Don Durston was obsessed with building model planes as a kid, and he never grew out of it. His models are just a whole lot more sophisticated these days!

Growing up, he assembled plastic models of various airplanes, from a Cessna 172 to an Air Force F-4 Phantom. And when he heard real fighter jets pass overhead at supersonic speeds, the sonic booms they produced got him excited about studying how airplanes fly.

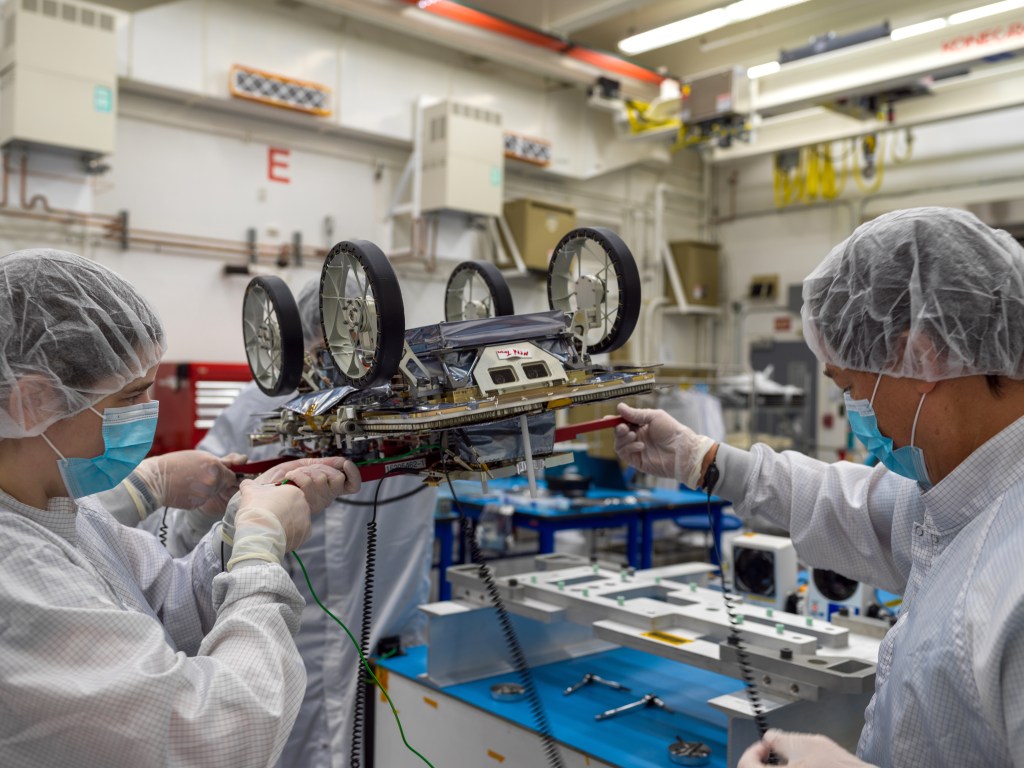

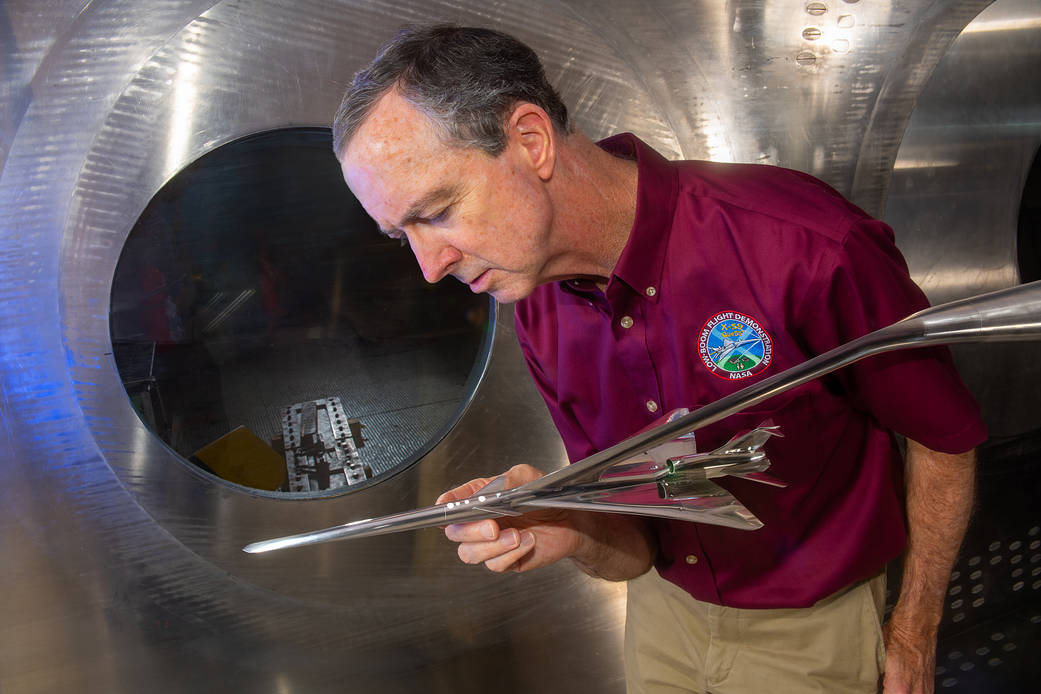

Today, Durston, an aerospace engineer at NASA’s Ames Research Center in California’s Silicon Valley, leads the agency’s wind tunnel testing for sonic boom research under the Commercial Supersonic Technology project. He is pictured here in October 2021 with a model he helped design of NASA’s X-59 Quiet SuperSonic Technology, or QueSST, aircraft, made ready for testing in the 8- by 6-foot supersonic wind tunnel at NASA’s Glenn Research Center in Cleveland.

The unique shape of the X-59 reduces the loud sonic boom typically associated with supersonic aircraft to a quiet thump for people on the ground. To study how the aircraft will perform, sophisticated models are tested in wind tunnels where air flows over them as if they were flying.

The X-59 model shown here is about 19 inches long and made almost entirely of solid, high-strength stainless steel. The plane itself has extremely thin wing and tail surfaces typical of supersonic aircraft. Scaled down to just 1.62% of the real aircraft’s size, the model’s edges would have approached the thickness of aluminum foil!

In the model’s final design, those edges were thickened slightly so it would be strong enough to handle the forces in the wind tunnel, where air flows faster than the speed of sound. The change did not interfere with testing, since it had such a small effect on the sonic booms – or mere thumps – produced and could be accounted for when the data was analyzed.

The model was built according to NASA’s requirements by Tri Models, Inc. of Huntington Beach, California. Durston made a special trip to inspect its construction and ensure it was made to the precise standards specified. He checked that all surfaces were flush, feeling by hand for even the slightest step of a thousandth of an inch between parts. He made sure holes for screws and pins were perfectly centered and removed every part before carefully reassembling the model piece by piece.

The data from the tests conducted in September and October 2021 using this model are helping validate computer-based tools for studying how air flows around the X-59 under different flight conditions. The wind tunnel and computer simulation data will ultimately be compared to actual flight test results when the X-59 flies later this year. By making supersonic flight quieter, the mission aims to support a rule change by the Federal Aviation Administration that would permit these flights over land.

Image credit: NASA/Glenn Research Center/Quentin Schwinn

Author: Abby Tabor, NASA’s Ames Research Center