Chapter 5

The Whitcomb Area Rule:

NACA Aerodynamics Research and Innovation

by Lane E. Wallace

As the 1940s came to a close, military aircraft manufacturers in the

United States faced a disturbing problem. The Bell X-1 had broken the so-called

"sound barrier," and both the Air Force and the Navy were looking for next

generation aircraft that could operate at supersonic speeds. But preliminary

tests of models indicated that even the best designs put forth by industry

engineers were not going to be able to achieve that goal. A sharp increase

in drag at speeds approaching Mach One was proving too much for the limited-power

jet engines of the day to overcome.

The solution to this frustrating impasse was found by Richard T Whitcomb,

a young aerodynamicist at the National Advisory Committee for Aeronautics

(NACA) Langley Research Center in Hampton, Virginia. His development of

the "area rule" revolutionized how engineers looked at high-speed drag

and impacted the design of virtually every transonic and supersonic aircraft

ever built. In recognition of its far-reaching impact, Whitcomb's area

rule was awarded the 1954 Collier Trophy.

Yet it is not just the significance of the concept that makes the discovery

and application of the area rule interesting. The story of its development

provides insights on how innovations are "discovered" and how, even at

a time when research projects were growing bigger and more complex in scope,

a single, creative individual could still play a critical role in the development

of new technology. In addition, while the area rule concept was applied

almost universally to supersonic aircraft designs, that "success" also

illustrates some of the factors that influence whether industry applies

a given technology, regardless of its inherent worth.

The Transonic Drag Problem and the Area Rule

Researchers in the Langley Research Center's wind tunnels had begun

working with transonic airflows and the problem of transonic drag (at speeds

approaching and surpassing the speed of sound) even before the end of World

War II. In 1943, John Stack, head of Langley's Eight-Foot High-Speed Tunnel

branch, obtained approval to increase the power in the tunnel from 8,000

horsepower to 16,000 horsepower. The upgrade, completed in the spring of

1945, allowed researchers to produce reliable airflow data in the tunnel

for speeds up to Mach .95. 1

One of the researchers working with Stack in the Eight-Foot High-Speed

Tunnel was a young engineer named Richard Whitcomb. Whitcomb had been fascinated

with airplanes and aerodynamics since he was a young boy, building and

testing airplane models

1. James R. Hansen, Engineer in Charge: A History of the Langley

Aeronautical Laboratory, 1917-1958 (Washington, DC: NASA SP-4305, 1987),

pp. 313-14.

135

136 THE WHITCOMB AREA RULE: NACA AERODYNAMICS RESEARCH AND INNOVATION

|

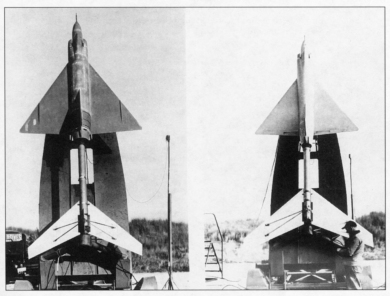

| NACA/NASA Langley engineer Richard T. Whitcomb was awarded the 1954

Collier Trophy for his development of the "area rule, " an innovation that

revolutionized the design of virtually every transonic and supersonic aircraft

ever built. Here Whitcomb inspects a research model in the 8-Foot Transonic

Tunnel at Langley. (NASA photo no. LAL 89118). |

made out of balsa wood. He was hired by the Langley Research Center

in 1943, aft receiving an engineering degree from the Worcester Polytechnic

Institute. The Langley managers initially wanted him to work in the Flight

Instrument Division, but Whitcomb stubbornly insisted that he wanted to

work in aerodynamics. Fortunately, he was granted his preference and was

assigned to Stack in the 8-foot wind tunnel.

Initially, Whitcomb was assigned the task of performing test monitoring

for other researchers. But for an eager young engineer, the key to advancement

was to "run the tests and keep your eyes open, your ears open," Whitcomb

recalled. "I kept coming to Gene (Draley, Stack's replacement as head of

the 8-foot tunnel) and saying maybe it ought to be done this way. Let's

try this. And somewhere along the way, Gene says 'OK, go try it,' and that's

where I got started." 2

By july 1948, Whitcomb had developed a reputation as "someone who had

ideas" 3 and was starting to pursue

his own research experiments. He proposed a series of wind tunnel tests

in the repowered 8-Foot High-Speed Tunnel for a variety of swept wing and

fuselage combinations. He hoped the tests would uncover a configuration

with significantly lower

2. Richard T. Whitcomb, interview with Walter Bonney, March 27, 1973.

3. Richard T. Whitcomb, telephone interview with author, May 2, 1995.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 137

drag at transonic speeds. The tests were run in late 1949 and 1950,

but the results were both perplexing and discouraging. None of the combinations

had much effect on reducing the drag of the models as they approached Mach

One.4 Clearly, the researchers needed

to know more about the behavior of airflow in the transonic region in order

to figure out what was causing such a stubborn drag problem. Unfortunately,

this data was difficult to obtain. Even the upgraded eight-foot wind tunnel

at Langley could only reach speeds of .95 Mach.

Because of the limitations of the available wind tunnels, researchers

in the mid-1940s had resorted to several "stopgap" methods to try to learn

more about transonic airflow. One series of experiments involved dropping

instrumented test missiles from a B-29 Superfortress. Test airfoils were

also mounted on the wing of a P-51 Mustang fighter plane that was then

put into a high-speed dive. With this configuration, the airplane's speed

remained subsonic but the airflow over the portion of the wing holding

the test airfoil surpassed the speed of sound. A third approach used rocket

models launched from Wallops Island, a remote beach location across the

bay from the Langley Research Center.

All three methods had their drawbacks, however. The falling-body and

wing-flow techniques offered less precise data than that obtained in a

wind tunnel. The rocket tests produced more precise data, but they were

"100 times as expensive as a wind tunnel test" and could only explore a

single parameter at a time. Furthermore, the Schlieren photographs that

illustrated the shock wave patterns of high-speed airflow could only be

obtained in a wind tunnel.5

Consequently, it was not until Stack and his team of engineers, which

included Whitcomb, developed a "slotted-throat" modification for the 8-foot

wind tunnel in 1950 that transonic flows could be thoroughly explored.6

The slotted-throat modification prevented the choking that had limited

the speeds in the test section of the tunnel and allowed the air to go

through the speed of sound. For the first time, researchers had a tool

to investigate precisely what airflow did in that speed range and what

might be causing the puzzling drag they had observed.

Actually, the slotted throat wind tunnel was only one of the tools Whitcomb

and his associates used to investigate transonic airflows. But once that

was in place, they could then employ other existing research tools to look

at what the airflow was doing. In late 1951, Whitcomb tested a swept-back

wing-fuselage combination in the now-transonic Eight-Foot High-Speed Tunnel.7

Tuft surveys, which used small pieces of yarn taped onto airfoil and fuselage

sections, were conducted to look at airflow disturbances. Coverings with

pressure-sensitive openings were put on model sections to determine the

velocity of the air over particular areas, and Schlieren photographs were

used to look at the shock wave characteristics of the model at transonic

speeds.8

4. Richard T. Whitcomb, "A Proposal for a Swept Wing Fuselage Combination

with Small Shock Losses at Transonic Speeds," Langley Central Files, AH

321-1, July 1948; Hansen, Engineer in Charge, pp. 332-33.

5. Richard T Whitcomb, telephone interview, May 2, 1995; Hansen, Engineer

in Charge, pp. 261-70.

6. The development of the slotted-throat transonic wind tunnel at the

Langley Research Center proved important enough to merit its own Collier

Trophy, awarded to Stack and his associates in 1951.

7. The time delay between each of Whitcomb's initial ideas and the

actual wind tunnel tests of them was a result of Langley's typical but

long process of designing and building wind tunnel models. It was not at

all unusual for that process to take fifteen-eighteen months. Nevertheless,

the time delay was frustrating and Whitcomb sometimes worked directly with

wind tunnel technicians to incorporate modifications in the tunnel to avoid

the delay of going through normal channels.

8. Richard T. Whitcomb and Thomas C. Kelly, "A Study of the Flow over

a 45-degree Sweptback Wing-Fuselage Combination at Transonic Mach Numbers,"

NACA RM L52DO1 June 25, 1952; Dr. Richard T. Whitcomb, "Research on Methods

for Reducing the Aerodynamic Drag at Transonic Speeds," address presented

at the ICASE/LaRC Inaugural Eastman Jacobs Lecture, Hampton, VA, November

14, 1994, pp. 1-2; Hansen, Engineer in Charge, pp. 332-33.

138 THE WHITCOMB AREA RULE: NACA AERODYNAMICS RESEARCH AND INNOVATION

The results, especially those revealed by the Schlieren photographs,

showed that the shock waves created as the airflow approached the speed

of sound were different and bigger than anticipated. Undoubtedly, it was

the losses from these unexpected shock patterns that was causing the sharp

increase in drag at transonic speeds. But the question of what was causing

the shockwaves still had to be answered before researchers could try to

find a way to combat the phenomenon.

Several weeks later, a world renowned German aerodynamicist named Dr.

Adolf Busemann, who had come to work at Langley after World War II, gave

a technical symposium on transonic airflows. In a vivid analogy, Busemann

described the stream tubes of air flowing over an aircraft at transonic

speeds as pipes, meaning that their diameter remained constant. At subsonic

speeds, by comparison, the stream tubes of air flowing over a surface would

change shape, become narrower as their speed increased. This phenomenon

was the converse, in a sense, of a well-known aerodynamic principle called

Bernoulli's theorem, which stated that as the area of an airflow was made

narrower, the speed of the air would increase. This principle was behind

the design of venturis,9 as well as

the configuration of Langley's wind tunnels, which were "necked down" in

the test sections to generate higher speeds.10

But at the speed of sound, Busemarm explained, Bernoulli's theorem did

not apply. The size of the stream tubes remained constant. In working with

this kind of flow, therefore, the Langley engineers had to look at themselves

as "pipefitters." Busemann's pipefitting metaphor caught the attention

of Whitcomb, who was in the symposium audience. Soon after that Whitcomb

was, quite literally, sitting with his feet up on his desk one day, contemplating

the unusual shock waves he had encountered in the transonic wind tunnel.

He thought of Busemann's analogy of pipes flowing over a wing-body shape

and suddenly, as he described it later, a light went on.

The shock waves were larger than anticipated, he realized, because the

stream tubes did not get narrower or change shape, meaning that any local

increase in area or drag would affect the entire configuration in all directions,

and for a greater distance. More importantly, that meant that in trying

to reduce the drag, he could not look at the wing and fuselage as separate

entities. He had to look at the entire cross-sectional area of the design

and try to keep it as smooth a curve as possible as it increased and decreased

around the fuselage, wing and tail. In an instant of clarity and inspiration,

he had discovered the area rule.

In practical terms, the area rule concept meant that something had to

be done in order to compensate for the dramatic increase in cross-sectional

area where the wing joined the fuselage. The simplest solution was to indent

the fuselage in that area, creating what engineers of the time described

as a "Coke bottle" or "Marilyn Monroe" shaped design. The indentation would

need to be greatest at the point where the wing was the thickest, and could

be gradually reduced as the wing became thinner toward its trailing edge.

If narrowing the fuselage was impossible, as was the case in several designs

that applied the area rule concept, the fuselage behind or in front of

the wing needed to be expanded to make the change in crosssectional area

from the nose of the aircraft to its tail less dramatic.11

9. A venturi, named after the 19th century Italian physicist G.B. Venturi,

is one method used to generate the suction or vacuum power necessary to

drive aircraft instruments. A venturi is mounted on the outside of air

aircraft, paralleling the fuselage. As the speed of airflow through the

cinched neck portion of the venturi increases, it is accompanied by a decrease

in air pressure, creating suction that runs the instruments connected to

the system inside the plane.

10. Whitcomb, interview, March 27, 1973.

11. Richard T Whitcomb, "A Study of the Aero-Lift Drag-Rise Characteristics

of Wing-Body Combinations Near the Speed of Sound," NACA Report 1273, Langley

Aeronautical Laboratory, Langley Field, Virginia, 1956, pp. 1, 20-21; Whitcomb,

interview, March 27, 1973; Whitcomb, "Research on Methods for Reducing

the Aerodynamic Drag at Transonic Speeds," p. 3.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 139

The Pieces of the Puzzle: Creative Innovation

Although the pieces may have come together in a flash of insight, there

were actually several important elements and processes that contributed

to Whitcomb's discovery. Whitcomb had developed a reputation as something

of a "Wunderkind" at Langley because of his unique combination of knowledge

and intuition about airflows; a combination that undoubtedly contributed

to his discovery of the area rule. 12

The intuition may have been a gift, but his knowledge of airflow behavior

was certainly enhanced by his seven years of experience working with Langley's

8-foot wind tunnel.

The discovery of the area rule concept was also dependent on the previous

invention of the slotted-throat tunnel design. Without that piece of technology,

Whitcomb could not have gathered the information necessary to understand

the causes of transonic drag. In fact, the very existence of the wind tunnels

at Langley was a critical factor in allowing a new approach in design to

surface and be tested. If the information had to be obtained through an

elaborate, expensive flight test program, fewer ideas could have been investigated,

and Whitcomb might not have had the opportunity to test his innovative

theory.

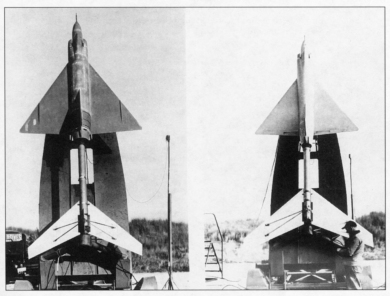

|

| At Wallops Station, in tidewater Maryland, in 1953,

Langleys Pilotless Aircraft Research Division (PARD) tested rocket-powered

models of the delta-winged Convair F-102 before, (left) and after (right)

modification to take advantage of Whitcomb's "area rule. " (NASA Photo). |

12. Eugene S. Ferguson, Engineering and the Mind's Eye (Cambridge,

MA: MIT Press, 1992), p. 54; Hansen, Engineer in Charge, p. 332.

140 THE WHITCOMB AREA RULE: NACA AERODYNAMICS RESEARCH AND INNOVATION

In addition, the projects conducted at Langley were still fairly small,

individual research efforts that allowed for experimentation. This kind

of atmosphere, while not entirely unique among government-funded facilities

in the early 1950s, was becoming more unusual. At one time, individual

or small-group research efforts had characterized many research laboratories.

But the exponential growth of technology and complex technological research

during World War II began to change that. The Manhattan Project, responsible

for the development of the atom bomb, symbolized for many a significant

shift in technological research from small, independent projects conducted

by single laboratories to large, complex research programs involving many

people, broad resources and funding, and multiple disciplines.13

In a bigger and more complex research environment, with approvals and

decisions dependent on higher-level program managers, Whitcomb might not

have had the latitude or opportunity to develop and test the area rule

concept. But the NACA Langley environment offered a middle ground between

a small, independent laboratory and a large research program. Whitcomb

had expensive technological tools at his disposal, such as the slotted-throat

wind tunnel, but he still had the independence and flexibility to develop

and test a radical new concept on his own.14

Whitcomb was also assisted by the informal management environment and

the orientation toward experimental research at the Langley Research Center,

both of which were conducive to individual innovation. As John Becker explained

in his case histories of four NACA programs,

Management (at Langley) assumed that research ideas would

emerge from an alert staff at all levels.... On a problem of major proportions

such as transonic facilities, any scheme for research that survived peer

discussions and gained section and division approvals was likely to be

implemented ... and very little (paperwork) was required in the simple

NACA system. Occasional chats with his division chief or department head,

or a brief verbal report at the monthly department meeting were about all

that was required of the NACA project engineer.15

This kind of environment was particularly well-suited to an introspective

thinker like Whitcomb. Managers knew he was a talented aerodynamicist,

and they were wise enough to keep his paperwork to a minimum and give him

the space and freedom to think, experiment, and explore.16

Langley's orientation toward hands-on, experimental research was a significant

factor in Whitcomb's discovery, as well. As opposed to research centers

that focused more on theoretical research, Langley encouraged exploratory

experiments such as the wind tunnel tests Whitcomb devised to investigate

wing-body combinations and airflow at transonic speeds. The breakthrough

on the transonic wind tunnel itself, in fact, was a result of a researcher

asking himself, "I wonder what would happen if I turned up the power?"

That simple question "I wonder what would happen if. . ." instigated numerous

experiments at Langley that , in turn, led to significant discoveries.

17

13. James H. Capshew and Karen A. Rader, "Big Science: Price to the

Present," OSRIS, 2nd series 7 (1992): 19; Thomas P. Hughes, American

Genesis: A Century of Invention and Technological Enthusiasm (New York,

NY. Penguin Books, 1989), pp. 440-42.

14. John V Becker, The High-Speed Frontier: Case Histories of Four

NACA Programs. 1920-1950 (Washington, DC: NASA SP-445, 1980), pp. 117-18.

15. Ibid.

16. Hansen, Engineer in Charge, p. 341.

17. Whitcomb, interview, May 2, 1995; information on transonic wind

tunnel development also in Hansen, Engineer in Charge, p. 322; and

in Ch. 1 of this book.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 141

This curiosity-driven, experimental approach was especially significant

in discovering the area rule, because there was no available theory to

explain the unusual drag encountered at transonic speeds. Researchers had

to come up with a creative way of reaching beyond the known, and the exploratory

experiments conducted by Whitcomb and others yielded the data that allowed

him to understand the cause of the transonic drag and shockwave phenomena.

Conducting hands-on experiments with an aircraft model in a wind tunnel

also helped Whitcomb "see" the airflow behavior in a way mathematical formulas

would not have.

Still, these factors only provided the tools and environment that made

Whitcomb's discovery possible. The breakthrough still required the insight

of a creative mind; a mind able to "see" the problem and able to step back

from accepted rules of design to contemplate a solution based on an entirely

new approach. The process by which Whitcomb was able to do that offers

insight itself as to how scientific or technological innovation occurs.

Science and technology are often viewed as fields completely divorced

from any of the arts. Common phrases that distinguish something as "a science,

not an art" and describe "the scientific method" as a way to discern an

unassailable truth indicate our collective view of science as a rational,

logical, linear, mathematical and precise process. Yet since almost the

beginning of time, artistic vision has played a critical role in the advancement

of technology and science. Undoubtedly, even the first cave dweller to

invent the wheel first had a picture in his or her mind of what the device

would look like.

Albert Colquhoun, a British architect, asserted that even scientific

laws are "constructs of the human mind," valid only as long as events do

not prove them wrong, and applied to a solution of a design problem only

after a designer develops a vision of the solution in his head.18

This artistic vision becomes even more important when a scientist or engineer

needs to go beyond the leading edge of knowledge, where existing theories

cease to explain events. At this point, a designer's imagination is critical

in

envisioning potential new solutions. As one analyst of technological development

said, "The inventor needs the intuition of the metaphor maker, some of

the insight of Newton, the imagination of the poet, and perhaps a touch

of the irrational obsession of the schizophrenic."19

Whitcomb was not the only person to look at the problem of transonic

drag. As early as 1944, German aerodynamacist Dietrich Kuchemann had designed

a tapered fuselage fighter plane that was dubbed the "Kuchemann Coke Bottle"

by American intelligence personnel. Kuchemann's design was not aimed at

smoothing the curve of the cross sectional area to displace the air less

violently, however. He had simply observed the direction of air flow over

a swept-wing design and was trying to design a fuselage that would follow

the contours of that flow.20

Whitcomb's area rule was also, in retrospect, said to be implicit in

a doctoral thesis on supersonic flow by Wallace D. Hayes, published in

1947. But the mathematical formulas employed by Hayes, as well as several

other researchers working on the general problem of transonic and supersonic

air flows, did not lead their creators to the necessary flash of inspiration

that crystallized the area rule for Whitcomb. Why didn't they see what

Whitcomb did? The answer, in part, may lie in the precise fact that they

were working with mathematical formulas, instead of visual images. The

answer may have been imbedded in the numbers in front of them, but they

couldn't see it.

18. Ferguson, Engineering and the Mind's Eye, p. 172.

19. Hughes, American Genesis, p. 76; Hansen, Engineer in

Charge, p. 311; Ferguson, Engineering and the Mind's Eye, pp.

172-73.

20. David A. Anderson, "NACA Formula Eases Supersonic Flight," Aviation

Week & Space Technology 63 (September 12, 1955): 13.

142 THE WHITCOMB AREA RULE: NACA AERODYNAMICS RESEARCH AND INNOVATION

What led to Whitcomb's insight was his talent to see and work with visual

metaphora skill described by Aristotle as a "sign of genius" and an important

tool for seeing things from a fresh perspective, or discovering new truths

about existing objects or ideas.21

In his history of American technological progress, Thomas Hughes also stressed

the importance of visual metaphors in developing innovative ideas, noting

that "although they are articulated verbally, the metaphors of inventors

have often been visual or spatial. Inventors, like many scientists, including

Albert Einstein, Niels Bohr, and Werner Heisenberg, show themselves adept

at manipulating visual, or nonverbal, images." 22

When Adolf Busemarm used his "pipefitting" metaphor to describe the

behavior of transonic air flow, Whitcomb painted a vivid picture in his

mind of air "pipes" flowing over an aircraft. He then incorporated into

that image the other information he had obtained through his experiments

with transonic air flow. Suddenly, he "saw" what was causing the unusual

shock waves and what could be done to combat the problem.

In order to see a solution that went beyond existing theory, however,

Whitcomb also had to be willing to break free from accepted rules, or paradigms,

of aerodynamics.23 In the late nineteenth

century, Ernst Mach had shown that a bullet-shaped body produced less drag

in flight than any other design. This accepted "paradigm" of aircraft design

led to the basic fuselage shape employed by transports, World War II fighter

planes, and even the Bell X-1 rocket plane. It was also still the accepted

rule of thumb as engineers began to design the first turbojet-powered supersonic

aircraft. The assumption that a bullet-shaped fuselage was the most efficient

aerodynamic shape, however, led researchers to look elsewhere for elements

that could be modified to reduce the drag of aircraft at transonic speeds.

To see the solution that Whitcomb envisioned indenting the fuselage in

the area of the wing to reduce the dramatic changes in the aircraft's overall

cross-sectional area from nose to tail required going against a "truth"

that had worked and had been accepted for over fifty years.

The same paradigm that had helped advance aircraft design for half a

century became, ironically, one of the barriers that kept researchers from

advancing aircraft design beyond subsonic flight. Why was Whitcomb able

to step back and consider an approach that broke this accepted rule? For

one thing, the circumstances required it. Kuhn noted that "the failure

of existing rules is the prelude to a search for new ones."24

Certainly, the stubborn problem of transonic drag presented Whitcomb with

a situation where existing theories and rules were not working.

Secondly, Kuhn observed that "almost always, the men who achieve ...

fundamental inventions of a new paradigm have been either very young or

very new to the field whose paradigm they change ."25

When he came up with the area rule concept, Whitcomb was only 30 years

old. Possibly, the fact that he had not spent twenty years designing bullet-shaped

fuselages contributed to Whitcomb's ability to conceive of a different

design. He was also something of an introspective thinker and individualistic

researcher, which may have made him more able to contemplate a "fringe"

idea that broke from his peer group's assumptions. In any event, Whitcomb

was willing to step back from accepted truths and

21. Aristotle, Poetics, translated by Ingram Bywater, in The

Rhetoric and the Poetics of Aristotle (New York: Random House, 1954),

p. 255.

22. Hughes, American Genesis, p. 82.

23. Thomas Kuhn described paradigms as "familiar notions," or "examples

that provide models from which spring particular coherent traditions of

scientific research." On the one hand, these accepted notions can help

lead to more detailed further research in a particular area. But Kuhn cautioned

that paradigms could also insulate the research community against seeing

new solutions. From: Thomas S. Kuhn, The Structure, of Scientific Revolutions,

2nd ed., Foundations of the Unity of Science Series: Vol. II, Number 2

(Chicago: University of Chicago Press, 1970), pp. 10-11, 24, 37.

24. Ibid., p. 68.

25. Ibid., p. 90.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 143

simply look at what his data was showing him; paint a visual picture

of it in his mind and see not what he expected to see, but what was really

there.

While this may seem a simple and obvious solution to outsiders with

forty years of hindsight, Whitcomb's ability to break free of the design

doctrines that dominated aeronautics in his day was, in fact, a unique

and remarkable ability that truly set him apart from many others in his

field. Once someone comes up with an answer, it often seems obvious. But

the researchers struggling with transonic drag were not aware they were

caught in a paradigm that did not work. They were focused on trying to

cut a workable path through a dense forest they knew as real and immutable.

Whitcomb's genius was his ability to see that the problem was not the path,

but the forest itself.

From Idea to Application

When Whitcomb presented his concept of the area rule to some of his

colleagues at Langley, he encountered skepticism. After all, it was a radical

approach to aircraft design. But division chief John Stack still allowed

Whitcomb to present the idea at the next technical seminar. And listening

to Whitcomb's presentation, this time, was Adolf Busemann, whose stature

in the aerodynamics community was such that his opinion carried a great

deal of weight. Busemann, whose visual pipefitting metaphor had provided

the catalyst to Whitcomb's discovery, understood what Whitcomb had seen.

He told the others present that Whitcomb's idea was "brilliant." The skepticism

among some of the others, including Stack, remained. But the support from

Busemann was enough to get Whitcomb the go-ahead to test his theory.26

Throughout the first quarter of 1952, Whitcomb conducted a series of

experiments using various area-rule based wing-body configurations in Langley's

8-Foot High-Speed Tunnel. As he expected, indenting the fuselage in the

area of the wing did, indeed, significantly reduce the amount of drag at

transonic speeds. In fact, Whitcomb found that "indenting the body reduced

the drag-rise increments associated with the unswept and delta wings by

approximately 60 percent near the speed of sound," virtually eliminating

the drag rise created by having to put wings on a smooth, cylindrical shaped

body.27

In a simple world, this validation of Whitcomb's theory would have been

sufficient for the principle to be applied to all new industry designs.

All that would have been necessary would have been to notify the aircraft

manufacturers that a better design approach had been developed. The world

is not that simple, however, and the inherent worth of an innovation is

rarely enough for it to be incorporated into commercial products. As Louis

B.C. Fong, director of the Office of Technology Utilization at NASA (National

Aeronautics and Space Administration) commented in 1963, "In this age of

automation, there is nothing automatic about the transfer of knowledge

or the application of an idea or invention to practical use ... there is

resistance to new ideas and new technologies; part psychological, part

practical ... and often economic."28

26. Whitcomb, interview, May 2, 1995; Hansen, Engineer in Charge,

p. 336.

27. Whitcomb, "A Study of the Aero-Lift Drag-Rise Characteristics of

Wing-Body Combinations Near the Speed of Sound," pp. 20-21.

28. Louis B.C. Fong, Dir., NASA Office of Technology Utilization, "The

NASA Program of Industrial Applications," address at the Third National

Conference on the Peaceful Uses of Space, Chicago, IL, May 8, 1963, NASA

Historical Reference Collection, NASA History Office, NASA Headquarters,

Washington, DC.

144 THE WHITCOMB AREA RULE: NACA AERODYNAMICS RESEARCH AND INNOVATION

NACA or NASA engineers tend to measure the success of a new idea or

technology strictly in terms of technical objectives met. Industry, on

the other hand, measures innovative success in terms of profit dollars

generated within a specified payback period.29

Consequently, a new approach or technology, even if it is technically "better,"

may be rejected by industry if its use involves extra costs for the manufacturer.

These costs can be in retooling for a new design, replacing machinery,

or even in retraining employees or changing the traditional ideas and approaches

of its engineers. All of these factors can produce resistance to a new

idea or technology within a company, and overcoming that resistance can

be a difficult process.30

There are a couple of situations in which new technology may be rapidly

assimilated into commercial products, however. One is if it can be incorporated

with minimal extra cost, and a second is if it solves a problem that a

manufacturer needs to solve.31 When

Whitcomb developed his area rule, there was a manufacturer in each of these

situations, and that fact played a significant role in the speed with which

his innovation began to impact the design of new aircraft.

While Whitcomb was conceiving and testing his area rule concept, the

Convair Division of General Dynamics was developing what it hoped would

be the company's first supersonic aircraft. The Convair F102 "Delta Dagger"

was designed to be a long-range interceptor, with delta wings and the most

powerful turbojet engine available at that time, the Pratt & Whitney

J-57. Early test results of an F-102 model in Langley's 8-Foot High-Speed

Tunnel, however, seemed to indicate that the design's transonic drag might

be too high for the aircraft to surpass Mach One.

The NACA had immediately classified any information pertaining to the

area rule, as it had the research on the slotted throat wind tunnel that

allowed the area rule to be developed. In 1952, the United States was engaged

in heated and high-stakes competition for military superiority with the

Soviet Union, and NACA realized the importance of transonic research in

developing superior military aircraft. Although the classification was

necessary, it made dissemination of information about the area rule more

difficult. Fortunately, NACA's history of successful technology transfer

efforts had been less a product of published writings than the various

levels of informal NACA-industry cooperation and researcher-to-engineer

discussions.32 The area rule would

prove no exception.

In mid-August 1952, a group of Convair engineers were at Langley to

observe the performance of the F102 model in the Eight-Foot High-Speed

Tunnel. Shown the disappointing test results, the engineers asked the Langley

engineers if they had any suggestions. Whitcomb's first research memorandum

on the area rule would not be published for another month, but he had completed

his tests on the various wing-body combinations using indented fuselage

shapes. He explained his findings and the area rule concept to the Convair

team.

Intrigued, the Convair engineers worked with Whitcomb over the next

few months to experiment with modifying the F-102 design and building a

model that incorporated the area rule concept. At the same time, however,

the company continued work on the original F-102 prototype. The engineers

may have been open to exploring a possible new

29. Denver Research Institute, "NASA Partnership with Industry: Enhancing

Technology Transfer," NASA CR-180-163, July 1983, pp. xx, Appendix D-3;

William D. Mace and William E. Howell, "Integrated Controls for a New Aircraft

Generation," Astronautics & Aeronautics 16 (March 1978): 48-53.

30. Denver Research Institute, "NASA Partnership with Industry," pp.

xx, Appendix D-3; R. P. Schmitt, et al., "Technology Transfer Primer,"

Wisconsin University-Milwaukee, Center for Urban Transportation Studies,

FHWA/TS-84/226, July 1985, pp. x, 1-5.

31. Schmitt, et al, "Technology Transfer Primer," p. 5.

32. Denver Research institute, "NASA Partnership with Industry," p.

xiv.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 145

option, given the uncertainty produced by the wind tunnel tests of the

original F-102 model, but the company had already made a commitment to

the Air Force to build two prototypes of the original F-102. In addition

to any mental and institutional resistance Convair might have had to changing

a design which it had touted so highly and had already made a commitment

to build, the company's commitment also created an issue of cost.

By mid-1952, when Convair tested the F-102 model at Langley, the company

had already begun setting up a production line at its San Diego, California,

facility for manufacturing the aircraft. To change the design would mean

not only delays and additional engineering costs, but revamping the production

line, as well. Consequently, far from being receptive to a new design approach,

Convair had a significant stake in proving that its new aircraft could

perform just fine without it. 33

Nevertheless, the company could not totally ignore the doubtful test

results of its original design, so its engineers began working on a "Plan

B" with Whitcomb while production of the prototype F-102s continued. Starting

in May 1953, the Convair engineers and Whitcomb began testing models of

a modified, area rule-based, F-102 design in Langley's wind tunnel. By

October 1953, they had developed a model that could meet the Air Force

performance specifications. Convair noted the results but continued working

on the original F-102 prototype, which flew for the first time on October

24, 1953. 34 The first prototype was

severely damaged on its maiden flight, so test flights had to be postponed

until January 11, 1954, when the second prototype flew for the first time.

The results of the flight tests, however, proved to be largely the same

as those predicted by the wind tunnel tests of the F-102 model in 1952.

The aircraft performed below expectations and could not attain supersonic

speeds in level flight. 35

Even at that point, Convair might have continued to press for production

of the design as it was, given that the tooling and production line in

its San Diego plant was already set, except for one crucial factor. The

Air Force officials working on the F-102 design were aware of Whitcomb's

area rule and the fact that a modified F-102 model, based on that concept,

had achieved supersonic speeds in wind tunnel tests. Consequently, the

Air Force realized that the F-102 was not the best that Convair could do.

Whitcomb's experiments had proven that a supersonic airplane was possible,

and the Air Force decided to settle for no less. The F-102 program manager

at Wright Field in Ohio informed Convair that if the company did not modify

the F-102 to achieve supersonic flight, the contract for the fighter/interceptor

would be cancelled. 36

Incorporating Whitcomb's innovative design approach involved extra expense,

but nothing compared to the cost of losing the entire F-102 contract. Convair

immediately halted the F-102 production line and began working on the modified

design Whitcomb and the company engineers had developed and tested. In

only 117 working days, the company had built a new, area rule-based prototype,

designated the F-102A. The F-102A flew for the first time on December 24,

1954, and surpassed the speed of sound not only in level flight, but while

it was still in its initial climb. The area rule had improved the speed

of the F-102 design by an estimated twenty-five percent. 37

33. Donald D. Baals and William R. Corliss, Wind Tunnels of NASA

(Washington, DC: NASA SP-440, 1981), p. 62; Hansen, Engineer in Charge,

p. 337; Whitcomb, interview, May 2, 1995.

34. Bill Gunston, ed., The Illustrated History of Fighters (New

York, NY. Simon and Schuster, 1984), p. 194.

35. Baals and Corliss, Wind Tunnels of NASA, p. 63.

36. Whitcomb, interview, May 2, 1995; Whitcomb, "Research on Methods

for Reducing the Aerodynamic Drag at Transonic Speeds," November 14, 1994;

Hansen, Engineer in Charge, pp. 337-39.

37. Baals and Corliss, Wind Tunnels, of NASA, p. 63; Hansen,

Engineer

in Charge, p. 338; Whitcomb, interview, May 2, 1995.

146 THE WHITCOMB AREA RULE: NACA AERODYNAMICS RESEARCH AND INNOVATION

While Convair was struggling with its F-102 design, the Grumman Aircraft

Engineering Corporation was also working to develop its first supersonic

carrier-based fighter, the F9F/F-11F Tiger.38

Although the area rule research was classified, the NACA released a confidential

Research Memorandum on the subject to appropriately cleared aircraft manufacturers

in September 1952. Just two weeks after receiving that memorandum, Grumman

sent a group of its engineers to Langley to learn more about it. The information

they brought back to Bethpage, New York, was immediately incorporated into

the design, and in February 1953, Whitcomb was flown in to review the final

design plans before construction on the prototype was begun. On April 27,

1953, the Navy signed a letter of intent with Grumman for the fighter,

based on the Whitcomb-approved design. On August 16, 1954, the Grumman

F9F-9 Tiger "breezed" through the sound barrier in level flight without

the use of the afterburner on its Wright J-65 turbojet engine.39

The enthusiastic incorporation of Whitcomb's innovation by Grumman stands

in stark contrast to the qualified experimentation and resistance that

characterized Convair's response. But the two companies were in different

situations. Convair had already completed a design for the F-102 and had

begun construction of two prototypes and a production line. Grumman, on

the other hand, was still working to design the F11F Tiger when Langley

published its confidential report on Whitcomb's area rule breakthrough.

It was the perfect time to incorporate a better design idea, and involved

few extra costs to the company. At the same time, the Navy had not yet

contracted for the fighter, and Grumman may well have recognized that its

chances of winning the contract would be improved by incorporating any

available new technology into its design; especially something that might

improve its speed.

In any event, Whitcomb's innovative idea was incorporated into two production

military aircraft only twenty-four months after he completed his initial

wind tunnel tests on the concept. This incredibly "successful" example

of technology transfer was a result of two important factors. First and

foremost, there was a "problem looking for a solution" 40

that the area rule was able to solve. Transonic drag was a real and seemingly

unsurmountable obstacle to supersonic flight. Whitcomb's area rule was

not one of a number of potential solutions; it was the only approach anyone

had developed that had proven itself capable of overcoming that barrier.

It also had the backing of a very powerful customer: the United States

military. When the Air Force decided to hold firm on its demand that Convair's

aircraft fly supersonically in level flight, Convair could not simply sell

its F-102s to another customer. The Air Force was its only client, just

as the Navy was for Grumman.

But another important element, especially with regard to Convair, was

the cooperation and individual relationships that existed between the Langley

researchers, including Whitcomb, and the industry engineers. The modified

F-102A model that proved to the Air Force that a fighter could achieve

supersonic flight was a cooperative effort between Whitcomb and Convair

engineers. Without that cooperation, or the informal discussions at Langley

that launched that work, the fate of the F-102 might have been different.

38. The prototype was designated first as the F9F-8, and then as the

F9F-9, although the original Grumman F9F-2 design was the straight-wing

Pantherjet, and the F9F-6 was the swept-wing Cougar. The Tiger was really

an unrelated design, but the prototypes were still labeled as variants

of the F9F design. The production model Tigers, however, were called F11Fs.

39. Michael J.H. Taylor, ed., Jane's Encyclopedia of Aviation

(New York, NY Portland House, 1989), pp. 447-48; Gunston, Illustrated

History of Fighters, p. 192; Hansen, Engineer in Charge, pp.

339-40.

40. Numerous NASA and industry engineers, including Whitcomb himself

(Whitcomb, interview, March 27, 1973), have used this phrase to describe

the kind of situation that tends to lead to quick acceptance of a new technology.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 147

The area rule undoubtedly would have been incorporated into aircraft

designs eventually, regardless of the individuals involved. But that timeframe

could have been different, which could have had an impact on the kind of

air defenses the United States had at its disposal in the early days of

the Cold War.

As it was, the success of the area rule-based F-102 and F11F was followed

by the incorporation of the area rule in virtually every supersonic aircraft

built after that point. The Vought F8U "Crusader" fighter and the Convair

B-58 "Hustler" bomber, both of which were on the drawing board at the time

the area rule was developed, were redesigned using Whitcomb's approach.

The F-106, which was Convair's follow-on design to the F-102A, adhered

even more to the area rule. It was able to incorporate a much deeper indentation

in the fuselage than its predecessor, because it was an entirely new aircraft,

unencumbered by existing design elements.

The fuselage of the Republic F-105 "Thunderchief" fighter/bomber, which

flew for the first time in 1955, incorporated the area rule in a slightly

different manner. It could not be indented because of its complex engine

inlets, so a bulge was added to the aft region of the fuselage to reduce

the severity of the change in the cross sectional area at the trailing

edge of the wing. The Rockwell B-1 bomber and the Boeing 747 commercial

airliner also used the addition of a cross-sectional area to reduce their

drag at transonic speeds. Both the B-1 and the 747 have a vertical "bump"

in the forward section of the fuselage ahead of the wing. It is perhaps

more visible in the 747, where it houses the airliner's characteristic

second story, but both airframe modifications were added to smooth the

curve of the design's crosssectional area .41

The Collier Trophy

Whitcomb's Area Rule research was classified until September 1955, so

he did not receive any immediate accolades or press on his discovery. But

two months after his work was made public, Whitcomb received the National

Aeronautic Association's Robert J. Collier Trophy in recognition of his

achievement the previous year, when the Grumman F9F-9 Tiger and the Convair

F-102A prototypes demonstrated just how significant the area rule was.

The Collier Trophy citation read, "For discovery and experimental verification

of the area rule, a contribution to base knowledge yielding significantly

higher airplane speed and greater range with the same power. " 42

Conclusion

Although an engineering design approach using formulas or algorithms

does not lend itself to the kind of notoriety that a project like the X-1

generated, the development of the area rule was no less significant. The

X-1 proved the sound barrier could be broken. The area rule made that discovery

practical by enabling production aircraft to operate at that speed.

The fact that the area rule was discovered by an engineer sitting with

his feet up on his desk, contemplating a vision in his mind, also shows

the importance of creativity and the individual in advancing technology.

Postwar science and research projects may have been growing in complexity

and size, but Whitcomb's discovery was a reminder that the

41. Whitcomb, interview, May 2, 1995; Whitcomb, "Research on Methods

for Reducing the Aerodynamic Drag at Transonic Speeds," November 14, 1994,

p. 3.

42. Bill Robie, For the Greatest Achievement: A History of the Aero

Club of America and the National Aeronautic Association, (Washington,

DC: Smithsonian Institution Press, 1993), p. 232; Richard T. Whitcomb,

telephone interview with author, May 15, 1995.

148 THE WHITCOMB AREA RULE: NACA AERODYNAMICS RESEARCH AND INNOVATION

individual researcher was more than a cog in a scientific, process-driven

wheel. Experimentation and the visions in the mind of an individual able

to put available information together in a new way have led to many innovative

"breakthroughs" in technology and knowledge.

The history of the area rule research also illustrates that even a "breakthrough"

discovery does not always win immediate acceptance by those who might implement

it. As opposed to projects that were wholly funded, developed and implemented

by the NACA and its successor, the National Aeronautics and Space Administration

(NASA), or other government agencies, Whitcomb's breakthrough was just

an idea. It may have been developed at a NACA laboratory, but it was not

up to NACA to apply it. In order for the innovation to have any impact

at all, industry had to agree to use it, which is not always as simple

a process as it might seem. Whitcomb's area rule was the answer to a tremendous

problem that industry needed to solve, but the enthusiasm with which it

was received differed greatly between Convair and Grumman. The advantages

offered by the innovation were the same; the costs of implementing it differed.

But even in the application of the area rule concept, individuals played

an important role. An Air Force demand was the primary reason Convair incorporated

the area rule into the F-102, despite the added cost. But the Air Force

might not have had the confidence to make that demand if it had not been

for the model work performed by a small number of individuals at Langley

and Convair. As scientific and engineering research and projects became

more expensive, complex, and systems-oriented, it was easy to lose sight

of the individuals that made those systems work. Richard T. Whitcomb, in

developing and helping to win acceptance for a concept that revolutionized

high-performance aircraft design, was a reminder that the individual still

mattered.