Interesting Fact: NASA Spinoffs Make Our Lives Better

Since NASA technology is taxpayer funded, it is shared with the American people and by extension, the people of the world. New technologies shared in this way are called Spinoff’s and the public has benefitted from over 2,000 of them since 1976, often in the form of commercial products. Some, such as Tang and Teflon, are widely known but many are not. Herewith is a short list of some of the more interesting and possibly surprising ways in which NASA engineering and research have become part of our lives, helping to solve some of our most pressing societal and environmental challenges.

1. Lightning in a Bottle.

From 1997 to 2017, the National Space Biomedical Research Institute (NSBRI) looked into how long-duration spaceflight affected people, funded with grants from NASA’s Johnson Space Center in Houston. One area of interest was light sources and how they affected brain activity. The NSBRI funded two professors, Thomas Jefferson University’s George Brainard and Harvard Medical School’s Steven Lockley, to learn more. Lockley and Brainard’s research found that exposure to excess blue light at the wrong time could throw off a person’s body. This happened because the body’s production of melatonin, a key hormone for managing circadian rhythms, was inhibited when certain wavelengths of blue light hit photoreceptors in the eyes.

When the fluorescent lighting fixtures on the space station needed to be replaced in 2011, NASA looked to the growing field of solid-state light-emitting diodes (LEDs). Solid-state means that there’s no physical reaction creating light, unlike an incandescent bulb or fluorescent plasma. In creating a new lighting system, the findings of the NSBRI’s research played a big role.

“When NASA started looking into [LED fixtures], the industry didn’t even have standards for solid-state lighting. They didn’t have any information, certainly not a lot of research on large-scale implementation of circadian lighting,” said Toni Clark, testing lead for spacecraft lighting at Johnson.

Researchers there and engineers at NASA’s Kennedy Space Center in Florida worked together on the Solid-State Lighting Assembly (SSLA) for the space station. The lamp module was primarily built by Bionetics Corporation, which also had labs and manufacturing facilities on-site at Kennedy. The new lighting modules, installed in 2016, consumed far less energy and emitted far less heat than previous fluorescent lighting on the station. In addition, they changed color, temperature, and intensity in a 24-hour cycle, in accordance with the NSBRI’s circadian lighting research.

The change paid off, as astronauts reported feeling better-rested. LED modules also helped in plant-growth experiments on the space station, with the lights providing the right wavelengths for photosynthesis.

2. Keeping Warmer in the Great Outdoors:

Not everyone would celebrate the new year camping out in the Rocky Mountains during some of the longest, coldest nights of the winter. But that’s how Jon Rosenberg and his wife rang in 2018, and they learned the hard way that the outdoor gear market still didn’t entirely take such extreme conditions into account. In just one night, the cold killed the batteries in the camera his wife, a professional photographer, brought with them.

“Other insulated products will keep groceries cold for a week, but if all you need is to keep batteries or a snack from freezing, there’s not much of a solution,” he said. Rosenberg, who worked in the outdoor gear industry, knew of a class of high-performance insulation pioneered by NASA to keep cryogenic rocket fuel chilled to minus 423 degrees Fahrenheit in the balmy heat of Florida. The key to these insulators is a substance called aerogel.

The first aerogels were invented before NASA even existed. They’re made by removing all the moisture from a gel – usually made of silica – while leaving the solid structure intact. The resulting material is almost entirely air, pocketed in tiny chambers. It weighs next to nothing and is nearly impervious to heat. However, until NASA got involved, it was also too fragile to use.

In the 1990s, NASA’s Kennedy Space Center in Florida was looking for better insulation to maintain the frigid temperatures needed for storing space shuttle fuel.

The best cryogenic insulations at the time were layered metallized thin films, invented by NASA in the early days of the space program. These reflected radiated heat and could be placed in a vacuum to prevent heat conduction or convection. But they were relatively expensive and heavy, and their ability to conduct heat along their surfaces caused complications.

A company called Aspen Systems, however, had an idea for incorporating aerogel into flexible insulating blankets. With Small Business Innovation Research (SBIR) funding from Kennedy, and then from a handful of other NASA field centers, Aspen developed a process to coat insulation fibers with aerogel to trap air while also stopping heat conduction.

First, Aspen treated the fibers, both to make them reflective and to help them bond with an aerogel. Then it soaked them in a liquid aerogel precursor material and flash-dried them at high temperature and pressure to turn the liquid to solid aerogel. Every fiber in the resulting blankets was enveloped in air-filled aerogel, preventing the fibers from touching each other to conduct heat. Moreover, the air molecules trapped in the aerogel’s countless microscopic cells also couldn’t touch each other to transfer heat, and they couldn’t move across the insulation or even escape when it was squeezed or soaked.

Today the space agency uses aerogel in myriad ways, and Aspen Aerogels has spun off to specialize in what became one of the most successful, widespread spinoffs in NASA’s history, incorporating aerogel into a host of outdoor wear, building and industrial insulations, and more. And like many of the agency’s most successful inventions, aerogel-infused insulation has spun off well beyond NASA, spawning partnerships and product lines that are two or more degrees removed from the original work but still owe their existence to NASA’s need-driven investment.

One company that’s recently entered the aerogel market is Latham, New York-based PrimaLoft, a brand known for high-performance insulation since the 1980s. After a group of PrimaLoft employees toured the Aspen Aerogels manufacturing facility and became inspired, the company began developing two new lines of aerogel insulations. Today that decision is paying dividends in bulk: scores of brands are already using this newest spin on NASA’s early forays into aerogel to make warmer outdoor gear.

3. Space Age Water Conservation:

The more difficult a problem is for NASA, the more solutions it eventually produces for the rest of us. Few challenges are more pressing for the space agency than the need for clean water. Water is heavy — much heavier than the liquid hydrogen and oxygen NASA uses for rocket fuel — and every pound launched into space costs thousands of dollars. So on the space station, nothing is wasted — sweat, urine, and even breath moisture are collected, purified, and recycled as drinking water. But despite its origins, the water astronauts drink is cleaner than what’s available to most people on Earth.

To achieve this, NASA has pushed the cutting edge of water purification since the agency’s early years. And most of these innovations have found plenty of use here on the ground, too, in homes and water bottles, in industrial settings, and in remote locations where safe drinking water is scarce. As the worldwide demand for fresh water grows, this technology becomes more essential every day, as it ensures that people have enough safe water to drink, treats polluted water, and eases the demand on natural aquifers.

These are just a few examples of NASA technology now cleaning water on Earth.

In one recent development, an unlikely partnership between NASA and a Swedish university — with the help of filter technology the space agency helped develop almost 20 years ago — led to the world’s first water-recycling shower. In 2012, Mehrdad Mahdjoubi, then a master’s student in industrial design at Lund University in Sweden, traveled to Johnson Space Center as part of an annual program to learn about the challenges of designing habitats for astronauts. The focus was on a five-year Mars stay. Current astronauts, short on water and gravity, take sponge baths, but Mahdjoubi thought spacefarers with feet planted on Martian ground would prefer a real shower. But water on Mars’ desert surface is still scarce, so Mahdjoubi came up with an idea for reusing the flow. “I’d have never thought about doing something like this if I didn’t have that NASA experience,” he says.

To rapidly purify and reuse water, he hit on an especially thorough water filtration technology developed in part with NASA funding, known as NanoCeram. Other filters have micropores tiny enough to physically filter out bacteria and even viruses, but these are painfully slow. A material invented by Argonide Corporation, however, made up of positively charged microscopic alumina fibers, can remove virtually all contaminants, including bacteria and viruses, despite having significantly larger pores — allowing a much higher flow rate. The positive charge of the fibers attracts and traps microorganisms and other contaminants, which generally carry a negative charge. Activated carbon in the filter aids in snaring particulate, chemical, and soluble contaminants.

Under two Small Business Innovation Research contracts from Johnson in the early 2000s, Argonide optimized its nanofibers for strength and virus adhesion and built, tested, and validated full-scale filter models. Since then, other companies have used the filters in water bottles, portable humanitarian units, and industrial water purification. And now Mahdjoubi has incorporated the filter into a recirculating shower known as Oas — Swedish for “oasis” — built and marketed by his new company, Orbital Systems.

The shower starts with less than a gallon of water and circulates it at a rate of three to four gallons per minute, more flow than most conventional showers provide. The system checks water quality 20 times per second, and the most highly polluted water, such as shampoo rinse, is jettisoned and replaced. The rest goes through the NanoCeram filter and then is bombarded with ultraviolet light before being recirculated. The Swedish Institute for Communicable Disease Control has verified that the recycled water is cleaner than tap water. And because the reused water is already warm, it takes minimal energy to heat it back to the target temperature.

“There’s a general assumption you can’t do anything about water conservation without compromising your life quality,” says Mahdjoubi. “But we don’t tell people to stop showering, and we don’t destroy their experience. We enhance it with a higher flow rate. The ability to save without sacrifice, I think, is the most important part of our value proposition.”

Orbital Systems, headquartered in Sweden with U.S. offices in Sausalito, California, has raised about $50 million in investments and employs 60 to 70 people. The company has sold several thousand units, so far mostly to hotel chains and real estate developers, and the showers are becoming available to individual consumers in Sweden, Denmark, and Germany this year. Mahdjoubi plans to expand to North America, Asia, and beyond but first needs to enlist distributors and certify installers. In the longer term, he wants to enable an entire habitat that runs on closed loops, recycling as much and using as little water as possible, just as a Martian habitat would.

“As humans, we’re really good at innovating, but we tend to be quite complacent until we actually have to do it,” Mahdjoubi says. “Designing for Mars forces more creativity.”

4. Using Nature’s R&D Lab

One of the most remarkable — and possibly most effective — water-treatment technologies NASA has explored is a membrane embedded with the same natural proteins that transport water through the membranes of living cells. Known as aquaporins, these proteins are what allow plant roots to absorb water from soil and human kidneys to filter about 45 gallons of blood per day. They can transport water through cell membranes one molecule at a time, while rejecting other substances.

Now companies all over the world are looking at various ways these membranes can be used, including many pilot wastewater treatment projects, whether adding efficiency to existing wastewater treatment facilities or purifying wastewater that until now has gone untreated, polluting groundwater and waterways.

The concept has been pioneered by Danish company Aquaporin A/S, and when Ames Research Center learned what the company was trying to do in 2007, the center became the first paying customer. Ames and the European Space Agency tested the membranes on flights to the International Space Station.

Astronauts on the ISS tested prototype water purification systems based on membranes infused with aquaporin proteins. The testing, which validated both forward and reverse osmosis-based systems, was sponsored by the European Space Agency and overseen by NASA. Image courtesy of the European Space Agency

These operate through reverse osmosis, using pressure to push water through the filters. But the company had even bigger plans for the membranes in forward osmosis, a process that drives itself without any outside influence. With saltwater on one side of the membrane and wastewater on the other, thermodynamics compel the salt to distribute itself evenly throughout all the water in the system. But because salt can’t pass through the membrane, it draws the fresh water through from the other side, leaving only waste.

And in healthcare, forward osmosis has the potential to make dialysis portable, improving patients’ quality of life, he says. Dialysis patients often spend hours traveling to and from treatment three or four times a week, where they spend another three or four hours bedridden, creating a sedentary lifestyle. This is partly because hemodialysis a massive water consumer. The process requires about 200 liters of water per treatment—all of which ends up as wastewater. If clean water were extracted from the waste and reused throughout the treatment, he says, dialysis could fit in a backpack.

“We’re testing forward osmosis in a closed water-recycling loop with a lot of players in dialysis,” Holme Jensen says. “Medical device companies understand and pick up on the technology because if you look at how a kidney works, it reuses water in a closed loop.”

And after all, the mechanism that makes that closed loop work is the aquaporin protein.

5. Making GPS more accurate:

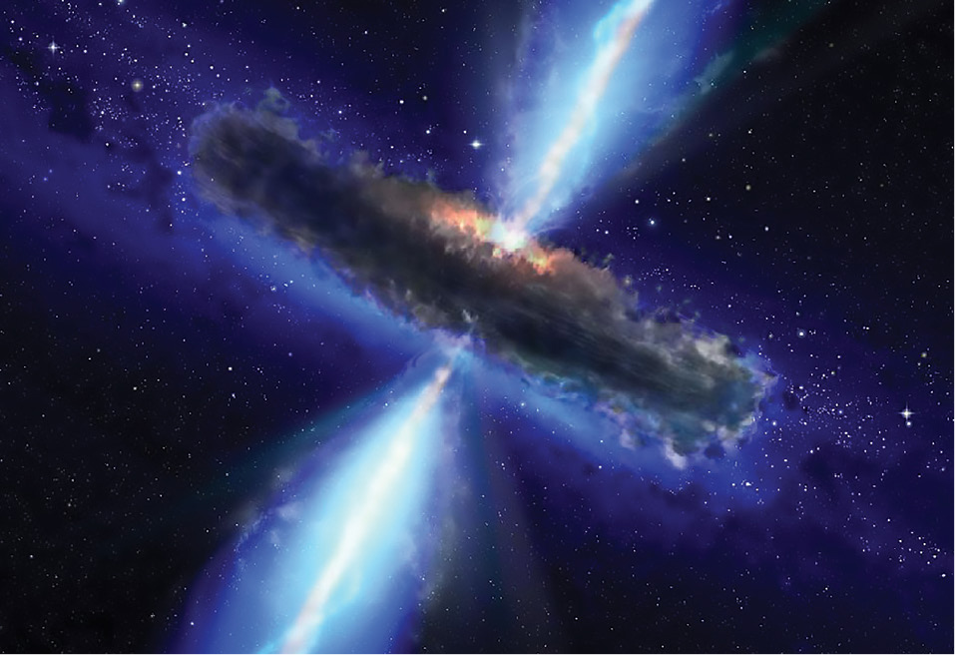

In the 1960s, NASA used a network of radio telescopes and a technique called very large baseline interferometry (VLBI) to capture images of quasars in distant galaxies. In the following decade, scientists reversed the process to determine the precise locations of the telescopes, painting a picture of Earth’s shape and orientation in space. Today, an evolution of that technology supports another location-based system that has arguably become the world’s most important communication infrastructure: the Global Positioning System (GPS).

When the first GPS satellite was launched in 1978, NASA’s Jet Propulsion Laboratory (JPL) already had experience in tracking radio signals from faraway sources and extracting valuable information from them. Using VLBI, for example, JPL scientists measured the time difference between when the same radio signals from quasars—some of the brightest objects in the universe—hit different telescopes around the world to conduct geodesy, assessing Earth’s size and shape.

These capabilities served as the springboard that let JPL recognize early on the potential that GPS held and compelled the center to invest in the technology and infrastructure to support it.

In the early 1980s, as the U.S. Air Force continued launching GPS satellites, JPL started building out a tracking network, collocating the first ground stations with VLBI tracking sites. These offered the necessary communications infrastructure and precise location information to tie the geodetic reference frame to that of GPS. Today the network includes more than 80 receivers, making it the world’s largest geodetic-quality, centrally managed GPS tracking network.

Raw GPS data can produce positioning errors of 30 feet or more if not calibrated for signal delays caused by electrons and gases in Earth’s atmosphere, errors in GPS satellite positions, and noise and drift in the satellites’ atomic clocks. The software JPL developed to model delays, correct for errors, and perform GPS orbit determination and receiver positioning was called GIPSY-OASIS (GPS-Inferred Positioning System and Orbit Analysis Simulation Software). It quickly became one of NASA’s most widely licensed software programs, with hundreds of licenses to academia and industry.

But no one was able to make these corrections in real time on a global scale until the Internet became widespread in the mid-1990s. Shortly after the GPS satellite fleet became fully operational in 1994, JPL received a small amount of funding from NASA’s Deep Space Network program to figure out how to use GPS data in real time to enable faster turnaround time for deep-space navigation. That seeded the development of JPL’s Real-Time GIPSY (RTG) software, which could make all these corrections and update them every second.

The corrections also were globally and uniformly valid, in contrast to the prevailing approaches at the time, which corrected signals based on local information, leading to corrections that were only valid regionally and suffered from degradation when the satellites rose and set on the target region.

Once JPL had demonstrated precision global GPS in real time, a host of new possibilities opened up.

“We took an innovative approach to the opportunities and challenges the free Internet offered, and we also had the vision to recognize that real-time GPS processing on a global scale could be revolutionary,” says Yoaz Bar-Sever, who was one of the developers of GIPSY and RTG and is now the manager of the Global Differential GPS (GDGPS) system at JPL. “But we were still surprised by the scope of the impact of the new capabilities we were building.”

In the mid-1990s, both industry and government began forays into the use of GPS corrections to improve positioning, navigation, and timing. In 1995, Satloc, a small company vying for the U.S. market of industrial GPS corrections, licensed RTG and became the first provider of RTG-corrected GPS service across most of North America.

The following year, the Federal Aviation Administration (FAA) selected the software as the prototype for its Wide Area Augmentation System (WAAS), with the goal of providing accurate GPS navigation for pilots, and offered funding for JPL to further mature the technology.

“We had the track record, and we had the only proven software to do what they wanted,” says Bar-Sever.

Another key investment in 2000 from the NASA Earth Science Technology Office helped JPL put in place the operational technology and infrastructure needed to launch a reliable, global, real-time service, and the GDGPS system was born. “As the Internet became more prevalent, we were able to get orbital determination in seconds globally,” Bar-Sever says. “That led a lot of industry to us.”

While NASA remained a key user of GDGPS, its ongoing development ever since has been funded almost entirely by other government users and commercial companies.

As word spread of the accuracy and global coverage of GDGPS, in 2002, the Air Force sponsored the development of a dedicated service to provide a wealth of information to its GPS operators, a service that has been enhanced over the years to adapt to the evolving GPS constellation and continues to this day. “In supporting operational GPS, the GDGPS system contributes to the reliability of the entire GPS enterprise,” says Bar-Sever.

Also in the early 2000s, GDGPS found its first major commercial customer in the farm equipment company John Deere, which invested heavily to help JPL engineers make the system practical and reliable for guiding self-driving tractors (Spinoff 2017). The technology made precision farming commonplace around the world. By this time, the system enabled positioning accuracy to within less than three inches.

These days, GDGPS also monitors and processes data from the world’s other navigation satellite systems—the Russian Global Navigation Satellite System, the Chinese BeiDou system, the Japanese Quasi-Zenith Satellite System, and the European Galileo system that’s expected to go into full operation this year. It’s an arrangement that benefits all users. “When you have more satellites, you can get more accurate and reliable positioning, especially in urban canyons,” Bar-Sever says. “It also improves atmospheric observation. It enhances the overall capability.”

The JPL team is working, for example, to achieve unprecedented accuracy to guide self-driving cars. “The accuracy that industry demands is very difficult to achieve,” Bar-Sever says. “We’re working on that with the support of the aggregate of our customers.”

5. Helping to Feed the World. A New Generation of Indoor Farming

The first vertical farm in the U.S. provided a foundation for expanding the controlled environment agriculture industry

Originally published 11/23/2021

The United Nations predicts Earth will have to feed another 2.3 billion people by the year 2050, with most concentrated in urban centers far from farmland. Current agriculture may not have the capacity to feed that many people, and it could threaten future production by depleting soil of essential nutrients and contaminating freshwater supplies and soil with pesticides and herbicides. Conventional farmers are working to make their fields more efficient and productive and less harmful to the environment – at times with innovations and other support from NASA – but these changes are only part of a long-term solution.

NASA has been working for decades to tackle similar problems for space exploration. Reusing a limited water supply, minimizing energy consumption, and eliminating soil as a growth medium are just a few ways the agency stretches the limited resources available in space. Research into solving these challenges to grow plants in a closed environment like a spacecraft inspired NASA to build the first vertical farm in the United States, creating a foundation for the controlled environment agriculture industry to build on. The lessons learned are inspiring an unconventional new generation of farmers.

Called controlled environment agriculture or CEA, this combination of plant science and environmental control techniques optimizes plant growth inside an enclosed space. Unlike a traditional greenhouse, this new vertical approach to cultivation leverages technology and data to maintain ideal growing conditions in a completely closed structure. These tools make it possible to filter contaminants from water for crops (keeping them out of food) and deliver the exact nutrient balance to feed any crop throughout its life cycle. Artificial lighting can eliminate the effects of fluctuating solar light, nurturing growth with a precise mix of beneficial red, blue, and green light at the right intensity and duration. Environmental controls also maintain proper temperature and humidity to prevent disease.

These practices could help feed Earth’s burgeoning future generations, said Nate Storey, chief science officer at Plenty Unlimited Inc., one of several companies building on NASA plant-growth research with an eye toward bringing agriculture into the urban environment.

Thanks and Attribution:

Mike DiCicco Managing Editor (Using Nature’s R&D Lab)