|

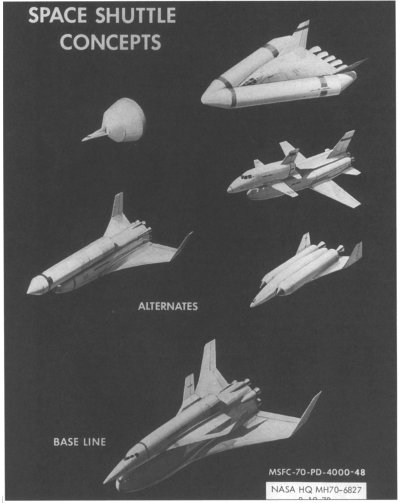

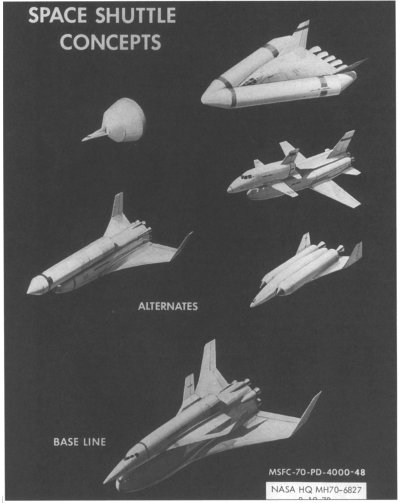

| Possible configurations considered for the Space Shuttle as of 1970. (NASA photo). |

The Space Shuttle's First Flight: STS-1

by Henry C. Dethloff

The first mission of the space transport system (STS-1) or Space Shuttle, flew on April 12, 1981, ending a long hiatus in American space flight. The last Apollo lunar mission flew in December 1972, and the joint American Russian Apollo-Soyuz Earth orbital mission closed in July 1975. The National Aeronautics and Space Administration (NASA) intended that the shuttle make that permanent link between Earth and space, and that it should become part of "a total transportation system" including "vehicles, ground facilities, a communications net, trained crews, established freight rates and flight schedules and the prospect of numerous important and exciting tasks to be done." It was to be "one element in a grand design that included a Space Station, unmanned planetary missions, and a manned flight to Mars."1

Awarded the Collier Trophy (in a tradition that began in 1911), the flight of STS-1 represented the greatest achievement in aviation for 1981. NASA, Rockwell International, Martin Marietta, Thiokol, and the entire government/industrial team responsible for the design, construction, and flight of the spacecraft, as well as the crew of the shuttle, John Young, Robert Crippen, Joe Engle, and Richard Truly, were all recipients of that award. Since 1962, NASA aerospace projects, including Mercury, Gemini, Apollo, Landsat, and Skylab, had received ten of the twenty Collier awards. Now, the eleventh in twenty years went to a NASA team that had designed and flown something remarkably different from those previous craft. For the Space Shuttle was a true aerospace craft, a reusable vehicle that could take off from the Earth, enter and operate in space, and return to an Earth landing. N. Wayne Hale, a missions flight director for the shuttle, likened it to a battleship, which while it may have only a few aboard, nevertheless had a crew of thousands stationed around the world and linked by Mission Control. Owen Morris, the Engineering and Systems Integration Division head for the shuttle Program Office, described the shuttle as a particularly complex, integrated machine and an enormous engineering challenge.2

Although it flew its maiden voyage only in 1981, NASA's shuttle program began many years earlier and predated Apollo. In the late 1950s, as human space flight began to be seriously considered and planned, most scientists and engineers projected that if space flight became a reality it would build upon logical building blocks. First, a human would be lofted into space as a passenger in a capsule (project Mercury). Second, the passengers would acquire some control over the space vehicle (project Gemini). Third, a reusable space vehicle would be developed that would take humans into Earth orbit and return them. Next, a permanent Space Station would be constructed in a near-Earth orbit through the utilization of the reusable space vehicle. Finally, planetary and lunar flights would be launched from the Space Station using relatively low-thrust and reusable (and thus lower cost) space vehicles. The perception of what became the shuttle as that reusable space vehicle associated with an orbiting space station held fast well into the vehicle's developmental stages.

277

278 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

One of the known quantities in space flight was that the velocity required for a vehicle to escape earth's gravitational pull was only 1.41 times the velocity required to achieve earth orbit. The great costs associated with space flight included the cost of fuel used to achieve orbit, the cost of the expendable boosters and fuel tanks used to drive a space vehicle into orbit or into space, and the effective loss of the inhabited capsule or vehicle which, while it returned, could not be reused. Space quickly came to be an expensive business, and as it developed, the shuttle, more so than previous projects, was cost-driven, both in its incentives and in its construction. But because the nation's mission in space came to be to put an American on the Moon within the decade of the sixties, NASA's Apollo lunar program preempted both the Space Station and the shuttle. And, when the shuttle appeared without a Space Station to build and service, it appeared emasculated and detached from its intended purpose to some extent an aerospace plane without a space mission.

When did the Space Shuttle begin?

At what Point was it Created?

It could have been in March 1966, when a NASA planning team developed a statement of work for a "Reusable Ground Launch Vehicle Concept and Development Planning Study." Or it could have been at an Apollo applications conference held at the Manned Spacecraft Center (later the Lyndon B. Johnson Space Center) in Houston on October 27, 1966, when leaders of the Marshall Space Flight Center and the Manned Spacecraft Center agreed to pursue independent studies of a shuttle system along the lines of a March 1966 statement of work. Or most certainly a point of inception would be January 23, 1969, when George E. Mueller, NASA's Associate Administrator for Manned Space Flight, approved contract negotiations for initial shuttle design work .3 Or it could have been even much earlier.

Under the authority of House Resolution 496, approved March 5, 1958,

the House Committee on Science and Astronautics, chaired by Senator Overton

Brooks, Democrat of Louisiana, convened hearings designed to provide direction

and guidance for the creation of a new Federal agency that would head America's

space program. During those hearings many "experts" described the development

of space stations and "controlled space flight" as the prerequisites for

expeditions to the Moon and beyond. Brigadier General A. H. Boushey, Air

Force Director of Advanced Technology listed the development of spacecraft,

piloted by humans, as "the most important" of the goals which must receive

attention before there could be true exploration of space:

By piloted spacecraft, I refer to a vehicle wherein a pilot operates controls and directs the vehicle. This is quite a different concept from the so-called man-in-space Proposal which merely takes a human 'along for the ride' to permit observation of his reactions and assess his capabilities.4

Boushey believed that by the end of the decade of the 1960s, a large

Space Station could be assembled by piloted "space tugs," that would remain

in orbit throughout their useful life and operate only outside the atmosphere.

"In addition to the 'tugs,' manned

FROM ENGINEERING SCIENCE TO BIG SCIENCE 279

resupply and maintenance spacecraft will shuttle from the Earth's equator to the orbiting satellites." Subsequently, a piloted spacecraft that would refuel at the Space Station in Earth orbit, "will land on the Moon."5

T. F. Morrow, vice president of Chrysler Corporation, thought that space stations or platforms might come in later decades, but that by 1969 one could expect "space trips encircling the Earth and the Moon." Dr. Walter R. Dornberger, rocket expert for Bell Aircraft, expected to see "manned and automatic space astronomical observatories; manned space laboratories; manned and automatic filling, storage, supply and assembly space facilities; manned space maintenance and supply and rescue ships-all climaxed by the first manned flight to the Moon."6

Roy K. Knutson, Chairman, Corporate Space Committee for North American

Aviation, offered a much more exact definition for a "winged" space vehicle.

While a piloted capsule (such as Mercury) would take a person into space

and provide important physiological data, "Ultimately ... consideration

must be given to the problem of reentering the Earth's atmosphere from

orbit in a winged vehicle capable of landing at a designated spot under

control of a pilot."7 He viewed North

American Aviation's X-15 (then under development) as a forerunner of an

aerospace craft, and believed solving the reentry problem would be the

most crucial engineering task associated with developing a reusable shuttle.

He offered, in 1958, a remarkably clear description of what would one day

become the shuttle:

A large rocket booster would be used to boost the vehicle to high altitudes. Then a rocket engine installed in the ship itself would be ignited to provide further acceleration to the 25, 000 miles per hour required for orbiting. In a low trajectory, the vehicle would pass halfway around the Earth in 45 minutes. A retrorocket would start the ship out of orbit at perhaps 10, 000 miles from the landing point. As the vehicle enters the denser atmosphere, the nose and edges of the wing and tail will glow like iron in a blacksmith's forge. The structure will be built to withstand this extreme condition, however, and the pilot glide down to a dead stick landing.8

If not a point of inception, there was at least in 1958 a sense

of direction for the development of a reusable aerospace craft.

Even earlier, before the launch of the Soviet Sputnik satellite, scientists and engineers seriously discussed the construction and operation of space craft. Krafft A. Eriche, for example, presented "Calculations on a Manned Nuclear Propelled Space Vehicle" to the American Rocket Society in September 1957. In January 1957, NACA engineers on the staff of the Ames Aeronautical Laboratory at Moffett Field, California, filed a secret report on their "Preliminary Investigation of a New Research Airplane for Exploring the Problems of Efficient Hypersonic Flight." It was to be an aircraft considerably exceeding the performance levels of the X-15 with "a rocket boost ... to Mach numbers of the order of 10 and altitudes of the order of 140,000 feet."9

280 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

With the insight and direction provided by Congress, the experiences of National Advisory Committee for Aeronautics (NACA), and the American (and Canadian) aircraft industry, NASA set about after its inception in 1958 to provide the United States leadership in space exploration, space science, and space technology.10 But American successes in space seemed painfully gained, and slowly realized.

Not only had the Soviet Union launched the first satellite into orbit on October 4, 1957, but in 1959 Soviet rocket scientists launched three successful interplanetary craft into space. The second, Luna II impacted on the Moon in September; Luna III flew behind the Moon in October 1959. On April 12, 1961, Major Yuri Gagarin became the first person to "leave this planet, enter the void of space, and return." By 1961, with the encouragement of the Democratic Party campaign for the presidency, Americans had begun agonizing over the "missile gap." After the elections and the inauguration, on May 25, 1961, President John F. Kennedy and Congress set a new course for NASA, preempting existing developmental programs and schedules. The United States, before the decade is out, should land "a man on the Moon" and return him safely to Earth.11

The Apollo program became the leading effort. An orbital Space Station and Earth-to-orbit spacecraft, while they might contribute to a continuing presence in space and provide a platform for further lunar or planetary exploration, did not contribute to the short term goal of an American lunar landing within the decade. NASA readjusted its schedules and priorities to accommodate Apollo. The Space Station and the reusable aerospace craft remained viable, but future, options. Marshall Space Flight Center (MSFC), in particular, continued to study the reusable vehicle concept and as early as January 1963, developed a statement of work for a fully reusable rocket-powered vehicle that could carry civilian passengers, and a sizable payload. Marshall awarded independent contracts to Lockheed Aircraft and North American Aviation for design and development studies. But the NASA focus continued to be on Mercury, Gemini, and Apollo. By the end of 1963, the Mercury program ended. The last Gemini mission flew on November 11, 1966. NASA scheduled the first Apollo flight for December 5, 1965. An Apollo with a Saturn booster, which was to send Apollo on its lunar voyages, flew an unpiloted test on February 26, 1966. 12 It appeared likely through most of 1966 that the Apollo-Saturn lunar program was on schedule. Should NASA complete its mission to land a man on the Moon within the decade, what would happen next?

NASA began to address that issue by establishing an Apollo Applications Office, in 1966, that would devise programs to utilize Apollo technology in non-lunar programs. In October 1966, the annual meeting of the American Institute of Aeronautics and Astronautics focused on the question, "After Apollo, What Next?" And, in 1966, just as the Apollo-Saturn program seemed on the verge of success, Congress and the American public began to divert attention and public funds from space and NASA to the more urgent business of a growing war in Vietnam. The war, and money, began, even in the midst of Apollo, to turn NASA's attention to the "more practical" approach to space.13 More practical meant more efficient, less costly, more economic. Discussion of an orbital space platform or station, and a reusable Earth-to-orbit supply vehicle revived.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 281

Thus, in March 1966, a special NASA planning team developed a statement

of work for a reusable ground launch vehicle, and in October Marshall Space

Flight Center and the Manned Spacecraft Center agreed to pursue independent

study and research on such a spacecraft. NASA budgets, however, were becoming

increasingly constrained, and at a January conference at NASA Headquarters

administrators reluctantly agreed that there should be no new launch vehicle

development in order to reduce the budget problems. The year, 1967, passed

without any real progress in the development of a reusable spacecraft,

but financial pressures became greater rather than less. In January 1968,

George Mueller rekindled sentiments for work on a reusable spacecraft as

potentially a cost-saving measure:

Where we stand now is the feasibility generally has been established for reusability. And we have much data on many concepts. We have an uncertain market demand and operational requirements. The R&D costs for fully reusable systems, including incremental development approaches, appear high. Personnel and cargo spacecraft seem to dominate Earth-to-orbit logistics costs. R&D costs for new logistics systems are in competition with dollars to develop payloads and markets (dollars are scarce).14

Nevertheless, NASA put a decision for the development of a reusable

vehicle on hold.

Meanwhile, in collaborative sessions with the Air Force, which was independently studying orbiting laboratories and aerospace planes, NASA and Air Force engineers agreed on the need to develop a logistics space vehicle with a payload range of 5,000 to 50,000 pounds for use with a Space Station. Marshall and Manned Spacecraft administrators again conferred in October, and agreed to issue a request to NASA Headquarters for a joint Phase A (concept definition) study for a logistics space vehicle. Headquarters tentatively agreed to award a study contract, but withheld approval pending the results of the Apollo 8 flight.15

Apollo 8 was the first Apollo flight carrying "human cargo" powered by the Saturn rocket. Its original flight plan was to go into Earth orbit, but again MSFC and MSC combined to convince leaders at NASA Headquarters that Apollo 8 should be a circumlunar flight. Although perceived to be a "high risk" effort, Apollo 8, launched on December 28, 1968, put astronauts Frank Borman, James A. Lovell, Jr. and William A. Anders into ten orbits about the Moon, and returned them safely to Earth. That flight provided greater assurance of the probability of completing a lunar landing within the decade, and accelerated the need to commit to a post-Apollo program. On January 23, 1969, George Mueller approved contract negotiations for design work on what would become the Space Shuttle.16 Touchdown by Apollo 11 on the Moon's surface in July 1969 brought work on the shuttle into sharper focus. The question, "After Apollo, What Next?" needed to be answered soon.

President Richard M. Nixon appointed a Space Task Group to study the problem and offer options. Internal NASA studies complemented the work of the task group. On January 29, NASA awarded Phase A study contracts for elements of an "integral launch and reentry vehicle" (ILRV). Lockheed Missile & Space Company studied clustered or modular reusable flyback stages. General Dynamics/Convair examined expendable fuel tanks and solid propulsion stages. Both contracts were administered by Marshall. The Manned Spacecraft Center in Houston directed a study by North American Rockwell for expendable tank configurations coupled with a reusable spacecraft. McDonnell Douglas,

282 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

working under Langley Research Center supervision, examined tank, booster, and spacecraft ("triamese") configurations. Martin Marietta conducted an independent design study also submitted to NASA.17 Concurrently, a joint DOD/NASA study began on space transportation which would also go to the President's Space Task Group.

In October 1969, Congressman Olin E. Teague, Chairman of the House Committee on Science and Astronautic's subcommittee for NASA oversight, asked the Director of each NASA Center involved directly in the manned space flight program to review various "levels of effort" as they might affect future programs when measured against the Space Task Group recommendations. He requested an evaluation of the Space Task Group's preliminary recommendations that NASA focus on a reusable space craft and a permanent space station. And he requested personal letters from Dale D. Myers (Associate Administrator for Manned Space Flight), Robert R. Gilruth (Director of the Manned Spacecraft Center), Kurt H. Debus (Director of Kennedy Space Center), Eberhard Rees (Director of Marshall Space Flight Center), and Wernher von Braun (Deputy Associate Administrator), "setting forth their views on the importance of moving forward with the Manned Space Flight Program at this time."18

Dale Myers described the changing focus of the mission in space from the single purpose pursued in the Apollo program, to a broader effort to use space technology for the benefit of man. "In earth orbit, a space station supplied by the reusable shuttle will provide additional economic gains and practical benefits." They would facilitate a considerable expansion in space activities and increase the number of visitors into space.19

Robert R. Gilruth, Director of the Manned Spacecraft Center, responded that he firmly believed "that the reusable Space Shuttle and the large Space Station are vital elements which must be developed." He described the "earth-to-orbit shuttle" as "the keystone to our post-Apollo activities." Kurt Debus described the broad technology advances required for the development of a shuttle and Space Station, and noted that one cannot always identify the total utility of an innovation. Throughout history, he noted, innovations have been made without identifying all the uses and applications-he named the wheel, the telephone, the car, and the airplane as good examples. He advised proceeding now with the development of a fully reusable Space Shuttle, and the initiation of Phase B studies. Eberhard Rees wrote that the answer to the high costs of space transportation is to develop a system "which operates much like the cargo and passenger airlines, namely a Space Shuttle System."20

Wernher von Braun reviewed the accomplishments of the past decade, noting

that the space program thus far "brought renewed strength in national leadership,

in security, in education, and in science and technology, and in the will

of America to succeed."

... the key to our future accomplishments in space will be willingness to undertake the developments that will advance this nation to new plateaus of operational flexibility and will give us the technological advances needed to assure economical operations in space. No one would question the justification for a jet aircraft that can be flown over and over again instead of just once. With the Space Shuttle and the Space Station we will have the space age equivalent of the jet liner.21

FROM ENGINEERING SCIENCE TO BIG SCIENCE 283

|

| Possible configurations considered for the Space Shuttle as of 1970. (NASA photo). |

284 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

Robert F. Thompson, who became the Manned Spacecraft Center's Space Shuttle Program Director in April 1970, explained that the emphasis in the initial Phase A and DOD studies was to develop a fully reusable system, which he perceived at the time as the most cost-effective configuration, because of anticipated lower operating costs. However, as early as May 1969, the costs of developing fully reusable systems became ominous. By the end of the year NASA Headquarters shifted the Phase A studies to an emphasis on a combination of expendable and recoverable boosters coupled with reusable spacecraft. The Phase A reports were received in November 1969, and the DOD/NASA joint studies were completed in December 1970. Both the NASA internal studies and the DOD/NASA study continued to support a fully reusable spacecraft.22

In May 1970, NASA awarded Phase B contracts to a North American Rockwell and General Dynamics team and to a McDonnell Douglas and Martin Marietta team for definition studies of a fully reusable shuttle. But in June, contracts were awarded to the Grumman Aerospace and Boeing partners for studies of various expendable and reusable booster and fuel tank designs, to Lockheed to examine an expendable fuel tank for the orbiter, and to Chrysler for design study of a single stage reusable orbiter. There were other contracts to study various assemblies through the remainder of 1970.23 The year ended without a decision as to the design of the shuttle, but with a number of interesting options.

But the estimated costs of developing a fully reusable shuttle were rising, and costs soon became the decisive element, not only in the shuttle design, but in determining future NASA programs.

The development of a fully reusable shuttle was conservatively estimated to "require more than a doubling of NASA's budget, unrealistic at any time and particularly so in the light of increasing military expenditures in Southeast Asia." During congressional hearings on the FY 1971 NASA budget, NASA Comptroller Bill Lilly responded to questioning that if choices had to be made, the shuttle had to precede the Space Station because, "if they could not be developed concurrently, the shuttle in extended sortie, could act as a surrogate Station and the long term future of space flight lay in reducing the cost of all operations, but foremost in the cost of delivery to low Earth orbit."24 As will be seen, funding was tenuous throughout the development program. The decision on a fully, or even a partially, reusable shuttle apparatus was still pending.

Finally, on April 1, 1971, NASA directed that the Phase B contracts shift the emphasis from "fully reusable" to consider an "orbiter" with external expendable hydrogen tanks. James C. Fletcher, who had replaced NASA Administrator Thomas O. Paine in April, believed that whatever the technical merits of a fully reusable space vehicle might be, the $10.5 billion price tag currently assigned shuttle development simply would "not fly" with Congress. In June 1971, Max Faget, who headed MSC's Advanced Missions Program Office, presented an alternate configuration, that is, a two-stage shuttle with a drop tank orbiter. Administrator Fletcher accepted the configuration as NASA's choice, and on June 16, 1971, sent Congress a letter of decision. Studies of the new configuration with a fully reusable orbiter, and expendable or reusable external booster rockets and tanks, subsequently lowered estimated R&D costs to about $5 billion, or one-half that of the fully reusable vehicle. 25

The new partially reusable configuration involved the lowest development costs, but also enhanced the aerodynamics of the shuttle's orbiter, and safety. An internal tank

FROM ENGINEERING SCIENCE TO BIG SCIENCE 285

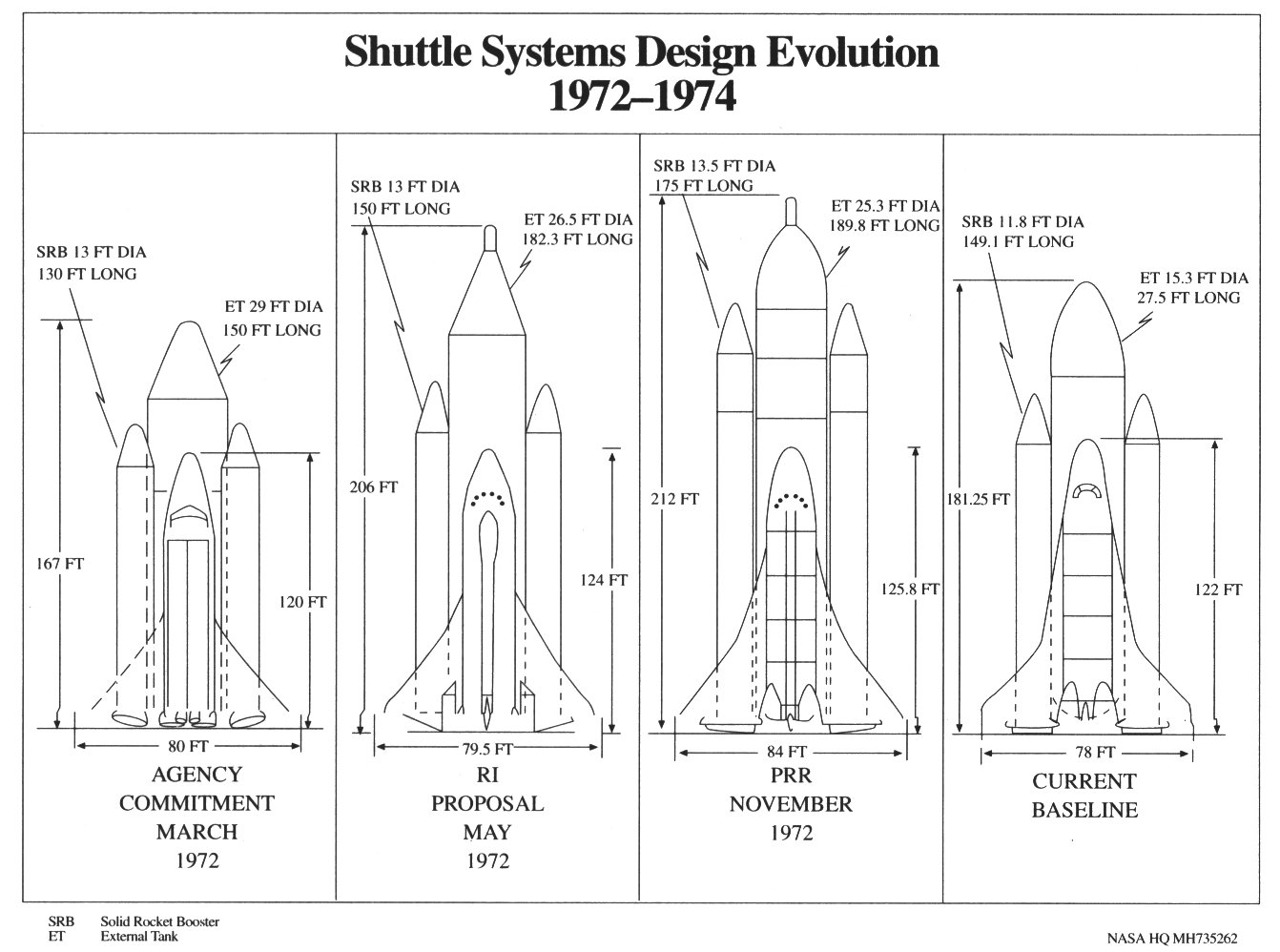

|

| Shuttle Design Evolution 1972-1974. |

design required heavy insulation of the spacecraft, much heavier launch weights, and flight difficulties resulting from tank torsion and "slosh." The very high pressure required in the fuel tanks also created higher risks and engineering and maintenance problems. 26 Refinement of the proposed new configuration took yet another two years. For the time, the solution seemed the best in terms of costs and technical development.

Despite NASA's June 1971 commitment to a reusable orbiter launched by an expendable or partially reusable propulsion system, there was no specific congressional funding for shuttle R&D. Shuttle funding came from general NASA spaceflight operations programs through FY 1973. Moreover, shuttle program expenditures had risen from $12.5 million in 1970 to $78.5 million in 1971 .27 Clearly, formal approval had to be secured or study on the shuttle project had to be terminated.

In June 1971, NASA's Associate Administrator for Manned Space Flight, Dale D. Myers, who had managed North American Rockwell's shuttle development work before he replaced George Mueller at NASA headquarters, assigned Marshall responsibility for development of the shuttle main engine and boosters, and the Manned Spacecraft Center responsibility for developing the orbiter. Throughout 1971 and into 1972, NASA extended the Phase B contracts, and awarded new ones to examine variously the use of existing Titan and Saturn rockets as shuttle launch vehicles, the feasibility of using liquid or solid propulsion boosters, and methods of recovering boosters and external tanks. In January 1972, Marshall Space Flight Center awarded contracts to Aerojet-General, Lockheed Propulsion Company, Thiokol Chemical, and United Technology Center to study the possibilities of using

286 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

existing 120-inch and 156-inch solid rocket motors as part of the shuttle booster system. 28 Preliminary and final reports confirmed the lower costs of the new shuttle configuration.

On January 5, 1972, Administrator Fletcher and Deputy Administrator George Low met with President Nixon and his staff assistant, John Erlichman, for a review of the shuttle program. Nixon approved the revised and less costly shuttle program, and wanted to stress both the civilian and the international aspects of shuttle development and future missions.29

Nixon's support for the shuttle, however, became hoisted on the petard of the growing difficulties in Vietnam, the proposed Air Force supersonic transport plane (SST) cancelled by Congress the previous year, and party politics. On January 7, Senator Edmund Muskie (D-ME), a Democratic candidate for the presidency, told Florida audiences while campaigning there that the Space Shuttle was an extravagance and should be shelved. Reflecting the sentiments of many Americans, the greater priorities of the nation, he said, were "hungry children, inadequate housing, decaying cities, and insecure old age." He accused President Nixon of practicing "pork barrel politics" by supporting the $5.5 billion space program. 30

Senator Walter Mondale (D-MN), another aspirant for president, called the Space Shuttle program "ridiculous" on a nationally televised debate. "At the present and known levels of space activity, to produce the Space Shuttle would be like buying a fleet of goldplated Cadillacs to go out and repair the tire of a Pinto.... It is not a new exploration weapon. It is simply a truck-a very expensive truck that is not worth the money."31

Senator William Proxmire (D-WI), who successfully led the fight against the SST in 1971, called Nixon's decision to go ahead with what he estimated to be the "$15.5" billion shuttle project, "an outrageous distortion of budgetary priorities." The President, Proxmire said, had chosen the Space Shuttle over schools, public health, housing, mass transit, open space, environmental needs and other vital programs.32 The space program also had powerful advocates in Congress, including Texas Congressman Olin E. Teague (and the entire Texas delegation), Mississippi Senator John C. Stennis, and Senator Stuart Symington of Missouri, among others. Nevertheless, the administrative decision to proceed with shuttle development rested upon Congressional approval and budgets. The future of the Space Shuttle seemed particularly tenuous in 1972 as Congress began the budget debates near the end of January.

Meanwhile, NASA increased its allocation for shuttle spending from $78 million in 1971 to $100 million for 1972 from its internal operations funds. In March 1972, Myers assigned the Manned Spacecraft Center in Houston "lead center" authority for overall Space Shuttle Program Development management and control. Robert F. Thompson, a member of the original Space Task Group at Langley Research Center (which became the nucleus of the Manned Spacecraft Center in Houston, Texas) continued as manager for the NASA-wide Shuttle Program Office. Thompson previously headed the Manned Spacecraft Center's Apollo Applications Program Office, concerned with postApollo planning.33

During 1971 and 1972, the Manned Spacecraft Center and Marshall Space Flight Center began to fold personnel from Apollo offices into the shuttle program. Under the duress of budget cutbacks, and tenure, and with the successful close of the Apollo program, many NASA administrators and engineers began to leave NASA. Wernher von Braun relinquished

FROM ENGINEERING SCIENCE TO BIG SCIENCE 287

the post of Director of Marshall Space Flight Center to Eberhard Rees in 1970. Robert Gilruth stepped down as Director of the Manned Spacecraft Center in January 1972. Chris Kraft, formerly head of Apollo flight operations, replaced him.34 At the very height of Apollo successes, NASA seemed to be imploding, while at the same time it redirected personnel and funds into the shuttle program. There were concurrent reductions in force and organizational realignments among NASA's aerospace contractors.

Although NASA had some 14 years of space flight experience behind it by 1972, the shuttle was something very new and very different from what had gone before. As Aaron Cohen, manager of the Orbiter Project Office in Houston explained, the "orbiter, although similar to Apollo in that it goes into space, is very different." The shuttle orbiter (which is usually identified in the public mind as the shuttle) is not simply a spacecraft, but a launch vehicle, a spacecraft, and an airplane combined. The transition from Apollo to shuttle, Cohen said, represented a transition of technology spanning ten years. There were major technological advances over Apollo in terms of materials, electronics, propulsion, and software. The launch configuration of the Space Shuttle was also different than had ever flown before. With Apollo the thrust was through the center of gravity, but with the shuttle the thrust was through the orbiter with an offset external tank. That configuration raised enormous problems with the structural dynamics of the assembly. In addition, whereas Apollo, Gemini, and Mercury launched from series burns, the shuttle utilized a parallel engine burn.35 Most significantly, perhaps, the shuttle engines, unlike the Saturn or Titan engines, were "throttlable," having a controlled engine burn.

Cohen stressed that certain technical elements of the shuttle were so advanced they were outside the existing state of the art." The controlled burn and the high pressures and temperatures at which the engines operated were an engineering challenge. Even to test the apparatus required innovative testing equipment and procedures. The thermal protection system involved the development of a heat-resistant tile that had never previously existed. Each individual tile fitted on the orbiter nose and underbody had to be individually designed and tested.36 One of the most highly sophisticated and advanced systems was the avionics (guidance, navigation, and control) system which fused electronics with aviation (hence avionics) and made the guidance and control systems responsive and complementary to human direction.

"The avionics system synchronized four centralized computers and had a single computer independent of the other four." The fifth computer was on standby to step in should there be a software problem in one of the other computers. The four synchronized computers, the "heart and brains" of the shuttle, "communicated with each other 440 times per second." One computer was the lead computer, the other three "voted" on the input and output of each other. "Should the three other computers disagree with the lead computer, it was voted out of the system." Air data, microwave sensors, gyros, accelerometers, star trackers, and inputs from ground based laboratories all fed into the avionics system.37 The shuttle avionics system represented revolutionary advances in electronics, computer technology, and guidance and control in the few short years since Apollo. Similarly, Apollo communications systems (using a unified S band) were inadequate to support shuttle missions.

Shuttle avionics systems were so advanced that special laboratories were required to design and develop them. NASA constructed a $630 million Shuttle Avionics Integration Laboratory (SAIL) at Johnson Space Center for the job. A special Shuttle Mission Simulator (SMS) trained crews to use the shuttle and fly missions in what is now popularly

288 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

termed a "virtual reality" setting. Astronauts returning from shuttle missions reported that the simulations were so accurate they felt they had flown the mission many times.38 Despite the advanced technologies used by the shuttle as compared to Apollo, Cohen believed that a permanent presence in space, that is the establishment of a Space Station, would require yet again major advances in new technologies.

New technologies were expensive. Research and development costs (R&D) grew rapidly. Inflation, which peaked at almost 13 percent in 1973, diminished appropriated funds and budgets proportionately. NASA and other government agencies were particularly affected by inflation because appropriations were approved in a previous year at fixed dollar levels. NASA found itself spending dollars that bought much less than anticipated. Congressional appropriations for NASA R&D declined by almost $450 million (15 percent) in 1971, and were reduced again in 1972 by another $40 million. R&D appropriations improved by about $80 million in 1973, but collapsed by over $400 million in 1974. During the most critical years of shuttle development, from 1971 through 1977, R&D appropriations remained remarkably stable. But the value of the dollars appropriated declined by about 50 percent in those five years. Budget stresses caused "slippage" and delays in development and production, and those in turn, raised the final costs of developing the shuttle.

Table 1, below, provides an overview of total NASA R&D funding and designated shuttle funding during the developmental stage of the shuttle.39

Table I

NASA Appropriations, 1969-1978

(in thousands of dollars)

| Fiscal

Year |

Research &

Development |

Space Shuttle

Funding |

| 1969

1970 1971 1972 1973 1974 1975 1976 1977 1978 1979 1980 1981 |

$3,530,200

2,991,600 2,630,400 2,623,200 2,541,400 2,421,600 2,420,400 2,748,800 2,980,700 2,988,700 3,138,800 3,701,400 4,223,000 |

$ -0-a

9,000b 160,000c 115,000 200,000 475,000 805,000 1,206,000 1,288,100 1,348,800 1,637,600 1,870,300 1,994,700 |

b for a space station only.

c for shuttle and station; $6 million requested for station definition. [Source: NASA Pocket Statistics (January 1994), and for shuttle funding, 1969-1977, see Linda Neuman Ezell, ed., NASA Historical Data Book, 3:69.]

FROM ENGINEERING SCIENCE TO BIG SCIENCE 289

That funding should be viewed in light of NASA's overall budget which, based on the value of 1992 dollars, dropped sharply from the FY 1965 peak in excess of $22 billion, to a 1974-1979 average of only $9 billion, as adjusted for inflation using 1994 constant dollars.

Although shuttle-specific funding by Congress did not begin until 1974,

in 1972 and 1973 NASA began to move from the planning and study stage of

shuttle development to the design and production stage. One of the great

achievements of shuttle development had to do with the production (and

business) management of complex disparate systems and integrating those

systems or machines into one wholly integrated greater machine. There were

many (in fact all) of the NASA centers involved in the creation of the

Space Shuttle. There were far more, literally hundreds, of independent

private manufacturers involved in its development. NASA, in effect, was

the management team assembled for the production of a single machine by

hundreds of diverse private manufacturers. NASA did not build the shuttle,

private industry did. Thus, the Space Shuttle continued the peacetime mobilization

of American science, engineering, and industry, begun at the inception

of NASA and America's entry into the space age albeit, perhaps, at a lower

level.

The general NASA management structure was, of course, inherited from

the Apollo and earlier programs, but there were important refinements.

In 1971, NASA Headquarters assigned Marshall Space Flight Center responsibility

for developing the booster stages and the shuttle main engines. Marshall,

of course, had basic propulsion (engine) responsibilities from the beginning.

Engine testing was assigned to Stennis Space Center, which had begun as

Marshall's testing laboratory for the Apollo-Saturn engines. The Manned

Spacecraft Center had responsibility for developing the orbiter, or piloted

vehicle. Such had been Houston's basic responsibility since its establishment

in 1961. Kennedy Space Center, formerly the Cape Canaveral Launch Operations

Directorate under Marshall, had responsibility for launch and recovery

of shuttle flights as it had throughout the program. The technical, developmental

work on the shuttle at all the NASA centers was coordinated through the

shuttle Program Office located at MSC in Houston. (Under the Apollo program,

many collaborative management decisions were reached informally between

the Manned Spacecraft Center and Marshall, or were coordinated or passed

through the Manned Space Flight Office in Washington.) The Shuttle Program

Office, in turn, reported to the Office of Manned Space Flight at NASA

Headquarters in Washington.40

The command and control management structure resembled the Apollo management systems, but there were some important differences. Production management was more decentralized than before, but control (integration) was more centralized. The shuttle program did rely (even more heavily) on Apollo-type Integration Panels which coordinated design and construction projects so that the pieces literally fit together and worked together. Integration was the critical element in shuttle production-which, as Owen Morris noted, was a so much more complex machine than Apollo. The Integration Panels reported to the Systems Integration Office in the Shuttle Program Office at the Manned Spacecraft Center and the Systems Integration Office reported to a Policy Review Control Board chaired by NASA Headquarters.41

Shuttle management became a "state-of-the-art" system for very large-scale industrial production. There were, of course, important precedents, such as the construction of the Panama Canal, a battleship, hypersonic aircraft, and Apollo. None of those systems, however,

290 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

involved the complexity of machinery, electronics, computers, and materials as entered into shuttle construction.

Within the three basic management levels for shuttle development technical engineering and management decisions flowed from the bottom up. The "bottom" consisted of the Level III project offices, such as the Orbiter Office at the Manned Spacecraft Center and the Booster Office at Marshall Space Flight Center. The Level III offices managed the production contracts. Level III offices maintained a Resident Office (or engineer) at the primary contractors production site, and often co-located a manager with the appropriate Level II division. The Level II office was the Shuttle Program Office. It had responsibility for systems engineering and integration, configuration, and overall design and development, or as Dale Myers stated: "program management responsibility for program control, overall systems engineering and system integration, and overall responsibility and authority for definition of those elements of the total system which interact with other elements." The Level II office established "lead center" authority for engineering and development management. Headquarters, or Level I, in turn had overall program responsibility and primary responsibility for the assignment of duties, basic performance requirements, the allocation of funds to the Centers, and control of major milestones.42

The management structure created a very decentralized, independent production system-very compatible, if not necessary, to the very diverse and autonomous private entities that made up the manufacturing or production base of the NASA program. One of the great achievements of the space program, contrary to the tendency in large scale bureaucratic enterprises, was to harness the basic strengths of American industry through decentralized management and production.

Although it was not designated "Level IV," the real production base of the shuttle program was private industry. The basic management tool was the NASA contract, and effectively, competition for the contract. It was the contract (and the primary contractor's subcontracts) that mobilized American industry in support of the space program.

The preliminary study, design, and feasibility contracts (Phases A & B), mentioned earlier, with in-house study and tests produced the technical parameters for issuing an RFP or Request for Proposal. NASA began issuing RFP's for shuttle procurement in the spring of 1971. Aerojet Liquid Rocket Company, Pratt & Whitney, and Rocketdyne were invited to submit proposals for the development of the shuttle main engines. Soon after, the Manned Spacecraft Center issued an RFP for a shuttle thermal protection system, to protect the orbiter and its occupants during the critical reentry phase. In July 1971, MSFC selected Rocketdyne as the primary contractor for the production of thirty-five shuttle main engines. Pratt & Whitney challenged the Rocketdyne award and during a GAO (General Accounting Office) review, Rocketdyne was given an interim contract. In March 1972, MSC issued an RFP for the development of containerized shuttle payload systems, and NASA issued an RFP for the development of the shuttle, with the design due in May.43

North American Rockwell (later Rockwell International), McDonnell Douglas, Grumman, and Lockheed submitted proposals for the shuttle. NASA approved an interim letter contract with Rockwell in August 1972, and issued a final contract on April 16, 1973. Rockwell, in turn, subcontracted major components of the shuttle orbiter to other aerospace firms. Fairchild Republic Division of Fairchild Industries constructed the vertical tail unit; Grumman, the delta wings; General Dynamics' Convair Aerospace Division subcontracted for the mid-fuselage section, and McDonnell Douglas had responsibility for

FROM ENGINEERING SCIENCE TO BIG SCIENCE 291

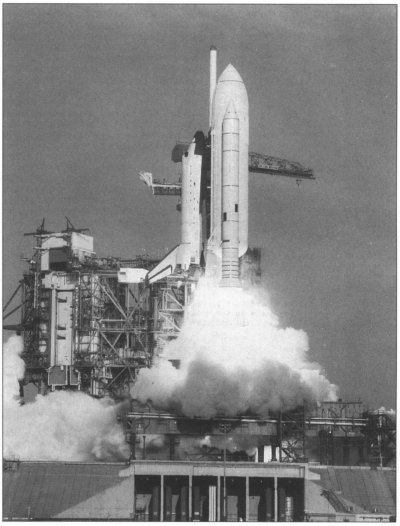

|

| The Space Shuttle rises from Launch Pad 39A at Kennedy Space Center Florida, a few seconds after 7 a.m., April 12, 1981. This first flight was flown by astronauts John Young, Commander and Robert Crippen, Pilot. (NASA photo no. 81-H-285). |

292 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

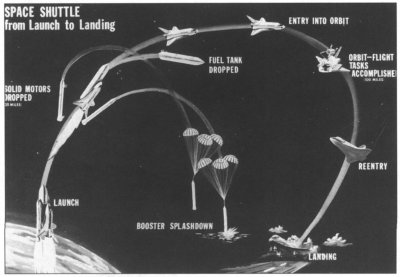

|

| The Space Shuttle Mission Profile. (NASA photo). |

the orbital maneuvering system.44 The contractor and subcontractors, in turn, had subcontracts and suppliers from the very broad gamut of American industry. Electronics, ceramics, metal fabrications, plastics, and chemicals were all heavy contributors to the shuttle. The shuttle was to be a composite creation of American industry, technology, and labor.

The shuttle grew and changed even as it came into being. New problems, new concerns, and new technologies altered the configuration and the engineering as the shuttle took shape. Each new alteration, in turn, often affected the design, performance, and configuration of other systems. The shuttle offers a classic study of "systems engineering." For example, the decision to utilize a "returnable" external fuel tank rather than build the tank as part of a fully integrated reusable vehicle, did not solve the fuel tank problem. Similarly, although NASA opted for a fully reusable orbiter, the decision as to how to build or equip the orbiter to resist the extreme reentry temperatures came later. And while the major function of the shuttle was to carry "payloads" into space, the design of the payload bay continued to change. Changing payloads altered flight characteristics and changed flight plans. Building an aerospace craft unlike anything built before, and one that could never be "test" flown in an unmanned version (unlike Apollo), placed engineering and design work on the creative edge.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 293

Robert F. Thompson, the Space Shuttle Program Manager from 1970 through 1981, credits "the decision to abandon the 'fully reusable' ground rule and employ expendable tankage for the orbiter main rocket engines propellant was perhaps the single most important configuration decision made in the shuttle program." And it occurred late in the definition stage of shuttle development. Through most of 1972, NASA intended to launch the shuttle into orbit with two solid rocket boosters fueled by an external propellant tank, which package would then be deorbited using smaller solid rocket motors, retrieved, and reused. On June 5, 1972, Howard W. (Bill) Tindall, John Mayer's deputy and data coordination chief for Apollo mission planning, flagged a critical problem in returning the fuel tank from orbit. "It's becoming increasingly evident that a probable major problem area and operations cost driver will be the HO tank separation and retrofire." It appeared, he said, that a very expensive, complex, and expendable attitude control system would be required for the tank to return it from orbit. The problem, he suggested, should be given high priority.45 It was.

The problem was directed to a team from the Advanced Mission Design Branch of the Mission Planning and Analysis Division in the office of the Director of Flight Operations at the Manned Spacecraft Center. The team reported in August that the fuel tank could be "staged" (dropped) prior to orbit. That would solve the expensive and difficult tank reentry problem. The idea was rejected, however, because for the orbiter to achieve orbit, it would need to do so with its own engines, and that would require additional internal liquid oxygen/liquid hydrogen fuel tanks. That would mean a heavier lifting body, higher risks, and redesign of the entire shuttle configuration. The Advanced Mission Design Branch restudied the problem and discovered that the existing orbital maneuvering system could accelerate the orbiter into orbital velocity after separation of the external tank.46

Thompson rejected the idea because the orbital maneuvering system would require more fuel and larger tanks. This was September. In December, new studies and a "resizing exercise," revealed that orbital maneuvers could be accomplished on less fuel than originally planned-meaning that additional fuel would be available for the use of the orbital maneuvering system to achieve orbital velocity. The Advanced Mission Design Branch passed this Information on in their Weekly Activity Report (January 29,1913) and in March the Advanced Mission Design Branch team planned a launch to include suborbital staging of the external propellant tank with a recovery in the Indian Ocean. It also became apparent that not only could the suborbital staging work, but it would give the orbiter an additional 5,000 pound payload capacity. NASA elected, however, to retain the previous 32,000 pound payload requirement, and use the savings to reduce the thrust of the solid rocket boosters, and substantially lower flight costs. NASA subsequently estimated total program savings of $238 million.47 Costs remained a compelling ingredient in shuttle design.

At almost every step design and development options constantly appeared. Thompson pointed out that NASA selected the more advanced, higher performance main liquid rocket engine over lower pressure but less costly engine as used in the upper stages of the Apollo program. Despite its higher developmental costs, the higher pressure engine could drive a larger orbiter, created maximum launch acceleration, and improved abort capabilities, and in total seemed to offer better capabilities at reasonable costs. Once the expendable tank design was accepted, NASA restacked the launch, enabling the use of the high

294 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

performance orbiter engines throughout the launch phase, and gained the protective margin of orbiter engine start and thrust verification before the main booster ignited. Another "developmental" decision had to do with attempting a crewless test flight. The guidance, navigation and control systems on the shuttle, however, were constructed for human control. Such a shuttle flight, if it could be accomplished, would not truly test the shuttle flight controls. The first flight of the shuttle then, would be a piloted flight. 48

One problem that seemed to defy a wholly satisfactory solution had to do with insulating the orbiter adequately for its return into the atmosphere, a journey that generated temperatures on its outer body of 3,000° F (1,650°C). Designers recognized two basic approaches to the problem. One was to use conventional aircraft materials such as aluminum, titanium, and composites for the body and then insulate over the external skin with silicate materials. Another was to build a "hot structure" of metals that could withstand the high temperatures and absorb and disperse the temperatures throughout the external skin. This entailed the development of new metals. NASA chose the more known quantities-that is building the shuttle of basic aircraft metals, and overlaying the leading edges with thermal protective coatings.49

There were, however, no thermal protective materials in use that could adequately insulate against the high temperatures. Those had to be developed. A task group of NASA engineers, working with Lockheed, McDonnell Douglas, Battelle/Columbus laboratories and university scientists and engineers, developed a silicone type tile (high purity foamed silica coated with borosilicate glass) that could withstand the temperatures. But once developed, the tile created new problems. For one, it was extremely fragile. The tile was tested by simply firing missiles (such as a .22 slug) at the material to simulate an impact by a meteorite. The prototype tile crumbled. The tiles were then thickened and redesigned with a ludox (silicon-boron) base. That seemed to work. Then, the next problem involved attaching the tiles to the leading edges of the orbiter. That required the creation of new glues, several of them in fact, before a suitable adhesive could be found. Finally, 31,000 tiles, each independently cast to fit the appropriate location on the shuttle, had to be hand glued to the leading edges. The job required 670,000 hours of labor (or 335 person-years).50 While tile development might euphemistically be called "leading edge" technology, the work did reflect the fact that building a Space Shuttle required invention and new technology ranging from flush toilets that would work in the environment of space and the development of adhesives and insulating materials, to the creation of intricate life support, avionics, and computer systems. One of the important and enduring elements of shuttle development relates to the inception of new technology and the application of that technology to other areas. Conventional airplane construction, air safety, navigation, and flight control have been rich recipients of NASA shuttle technology, as have human medicine, computers, plastics and metallurgy. The shuttle and space flight have had a much more pervasive and profound influence on Americans than is evidenced by the construction of the vehicle, or by its flights into space. Its greatest impact has been on Earth, rather than in space.

The significance of the Space Shuttle lay not in its flight per se, but in its payload, that is the freight, cargo, laboratory, or experiments delivered from the earth into space, and returned safely to earth. Shuttle payloads became one of NASA's most complex problems, as much in the social and political context as in the technical realm. Because of the changing

FROM ENGINEERING SCIENCE TO BIG SCIENCE 295

payloads to be carried by the shuttle, each flight involved unique technical preparations and refitting. But the social and organizational structuring required for payload delivery proved most troublesome.

A special Ad Hoc Shuttle Payload Activities Team, headed by Charles J. Donlon, manager of the Shuttle Program Office, concluded that what would be needed in NASA would be "a radical change in thinking ... to meet the vastly different "ferris wheel" mode of operation ... required in the shuttle operational period." NASA must disassociate the transportation system from the hardware. Authorization for shuttle payloads within and without NASA must be carefully defined. The authority of the payload project manager and the transportation operator must be carefully delineated, and the flight people must be out of the "payload approval loop." Science payloads cannot be given lower priority than commercial payloads. Lead times for the development of payloads and the boarding of payloads need to be short in order to make the system work. And the committee particularly (and repeatedly) warned of the problem of competition among NASA Centers for control over payload operations and decisions. There was considerable skepticism that NASA could ever truly become a service organization, which would be required for effective shuttle operations, as opposed to its traditional mode of operation as a research and development agency.51 Thus, the effort to build and launch the first shuttle involved some very basic social and philosophical re-evaluations, as well as technological innovation.

Despite the problems, and continuing financial constraints, NASA anticipated the first shuttle flight could occur in 1978. But budget pressures and technical problems continued to cause "slippages." As early as 1972, Dale Myers believed that cost overruns being experienced in the Skylab program would delay shuttle development and possibly cause it to be cancelled: "The Shuttle Program will live or die based on our capability to keep it reasonably on schedule, and this first schedule impact caused by funding limitations will cause an increase of cost at completion which cannot now be estimated'' Delays did increase costs, and technical problems as with the tiles, the tanks, and the rocket motors did so as well.52

For example, Rockwell engineers working on the Orbiter's Thermal Protection System (the insulating tiles) complained that funding shortages caused work on the thermal protection system to be performed out of sequence and later than planned. Budget constraints often led to deferring quality testing. Problems were identified much later than they should have been. More work had to be done (at additional costs) simply to try to minimize the impact of performing tasks out of sequence. Design work on the thermal protection system originally required 18,750 drawings-by 1981 the required engineering drawings had increased to 25,456 (a 35 percent increase) because of delays and changes. Rockwell sought a "Program Adjustment," that is more money to compensate for the additional Costs.53

Wayne Young, whose job was management integration in the Shuttle Program Office at the Johnson Space Center, explained that the shuttle came into being in "an austere budget environment." NASA had to first look at the budget, and then decide what could be done within that financial framework. Decisions sometimes had to be made on the basis of costs, rather than on the basis of engineering, As costs rose, scheduling and integration became even more critical .54

296 THE SPACE SHUTTLE'S FIRST FLIGHT: STS-1

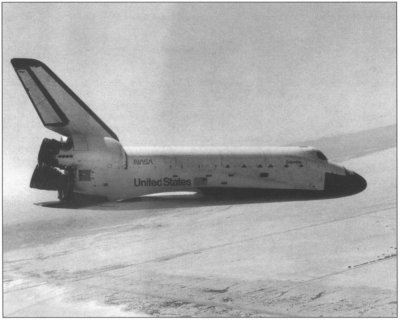

|

| The orbiter Columbia is seen in the final approach prior to landing on Rogers Drylake Runway 23 at NASA's Dryden Flight Research Center April 14, 1981. (NASA photo no. 81-H-342). |

In 1977 the fuselage of orbiter 101, designated the Enterprise (which would not be the first shuttle to be launched), had been completed and the Columbia neared completion. Congress authorized, before the end of the decade, the construction of five shuttles (including the Challenger, Discovery, and Atlantis) estimated at a cost of $550 to $600 million each. Each finally exceeded $1 billion. During the year, NASA conducted five unpowered glide tests by dropping the craft from a Boeing 747. Rockwell's Rocketdyne Division began testing the Space Shuttle main engine at the National Space Testing Laboratory (formerly the Mississippi Test Facility, and soon to be Stennis Space Center) in March. Tests on the engine terminated after 70 seconds when a fire erupted in the engine causing damage to the A-1 test stand. Rockwell and NASA engineers conducted over 650 test firings between 1977 and 1980 before the first shuttle flight in 1981.55 The problems most often encountered had to do with the use of conventional valves and fittings in a very unconventional 6.5 million pound thrust hydrogen-oxygen engine.

By the time the Columbia fired its engines on the launch pad at Kennedy Space Center in Florida, on April 12, 1981, the Space Shuttle already had experienced a long and

FROM ENGINEERING SCIENCE TO BIG SCIENCE 297

difficult history. Simply being there, on the launch pad, was something of a triumph. The greater achievement lay ahead. The three main shuttle engines fired in rapid sequence. Then the twin solid rocket boosters, each generating 2.65 million pounds of thrust, ignited. Columbia lifted off. just short of leaving the Earth's gravitational pull, the solid rocket boosters burned out, separated from the orbiter, and parachuted into the Atlantic where they were retrieved. The shuttle main engines continued to burn, taking fuel from the external tank. The main shuttle engine cut off, and the external tank detached and disintegrated as it reentered the atmosphere. The Columbia then fired its two orbital maneuvering system engines. The first burn put it into orbit, a second bum stabilized the circular orbit about the earth. Twelve minutes had elapsed since launch.56

The shuttle carried mission commander John W. Young, a Georgia Tech aeronautical engineer and a space veteran who made his first space flight aboard Gemini 3, and then was command module pilot for Apollo 10 and commander of the Apollo 16 flight. Robert L. Crippin, a native of Beaumont, Texas, and graduate of the University of Texas, had come into the astronaut training program by way of an aborted Air Force Manned Orbiting Laboratory Program. During the launch his heartbeat rose from 60 to 130 per minute. He described it as "one fantastic ride!"57

The Columbia changed orbits, and for most of the flight flew in a tail-forward upsidedown position, relative to the Earth, giving the crew a better view of Earth and its horizon. Young and Crippin checked all systems, the computers, navigational jet thrusters, and huge cargo bay doors. The ship began the return at 12:22 EST on April 14. Young and Crippin fired the orbital maneuvering rockets for two minutes and twenty-seven seconds to reduce their speed to less than the orbital velocity of 17,500 miles per hour. Gravity would do the rest. They began an hour-long descent. They fired their attitude control thrusters to turn Columbia right side up and nose forward. Thrusters were fired again to keep the nose up so that the thermal protective tiles could absorb the heat of reentry. The Columbia lost speed as its altitude dropped, and over Rogers Dry Lake in the Mojave Desert, Crippen and Young banked the ship sharply, looped back into a landing pattern, and touched down at a speed of 215 miles per hour, about twice that of a commercial airliner. "The touchdown marked the successful conclusion of STS-1, 2 days, six hours, twenty minutes and fifty-two seconds after lift-off from Florida." President Ronald Reagan greeted the returning crewmen, "Today our friends and adversaries are reminded that we are a free people capable of great deeds. We are a free people in search of progress for mankind."58 That search for progress, in the form of a reusable spacecraft, involved not only NASA, and the industries and astronauts who were identified as the recipients of the 1981 Collier Trophy, but reflected more fully the past and present energies, initiatives, technologies, aspirations, and capital investments of the American people.