Instruments

Greenhouse Gas (GHG) Instrument Details

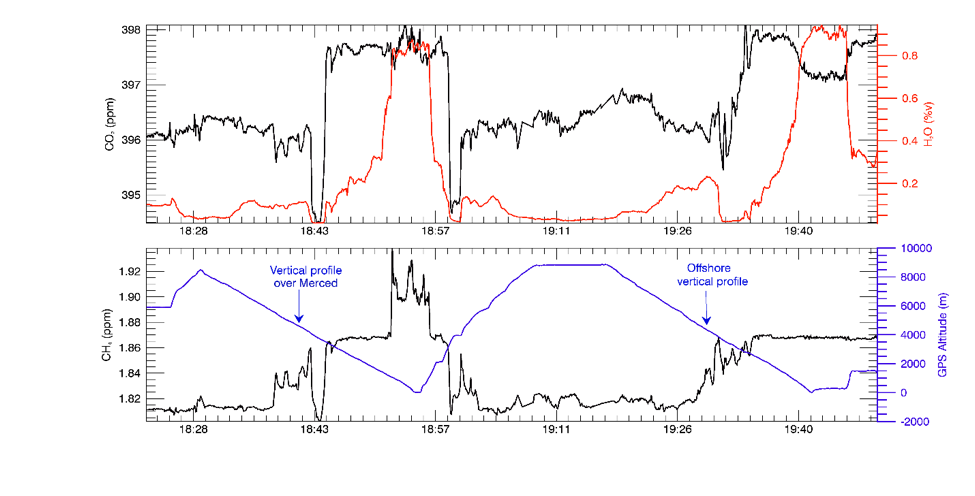

Measurements of carbon dioxide (CO2), methane (CH4) and water vapor mixing ratios are performed using a commercial sensor modified for flight worthiness (Picarro Inc., model 2301-m). Based on cavity ring-down spectroscopy the sensor measures ambient GHG concentrations every 0.3 Hz. Raw GHG flight data is typically averaged to report data at 3 s frequency and data is filtered to remove artefacts due to cavity pressure and temperature fluctuations, water vapor corrections and the correct calibration factor is applied. This results in typical uncertainties of 0.16 ppm for CO2 and 2.2 ppb for CH4 (Tanaka et al., 2015).

GHG Instrument Calibrations

The GHG instrument has undergone thorough instrument testing in the laboratory to determine the precision, linearity and overall accuracy. Laboratory calibrations with whole air standards provided by NOAA/ERSL (and certified by the World Meteorological Organization Central Calibration Laboratory) are typically performed before and after each flight. Calibrations in a pressure- and temperature-controlled environmental chamber have also been carried out using the over the pressure range 200 – 800 mbar and temperature range -15 to +25 ⁰C; typical pressure and temperature ranges observed in the wing-mounted instrument pod during flight.

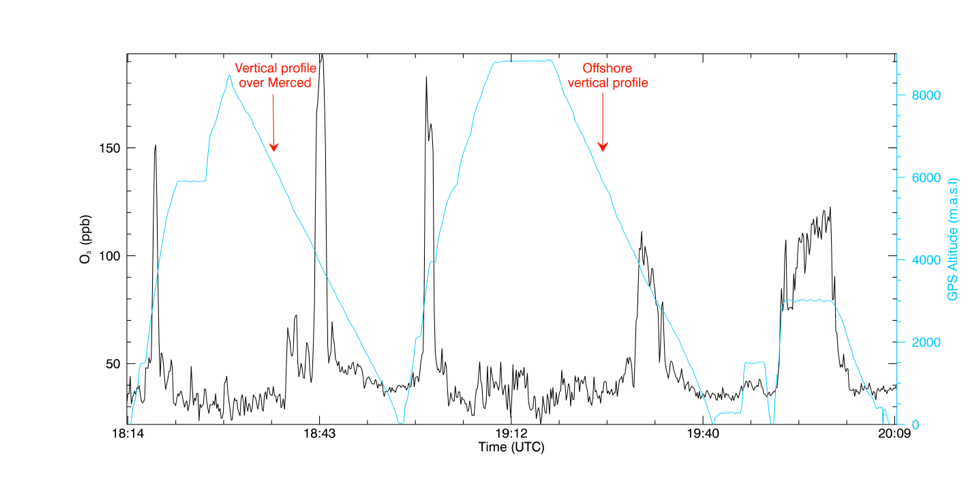

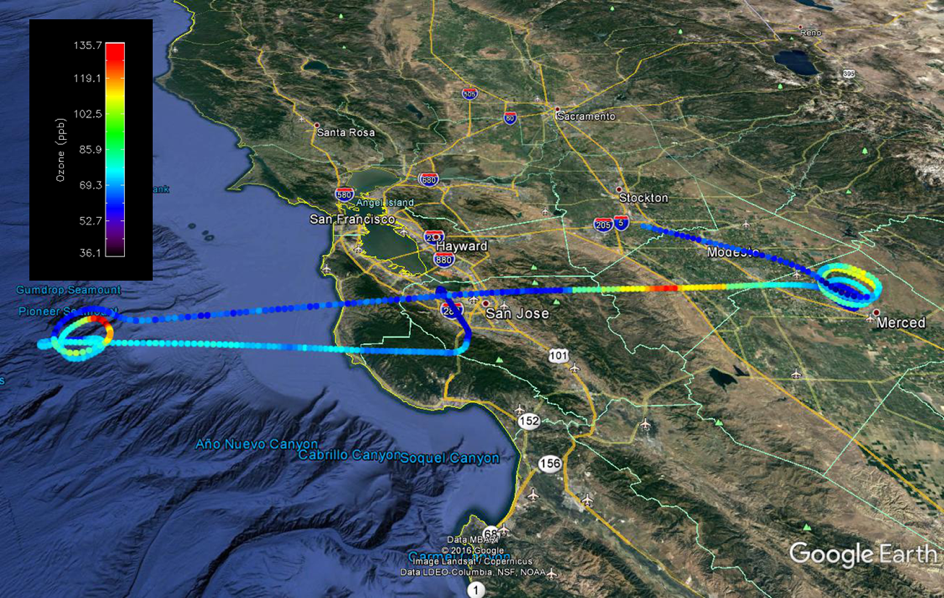

Ozone (O3) Instrument Details

Measurements of O3 mixing ratios are performed using a commercial O3 monitor (2B Technologies Inc., model 205) based on ultraviolet (UV) absorption techniques and modified for flight worthiness. The dual-beam instrument uses two detection cells to simultaneously measure UV light intensity differences between O3-scrubbed air and un-scrubbed air to give precise measurements of O3. The monitor has been modified by upgrading the pressure sensor and pump to allow measurements at high altitudes, including a lamp heater to improve the stability of the UV source, and the addition of heaters, temperature controllers and vibration isolators to control the monitor’s physical environment.

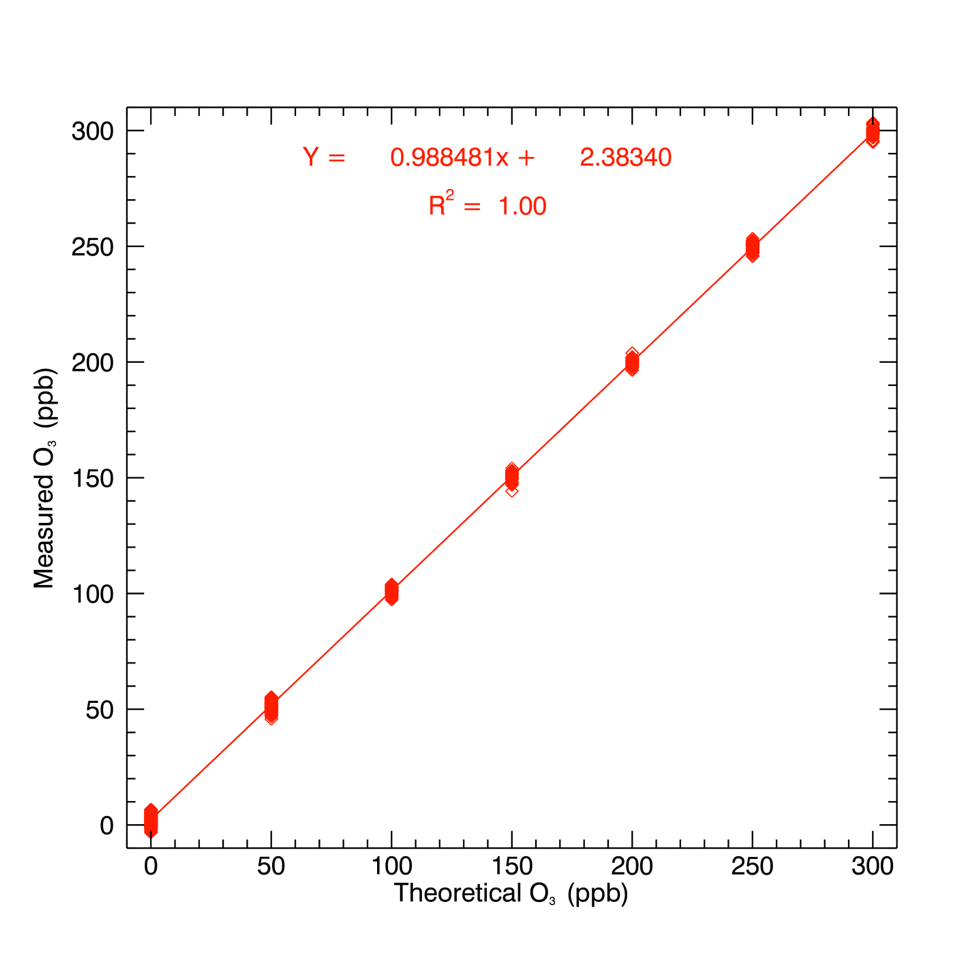

Ozone Instrument Calibrations

The O3 monitor has undergone thorough instrument testing in the laboratory to determine the precision, linearity and overall accuracy. Eight-point calibration tests (ranging from 0 – 300 ppbv) are typically performed before and after each flight using an O3 calibration source (2B Technologies, model 306 referenced to the WMO scale). Calibrations in a pressure- and temperature-controlled environmental chamber have also been carried out using the O3 calibration source over the pressure range 200 – 800 mbar and temperature range -15 to +25 ⁰C; typical pressure and temperature ranges observed in the wing-mounted instrument pod during flight.

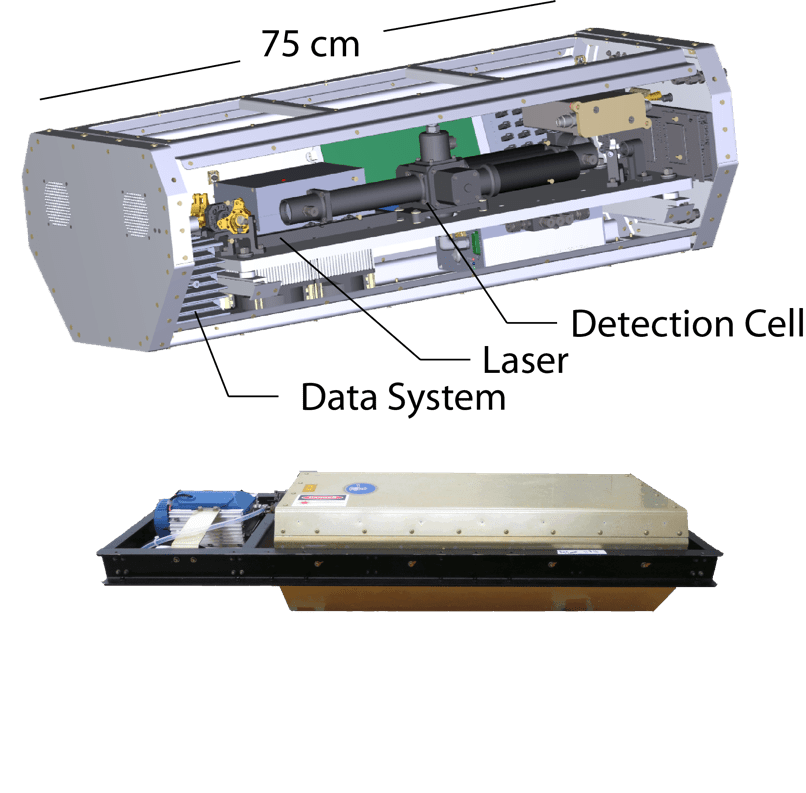

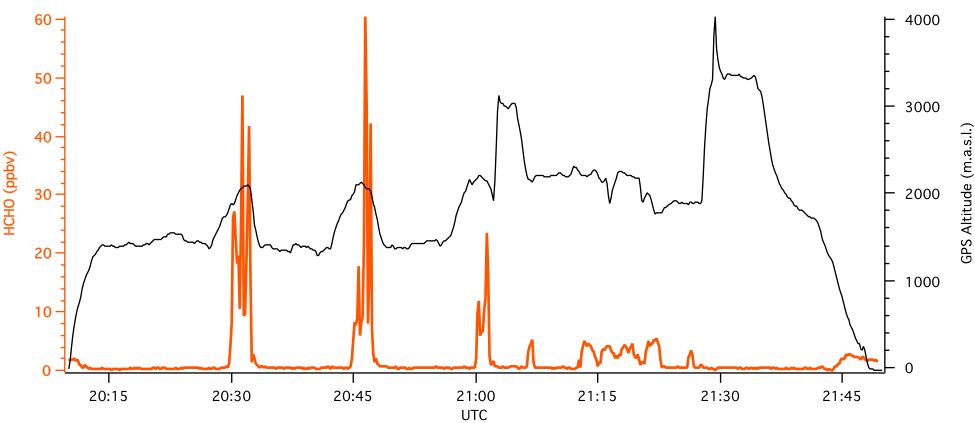

Formaldehyde Instrument Details

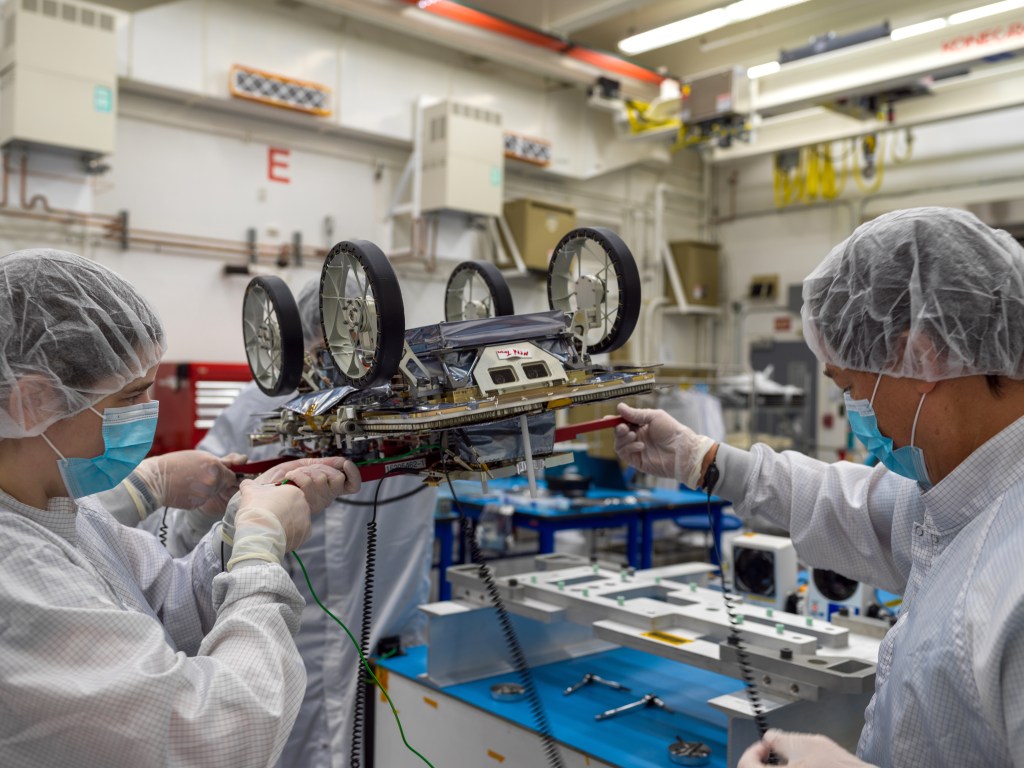

The COmpact Formaldehyde FluroescencE Experiment (COFFEE) instrument was developed and built at NASA Goddard Space Flight Center specifically for integration into the AJAX port-side wingpod to measure formaldehyde (HCHO) (Tom Hanisco and team). The instrument uses a non-resonant laser-induced fluorescence technique. A pulsed UV laser at 355 nm is used to excite HCHO molecules and the resultant fluorescent spectrum is detected. Photo counts are proportional to the amount of HCHO in the sample.

COFFEE Instrument Calibrations

Calibrations are carried out in the laboratory and are achieved by standard additions of a primary standard (~600 ppb) to zero air. COFFEE is capable of 0.2 ppb sensitivity, has a 1 Hz sampling frequency, and 20% accuracy.

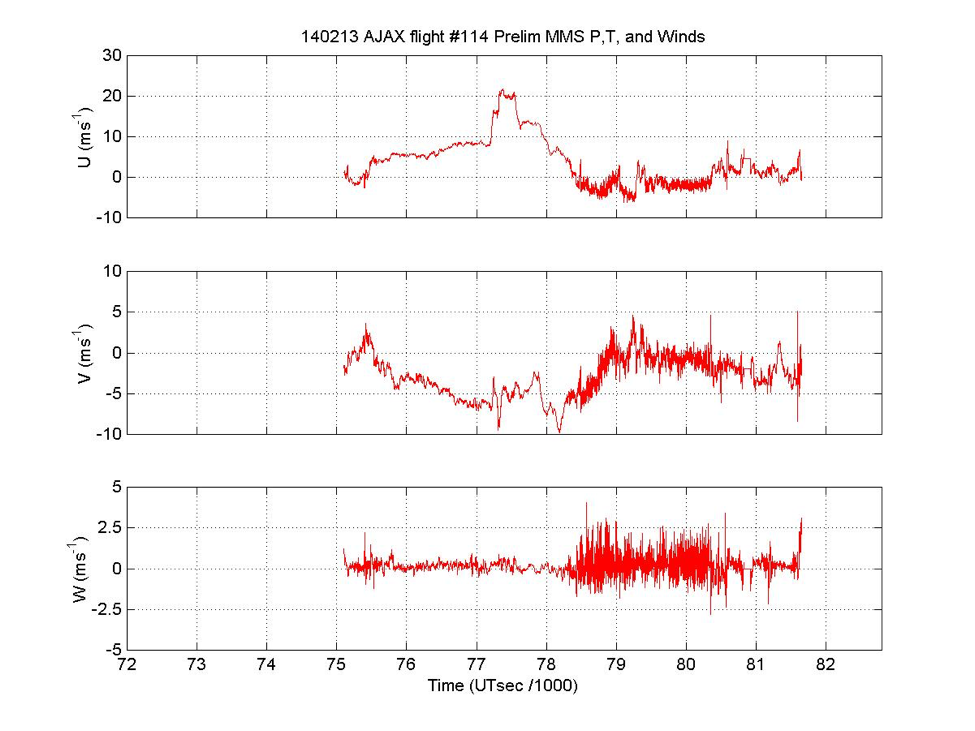

MMS Instrument Details

The Meteorological Measurement System (MMS) was designed and built at NASA Ames Research Center for integration into the starboard-side wingpod nose cone to measure high-resolution pressure, temperature and 3D winds (Paul Bui and team). This system flies on nearly all NASA aircraft and has been involved in most major NASA airborne field campaigns (ref).

MMS Consists of Three Major Systems

Air motion sensing system to measure the air velocity with respect to the aircraft

Aircraft motion sensing system to measure the aircraft velocity with respect to the earth

Data acquisition system to sample, process and record the measured quantities.

System components include 7 static pressure ports with pressure transducers, INS/GPS system, fast temperature probe, GPS L1/L2 antenna and a digital compass.