite Down-converting Armor (PANDA) technology could be used to protect solar cells and increase their durability. The following year the team received a Phase II contract helping them advance their technology and develop a prototype.

Dr. Patel, the principal investigator for the project, shared advice for others interested in NASA SBIR/STTR, “Keep your eyes wide open and try to reach out to nearby small businesses interested in transferring your technology to the market. And remember: it should line up with what NASA is looking for.”

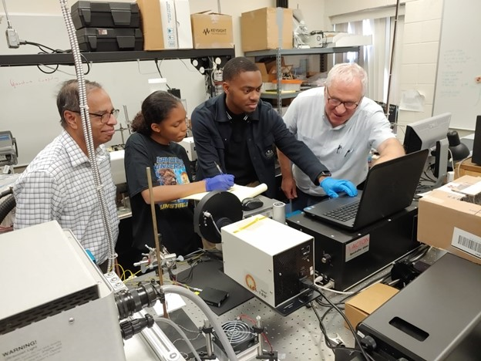

Spectral Energies

Spectral energies is developing a pulse-burst laser system, a technology that helps test new designs for a space vehicles or commercial aircrafts. Researchers use wind tunnels — controlled environments that simulate the wearing conditions of being in the sky — when testing new designs. Spectral energies’ technology provides detailed video data of how wind moves around the new designs showing whether they are effective and safe.

This technology could cut millions of dollars from the approval of new commercial aircrafts, allowing new, faster, and cheaper planes to be available for passengers.

Awardee Contact: admin1@spectralenergies.com

Innovation

Pulse burst laser systems that improve aeronautics testing

Year of first award

2007

Number of Employees

37

Location

Beavercreek, Ohio

SBIR from NASA and the Air Force (2009)

SBIR/STTR awardees receive funding from different agencies across the federal government and are allowed pivot to a different agency between phases.

Spectral Energies received NASA SBIR Phase I funding in 2009 to further advance the aerodynamics testing technology. For Phase II, the firm pivoted and applied to the U.S. Air Force who also awarded them Phase III SBIR funding.

The support from NASA and the Air Force allowed Spectral Energies to develop a commercial pulse-burst laser system that was easy to transport, resilient, and simple to operate.

In the image, the United States Air Force Thunderbirds flying over NASA Langley Research Center while practicing for an air show at Langley Air Force Base Virginia.

NASA SBIR (2014)

Post Phase II: turn the prototype into a successful product

Spectral Energies continued its work with multiple NASA SBIR awards. The firm enhanced pulse-burst laser systems enabling two-color thermometry — typically done at 10 Hz speeds with two lasers and two cameras— to be done at high-speed with a single-laser and single-camera system. These improvements, developed three- and four-dimensional images (i.e., three spatial coordinates and time) temperature measurement of chemical flows, a critical capability when designing new chemical propulsion systems.

The innovations were further infused into the marketplace with multiple Post Phase II opportunities, including three Phase II Extended (II-E) and three Phase III contracts. Post Phase II are awards aim to take the previously developed prototype into an successful commercial product.

Systems are implemented at Langley Research Center (2017)

The SBIR/STTR program connects small businesses to industry consumers, including NASA

In the years that followed, NASA acquired two of Spectral Energies’ pulse-burst laser systems. Dr. Paul Danehy, Senior Technologist for Advanced Measurement Systems at NASA’s Langley Research Center, has worked with Spectral Energies on a number of projects through the program. According to Dr. Danehy, not only did NASA SBIR funding aid the company’s technology growth, program funding also made it possible for NASA researchers to make use of this technology.

As Dr. Danehy explains, SBIR/STTR Post Phase II funding vehicles like Phase II-E and Phase III allow increases the purchasing power of NASA by allowing programs within the agency to pool money together and then receive matching funds from the SBIR/STTR program.

Techshot

Note: In 2021 Techshot was acquired by Redwire

Techshot, who obtained their first SBIR award in 1991, has been a trailblazing innovator in the realm of bioprinting — 3D printing with organic materials like cells. On Earth, the effects of gravity cause bio printed materials to sag and disform under their own weight. One solution is to give them structure is using non-organic materials, however these can harm the printed tissue. Techshot’s solution to keep gravity from deforming the tissues was to print them in space.

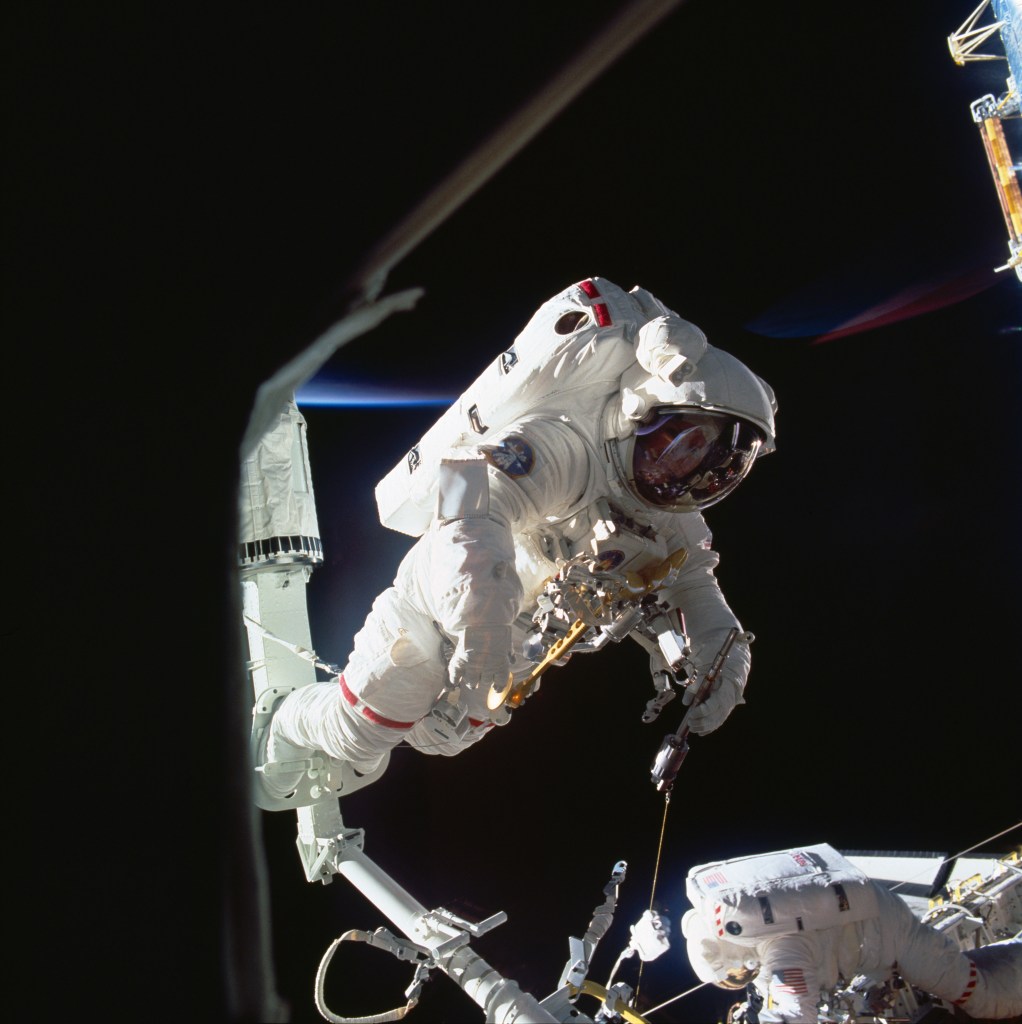

Through multiple NASA SBIR awards, Techshot developed a strong connection to NASA which allowed the firm to access the International Space Station (ISS). On 2019 they launched their innovations, the BioFabrication Facility (BFF) and the Advanced Space Experiment Processor (ADSEP), to the ISS. BFF and ADESEP have successfully completed knee meniscus tissue — which the human body has a hard time regenerating — and printed a large volume of human heart cells.

Innovation

3D printing with cells in space

Year of first award

1991

Number of Employees

50

Location

Greenville, Indiana

SBIR from NASA, DoD and HHS

(1991)

SBIR/STTR funding is granted through many different agencies across the federal government.

Techshot received multiple SBIR and STTR awards from agencies including NASA, the Department of Health and Human Services (HHS), and several branches within the Department of Defense (DoD).

Inside the DoD, the Army Medical Research and Materiel Command (USAMRMC) awarded Techshot with SBIR awards to use the technology on Earth to improve vascular grafts for soldiers. Following success with these advanced artificial grafts, Techshot sought to combine them with bio printed tissue. Similarly the USAMRMC funded the development of the BioFabrication Facility alongside NASA.

NASA SBIR (2016)

SBIR Phase I: Idea

In 2016, NASA continued supporting Techshot with an SBIR Phase I award to mature additive manufacturing capabilities in space.

The equipment they developed as a result, the Sintered Inductive Metal Printer with Laser Exposure (SIMPLE) unit, was further developed with Phase II and II-E funding from the NASA SBIR/STTR program and the NASA In-Space Manufacturing Project.

Civilian Commercialization Readiness Pilot Program

(2018)

Civilian Commercialization Readiness Pilot Program (CCRPP): enables near-term infusion and/or commercialization of SBIR/STTR-developed technologies.

Upon completion of Phase II awards, firms can apply to a number of Post Phase II opportunities including CCRPP, which aims to accelerate the near-term transition of SBIR- and STTR-funded technologies to infusion and/or commercialization. NASA SBIR/STTR matches investments between $500,000 and $2.5 million. In 2018, Techshot received $2.5 million from the ISS Program, for a pre-purchase of BFF services and data, CCRPP matched $1.5 million.

How can CCRPP help small businesses?

Techshot launched their technology aboard the International Space Station

(2019)

International Space Station (ISS): microgravity laboratory 260 miles above Earth

After being involved with the SBIR/STTR program for over three decades, in 2019 Techshot launched the BioFabrication Facility and the Advanced Space Experiment Processor to the International Space Station.

Richard Boling, Vice President of Corporate Advancement at Techshot, remarks on the influence of the SBIR/STTR program on the company’s success: “Every payload we fly to the ISS starts with an SBIR. Our company has been able to provide jobs in a rural area in a non-space state, and we really tie that back to the SBIR program.”