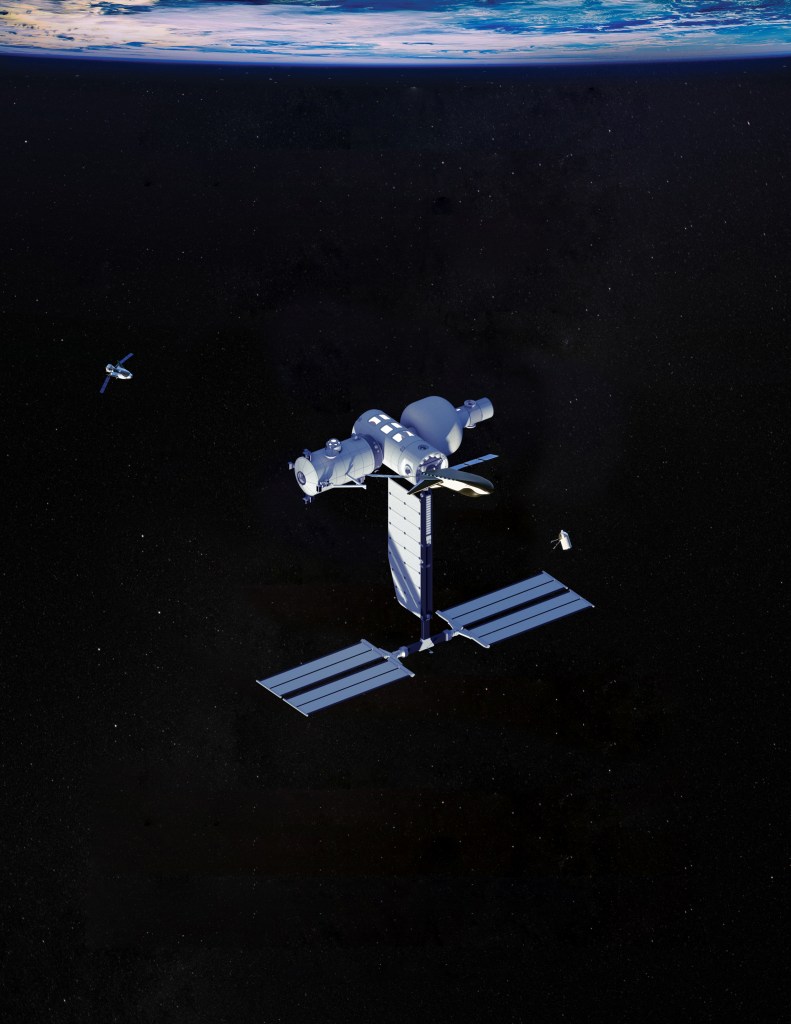

After completing major welding on the liquid hydrogen tank for NASA’s Space Launch System’s (SLS) first flight, all five parts of the rocket’s core stage are built and ready for additional outfitting and testing. NASA also finished manufacturing all four core stage test articles, and testing is underway on the engine section structural test article at NASA’s Marshall Space Flight Center in Huntsville, Alabama.

“The big items are done, and the team is focused on the intricate details of outfitting the flight hardware to perform specific tasks for the most powerful rocket in the world,” said Chad Bryant, the SLS core stage manufacturing lead at Marshall. “When assembled, the core stage will stand taller than a 20-story building and include hundreds of cables for everything from data collection to propulsion systems.”

Outfitting the Core Stage

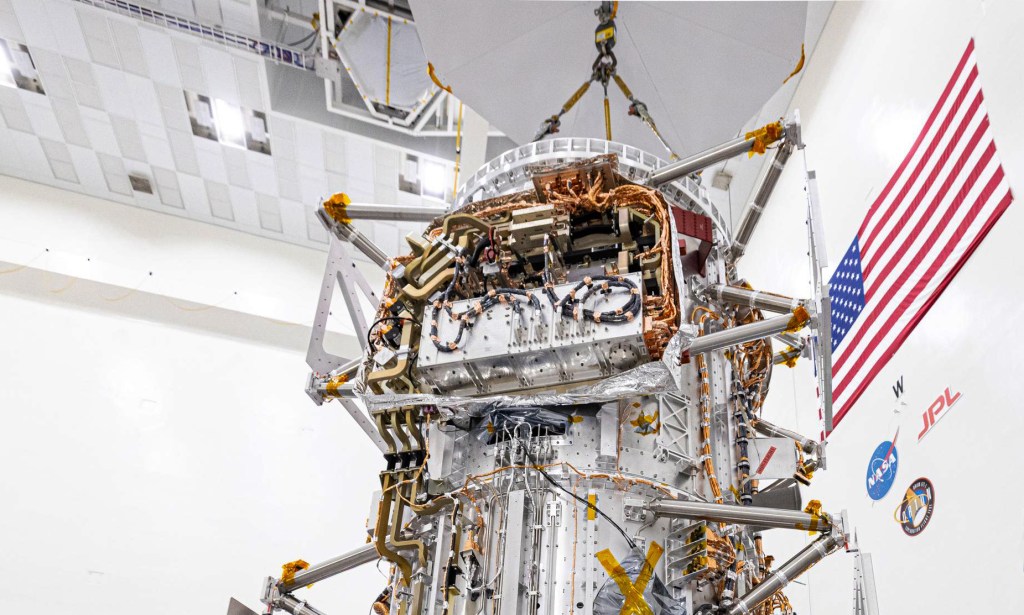

Three core stage parts that require the most work inside are the engine section, where the four RS-25 engines will be housed, and the intertank and forward skirt that hold most of the avionics, or the brains of the rocket, that tell it how and where to fly.

“Think about this work like building a car,” explained Bryant. “We have the main structure or frame built. Now, we are installing the guts and electronics that turn the rocket into a transportation system: propulsion systems in the engine section, computer and other electronics in the forward skirt and the intertank.”

Then, to keep cryogenic propellant as cold as minus 423 degrees Fahrenheit and to protect the rocket against the harsh temperature environments experienced during launch and flight, engineers apply thermal protection insulation to every large piece on the outside as well as in critical places on the inside.

Testing the Tanks

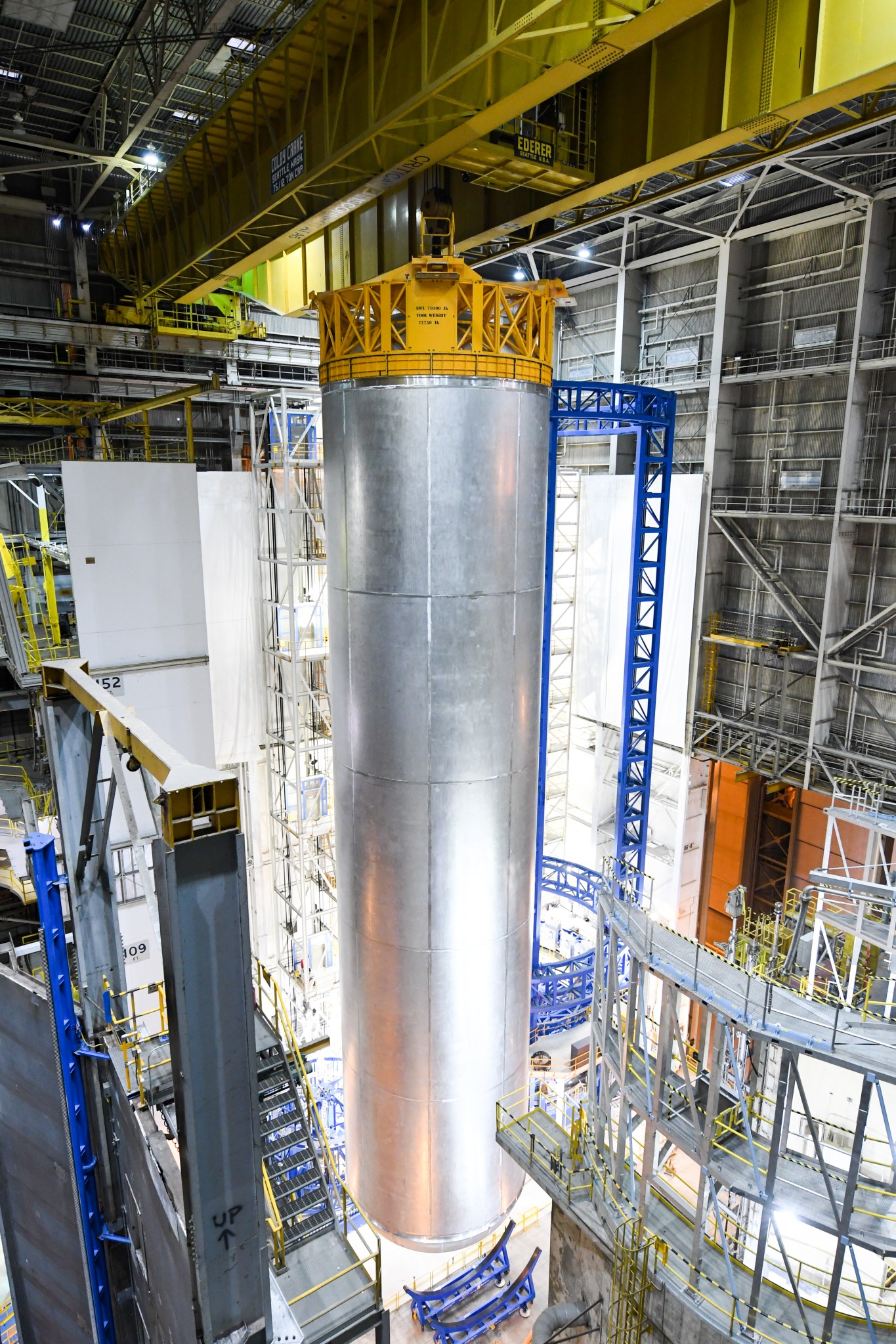

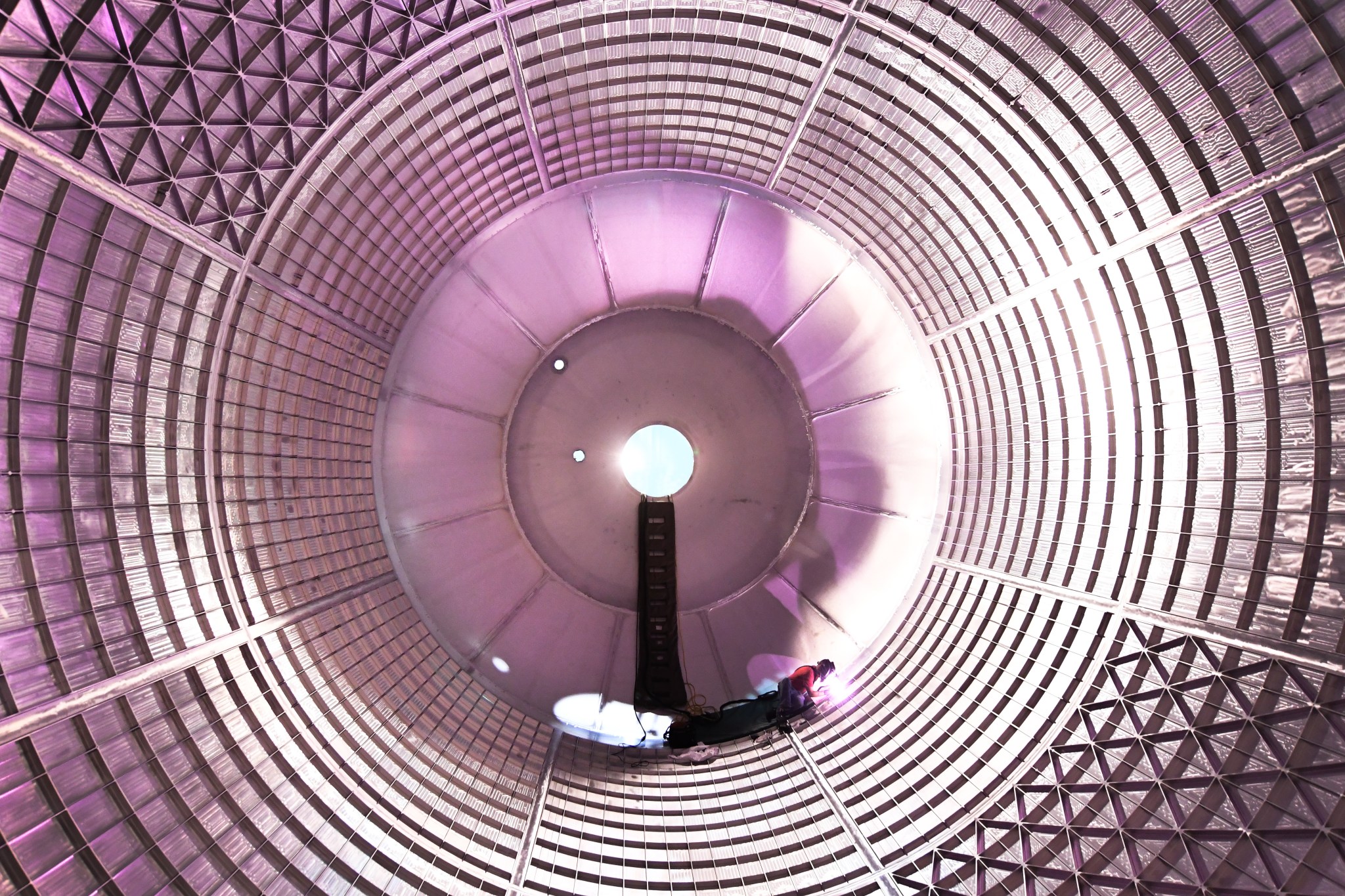

To build the two largest core stage structures — the liquid hydrogen and liquid oxygen tanks that hold more than 700,000 gallons of propellant — NASA welded the thickest structures ever joined using self-reacting friction stir welding. The Vertical Assembly Center, the world’s largest robotic welder at NASA’s Michoud Assembly Facility in New Orleans, did the job. NASA and Boeing, the core stage prime contractor, had to overcome challenges to weld aluminum at the thicknesses required for the massive rocket tanks.

The liquid oxygen tank is undergoing hydrostatic testing, which tests the weld strength by filling the tank with 200,000 gallons of water and subjecting the tank to similar pressures and forces that it will experience during flight.

“This is the first time we are doing this test for an SLS tank, and it’s a major milestone,” said Ben Birkenstock, SLS stages manufacturing engineer at Marshall. “We’ve covered the tank with sensors, and we’ll collect data to show the tank welds hold up when it is loaded with water that simulates propellant.”

The liquid hydrogen tank is being plug welded to fill in holes left during the robotic welding process, and then it will undergo a different type of proof testing using nitrogen gas and load cells to simulate pressures and loads seen during flight. The liquid hydrogen structural qualification test article already completed this proof test.

SLS Pathfinder: Paving the Way for Core Stage Operations

The SLS core stage pathfinder arrived at Michoud on September 27, and now, the team will use it to hone upcoming SLS operations. The SLS pathfinder mockup and other ground support equipment are helping NASA prepare for upcoming operations with the entire core stage. Critical operations include assembling and moving the core stage at Michoud, transporting the core stage on NASA’s barge Pegasus to the agency’s Stennis Space Center in Bay St. Louis, Mississippi, and lifting it into the giant B-2 test stand where it will be hot-fired in a crucial pre-launch test called “the green run.” After a successful test, Pegasus will take the entire stage to NASA’s Kennedy Space Center in Florida, where it will be integrated with the rest of the SLS hardware and Orion.

The core stage pathfinder, built and assembled at G&G Steel in Cordova, Alabama, is the same size, shape, and weight as the core stage, and it will help NASA develop and practice all these crucial logistics and operations. Dynetics Corporation of Huntsville will be completing final outfitting of pathfinder and will turn it over to NASA in early October.

“NASA did not want to do complex operations for the first time with a one-of-a-kind piece of flight hardware,” said Tim Flores, manager for stages ground support equipment. “The SLS core stage pathfinder will allow us to practice all these critical maneuvers with a dimensional replica of the core stage that is the same size, shape and weight as the valuable flight hardware.”

Tracy McMahan

Marshall Space Flight Center, Huntsville, Alabama

256-544-0034

Tracy.McMahan@nasa.gov