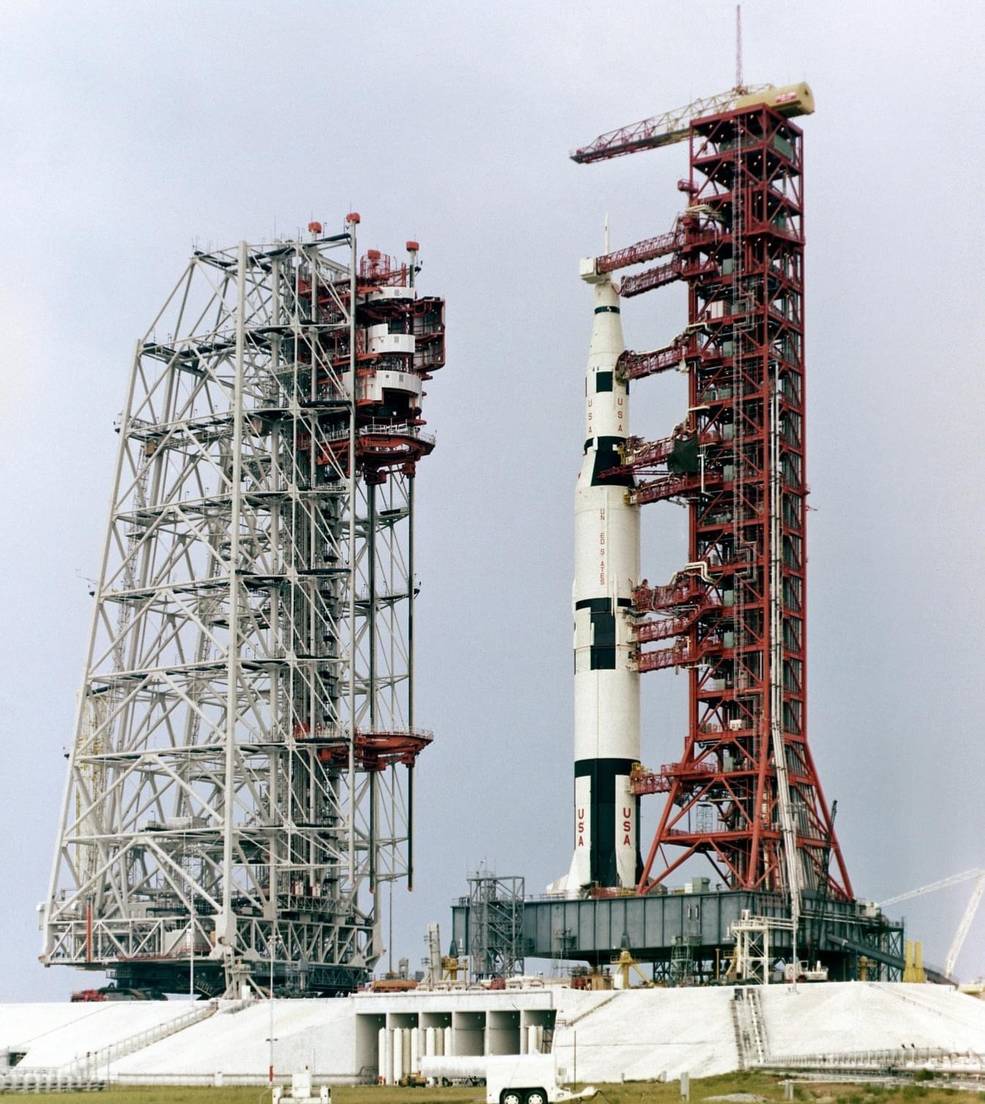

On May 25, 1966, the first Saturn V Moon rocket rolled out to its seaside launch pad at NASA’s Kennedy Space Center (KSC) in Florida, exactly five years to the day after President John F. Kennedy committed the nation to a Moon landing before the end of the decade. While only a test rocket and not destined to fly into space, rollout of the Saturn 500F facility verification vehicle marked a significant milestone on the way to landing humans on the Moon a little more than three years later. The stacking of the rocket and Apollo spacecraft, rollout to the launch pad, verification of interfaces between the rocket and the pad, and rollback provided ground crews the needed experience for future Apollo-Saturn missions to the Moon.

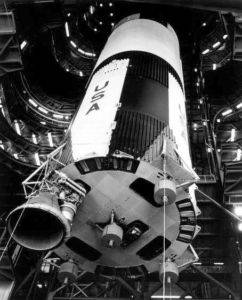

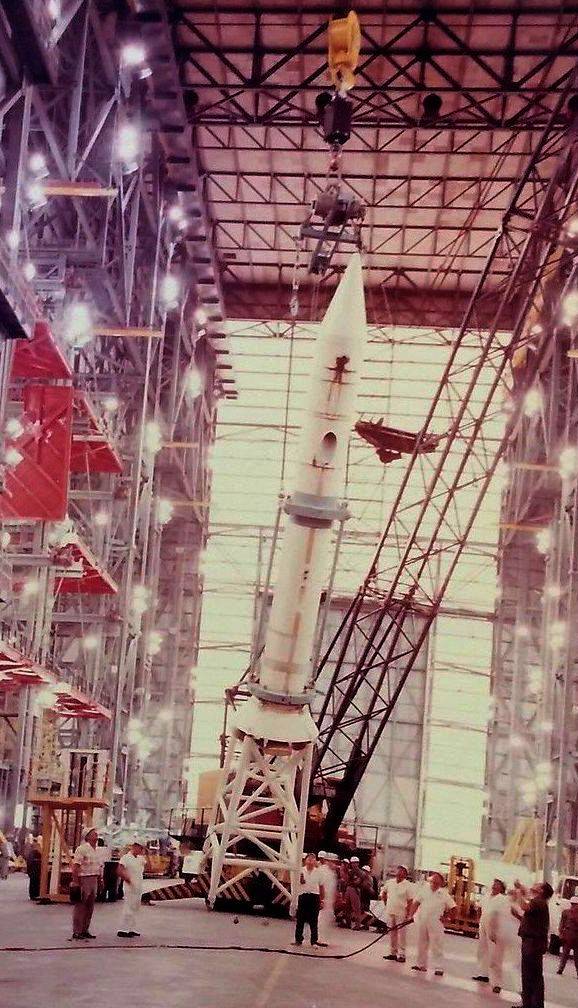

Left: A Launch Umbilical Tower during its fit check at Launch Pad 39A. Middle: Workers lowering the S-1C first stage of the Saturn 500F rocket onto the mobile launcher in the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center in Florida – note the single mockup F-1 engine. Right: Ground crews in the VAB prepare to lift the S-II second stage of the Saturn 500F rocket for stacking onto the first stage – note the mass simulators instead of J-2 engines.

In response to President Kennedy’s challenge for a crewed lunar landing before the end of the 1960s, NASA developed KSC’s Launch Complex 39 to handle the preparation and launch of the Saturn V Moon rocket. The complex consisted of the Vehicle Assembly Building (VAB) where ground crews stacked the Saturn V rocket’s stages, the Launch Control Center (LCC) from which engineers monitored the countdown and launch of the rocket and spacecraft, and two launch pads, 39A and 39B, from which the rockets lifted off. By early 1966, construction workers had completed the VAB, LCC, and Launch Pad 39A as they continued work on Launch Pad 39B, finishing in 1967. To verify launch facilities, train ground crews, and develop test and checkout procedures, NASA used a non-flight version of a Saturn V, called 500F, as a facility verification vehicle. Preparations began on Jan. 28, 1966, when a crawler transporter rolled a mobile launcher (ML) and a launch umbilical tower (LUT) into the VAB. The transporter rolled a second LUT without a rocket out to Launch Pad 39A for interface tests on March 6. Ground crews stacked the S-IC first stage, outfitted with only one F-1 mockup engine and mass simulators to stand in for the other four engines, onto the ML on March 15. They added the second S-II stage with five simulated J-2 engines on March 25, followed by the S-IVB third stage, previously used to test the smaller Saturn IB rocket, four days later. Workers added the M-11 model Command and Service Module and a mockup of the Spacecraft Lunar Module Adapter on May 2. Shortly before the rollout, they replaced it with the BP27 boilerplate spacecraft, then topped off the stack with a model Launch Escape System (LES).

Left: The three stages of the Saturn 500F rocket stacked in the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center in Florida. Middle: View of the Saturn 500F rocket from below the mobile launcher in the VAB. Right: Ground crews stack the M-11 model Apollo Command and Service Module and boilerplate Spacecraft Lunar Module Adapter onto the Saturn 500F rocket.

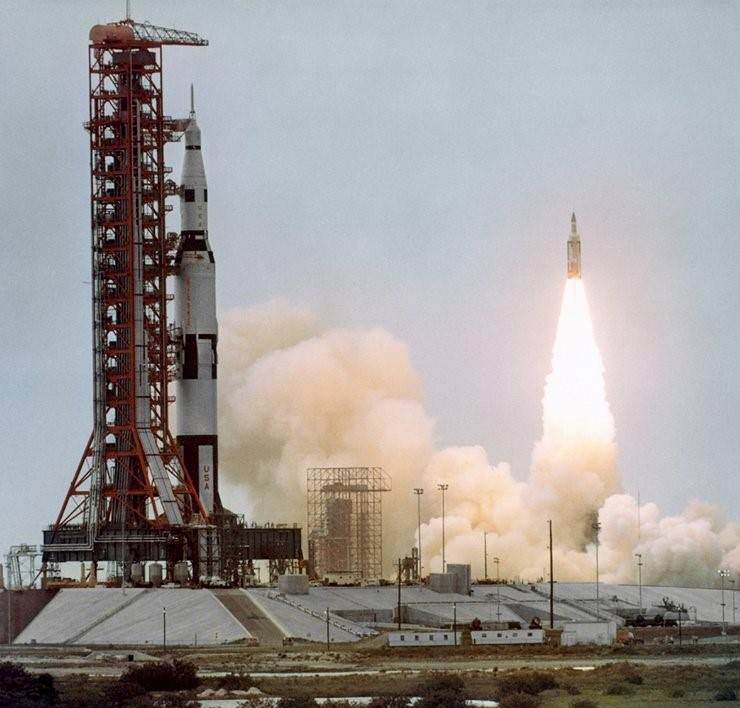

On the morning of May 25, 1966, before hundreds of guests, the Saturn V 500F rocket rolled out of the VAB bound for Pad 39A. George E. Mueller, Associate Administrator for Manned Space Flight at NASA Headquarters in Washington, D.C., KSC Director Kurt H. Debus, Marshall Space Flight Center (MSFC) Director and designer of the Saturn V rocket Wernher von Braun, and director of the Manned Spacecraft Center, now NASA’s Johnson Space Center in Houston, Robert R. Gilruth, attended the rollout ceremony. Reaching top speeds of one mile per hour, the rocket reached Launch Pad 39A by evening and ground crews secured it. With Saturn IB rockets mounted on Launch Pads 34 and 37A several miles away for upcoming missions, this marked the first time that three Saturn rockets stood on their respective pads.

Left: Director of NASA’s Marshall Space Flight Center in Huntsville, Alabama, and designer of the Saturn V rocket Wernher von Braun and NASA’s Kennedy Space Center Director Kurt H. Debus stand in the Vehicle Assembly Building (VAB) as the Saturn 500F rocket begins its rollout to Launch Pad 39A. Middle: View of the Saturn 500F rocket from the top of the VAB as it begins its rollout to the launch pad. Right: The Saturn 500F rocket on the crawler way on its trip to the launch pad.

Two weeks later, on June 8, as Hurricane Alma approached the Florida coast, NASA managers decided to roll 500F back to the VAB to safeguard the vehicle. After just two days in the hangar, it was time to roll out again to the pad – an unexpected bonus for ground crews to gain additional experience in the rollout procedures. The Mobile Service Structure that provided ground crews access to maintain the rocket while at the pad rolled into place for the first time on July 20, followed by “wet” tests that filled the rocket’s tanks with fuel and oxidizer. A mishap on Aug. 19 caused a spill of 2.7 million liters of super cold liquid oxygen onto the ground, resulting in a month-long delay in testing until workers repaired the leak and ruptured tank. Engineers completed all the required tests by Oct. 12.

Left: The Saturn 500F at Launch Pad 39A, with several launch pads visible in the background – Saturn IB rockets stood on Launch Pads 34 and 37A. Right: The Mobile Service Structure approaches the Saturn 500F rocket on Launch Pad 39A.

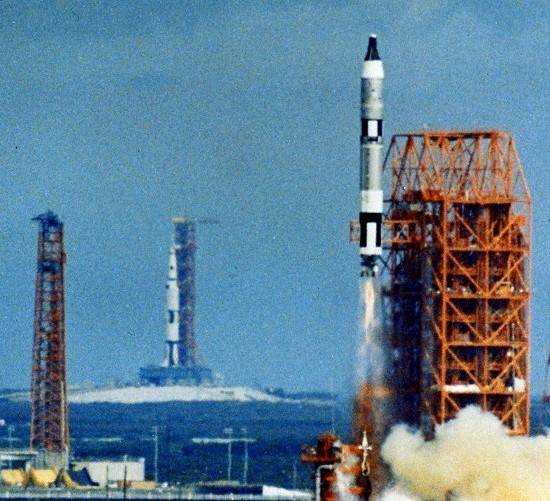

During the five months that the Saturn 500F rocket stayed on Launch Pad 39A, Cape Canaveral Air Force Station adjacent to KSC maintained a busy pace of space launches. On June 16, a U.S. Air Force Titan-IIIC rocket lifted off from Pad 41 about 3.6 miles from the Saturn V. The Apollo-Saturn 203 mission launched on a Saturn IB on July 5 from Pad 37A to test the dynamics of liquid hydrogen in weightlessness and the Apollo-Saturn 202 flight on Aug. 25, also a Saturn IB, launched an Apollo Command and Service Module on a 90-minute mission to test the spacecraft’s heat shield and fuel cells. On Sep. 12, the Gemini-XI mission took off from Pad 19, with astronauts Charles “Pete” Conrad and Richard F. Gordon on a three-day mission to rendezvous with a target spacecraft and perform two spacewalks.

Left: A Titan-IIIC rocket lifting off from Launch Pad 41, with Saturn 500F in the foreground. Middle left: Apollo-Saturn 203 lifting off from Launch Pad 37A. Middle right: Apollo-Saturn 202 on Launch Pad 34. Right: Gemini-XI lifting off from Launch Pad 19, with Saturn 500F in the background.

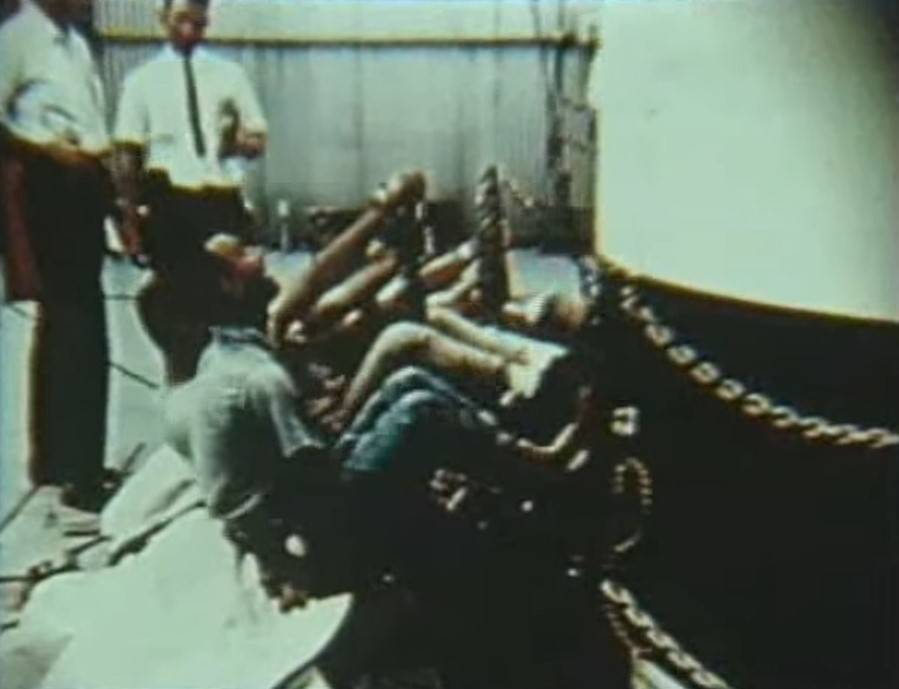

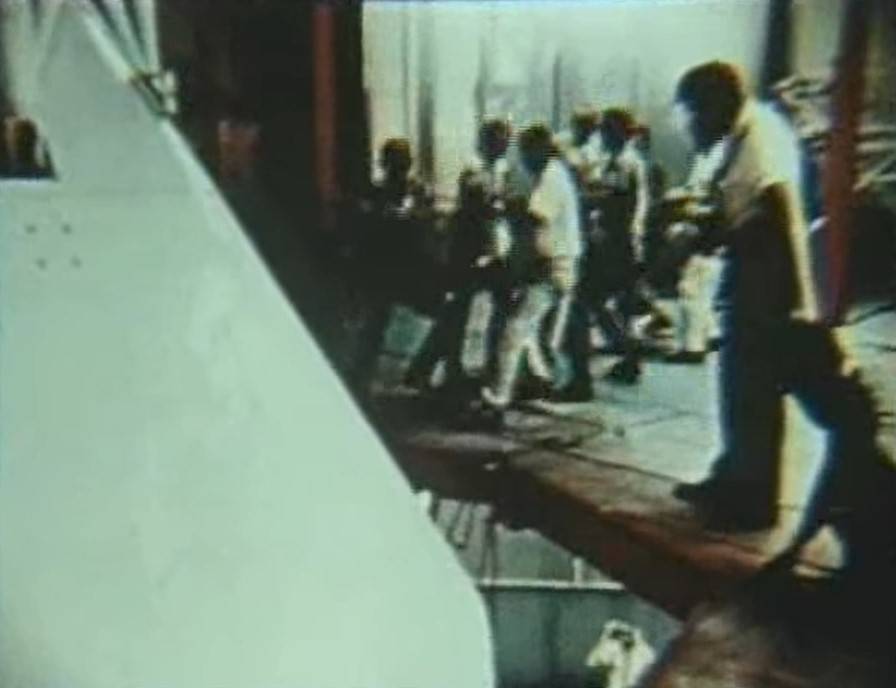

With all the launch pad tests completed, Saturn 500F rolled back to the VAB on Oct. 14. But before destacking the rocket’s stages, NASA engineers wanted to perform one more test on the vehicle, variously known as a “sway test” or a “twang test.” Normally, this type of test would be conducted under controlled conditions in a vibration chamber, but the Saturn V’s enormous size precluded such an activity, so engineers resorted to somewhat more low-tech methods. Initially, a group of engineers laying on their backs on one of the upper work platforms at the Service Module level began pushing against the rocket with their feet. When this didn’t provide the needed motion, other engineers looped a sling around the Command Module and began pulling on the rope to get the rocket swaying at its natural frequency. While this had the desired effect for a vibration test it had the unintended consequence of causing the LES to come loose and fall on one of the work platforms. Fortunately, no injuries or significant damage resulted from this underreported incident.

Left: Engineers in the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center pushing on the Saturn 500F rocket at the Service Module level during the sway test. Middle: Engineers in the VAB pulling on a rope looped around the Command Module during the sway test. Right: Ground crews securing the Launch Escape System tower after it toppled off the rocket during the sway test.

One week after its return to the VAB, ground crews began to destack the Saturn 500F. They shipped the first stage to MSFC for extended storage, where it was eventually scrapped. Likewise, they shipped the second stage to MSFC where engineers used it for dynamic testing and it is now incorporated into the Saturn V display at the U.S. Space & Rocket Center in Huntsville, Alabama. Workers modified the third stage into a Skylab dynamic test article and shipped it first to MSC and then to MSFC, before it was scrapped. The M-11 model spacecraft is part of the Saturn IB display at KSC’s Visitor Complex while the BP-27 boilerplate spacecraft is part of the Saturn I display at the U.S. Space & Rocket Center.

Left: Saturn 500F about to enter the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center in Florida, following completion of tests at Launch Pad 39A. Middle: In the VAB, the stacked Saturn 501 rocket for the Apollo 4 mission before repainting of the first stage. Right: Rollout of the Apollo 4 Saturn 501 rocket, with the white repainting visible on the first stage.

Managers scrapped plans to roll out Saturn 500F to test Launch Pad 39B in 1967 since all objectives were met in the tests at Pad 39A. Workers in the VAB remained busy, however, as only six days after completing the destacking of Saturn 500F, they began to stack the next Saturn V rocket, Saturn 501, which in November 1967 completed the first successful flight of the Saturn V rocket during the uncrewed Apollo 4 mission. Among the lessons learned from the 500F included the paint scheme on the rocket’s first stage. The tall T-shaped black markings with a horizontal black stripe around the intertank area absorbed sunlight, causing significant overheating inside the rocket. Because rocket stages for subsequent missions had already been assembled, painted, and delivered to KSC, workers in the VAB covered the black areas with white paint.