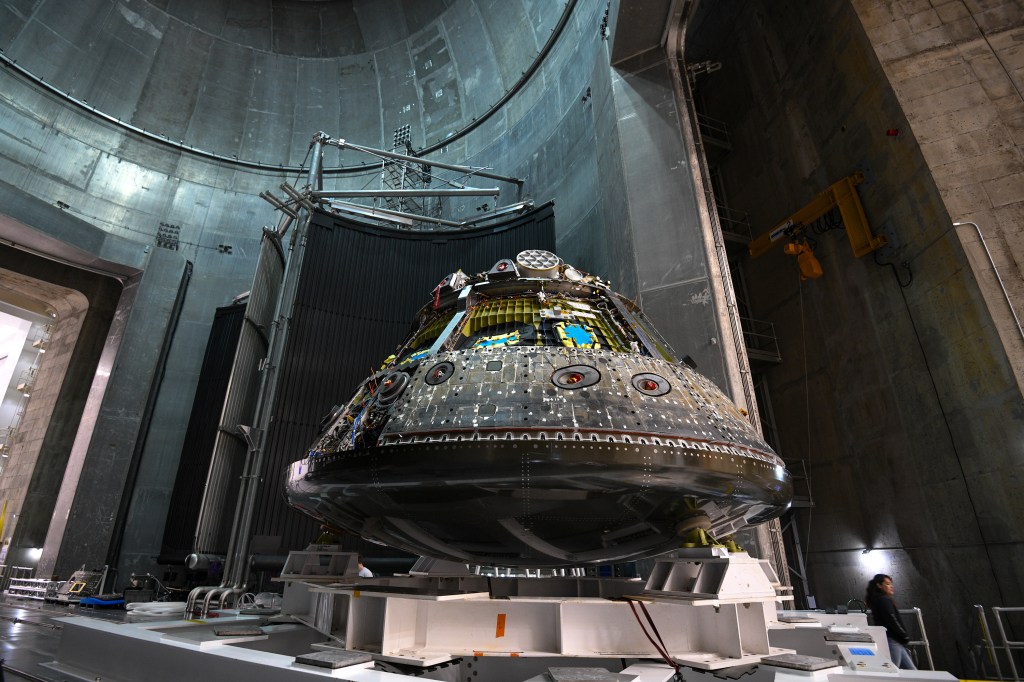

Extreme temperatures — ranging from minus 423 degrees Fahrenheit to more than 200 degrees Fahrenheit — call for novel thermal protection systems on NASA’s new heavy-lift rocket, the Space Launch System (SLS). NASA is advancing state-of-the-art technology for thermal protection with more environmentally friendly materials and 3D printed molds for smaller parts. With the power and precision needed for sending humans to deep space, SLS will launch astronauts in NASA’s Orion spacecraft to distant destinations such as the Moon and Mars.

Spray-on foam insulation, along with other traditional insulation materials such as cork, will provide thermal protection for every rocket part, large and small. The insulation is flexible enough to move with the rocket but rigid enough to take the aerodynamic pressures as SLS accelerates from 0 to 17,400 miles per hour and soars to more than 100 miles above Earth in just 8 minutes. The cryogenic fuel, made up of liquid hydrogen and liquid oxygen, that powers the rocket has to stay extremely cold to remain liquid. Hydrogen has to remain at minus 423 degrees Fahrenheit and oxygen at minus 298 degrees Fahrenheit. If temperatures rise too high, the fuel would become a gas.

“As the Space Launch System flies, it builds up tremendous heat. Without insulation, heat from launch would affect the stability of the cryogenic propellants and the rocket’s structural integrity would be compromised,” said Michael Alldredge, who leads the thermal protection system team for the SLS core stage at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “NASA is asking this unique foam material to do the incredible job of protecting critical rocket systems, which vary from large structures to electronics and fuel lines, in an unforgiving launch environment with extreme temperatures and pressures.”

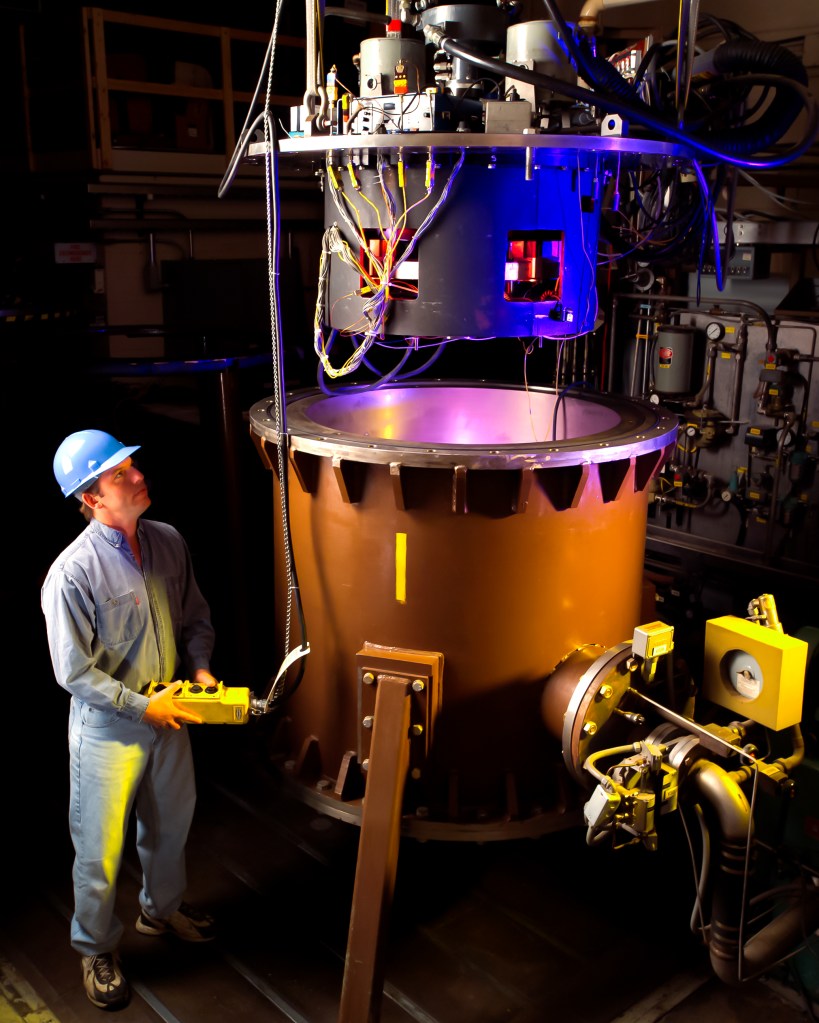

Materials engineers qualified the third-generation, orange-colored spray-on foam insulation to meet the harsh environments that the SLS will experience. At the same time, they made the foam more environmentally friendly. The foam insulation is composed of two liquids — isocyanate and a special polyol blend — that stay separate in the pumping system and mix in the spray gun before releasing and rising into foam — similar to hair mousse. When the foam is applied, it gives the rocket a light-yellow color that the Sun’s ultraviolet rays eventually “tan,” giving the SLS core stage its signature orange color.

Spray the Big Stuff

Foam will protect the larger of the hardware, including the entire SLS core stage that is the 212-foot-tall backbone of the rocket. The foam is applied with robotic or hand-held spray guns, and, much like painting walls in a home, hardware has to be primed and taped off before spraying begins. Primer serves as corrosion protection from the environment and enhances the bond between the insulation and the rocket.

Engineers will use a robotic system to apply both primer and foam to the cryotanks at NASA’s Michoud Assembly Facility in New Orleans where the core stage is being built. Manually-sprayed foam will cover the domes, or bottoms, of both cryotanks. The largest piece of SLS hardware built at Marshall, the launch vehicle stage adapter, which serves as a connector between the core stage and the interim cryogenic propulsion stage will have manually-sprayed foam.

The original plan was to use cork for the SLS launch vehicle stage adapter, according to Amy Buck, Marshall’s launch vehicle stage adapter thermal protection systems lead, but the team determined that foam would be more efficient. “The foam is lighter,” she said. “And since we have the resources to spray it by hand at Marshall, we are saving time and money because we don’t have to ship it to Michoud. We spray on the foam at Marshall at the same time the core stage pieces for the first SLS mission get their foam applied at Michoud.”

“It takes about three months for the entire foam application process,” Buck explained. “The prep work takes longer than the actual spraying. The hand-spraying only takes about 30 minutes for each 4-foot-wide section.”

3-D Printed Molds Help Protect Smaller Stuff

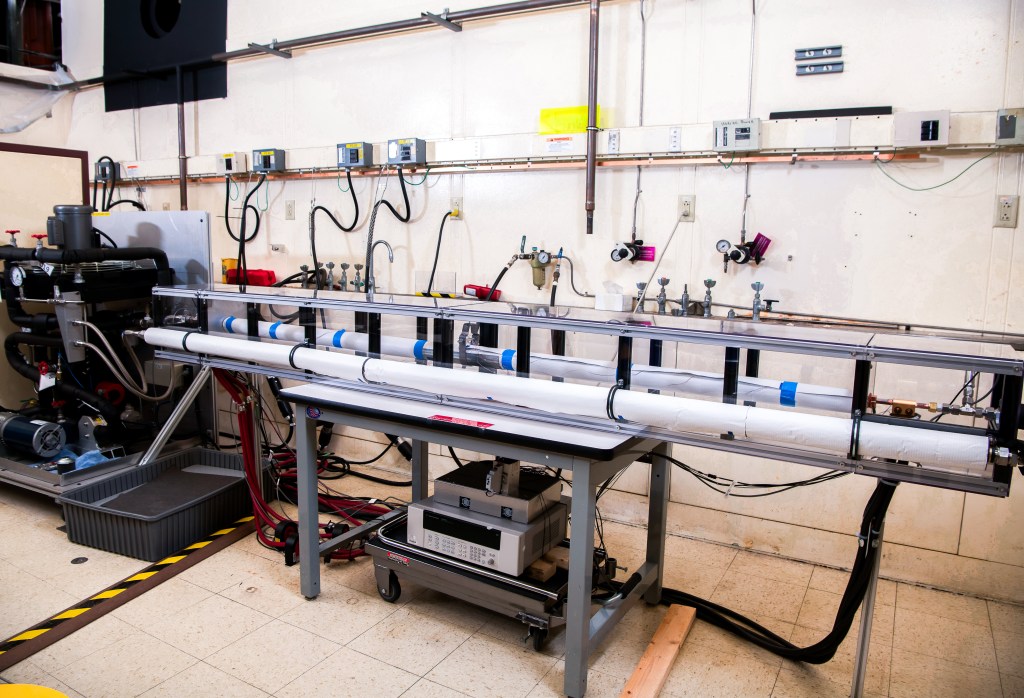

Insulation protects many small parts of the rocket that play big roles. The avionics, the “brains” of the rocket, are located throughout the vehicle. Other small parts like the intertank’s exterior pockets, the engine section’s internal ducts and close-out areas of hardware — where two major pieces connect — require manually-sprayed foam or foam cast with 3-D printed molds.

“NASA is using a novel 3-D printing process to make customized molds for certain parts,” said Alldredge. “Some parts have unique geometries or are in locations in the rocket where it is difficult to cover them with spray foam. The 3-D printed molds allow us to shape insulation to protect specific parts.”

Small hardware like internal fuel systems and brackets on the feedline that run along the outside of the core stage and connect it to the engine section need pour foam. The foam is mixed and poured into a mold before it expands to fill the shape it enters.

Put Some Cork on It

Cork is heavier than foam but provides even stronger protection for certain applications. Cork comes in sheets and is applied to areas that have high predicted heat loads, like the core stage engine section, which houses four RS-25 engines that produce 2 million pounds of thrust. Cork is applied under the solid rocket boosters that provide 75 percent of thrust at liftoff and on the fairings, the areas where feedlines come out of the intertank and run down the rocket to connect the intertank to the other hardware.

After thermal protection material density and adhesion are verified for both foam and cork, engineers take thickness measurements to ensure the required amount of thermal protection has been applied. Overall thermal protection systems thickness for SLS ranges from about a half-inch to 2 inches. The launch vehicle stage adapter requires 0.7 inches of foam while the hydrogen tank requires around 1.2 inches because of its extremely cold temperature. The final system level test of the insulation, prior to flight, will be when the entire core stage will be tested with all four RS-25 engines firing, and the foam and cork guarding the hardware as hot and cold collide.