By Linda Herridge

NASA’s John F. Kennedy Space Center

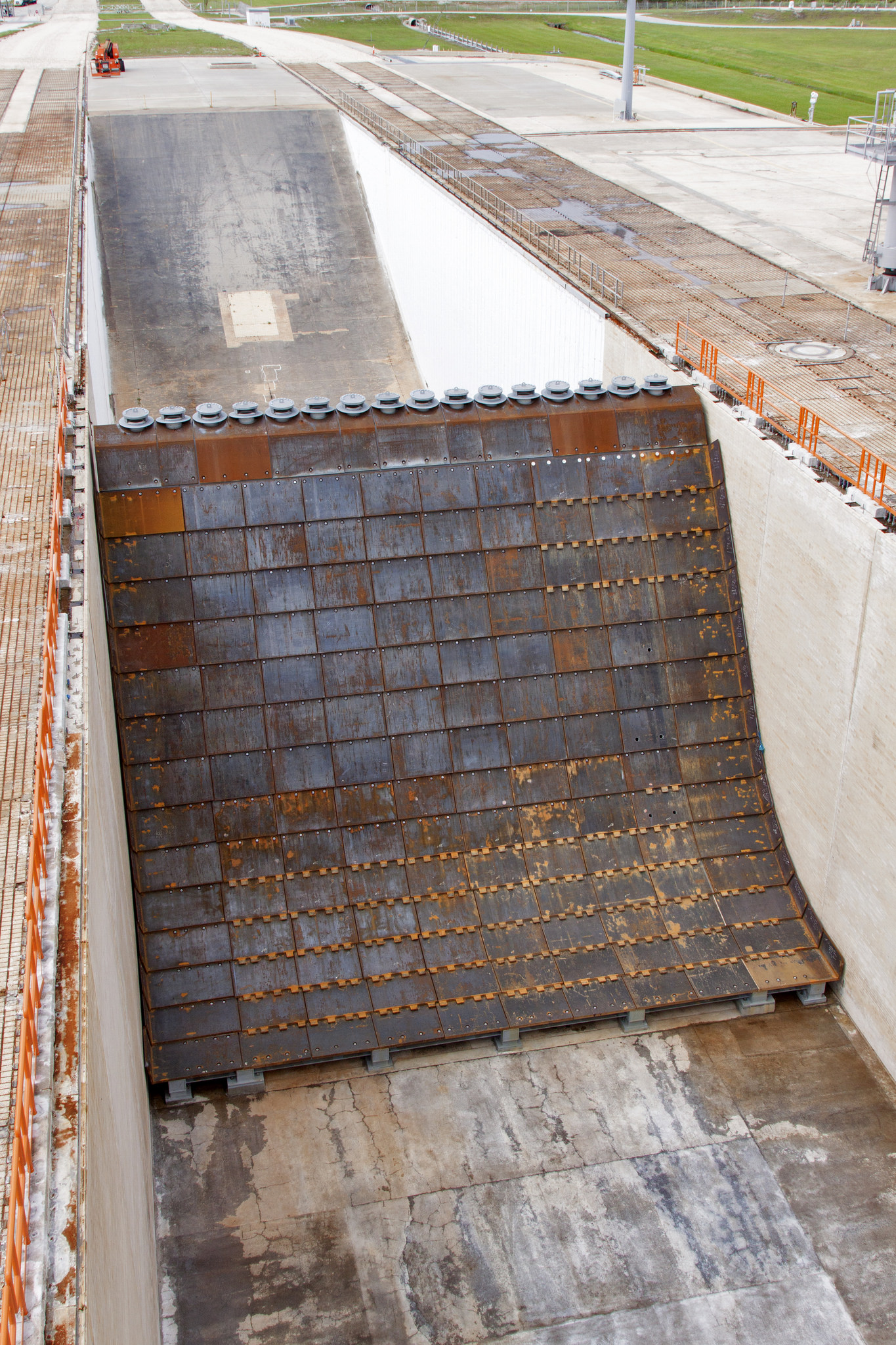

The nearly nine million pounds of thrust expended during lift-off of the agency’s new Space Launch System (SLS) rocket would cause quite a bit of damage if it wasn’t for modifications made to Launch Pad 39B. Exploration Ground Systems at NASA’s Kennedy Space Center in Florida achieved a significant milestone on the path to supporting the agency’s first integrated launch of the SLS and Orion spacecraft by completing the major construction on the main flame deflector in the upgraded flame trench at Pad B.

“With a lot of hard work, a lot of bricks, and tons of steel, we now have a flame trench and deflector system ready to support SLS,” said Regina Spellman, EGS pad senior project manager. “It has been truly exciting to see the main flame deflector come together.”

The new main flame deflector is critical to safely deflecting the plume exhaust from the massive rocket during launch. Measuring approximately 57 feet wide, 43 feet high and 70 feet long, the deflector’s north side is slanted at about a 58-degree angle and will divert the rocket’s exhaust, pressure and intense heat to the north at liftoff. Two side deflectors soon will be installed. They will help to contain and protect the vehicle and surrounding pad structures from the solid rocket boosters during liftoff.

Construction began on the main flame deflector in July 2017. The deflector incorporates several novel design approaches, including steel cladding plates, an open structure on the south side, and a configuration that maximizes functionality with commercial launch vehicles. The open south side allows easy access for inspection, maintenance and repair.

“The thick steel plates are designed to withstand the exhaust and heat from several launches,” said Nick Moss, EGS pad deputy project manager. “There is flexibility of maintenance; as steel plates closest to the exhaust plume begin to erode, they can be replaced.”

New water pipes used for sound suppression were installed on the crest of the main flame deflector. At launch, thousands of gallons of water flow from a tank through the pipes and out to cool the main flame trench and absorb and re-direct shock waves while reducing sound levels that can damage the vehicle and surrounding structures.

The flame trench beneath the pad was completely upgraded in 2017. All of the Apollo-era wall bricks were removed and new heat-resistant bricks were installed from the flame deflector to the northern extent of the walls. Approximately 100,000 heat-resistant bricks, in three different sizes, were secured to the walls using bonding mortar, and where required, steel plate anchors. In areas where significant temperature and pressure will occur, steel plate anchors were fastened into the walls at intervals to reinforce the brick system.

“We’re one step closer to launching the world’s most powerful rocket,” Moss said. “I’m happy to be a part of it.”

EGS is preparing Kennedy’s infrastructure to support not only SLS and Orion, but several different kinds of spacecraft and rockets that are in development. A key aspect of the program’s approach to long-term sustainability and affordability is to make processing and launch infrastructure available to commercial and other government customers, thereby distributing the cost among multiple users and reducing the cost of access to space.

/quantum_physics_bose_einstein_condensate.jpg?w=1024)