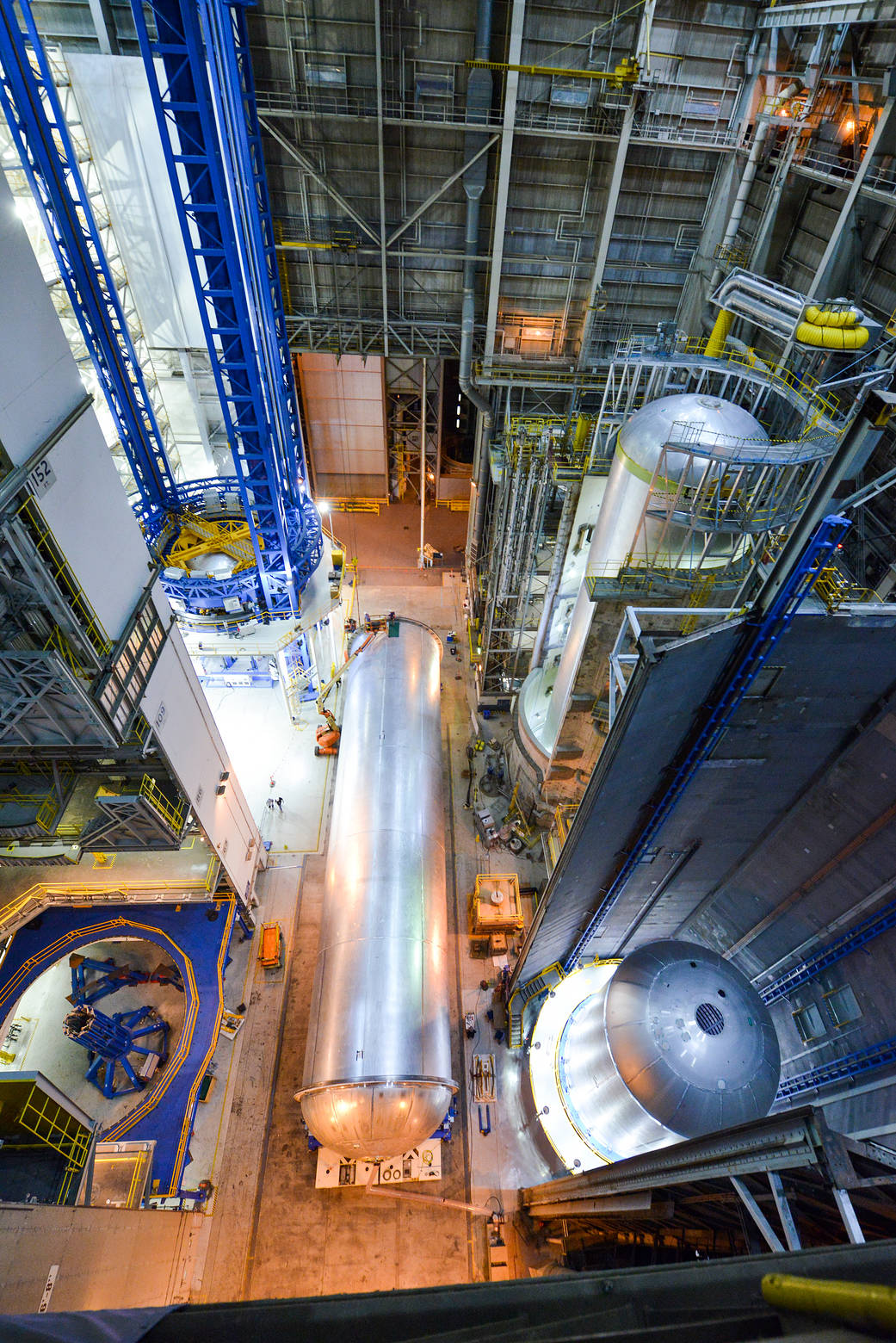

NASA has met a milestone completing the welding on a liquid oxygen tank test article and beginning welding the liquid oxygen tank that will be part of the first Space Launch System deep space rocket. This tank and the liquid hydrogen tank are the parts of the SLS core stage that hold more than 700,000 gallons of propellant to power the rocket’s four RS-25 engines. Inside the Vertical Assembly Building at NASA’s Michoud Assembly Facility in New Orleans, four fuel tanks are being built and processed simultaneously. Engineers are building core stage tanks that will fly on the first SLS flight and tanks that will provide valuable test data. In the world’s largest robotic rocket welder, the Vertical Assembly Center (left back), the prime contractor for the SLS core stage, Boeing, is welding a flight tank for the first SLS flight with Orion. Engineers just built an almost identical tank, the liquid oxygen tank qualification test article (right front). On the same side of the building, technicians are washing the interior of the liquid hydrogen structural qualification test article (right back). When completed, these core stage test articles travel by barge to NASA’s Marshall Space Flight Center in Huntsville, Alabama, for structural testing that will demonstrate that the tanks structures can withstand the harsh environments of flight and perform as designed. In the middle of the floor in the above image, engineers are practicing operations with a liquid hydrogen tank built for flight. The left front of the building is currently empty, but it serves as a vertical stacking area where tanks and other core stage hardware can be stacked, assembled and inspected.

Image credit: NASA/Michoud/Jude Guidry