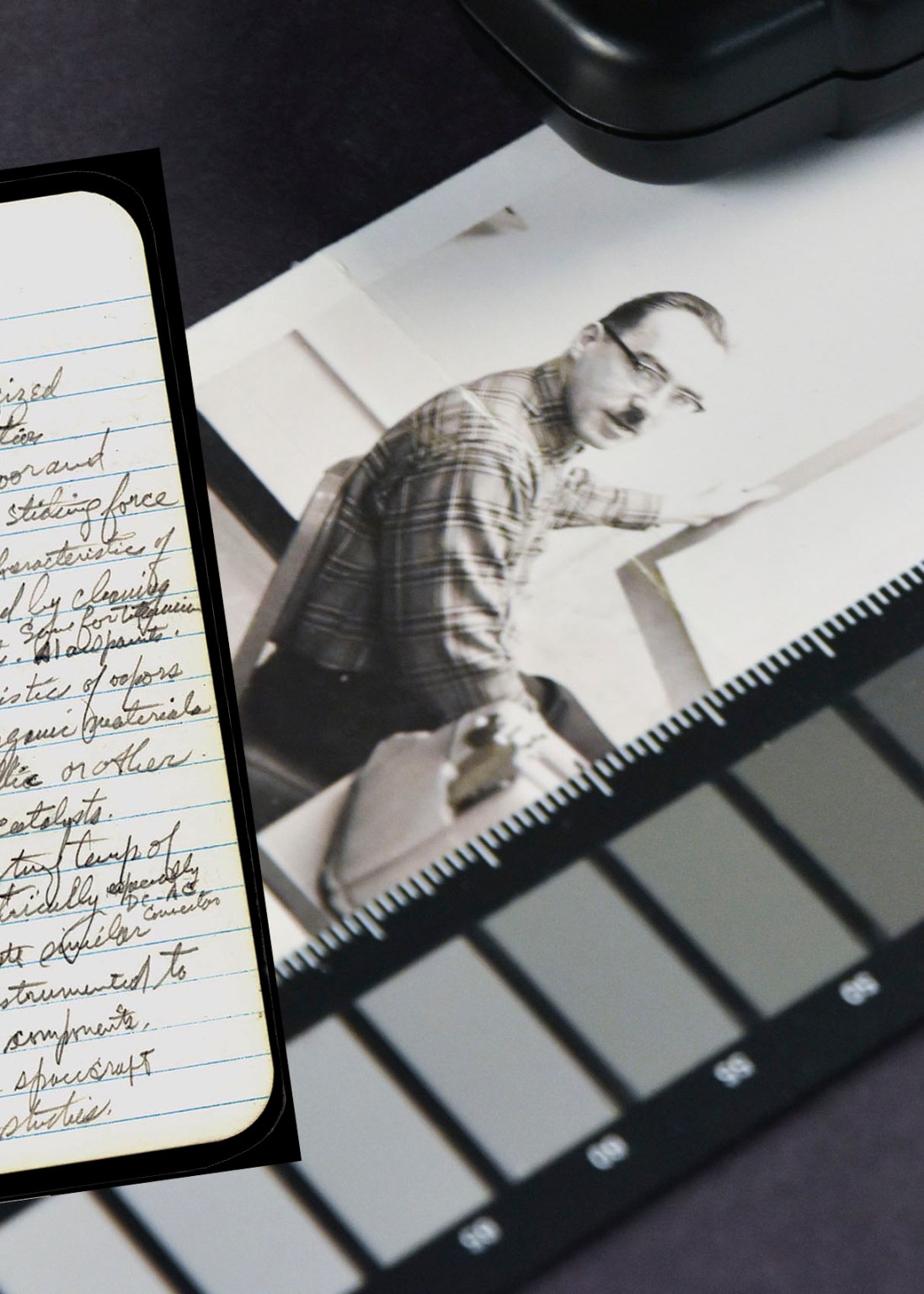

In late 1965, at the request of NASA Associate Administrator for Manned Space Flight George E. Mueller, Major General Samuel C. Phillips, Apollo Program Director at NASA Headquarters, initiated a review of NASA’s contract with North American Aviation, Inc., to determine why work on both the Apollo spacecraft and Saturn V second stage was behind schedule and over budget. This highly critical study, known as the Phillips Report, took on added significance when in the aftermath of the fire, it was discovered that NASA Administrator James E. Webb was apparently unaware of the existence of the report. General Phillips provided a set of the notes which comprised the study to J. Leland Atwood, North American President, and George Mueller added his views in a separate letter.

Source: NASA Historical Reference Collection, NASA History Office, NASA Headquarters, Washington, DC. Page numbers are indicated in square brackets.

Letter Dated December 19, 1965

IN REPLY REFER TO: MA

December 19, 1965

Mr. J. L. Atwood

President

North American Aviation, Inc.

1700 E. Imperial Highway

El Segundo, California

Dear Lee:

I believe that I and the team that worked with me were able to examine the Apollo Spacecraft and S-II stage programs at your Space and Information Systems Division in sufficient detail during our recent visits to formulate a reasonably accurate assessment of the current situation concerning these two programs.

I am definitely not satisfied with the progress and outlook of either program and am convinced that the right actions now can result in substantial improvement of position in both programs in the relatively near future.

Enclosed are ten copies of the notes which was compiled on the basis of our visits. They include details not discussed in our briefing and are provided for you consideration and use.

The conclusion expressed in our briefing and notes are critical. Even with due consideration of hopeful signs, I could not find a substantive basis for confidence in future performance. I believe that a task group drawn from NAA at large could rather quickly verify the substance of our conclusions, and might be useful to you in setting the course for improvements.

The gravity of the situation compels me to ask that you let me know, by the end of January if possible, the actions you propose to take. If I can assist in any way, please let me know.

Sincerely,

/signed/

SAMUEL C. PHILLIPS

Major General, USAF

Apollo Program Director

The Phillips Report (1965–1966)

I. Introduction

This is the report of the NASA’s Management Review of North American Aviation Corporation management of Saturn II Stage (S-II) and Command and Service Module (CSM) programs. The Review was conducted as a result of the continual failure of NAA to achieve the progress required to support the objective of the Apollo Program.

The scope of the review included an examination of the Corporate organization and its relationship to and influence on the activities of S&ID, the operating Division charged with the execution of the S-II and CSM programs. The review also included examination of NAA off-site program activities at KSC and MTF.

The members of the review team were specifically chosen for their experience with S&ID and their intimate knowledge of the S-II and CSM programs. The Review findings, therefore, are a culmination of the judgements of responsible government personnel directly involved with these programs. The team report represents an assessment of the contractor’s performance and existing conditions affecting current and future progress, and recommends actions believed necessary to achieve an early return to the position supporting Apollo program objectives.

The Review was conducted from November 22 through December 6 and was organized into a Basic Team, responsible for over-all [2] assessment of the contractor’s activities and the relationships among his organizational elements and functions; and sub-teams who assessed the contractor’s activities in the following areas:

- Program Planning and Control (including Logistics)

- Contracting, Pricing, Subcontracting, Purchasing

- Engineering

- Manufacturing

- Reliability and Quality Assurance.

Review Team membership is shown in Appendix 7.

Team findings and recommendations were presented to NAA Corporate and S&ID management on December 19.

II. NAA’s Performance to Date – Ability to Meet Commitments.

At the start of the CSM and S-II Programs, key milestones were agreed upon, performance requirements established and cost plans developed. These were essentially commitments made by NAA to NASA. As the program progressed NASA has been forced to accept slippages in key milestone accomplishments, degradation in hardware performance, and increasing costs.

I. S-II–1.Schedules

As reflected in Appendix VI key performance milestones in testing, as well as end item hardware deliveries, have slipped continuously in spite of deletions of both hardware and test content. The fact that the delivery [3] of the common bulkhead test article was rescheduled 5 times, for a total slippage of more than a year, the All System firing rescheduled 5 times for a total slippage of more than a year, and S-II-1 and S-II-2 flight stage deliveries rescheduled several times for a total slippage of more than a year, are indicative of NAA’s inability to stay within planned schedules. Although the total Apollo program was reoriented during this time, the S-II flight stages have remained behind schedules even after this reorientation.

- Costs

The S-II cost picture, as indicated in Appendix VI has been essentially a series of costs escalations with a bow wave of peak costs advancing steadily throughout the program life. Each annual projection has shown either the current or succeeding year to be the peak. NAA’s estimate of the total 10 stage program has more than tripled. These increases have occurred despite the fact that there have been reductions in hardware. - Technical Performance

The S-II stage is still plagued with technical difficulties as illustrated in Appendix VI. Welding difficulties, insulation bonding, continued redesign as a result of component failures during qualification are indicative of insufficiently aggressive pursuit of technical resolutions during the earlier phases of the program.

II. Schedules

A history of slippages in meeting key CSM milestones is contained in Appendix VI. The propulsion spacecraft, the systems integration spacecraft, and the spacecraft for the first development flight have each slipped more than six months. In addition, the first manned and the key environmental ground spacecraft have each slipped more than a year. These slippages have occurred in spite of the fact that schedule requirements have been revised a number of times, and seven articles, originally required for delivery by the end of 1965, have been eliminated. Activation of two major checkout stations was completed more than a year late in one case and more than six months late in the other. The start of major testing in the ground test program has slipped from three to nine months in less than two years.

- Costs

Analysis of spacecraft forecasted costs as reflected in Appendix VI reveals NAA has not been able to forecast costs with any reasonable degree of accuracy. The peak of the program cost has slipped 18 months in two years. In addition, NAA is forecasting that the total cost of the reduced spacecraft program will be greater than the cost of the previous planned program. - Technical Performance

Inadequate procedures and controls in bonding and welding, as well as inadequate master tooling, have delayed fabrication of airframes. In addition, there are still major development problems to be resolved. SPS engine life, RCS performance, stress corrosion, and failure of oxidizer tanks has resulted in degradation of the Block I spacecraft as well as forced postponement of the resolution of the Block II spacecraft configuration.

III. NASA Assessment – Probability of NAA Meeting Future Commitments

A. CSM

Today, after 4 1/2 years and a little more than a year before first flight, there are still significant technical problems and unknowns affecting the stage. Manufacture is at least 5 months behind schedule. NAA’s continued inability to meet internal objectives, as evidenced by 5 changes in the manufacturing plan in the last 3 months, clearly indicates that extraordinary effort will be required if the contractor is to hold the current position, let alone better it. The MTF activation program is being seriously affected by the insulation repairs and other work required on All Systems stage. The contractor’s most recent schedule reveals further slippage in completion of insulation repair. Further, integration of manual GSE has recently slipped 3 weeks as a result of configuration discrepancies discovered during engineering checkout of the system. Failures in timely [6] and complete engineering support, poor workmanship, and other conditions have also contributed to the current S-II situation. Factors which have caused these problems still exist. The two recent funding requirements exercises, with their widely different results, coupled with NAA’s demonstrated history of unreliable forecasting, as shown in Appendix VI, leave little basis for confidence in the contractor’s ability to accomplish the required work within the funds estimated. The team did not find significant indications of actions underway to build confidence that future progress will be better than past performance.

B. CSM

With the first unmanned flight spacecraft finally delivered to KSC, there are still significant problems remaining for Block I and Block II CSM’s. Technical problems with electrical power capacity, service propulsion, structural integrity, weight growth, etc. have yet to be resolved. Test stand activation and undersupport of GSE still retard schedule progress. Delayed and compromised ground and qualification test programs give us serious concern that fully qualified flight vehicles will not be available to support the lunar landing program. NAA’s inability to meet spacecraft contract use deliveries has caused rescheduling of the total Apollo program. Appendix VI indicates the contractor’s schedule trends which cause NASA to have little confidence that the S&ID will meet its future spacecraft commitments. While our management review indicated that some progress is [7] being made to improve the CSM outlook, there is little confidence that NAA will meet its schedule and performance commitments within the funds available for this portion of the Apollo program.

IV. Summary Findings

Presented below is a summary of the team’s views on those program conditions and fundamental management deficiencies that are impeding program progress and that require resolution by NAA to ensure that the CSM and S-II Programs regain the required program position. The detail findings and recommendations of the individual sub-team reviews are Appendix to this report.

A. NAA performance on both programs is characterized by continued failure to meet committed schedule dates with required technical performance and within costs. There is no evidence of current improvement in NAA’s management of these programs of the magnitude required to give confidence that NAA performance will improve at the rate required to meet established Apollo program objectives.

B. Corporate interest in, and attention to, S&ID performance against the customer’s stated requirements on these programs is considers passive. With the exception of the recent General Office survey of selected functional areas of S&ID, the main area of Corporate level interest appears to be in S&ID’s financial outlook and in their cost estimating and proposal efforts. While we consider it appropriate that the responsibility and authority for execution of NASA programs be vested in the operating Division, this does not relieve the Corporation of its responsibility, and accountability to NASA for results. [9] We do not suggest that another level of program management be established in the Corporate staff, but we do recommend that the Corporate Office sincerely concern itself with how well S&ID is performing to customer requirements and ensure that responsible and effective actions are taken to meet commitments.

C. Organization and Manning

We consider the program organization structure and assignment of competent people within the organization a prerogative of the manager and his team that have been given the program job to do. However, in view of what we consider to be an extremely critical situation at S&ID, one expected result of the NASA review might be the direction of certain reorganizations and reassignments considered appropriate, by NASA, to improve the situation. While we do have some suggestions for NAA consideration on this subject, they are to be accepted as such and not considered directive in nature. We emphasize that we clearly expect NAA/S&ID to take responsible and thoroughly considered actions on the organization and assignment of people required to accomplish the S-II and CSM Programs. We expect full consideration, in this judgement by NAA, of both near and long term benefits of changes that are made.

Frankly stated—we firmly believe that S&ID is overmaned and that the S-II and CSM Programs can be done, and done better, with fewer people. This is not to suggest that an arbitrary [10] percentage reduction should be applied to each element of S&ID, but we do suggest the need for adjustments, based on a reassessment and clear definition of organizational responsibilities and task assignments.

It is our view that the total Engineering, Manufacturing, Quality, and Program Control functions are too diversely spread and in too many layers throughout the S&ID organization to contribute, in an integrated and effective manner, to the hard core requirements of the programs. The present proliferation of the functions invites non-contributing, “make-work” use of manpower and dollars as well as impediments to program progress.

We question the true strength and authority of each Program Manager and his real ability to be fully accountable for results when he directly controls less that 50% of the manpower effort that goes into his program. This suggests the need for an objective reappraisal of the people and functions assigned to Central versus Program organizations. This should be done with full recognition that the Central organization’s primary reason for existence is to support the requirements of the Program Managers. Concurrently, the Program Manager should undertake a thorough and objective “audit” of all current and planned tasks, as well as evaluate the people assigned to these tasks, in order to bring the total effort down to that effort down to that which truly contributes to the program.

It is our opinion that the assignment of the Florida Facility to the Test and Quality Assurance organization creates an anomaly since the Florida activities clearly relate to direct program responsibilities. We recognize that the existence of both CSM and S-II activities at KSC may require the establishment of a single unit for administrative purposes. However, it is our view that the management of this unit is an executive function, rather than one connected with a functional responsibility. We suggest NAA consider a “mirror image” organizational relationship between S&ID and the Florida operation, with the top man at Florida reporting to the S&ID President and the two program organizations reporting to the S&ID Program Managers.

D. Program Planning and Control

Effective planning and control from a program standpoint does not exist. Each organization defines its own job, its own schedules, and its own budget, all of which may not be compatible or developed in a manner required to achieve program objectives. The Program Managers do not define, monitor, or control the interfaces between the various organizations supporting their program.

Organization—S&ID’s planning and control functions are fragmented; responsibility and authority are not clearly defined.

- Work Task Management—General Orders, task authorizations, product plans, etc., are broad and almost meaningless from a standpoint of defining end products. Detailed definitions of work tasks are available at the “doing level”; however, these “work plans” are not reviewed, approved, or controlled by the Program Managers.

- Schedules—Each organization supporting the programs develops its own detailed schedules; they are not effectively integrated within an organization, nor are they necessarily compatible with program master schedule requirements.

- Budgeting System—Without control over work scope and schedules, the budget control system cannot be effective. In general, it is an allocation system assigning program resources by organizations.

- Management Reports—There is no effective reporting system to management that evaluates performance against plans. Plans are changed to reflect performance. Trends and performance indices reporting is almost nonexistent.

E. Logistics

The CSM and S-II Site Activations and Logistic organizations are adequately staffed to carry out the Logistics support. The problems in the Logistics area are in arriving at a mutual agreement, between NAA and NASA, clearly defining the tasks required to support the programs. The areas requiring actions are as follows:

- Logistics Plan

- Maintenance Manuals

- Maintenance Analysis

- NAA/KSC Relationship

- Common and Bulk Item Requisitioning at KSC

- Review of Spare Parts, Tooling, and Test Equipment Status

F. Engineering

The most pronounced deficiencies observed in S&ID Engineering are:

- Fragmentation of the Engineering function throughout the S&ID organization, with the result that it is difficult to identify and place accountability for program-required Engineering outputs.

- Inadequate systems engineering job is being done from interpretation of NASA stated technical requirements through design release.

- Adequate visibility on intermediate progress on planned engineering releases is lacking. Late, incomplete, and incorrect engineering releases have caused significant hardware delivery schedule slippages as well as unnecessary program costs.

- The principles and procedures for configuration management, as agreed to between NAA and NASA, are not being adhered to by the engineering organizations.

G. Cost Estimating

The “grass roots” estimating technique used at S&ID is a logical step in the process of arriving at program cost estimates and developing operating budgets. However, there are several aspects of the total process that are of concern to NASA:

- The first relates to the inadequate directing, planning, scheduling, and controlling of program work tasks throughout S&ID. While the grass roots estimates may, in fact, represent valid estimates (subject to scrubbing of “cushion”) of individual tasks by working level people, we believe that the present deficiencies in Planning and Control permit, and may encourage, the inclusion in these estimates of work tasks and level of efforts that are truly not required for the program.

- The second concern is that the final consolidation of grass roots estimates, developed up through the S&ID organization in parallel through both Central functional and Program organizations, does not receive the required [15] management judgements, at successive levels for (a) the real program need for the tasks included in the estimate, or (b) adequate scrubbing and validation of the man-hours and dollars estimates.

- The third concern, which results from 1 and 2 above, is that the final estimate does not represent, either in tasks to be done or in resources required, the legitimate program requirements as judged by the Program Manager, but represents total work and dollars required to support a level of effort within S&ID.

Several recommendations are made in the appended reports for correcting deficiencies in the estimating process. The basic issue, however, is that an S&ID Management position must be clearly stated and disciplines established to ensure that the end product of the estimating process be only those resources required to do necessary program tasks. In addition, the Program Management must be in an authoritative position that allows him to accept, reject, and negotiate these resource requirements.

H. Manufacturing Work Force Efficiency

There are several indications of less that effective utilization of the manufacturing labor force. Poor workmanship is evidenced by the continual high rates of rejection and MRB actions which result in rework that would not be necessary if the workmanship [16] had been good. This raises a question as to the effectiveness of the PRIDE program which was designed to motivate personnel toward excellence of performance as a result of personal responsibility for the end product. As brought out elsewhere in this report, the ability of Manufacturing to plan and execute its tasks has been severely limited due to continual changing engineering information and lack of visibility as to the expected availability of the engineering information. Recognizing that overtime shifts are necessary at this time, it is our view that strong and knowledgeable supervision of these overtime shifts is necessary, and the a practical system of measuring work accomplished versus work planned must be implemented and used to gauge and to improve the effectiveness of the labor force. The condition of hardware shipped from the factory, with thousands of hours of work to complete, is unsatisfactory to NASA. S&ID must complete all hardware at the factory and further implement, without delay, an accurate system to certify configuration of delivered hardware, properly related to the DD 250.

I. Quality

NAA quality is not up to NASA required standards. This is evidence by the large number of “correction” E.O.’s and manufacturing discrepancies. This deficiency is further compounded [17] by the large number of discrepancies that escape NAA inspectors but are detected by NASA inspectors. NAA must take immediate and effective action to improve the quality of workmanship and to tighten their own inspection. Performance goals for demonstrating high quality must be established, and trend data must be maintained and given serious attention by Management to correct this unsatisfactory condition. J. Following are additional observations and findings that have resulted from discussions during the Review. Most of them are covered in most detail in the appended sub-team reports. They are considered significant to the objective of improving NAA management of our programs and are therefore highlighted in this section of the report:

- S&ID must assume more responsibility and initiative for carrying out these programs, and not expect step-by-step direction from NASA.

- S&ID must establish work package management techniques that effectively define, integrate, and control program tasks, schedules, and resource requirements.

- S&ID must give concurrent attention to both present and downstream tasks to halt the alarming trend of crisis operation and neglect of future tasks because of concentration on today’s problems.

- A quick response capability must be developed to work critical “program pacing” problems by a short-cut route, with follow-up to ensure meeting normal system requirements.

- S&ID must maintain a current list of open issues and unresolved problems, with clear responsibility assigned for resolving these and insuring proper attention by Program and Division Management.

- Effort needs to be applied to simplify management systems and end products. There must be greater emphasis on making today’s procedures work to solve today’s problems, and less on future, more sophisticated systems. The implementation and adherence to prescribed systems should be audited.

- NAA must define standards of performance for maintaining contracts current then establish internal disciplines to meet these standards. Present undefinitized subcontracts and outstanding change orders on the S-II prime contract must be definitized without delay.

CONCLUSIONS AND RECOMMENDATIONS

The NASA Team views on existing deficiencies in the contractor’s management of the S-II and CSM Programs are highlighted in this section of the report and are treated in more detail in the appended sub-team reports. The findings are expressed frankly and result from the team’s work in attempting to relate the end results we see in program conditions to fundamental causes for these conditions.

In most instances, recommendations for improvement accompany the findings. In some cases, problems are expressed for which the team has no specific recommendations, other than the need for attention and resolution by NAA.

It is not NASA’s intent to dictate solutions to the deficiencies noted in this report. The solution to NAA’s internal problems is both a prerogative and a responsibility of NAA Management, within the parameters of NASA’s requirements as stated in the contracts. NASA does, however, fully expect objective, responsible, and timely action by NAA to correct the conditions described in this report.

It is recommended that the CSM incentive contract conversion proceed as now planned.

Incentivization of the S-II Program should be delayed until NASA is assured that the S-II Program is under control and a responsible proposal is received from the contractor.

Decision on a follow-on incentive contract for the CSM, beyond the present contract period, will be based on contractor performance.

It is recommended that NAA respond to NASA, by the end of January 1966, on the actions taken and planned to be taken to correct the conditions described in this report. At that time, NAA is also to certify the tasks, schedules, and resource requirements for the S-II and CSM Programs.

It is further recommended that the same NASA Review Team re-visit NAA during March 1966 to review NAA performance in the critical areas described in this report.

December 19, 1965 Letter from George E. Mueller to Mr. J.L. Atwood

Document III-18

December 19, 1965

Mr. J. L. Atwood, President

North American Aviation, Inc.

1700 E. Imperial Highway

El Segundo, California

Dear Lee:

In my letter of October 27, 1965, I conveyed to you the seriousness with which I viewed the state of affairs in both the Apollo and S-II Programs at your Space and Information Systems Division. Phillips’ report has not only corroborated my concern, but has convinced me beyond doubt that the situation at S&ID requires positive and substantive actions immediately in order to meet the national objectives of the Apollo Program.

Since I am not sure that you see the performance of S&ID in the same light that I do, let me give you a perspective from my point of view.

When I joined NASA in the Fall of 1963, I restructured the Apollo Program to bring its several elements into balance and to establish a schedule that could be achieved based on the state of development at that time. Since that time, in the spacecraft project, we have found it necessary to:

- Omit several sub-systems from 009.

- Delay flight of 201 from November 65 until probably February or March 66 due to late delivery of 009 and its GSE together with the many difficulties of getting things [2] to work together at the Cape.

- Reschedule the first manned flight from 203 to 204 to relieve the spacecraft schedule. NAA ability to support the 204 flight scheduled in October 66 now looks doubtful.

- Reschedule 202 from April to June 1966 because 011 is several months behind schedule. NAA ability to support the June schedule now looks doubtful.

- Reschedule the first Block II spacecraft flight from 206 in April 67 to 207 in July 67. Late last year, when the Block II Program was defined, your people agreed that they could and would do a better job on Block II engineering and that they would meet their design review and drawing release schedules. I’m very disturbed to learn now that Block II engineering has been neglected and that it is some months behind schedule. To me, considering performance to date, it looks like the danger flags protend delay of the critical 207 flight.

- Delay the delivery of 008 by several months. This is a critical vehicle to perform thermal vacuum tests in the Houston Chamber as a prerequisite to manned flight. People will argue that the Chamber isn’t ready, but we urgently need that spacecraft to get it working as a system vehicle and with its ground equipment and crews.

- Delete seven boilerplate and flight spacecraft from the Block I Program to reduce cost growth and relieve the schedule to minimize slippage.

I could go on; there are other things that we’ve had to accommodate such as cost growth, but I believe this list gives you some insight into my evaluation of performance in the spacecraft project. Now, regarding the S-II Project:

- I am facing the probability that the flight of 501 will be delayed between three and nine months. I [3] assure you that this is due entirely to the status of the S-II stage. It is clear to me that it didn’t have to come out this way, and I regret now that I wasn’t more insistent a year and a quarter ago when you and I discussed the danger flags then flying, and the possibility of such far reaching actions as transferring the project to your Los Angeles Division.

- The cost proposal which S&ID presented to MSFC in October of this year was shocking in light of cost projections reported only one month earlier. Perhaps I should even go so far as to suggest that it was irresponsible; in any case, it surely was a gross demonstration of management shortcomings.

- The Battleship Program is another significant case. You got behind it personally and an ignition test in November 64 resulted; but that achievement was one year behind the original schedule and the test fixture was so devoid of systems as to be little more than a facade. Further, the firing record indicates that only about one-third of the firings really achieved their objectives. The firing program was stopped last April to incorporate flight systems; it has not yet resumed firing.

- S-II-T is a reel problem. It was delivered late with what was stated to be approximately 21,000 manhours of work to incorporate EO’s and perform work that was not completed in the factory due to parts shortages. Today, the work stands at over 50,000 manhours and the firing scheduled for January 66 will most likely occur in March or April. Based on what I have seen so far, I am very concerned that the engineering on which S-II-I is based will require many changes when S-II-T is fired, and further delays of 501 will result.

It is hard for me to understand how a company with the background and demonstrated competence of NAA could have spent 4 1/2 years and more than half a billion dollars on the S-II Project and not yet have fired a stage with flight systems in operation.

Again, I could go on and enumerate additional problems, but the points I have discussed should show you how I see the performance of NAA on these two programs.

I have been in this business long enough to understand quite well the difficulties and setbacks that occur and manifest themselves in many forms in government – industry programs which have as their objective the development, building, and operation of sophisticated systems involving advanced technology and real forward projection of thought. My experience indicates that results are a function of management and technical competence. I submit that the record of these two programs makes it clear that a good job has not been done. Based on what I see going on currently, I have absolutely no confidence that future commitments will be met.

I can see no way of improving future performance, and meeting commitments which NAA must meet if we are to achieve the national objectives of Apollo, except to improve the management and technical competence of your Space and Information systems Division.

Sam Phillips is convinced that S&ID can do a better job with less people. He and his team discussed the reasons why they believe this in their briefing.

I suggest that you can go even further to concentrate management and technical talent on the two programs that constitute 98 percent of the business of S&ID. For example:

- Eliminate or transfer to another Division those activities at S&ID that are not contributing directly to the progress of the Spacecraft and S-II projects. Examples are the Federal programs Group, parts of the Information Systems Division, and parts of the Advanced Systems Division. This should make possible a substantial consolidation of central engineering and insure that [5] available talent concentrates on the two important programs.

- Take a hard look at the competence and effectiveness of individuals, especially in the upper echelons of the organization; and move out those who are not really contributing, due either to the organization or to their own competence.

I urge you to consider the potential payoff of extending the project management principle beyond the “designated subsystems project manager” as now practiced in Dale Meyers’ organization. I am convinced that there is no substitute for clear assignment of responsibility and accountability to individuals for delivering results. Work packages can be defined quite clearly in both projects and I am sure it is possible to assign responsibility to individuals who are given control of the applicable budget and who are held accountable for delivering on schedule and within budget.

I had hoped that a letter such as this would not be necessary. However, I consider the present situation to be intolerable and can only conclude that drastic action is in the best national interest. I assure you that I have only one purpose, and that is to carry out the Apollo Program on schedule and within planned costs.

I have instructed Sam Phillips to keep his team together so that they can visit S&ID again in March to see if progress is consistent with that required to achieve program objectives.

Sincerely,

/signed/

George E. Mueller

Associate Administrator

For Manned Space Flight