Woven Thermal Protection Systems (WTPS) uses a new approach to produce TPS materials from precisely engineered 3D weaving techniques. WTPS customizes material characteristics needed to meet specific missions requirements for protecting space vehicles from the intense heating generated during atmospheric entry. Using WTPS, sustainable, scalable, mission-optimized TPS solutions can be achieved with relatively low life cycle costs compared with the high costs and long development schedules currently associated with material development and certification.

WTPS leverages the mature state-of-the-art (SOA) weaving technology that has evolved from the textile industry to design TPS materials with tailorable performance by varying material composition and properties via the controlled placement of fibers within a woven structure. The resulting material can be designed to perform optimally for a wide range of entry conditions encompassing NASA’s current and future mission needs. WTPS enables these optimized TPS designs to be translated precisely into mission-specific, manufactured materials that can dramatically increase the efficiency, utility, and robustness of heat shield materials compared to the current SOA material options.

WTPS customizes material properties and performance by the accurate placement of fibers of different compositions and with different spacings using commercially available weaving technology and by using modeling, design, and manufacturing tools to optimize the weave for overall improved performance. Follow on projects from WTPS include 3DMAT and HEEET.

3-Dimensional Multifunctional Ablative Thermal Protection System

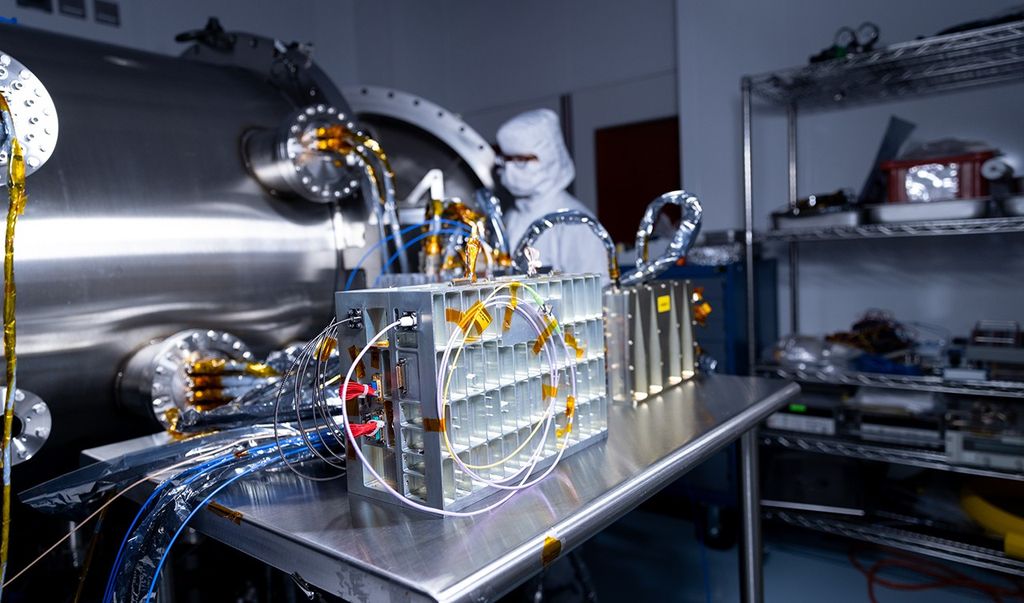

The 3-Dimensional Multifunctional Ablative Thermal (3D-MAT) Protection System project designed and developed a game changing woven thermal protection system (TPS) technology tailored to the needs of the Orion Multi-Purpose Crew Vehicle (MPCV) compression pad for the lunar return mission, EM-1, and beyond. 3D-MAT leveraged the efforts of NASA’s Space Technology Mission Directorate’s investment in Woven TPS to design, manufacture, test, and demonstrate a prototype material for Orion compression pads. The project combined the 3D weaving of quartz yarns with resin transfer molding to develop a robust multifunctional material architecture capable of meeting both structural and thermal performance needs for lunar return and beyond. 3D-MAT was developed to meet the strict structural and thermal protection requirements of the compression pad portion of the Orion spacecraft’s heat shield. The technology has undergone a battery of structural, thermal, and aerothermal tests, qualifying it for Orion and was selected for NASA’s Materials International Space Station Experiment (MISSE)-11 mission. The MISSE-11 mission will enable further evaluation of the effects of long-term, on-orbit exposure for this new aerospace composite, further validating its robustness for Orion and other applications.

Heat Shield for Extreme Entry Environment Technology (HEEET)

The HEEET Project, co-funded by NASA’s Space Technology Mission Directorate under the Game Changing Development Program (GCDP) and NASA’s Science Mission Directorate (SMD), has matured a game changing Woven Thermal Protection System (WTPS) technology to enable in-situ robotic science missions recommended by the NASA Research Council (NRC) Planetary Science Decadal Survey (PSDS) committee. A primary deliverable for the HEEET Project is an Engineering Test Unit (ETU). A flight-like woven TPS heat shield was assembled on a flight-like carrier structure and put through a series of environmental tests. There are four primary goals associated with the development, manufacturing, and testing of the ETU:

- Verification of structural performance of ETU and model correlation

- Demonstration of manufacturability at a 1 meter scale

- Demonstration of inspection and defect identification of entire heat shield at 1 meter scale

- Demonstration of NASA’s ability to transfer prototype component manufacturing insight to outside partners, levy efficient and effective requirements, and verify that delivered hardware is acceptable