The primary goal of NASA’s ISRU Pilot Excavator (IPEx) project is to dig up lunar soil, known as regolith, and transport it across the Moon’s surface. This process is designed to enable the extraction of vital resources, such as hydrogen, oxygen, and water, which are essential for life support systems.

LEAD CENTER

Kennedy Space Center

INTRODUCED

October 2020

PROJECT MANAGER

Jason Schuler

PRINCIPAL TECHNOLOGIST

Mark Hilburger

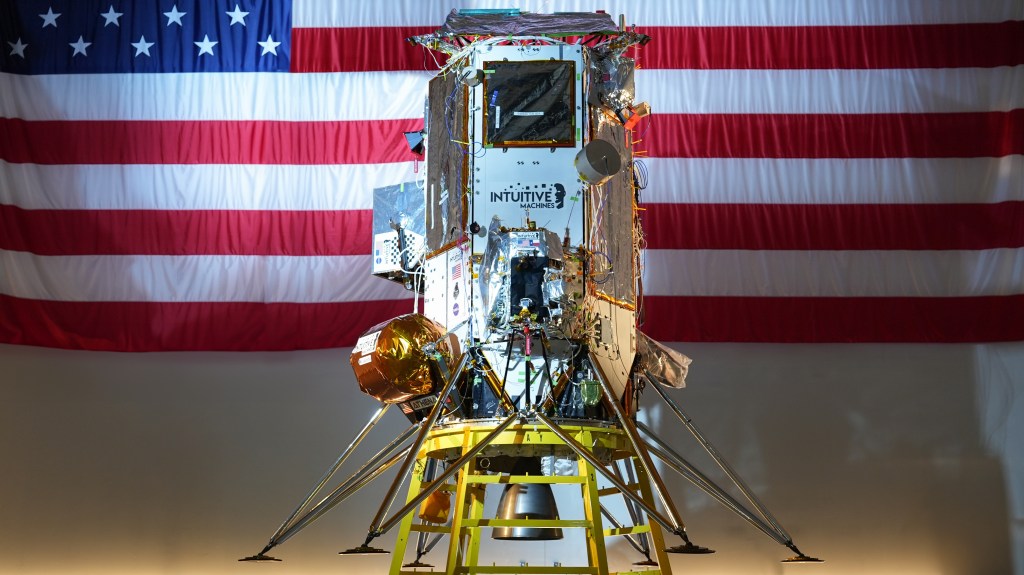

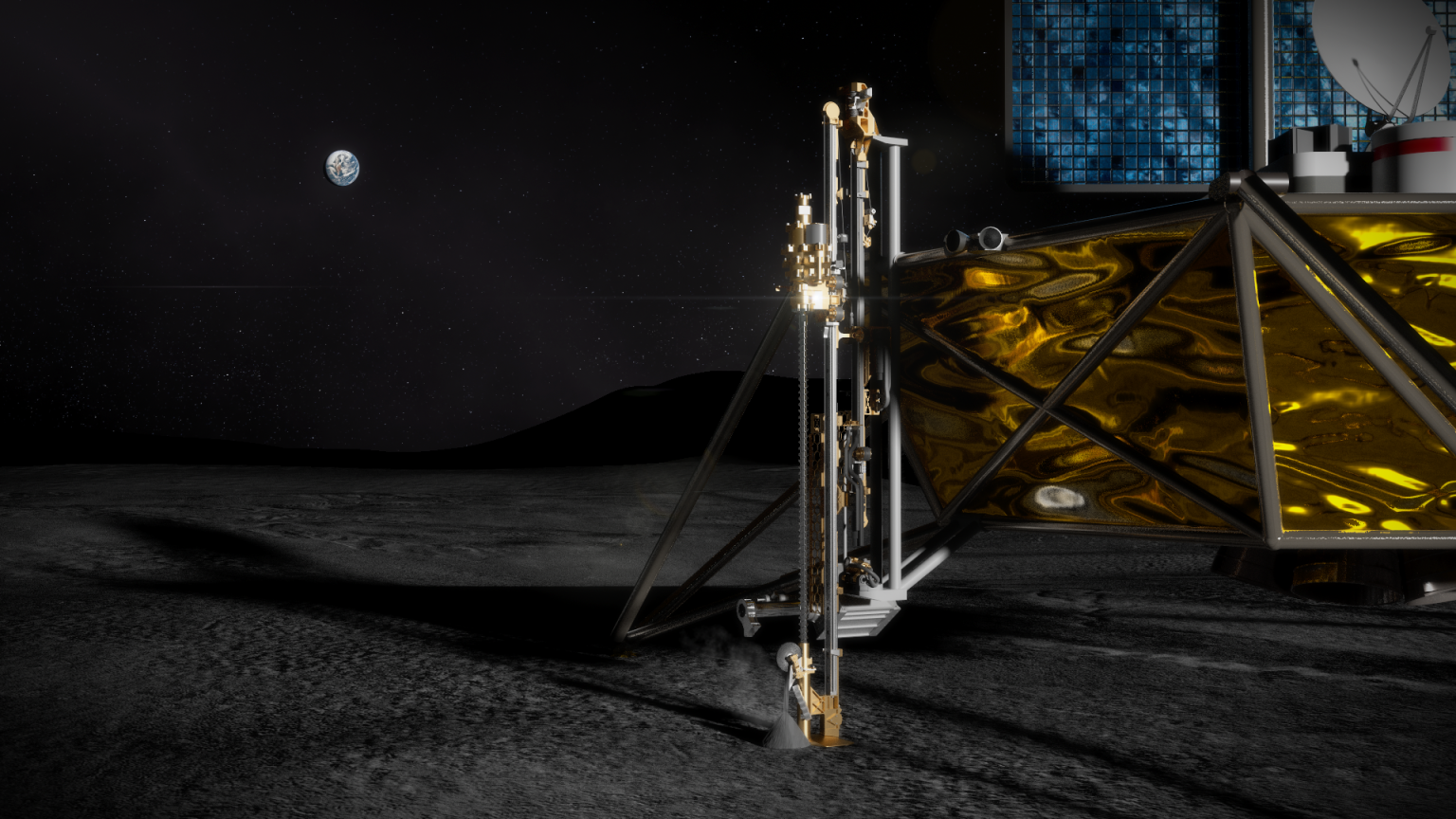

The ISRU Pilot Excavator (IPEx) is a groundbreaking robotic system designed by NASA to revolutionize lunar excavation. Functioning as both a bulldozer and a dump truck, IPEx is engineered to efficiently mine and transport lunar regolith, the loose rocky material on the Moon’s surface, which is crucial for future lunar missions and In-Situ Resource Utilization (ISRU) processes. This dual capability makes IPEx an indispensable tool for sustainable lunar exploration.

IPEx Testbed

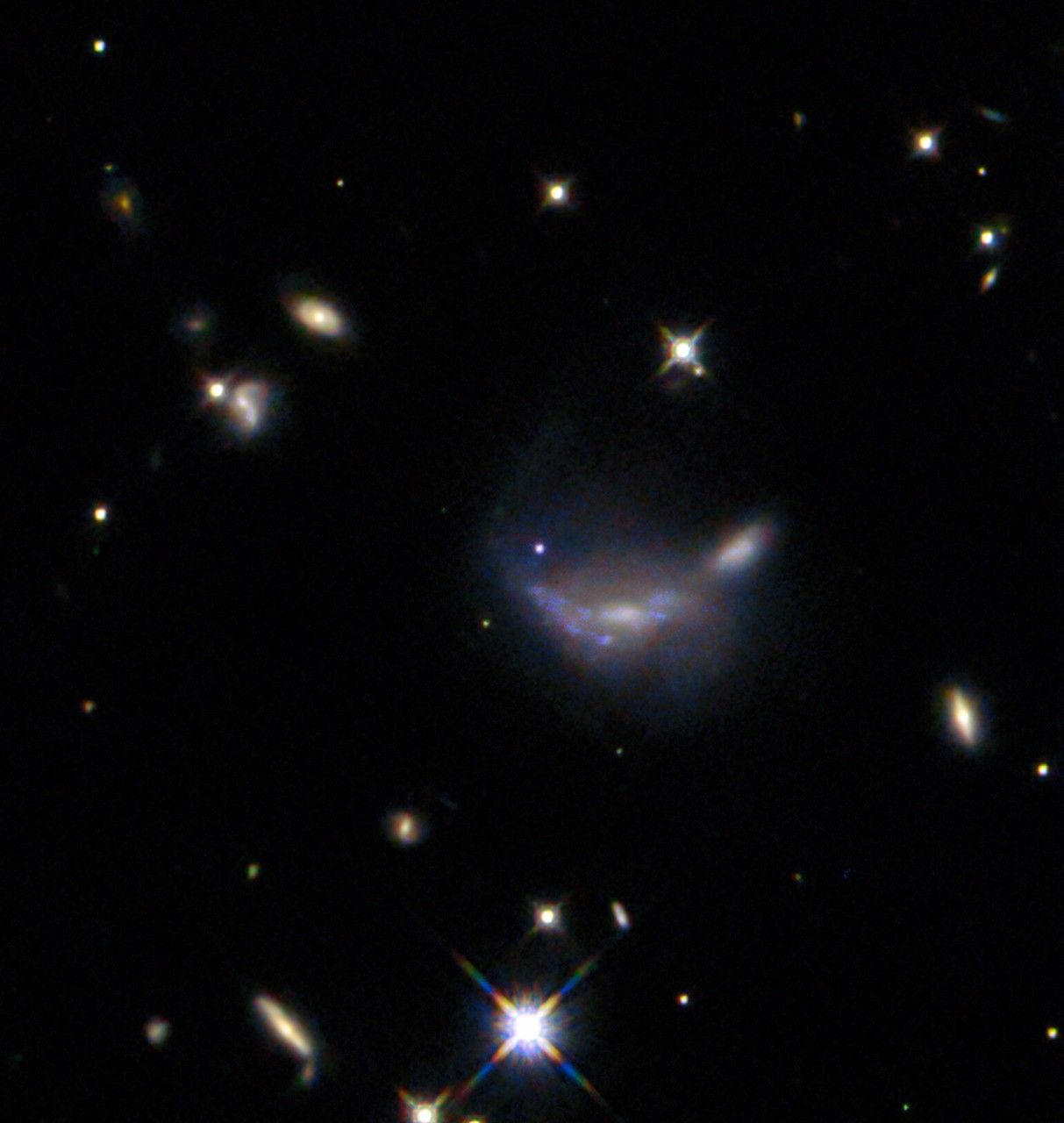

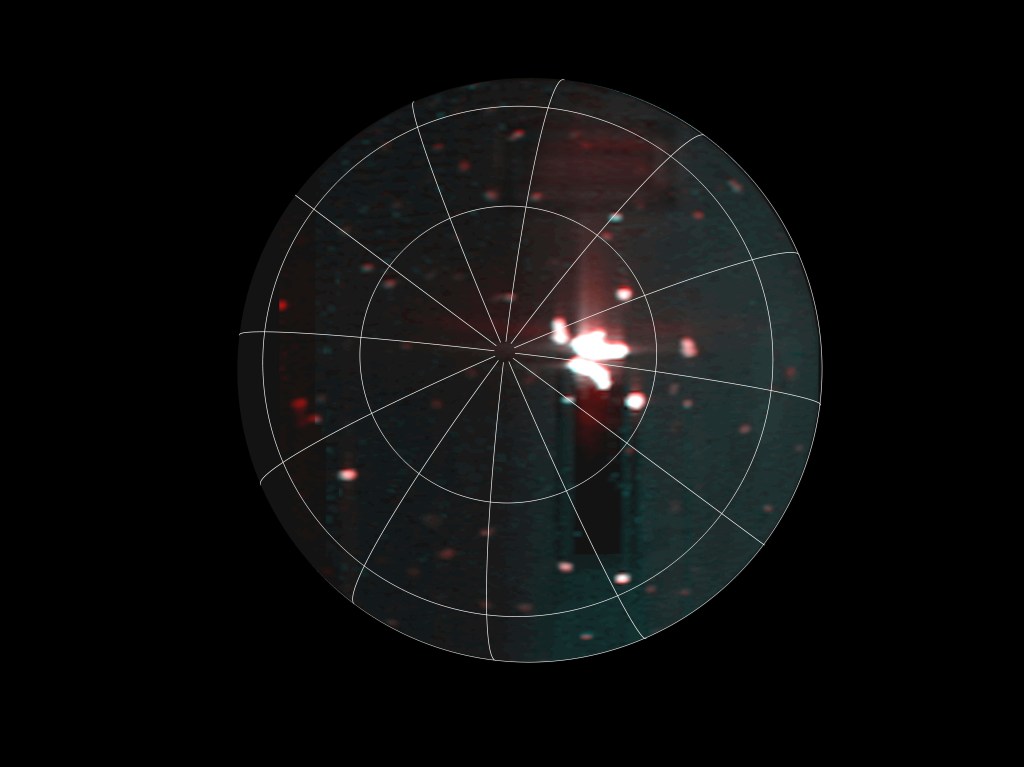

Want to be a fly of the wall of a real simulation with NASA engineers? Take a closer look as IPEx performs a simulated lunar mission in a testbed at Kennedy Space Center. The autonomous excavator demonstrates its ability to operate with lunar environmental challenges such as harsh lighting and rock hazards.

Watch the full video hereThe development of IPEx incorporates modern tools and algorithms to enhance its functionality and reliability. Some of the IPEx subsystems include:

Camera and Dust Mitigation System

- This system includes cameras, lenses, wiring, and lighting used for navigation and orientation during the mission. It helps the equipment move autonomously and safely by using visual cues. To protect the equipment from dust, it features electro-dynamic dust shields to maintain clear visuals and protect sensitive equipment.

Mobility System

- The Mobility System supports other systems and provides the necessary equipment to move across the lunar surface. Its main parts include the structure, wheels, and devices that control the wheels.

Thermal Control System

- The Thermal Control System (TCS) ensures that the equipment remains within safe temperature ranges during travel and while on the Moon. Its key components include a radiator with a cover and motor, phase change material (PCM), heat spreaders, heater strips, an enclosure for electronics, and multi-layer insulation (MLI).

Regolith Delivery System

- The Regolith Delivery System (RDS) is designed to collect lunar soil, known as regolith. It uses rotating bucket drums on each side of the excavator, which are lifted by arms to gather and transport the soil. This system includes motors for both the bucket drums and the arms, as well as the bucket drums, arms, and their respective motors.

IPEx employs innovative excavation tools known as bucket drums, which are hollow cylinders equipped with scoops that dig and collect regolith. These drums rotate in opposite directions, reducing reaction forces and enabling the lightweight robotic system to operate effectively in the Moon’s reduced gravity environment. The system is designed to excavate up to 10,000 kg of regolith, similar to the weight of 20 adult elephants, in a single lunar day. This is a significant improvement over previous missions that have collected tens of kilograms. This capability is essential for future ISRU operations, which aim to extract resources such as oxygen from the lunar regolith to support sustained human presence on the Moon.

IPEx’s design is informed by the Regolith Advanced Surface Systems Operations Robot (RASSOR), which served as a precursor to this advanced technology. By building on RASSOR’s foundation, IPEx is built with a focus on modularity and adaptability, allowing it to be customized for various mission needs. This flexibility is achieved using common parts across its actuators, reducing complexity and cost while ensuring that the system can operate effectively both on Earth for testing and on the lunar surface. This approach ensures that IPEx can be easily adapted to different mission scenarios, making it a versatile tool for lunar exploration.

IPEx is poised to revolutionize lunar excavation with its innovative design and advanced technology, setting the stage for future missions that will rely on locally sourced resources to support human exploration of the Moon and Mars.

Featured GCD Collaboration

A New Student Lunar Autonomy Challenge

Space is hard, but it's not all hardware!

The new Lunar Autonomy Challenge invites teams of students at U.S. colleges and universities to test their software development skills. Working entirely in virtual simulations of the Moon’s surface, teams will develop an autonomous agent, or software that can accomplish pre-defined tasks without help from humans. These agents will be used to navigate a digital twin of NASA’s ISRU Pilot Excavator (IPEx) and map specified locations in the digital environment. IPEx is an autonomous mobility robot engineered to efficiently mine and transport lunar regolith, the loose rocky material on the Moon’s surface.

Learn More about A New Student Lunar Autonomy Challenge

A Closer Look at IPEx

Kurt Leucht, of Swamp Works at NASA’s Kennedy Space Center, explains how this technology demonstration will pave the way for exploration of the Moon with Artemis. Check it out!

Learn More about Swamp WorksISRU Pilot Excavator

Autonomy Testing

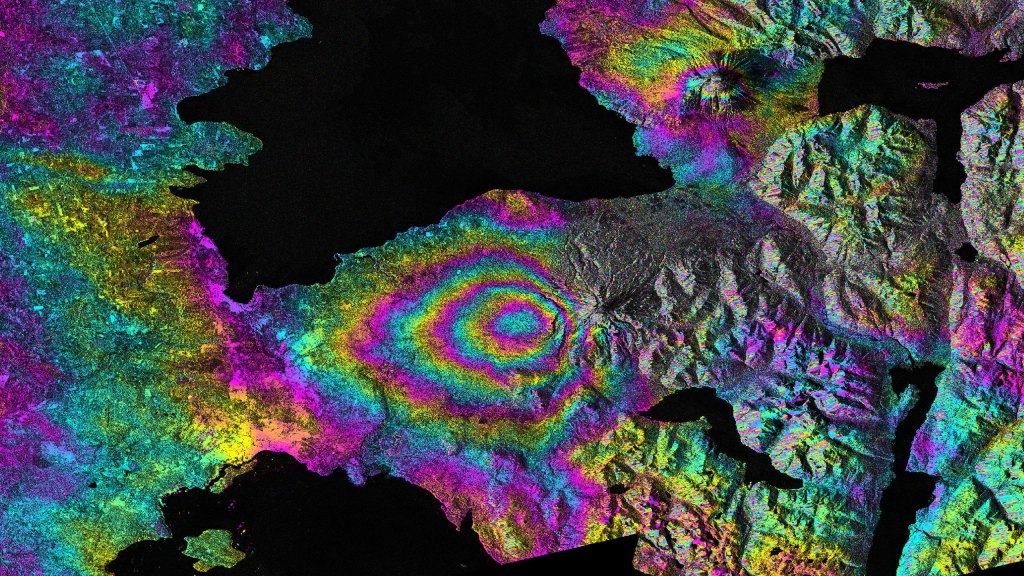

Harsh, low-angle sunlight, long and dark shadows, and a featureless terrain will make navigation difficult when NASA’s ISRU Pilot Excavator (IPEx) is sent to the Moon. The IPEx team has begun testing various approaches to autonomously drive the excavator on the lunar surface.

Learn More