Peter Curreri

Lunar Resources, Inc.

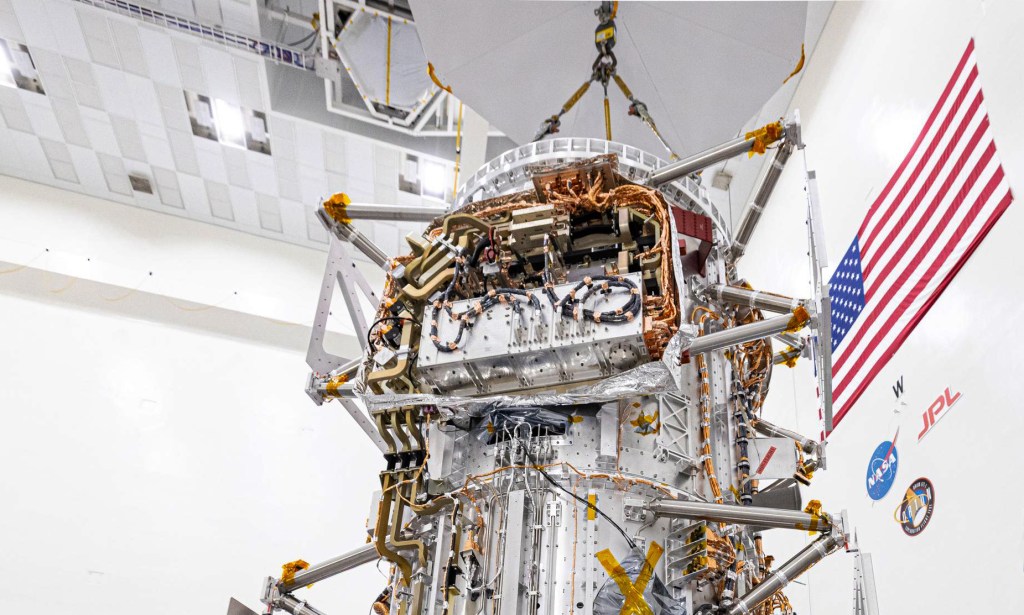

The sustainability of the Artemis program and its goal of developing a permanent human presence on the Moon is dependent on the ability to utilize in-situ resources to reduce the cost and risk of lunar operations. NASA and the US government have invested significant funding in developing the ability to extract oxygen from lunar regolith and water from lunar ice. The oxygen will be used for: 1) human habitats, rovers, other life support systems with a constant supply of high purity oxygen for human consumption; 2) oxidizer for launch vehicles departing the Moon. These oxygen extraction technologies are planned to be demonstrated at large scale on the Moon as early as 2024 and provide direct support to Artemis astronauts as early as 2026.

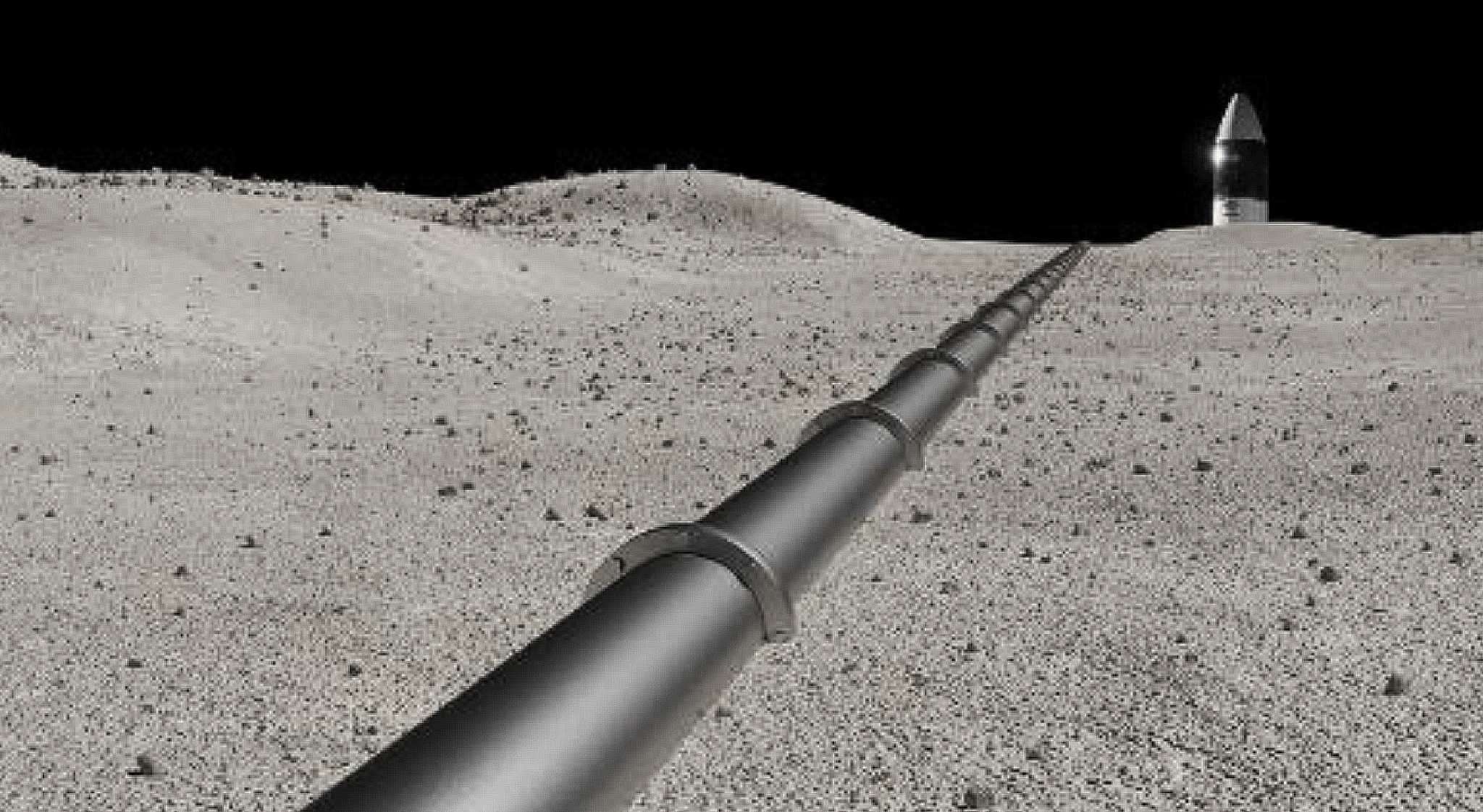

Current funded efforts for in-situ oxygen extraction consists of bottling the oxygen in compressed gas tanks or to liquefy and store it in dewars. Either approach requires trucking tanks or dewars to various facilities for use. The process of moving this oxygen on rovers is more energy intensive than the extraction process and is thought to be the MOST expensive aspect in obtaining in-situ oxygen for use on the Moon considering the long distances (1 10 km) a resource extraction area will be from a human habitat or liquification plant.

We propose, Lunar South Pole Oxygen Pipeline (L-SPoP), a gaseous oxygen pipeline at the Moons South Pole. For this Phase I NIAC project, we propose to do an end-to-end system-level design study of the L-SPoP. A lunar pipeline has never been pursued and will revolutionize lunar surface operations for the Artemis program and reduce cost and risk!

We plan to explore and assess multiple system architectures for a lunar pipeline, identify enhancing and enabling technologies, and produce a comprehensive roadmap to develop this breakthrough infrastructure. Our starting concept is for a 5 km pipeline to transport oxygen gas from an oxygen production source, for example our molten regolith electrolysis (MRE) extraction site or any other source, to an oxygen storage/liquification plant near a lunar base. L-SPoP is composed of in-situ manufactured pipe segments that are passivated and welded or fitted together to span the 5 km distance. Based on preliminary analysis, we are assuming the in-situ pipe is built in modular segments from in-situ aluminum as its prevalent at the South Pole, is extractable in high purity with MRE, can be directly extruded into pipe shape, and can be oxidized to passivate. Other in-situ metals which will also be analyzed for consideration include iron and magnesium, with a lunar glass passivation coating applied through vacuum deposition onto the internal diameter of the pipe. This modular design is adaptable, repairable, and evolvable because of the in-situ resource extraction and manufacturing techniques (with occasional system upgrades from Earth), resulting in a long life for the pipeline and lower cost and risk than other approaches. The pipeline will be designed to: 1) be constructed robotically from regolith-derived metals with minimal material transferred from Earth, 2) be repairable robotically, 3) have an oxygen flow rate of ~2 kg/hour which is commensurate with the NASA initial projected need of 10,000 kg/year, 4) operate with minimal power over the lifetime of the pipeline, and 5) have a high operational reliability and be able to survive in the lunar environment for > 10 years.