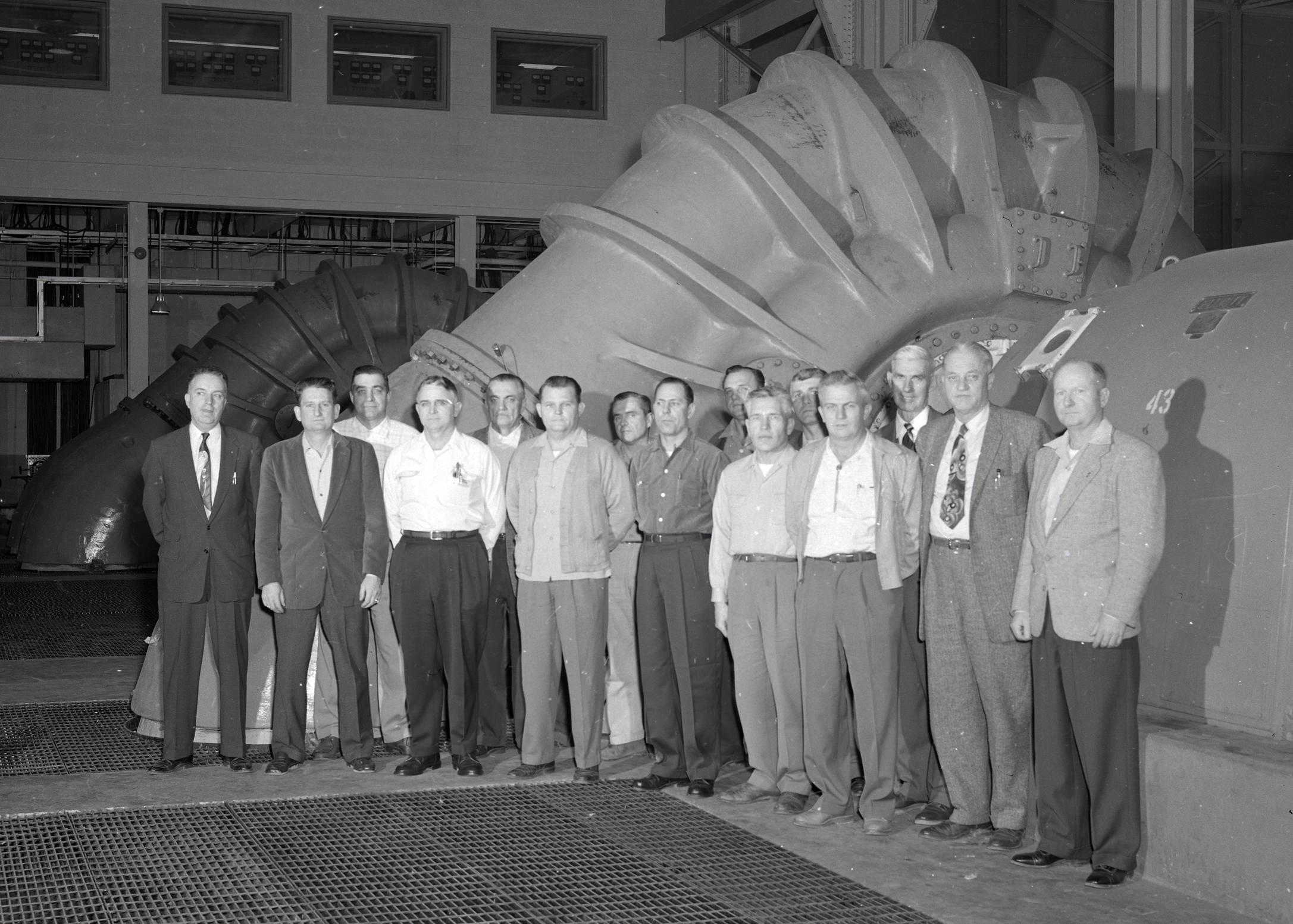

Stationary Engineers at the Propulsion Systems Laboratory

The Propulsion Systems Laboratory at the National Advisory Committee for Aeronautics (NACA) Lewis Flight Propulsion Laboratory required 15 stationary, or operations, engineers to conduct its testing of full-scale engines and rockets. The Propulsions Systems Laboratory included two 14-foot diameter test chambers which were used to test engines at simulated altitudes. The Equipment Building, seen in this photograph, was the heart of the facility. It contained the compressors, exhausters, refrigeration equipment, and other apparatus used to condition the air for the tests. The Equipment Building had its own control room with a view of all the air handling equipment. The exhausters and compressors were started from the main control room near the test chambers. In emergency situations, however, the machines could be stopped from the floor of the Equipment Building. The system was linked to the lab’s central air system and augmented the compressors and exhausters in other test facilities. The lab’s Equipment Operations Branch posed in front of one of the Roots-Connersville exhausters for this photograph. In 1957, 12 of the 15 were retired Navy Chief Petty Officers, including a Chief Warrant Officer, Branch Chief, and an Assistant Branch Chief. From left to right, the engineers are: Robert H. Harrison, Branch Chief; Earl W. Lear, Chief Machinist Mate; John G. Lurtz, Chief Engineman; George H. Hartle, Chief Electricians Mate; Karl D. Martz, Chief Warrant Officer; Joseph Wozny, Chief Machinist Mate; Richard S. Thomas, Chief Machinist Mate; Julian Vincent, Chief Machinist Mate; Raymond J. Eland, Chief Machinist Mate; Richard E. Preston, Chief Electricians Mate; James H. Vander stein, Jr., Chief Machinist Mate; William Lorenz, Chief Machinist Mate; Percy E. Cheesman, Chief Machinist Mate; E. C. Wrege, Assistant Branch Chief; Piersel R. Penning, Chief Machinist Mate.

- X