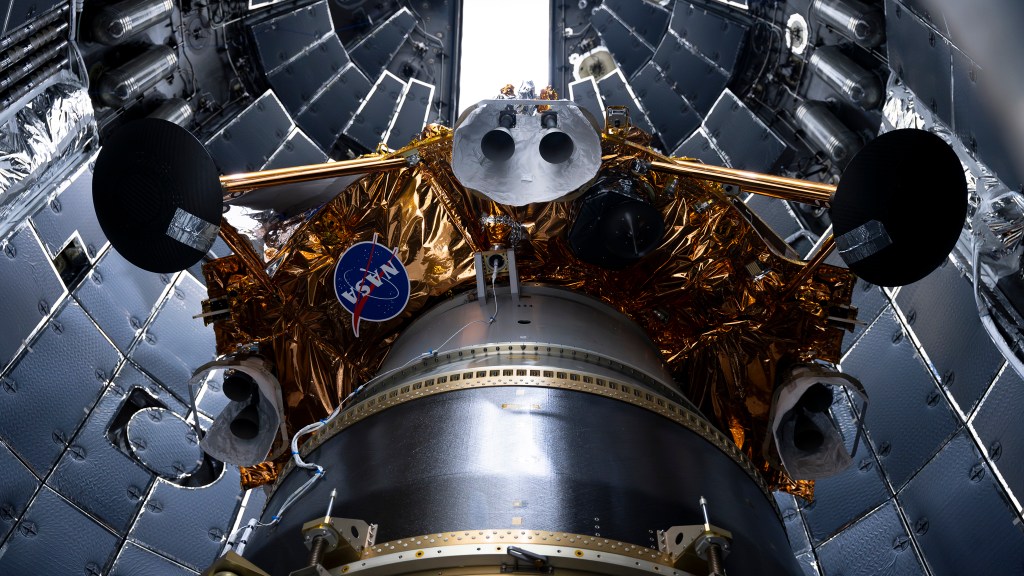

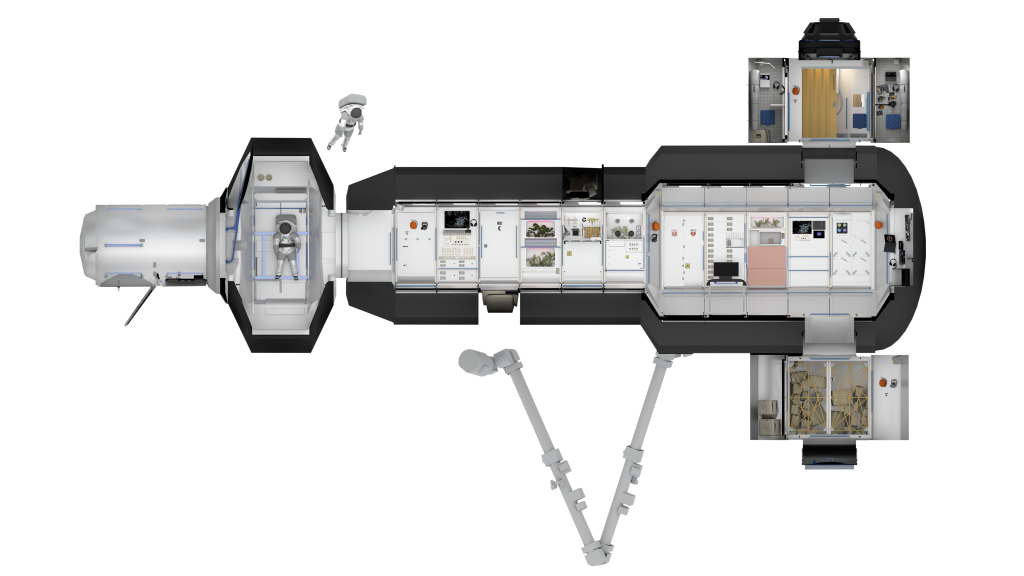

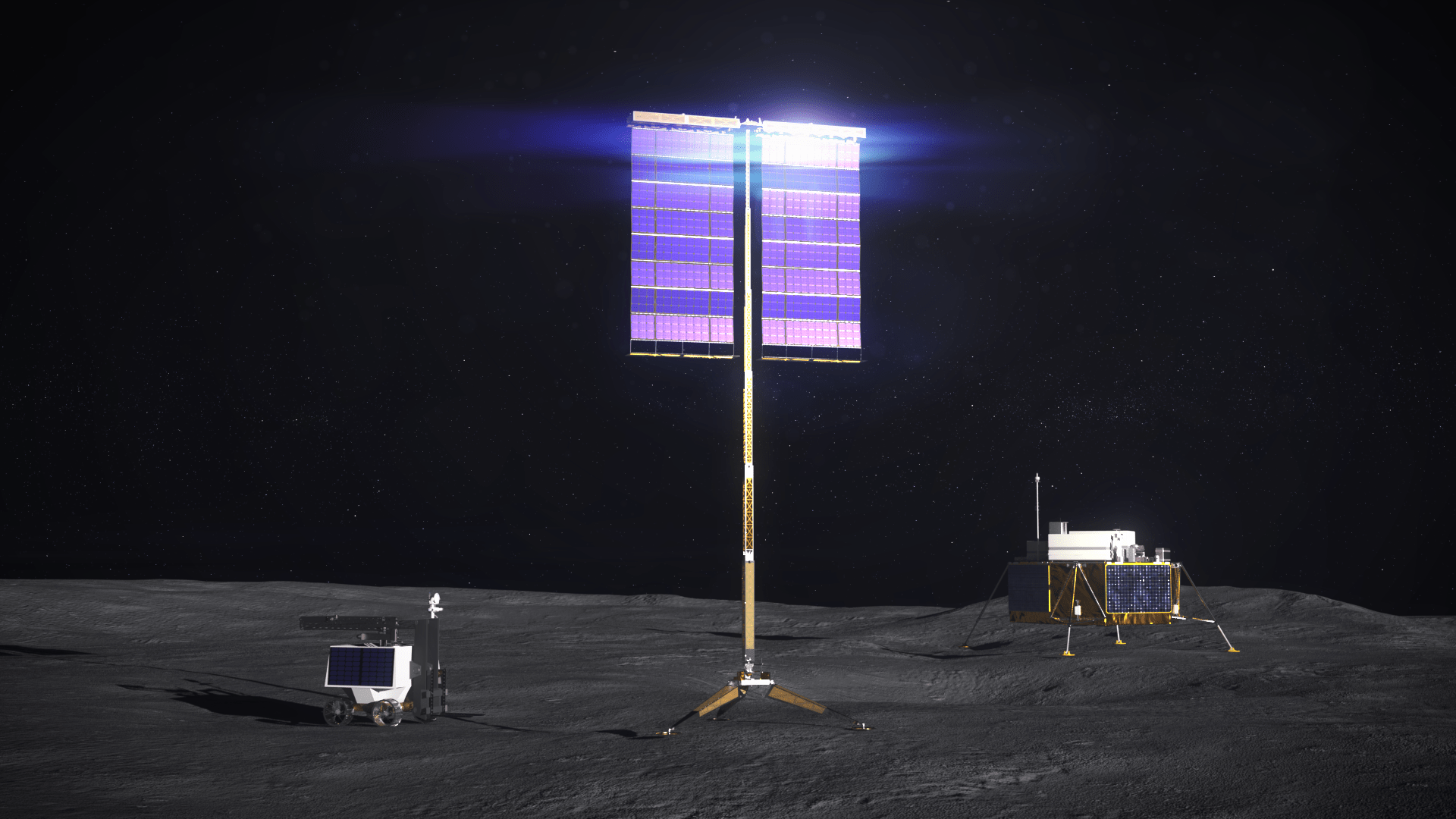

NASA will soon return humans to the Moon for decades to come, and the system that will transport astronauts from Earth to the Gateway near the Moon is literally coming together. Building on progress in 2018, most of the major manufacturing for the first mission is complete, and this year, teams will focus on final assembly, integration, and testing, as well as early work for future missions. NASA is focused on launching the first mission, Exploration Mission-1 (EM-1), in 2020 to send an Orion spacecraft on the Space Launch System (SLS) rocket from the modernized spaceport at Kennedy Space Center in Florida on an uncrewed test flight before sending crew around the Moon and back on the second mission, Exploration Mission-2 (EM-2) by 2023.

The Crew Capsule — Orion

For the Orion spacecraft that will fly on EM-1, engineers will continue stacking the crew and service modules together at Kennedy and performing tests to ensure the modules operate properly together. In the summer, the stacked modules will fly aboard the agency’s Guppy aircraft to NASA’s Plum Brook Station in Sandusky, Ohio, where together they will undergo thermal vacuum testing as well as electromagnetic interference and compatibility evaluations during a four-month test campaign. When Orion returns from Ohio, it will undergo final checks and processing before final preparations for launch and integration with SLS.

At the same time, Orion teams are also working on the spacecraft and other critical systems for the second mission that will carry a crew of astronauts around the Moon and back. Engineers will continue outfitting and testing the crew module, including pressuring the capsule to verify its structural integrity, powering it on for the first time to ensure it can route commands properly, and routing electrical and propulsion lines. Teams will also perform welding for the environmental control system and fit it for the outer back shells and heatshield.

In preparation for the first mission with crew, the agency will also test the spacecraft’s launch abort system this June to demonstrate that it can carry the crew to safety if an emergency were to happen on the way to space. During the three-minute test, called Ascent Abort-2, a booster will carry an Orion test vehicle to an altitude of 31,000 feet at more than 1,000 mph to test the launch abort system when the spacecraft is under the highest aerodynamic loads it will experience during a rapid climb into space.

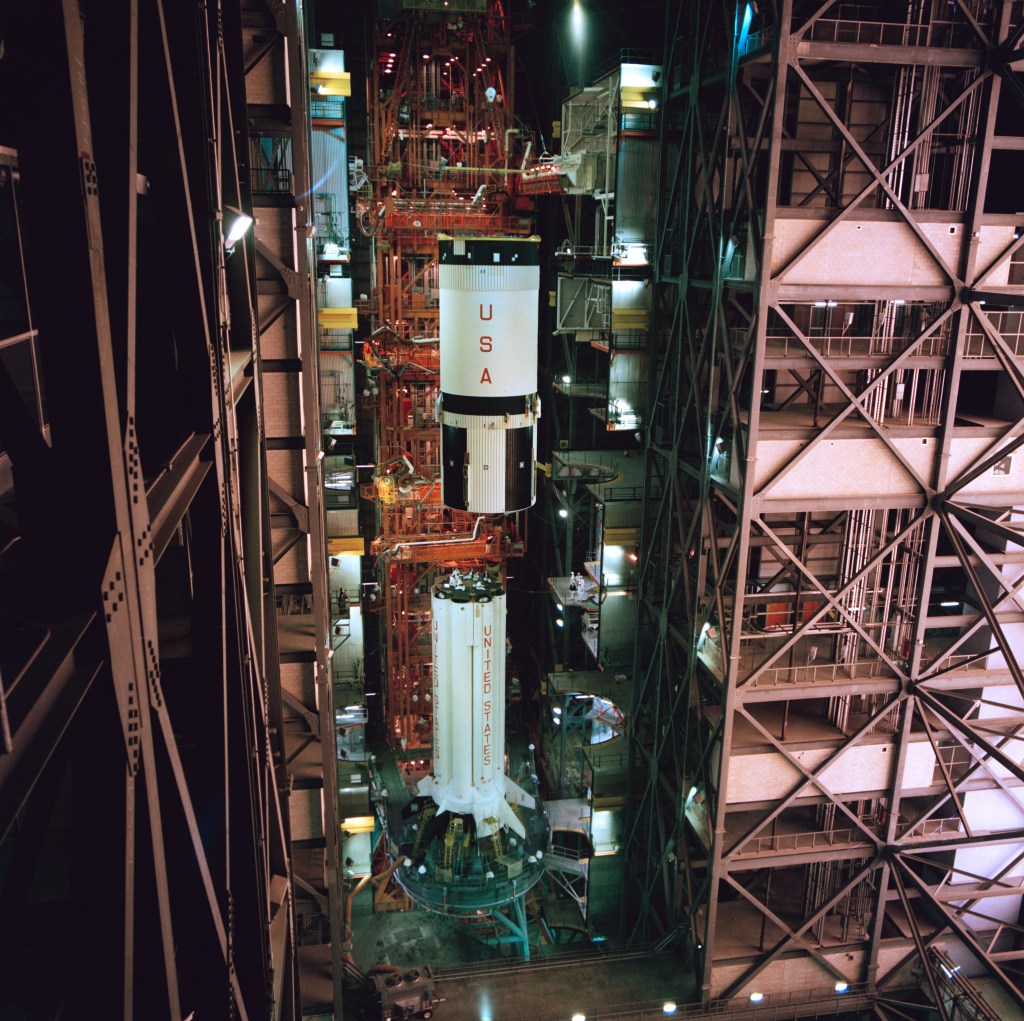

The Rocket — Space Launch System (SLS)

Technicians at NASA’s Michoud Assembly Facility in New Orleans are nearly finished with production of the first flight’s core stage, the largest element of the most powerful rocket in the world. Technicians have almost completed outfitting the engine section, the complex bottom section of the core stage. Its sophisticated systems feed propellant to the four RS-25 engines. The section will be joined to the 130-foot-long liquid hydrogen propellant tank to form the stage’s aft section. The aft section will then be connected to the 66-foot forward section, which consists of the forward skirt, liquid oxygen tank, and intertank, in a horizontal configuration to form the full stage.

The four core stage engines for EM-1 will be delivered to Michoud later this year and installed into the core stage engine section. NASA’s Pegasus barge will move the completed stage to Stennis Space Center near Bay St. Louis, Mississippi, where all four engines will roar to life to test the completed stage.

The team at Stennis has already completed two engine tests this year, concluding a series of nine tests that began last August. This spring, NASA will mark a major milestone to complete testing of all engines for the first four SLS missions. Aerojet Rocketdyne has already started making the engines for additional flights with the goal of reducing the costs of manufacturing by at least 30 percent using smart manufacturing techniques.

The last structural test article for the core stage, a full-sized flight-like liquid oxygen tank, will arrive at Marshall Space Flight Center in Huntsville, Alabama, this summer on the Pegasus barge. Engineers will finish up structural testing on the intertank and liquid hydrogen tank and then begin with the liquid oxygen tank to push the hardware to the limits under forces that exceed what the hardware will experience in flight. Testing will also continue for multiple avionics and software systems this year as well.

Building and moving the 212-foot-tall core stage, the largest rocket stage that NASA has ever built, has been one of the most challenging aspects of SLS construction. NASA is applying this experience to the core stage for the second mission, which is already in production

Engineers at Marshall, are putting the finishing touches on the 30-foot-tall launch vehicle stage adapter that will connect the top of the core stage to the interim cryogenic propulsion stage, which was previously delivered to Kennedy. This year, Pegasus will deliver the adapter to Kennedy. The SLS booster team in Utah finished the ten solid rocket motor segments needed for EM-1 earlier this year, and they will also be delivered to Kennedy when needed, where they will join other booster parts.

For the second SLS flight, building is complete for most of the barrels, domes and other structures needed to build the core stage for EM-2. Nearly all the solid rocket motor sections for the boosters on the second mission are cast and being outfitted. Teams are beginning work on additional parts including the Orion Stage Adapter where other small payloads can be carried, the launch vehicle stage adapter and the interim cryogenic propulsion stage.

The Launch Team — Exploration Ground Systems

At Kennedy, the Exploration Ground Systems team also has a busy year ahead in 2019. The crawler team will finish engine maintenance and crawlerway conditioning, and engineers will complete testing of the mobile launcher in the Vehicle Assembly Building. In the spring, the mobile launcher will roll back out to Pad 39B for its final testing at the pad. NASA plans to award a contract for a second mobile launcher this year, allowing more flexibility for upcoming exploration missions.

At the pad, engineers will start to install a new liquid hydrogen tank that will be used for EM-2. In firing rooms 1 and 2, final upgrades will be made while the launch team finalizes the new countdown procedures for SLS. Teams across the agency will participate in flight simulations with the launch control center at Kennedy, mission control center at Johnson and the SLS Engineering Support Center at Marshall. By the end of 2019, EGS will begin processing the Orion crew capsule and SLS hardware for launch of EM-1.