NASA’s X-57 Maxwell all-electric aircraft project will conclude aircraft operational activities by the end of September, with documentation and close-out activities continuing for several months afterwards. The research from the X-57 provides aviation researchers with hundreds of lessons learned, as well as revolutionary development in areas ranging from battery technology to cruise motor control design.

“NASA’s goal is to drive innovation through groundbreaking research and technology development. The X-57 project team has done just that by providing foundational information to industry through lessons learned, and we’re seeing the benefits borne out by American commercial aviation companies that are aiming to change the way we fly,” said Brad Flick, director of NASA’s Armstrong Flight Research Center in Edwards, California, where the X-57 aircraft was developed. “I’m incredibly proud of their tenacity and ingenuity as they led the way in advancing electrified propulsion. The future of electrified propulsion is possible because of their contributions.”

Finalizing aircraft operations by September 2023 will not incorporate first flight of the X-57 aircraft. The project encountered several challenges to safe flight, including mechanical issues late into its lifecycle and a lack of availability of critical components required to develop experimental hardware. Given the approaching planned end of aircraft operations, the timeline would not allow the team to reach acceptable flight conditions.

Although most of the X-57’s development will complete by September 2023, the team will officially conclude its work several months afterward with additional technical publications.

The primary goal of the X-57 project was to provide knowledge about the aircraft’s electric-propulsion-focused design and airworthiness process with regulators. This information has already impacted and will continue to impact the development of advanced certification approaches for electric propulsion in emerging electric aircraft markets. The objective was not to develop a prototype, but to develop a test platform for technologies and design methods. And the team did just that, documenting and publishing the technology gaps and their solutions as they were discovered so that industry stakeholders could take advantage of those lessons as soon as possible.

“They did things that had never been done before, and that’s never easy,” Flick said. “While we prepare to finish this project later this year, I see a long list of achievements to celebrate and an industry that’s better today because of their work.”

The X-57 is part of NASA’s commitment to supporting the U.S. climate goal of achieving net-zero greenhouse gas emissions from the aviation sector by 2050. Since 2016, the project has shared lessons learned about battery technology, electromagnetic interference, motor controller design, and so much more. NASA will continue its research into electric aircraft through other projects, including its Electrified Powertrain Flight Demonstration.

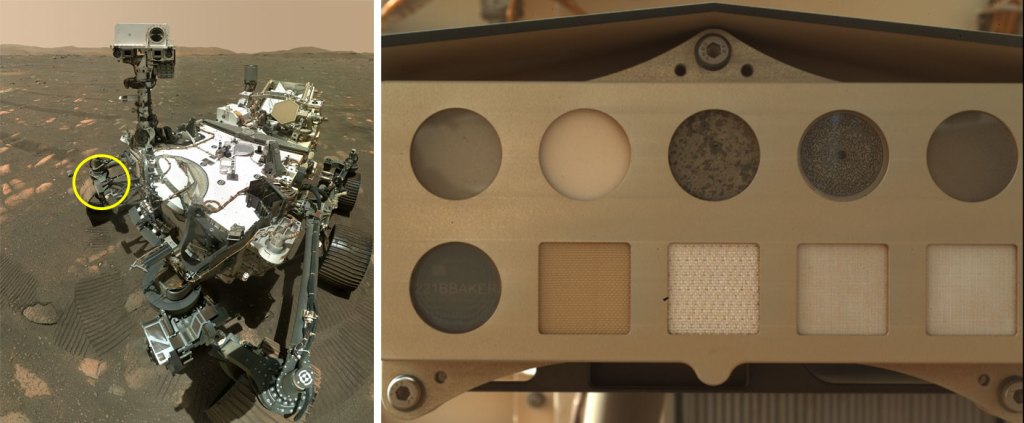

The aircraft was built by modifying an Italian Tecnam P2006T to be powered by an electric propulsion system. Using an existing aircraft design allowed the team to compare their data to that of a baseline model powered by traditional combustion engines.

Successes of X-57

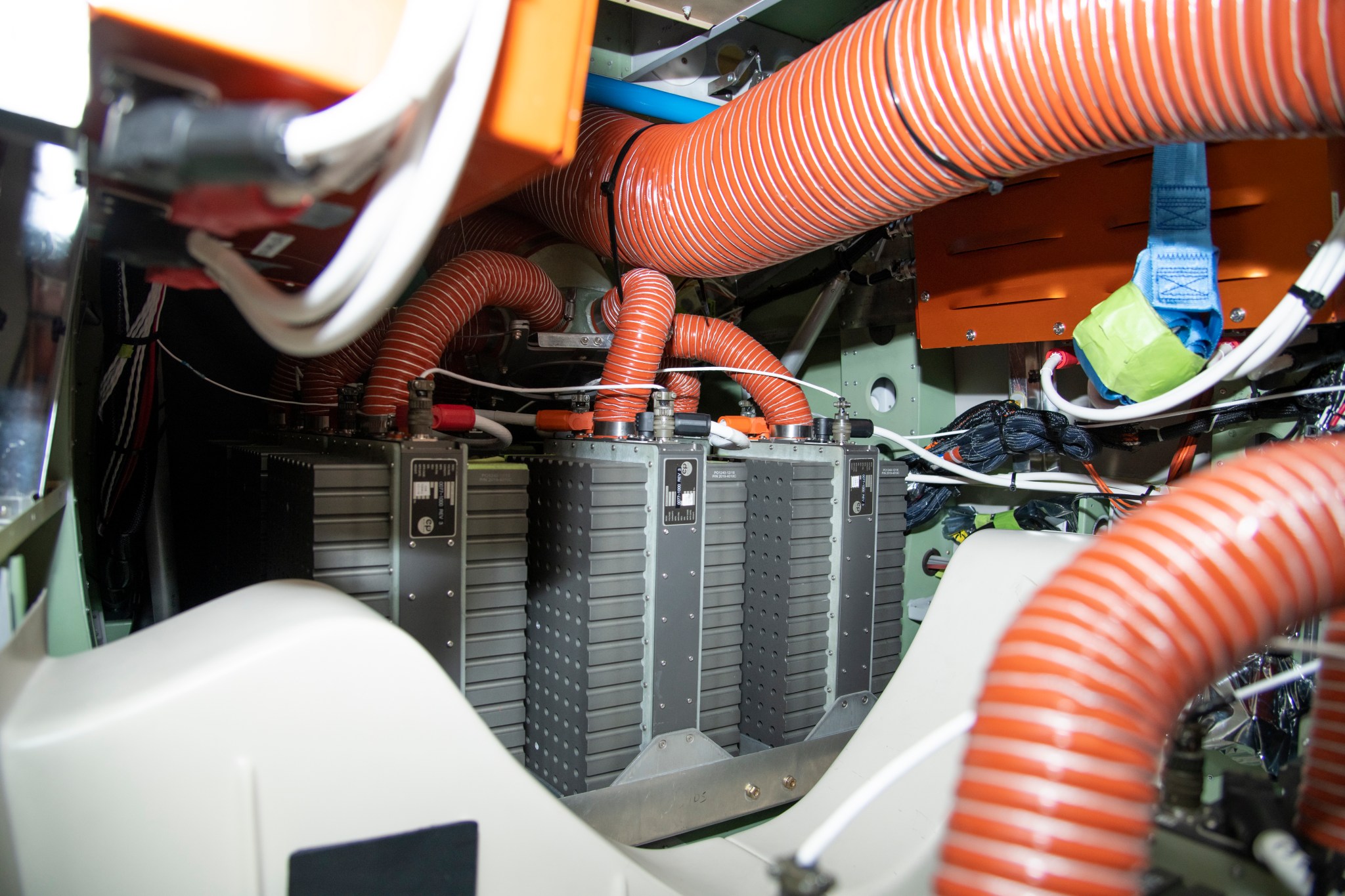

Early in the project, the X-57 team members found they would need significant developments in battery technology. The lithium-ion batteries installed on the aircraft warm up as they discharge energy and too much warming could result in overheating. The project worked with Electric Power Systems in North Logan, Utah to address this issue. Engineers demonstrated that the new battery system design would stay within acceptable, safe limits while powering the aircraft.

The design of the cruise motor controllers is another success of the X-57 project. These controllers convert energy stored in the aircraft’s lithium-ion batteries to power its motors, which drive its propellers. The controllers use silicon carbide transistors to deliver 98% efficiency intended for high power take-off and cruise, meaning they do not generate excessive heat and can be cooled off by the air flowing through the motor. The team designed inverters to meet demanding mass and thermal requirements and are sharing these designs in technical publications so that industry can use them as a launchpad for new aircraft products. Most recently, the cruise motor controllers went through successful thermal testing.

The aircraft reached another milestone with the installation of two 400-pound lithium-ion battery packs in its cabin, followed by successful tests of its motors spinning off battery power. The motors had previously spun, but were drawing energy from either the test facility, or from the batteries when they were sitting outside of the aircraft. To reach this point, the X-57 project team repeatedly tested the batteries to ensure they could safely power the aircraft, and designed custom, lightweight cases to keep those batteries secure.

During the integration phase the team encountered electromagnetic interference that affected the operation of onboard systems and required a solution. After extensive research the team designed, developed, and installed filters that resolved the issue. The approach will be added to the technical papers and shared with industry and the electric propulsion community.

The value of the pathfinding work done on the X-57 project is well established and recognized by industry and additional research findings will continue to be published and shared with the technical community. A list of the contributions X- 57 has made to-date can be found on the technical papers site.

/quantum_physics_bose_einstein_condensate.jpg?w=1024)