By Bob Granath

NASA’s Kennedy Space Center, Florida

As NASA continues preparations for the first launch of its Space Launch System (SLS) rocket and Orion spacecraft that will send humans beyond low-Earth orbit, Exploration Ground Systems (EGS) at the agency’s Kennedy Space Center in Florida is preparing to build the world’s largest liquid hydrogen storage tank. It will involve new technologies developed by researchers at the spaceport’s Cryogenics Test Laboratory.

The innovation is like going from an ice box to a modern refrigerator.

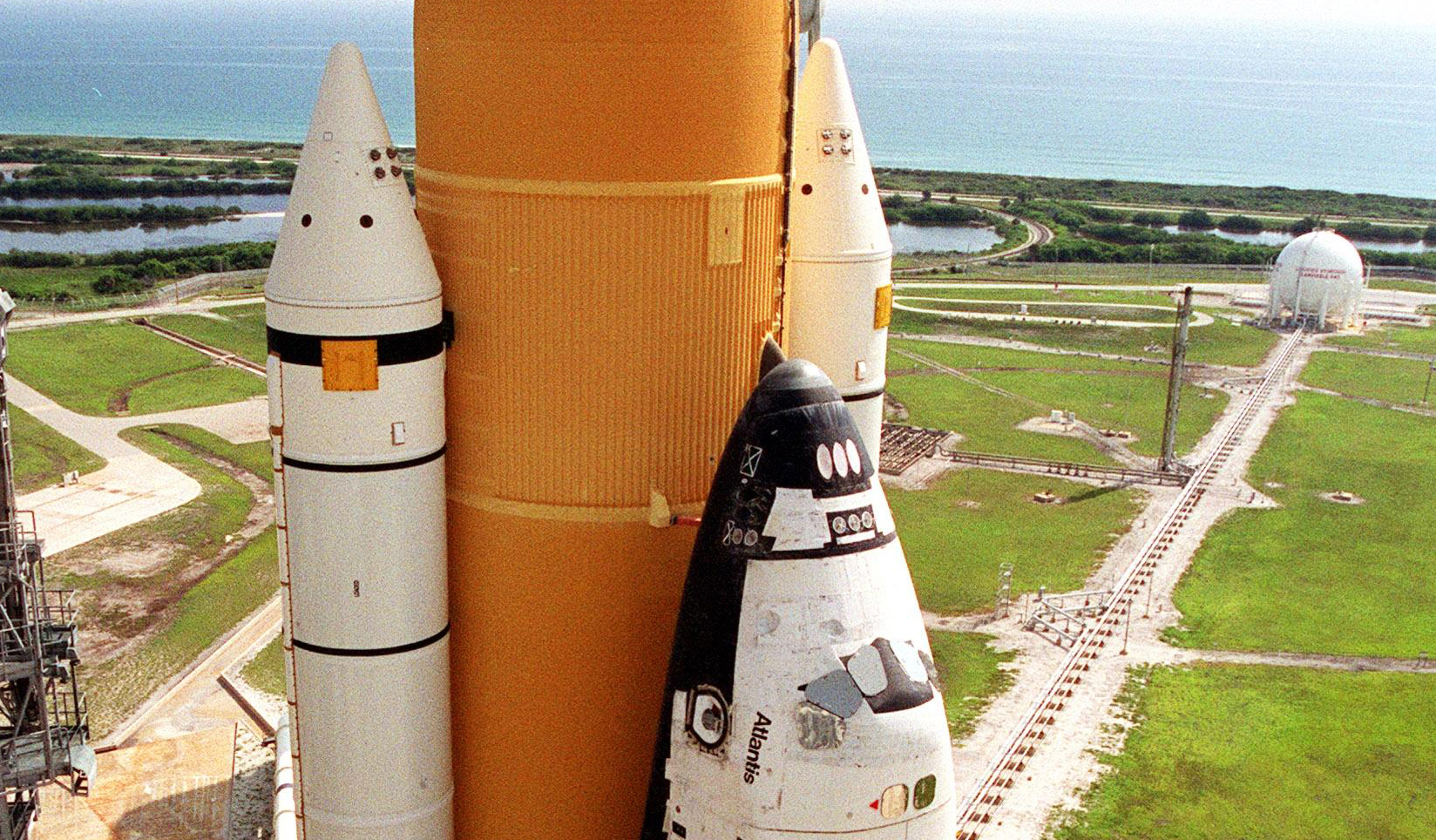

When NASA launched the first astronauts to the Moon, propellants for the Saturn V’s second and third stages were liquid hydrogen and liquid oxygen. Prior to being loaded into the launch vehicle, they were stored in 850,000 gallon spherical containers — each about 1,500 feet from the pad. These storage tanks served the same purpose during the 30-year Space Shuttle Program.

But the equipment design was dated, explains James Fesmire, senior principal investigator for Kennedy Exploration Research and Technology Programs.

“The technology for storing large quantities of liquid oxygen was developed during the early stages of World War II,” he said. “Material and process for the liquid hydrogen and liquid oxygen tanks at Pads 39A and B were made of stainless steel, developed in the 1950s.”

The ongoing problem during Apollo and the shuttle era was significant boil off or evaporation and the operational limitations.

While liquid hydrogen and liquid oxygen are excellent, high-performance rocket propellants, they are cryogenic — meaning super cold. The oxygen in liquid state is minus 297 degrees Fahrenheit and hydrogen is minus 423 degrees Fahrenheit. Because of ambient temperatures, storing these commodities is like storing ice in an oven.

“The existing storage tanks were vacuum-jacketed with three-foot-thick perlite insulation,” said Adam Swanger, a research engineer in Kennedy Engineering. “They were state-of-the-art in 1965. But boil off was on an ongoing problem and substantial losses were unavoidable.”

Fesmire noted that roughly half of the liquid hydrogen purchased to fuel the space shuttle’s three main engines was lost due to boil off evaporation.

“We felt like there had to be a better way,” he said.

Since 2001, Dr. Bill Notardonato, a principal investigator in Kennedy’s Exploration Research and Technology Programs, and Dr. Jong Baik, of the Florida Solar Energy Center, have been working at the center’s Cryogenics Test Laboratory pioneering a technology to mitigate these loses.

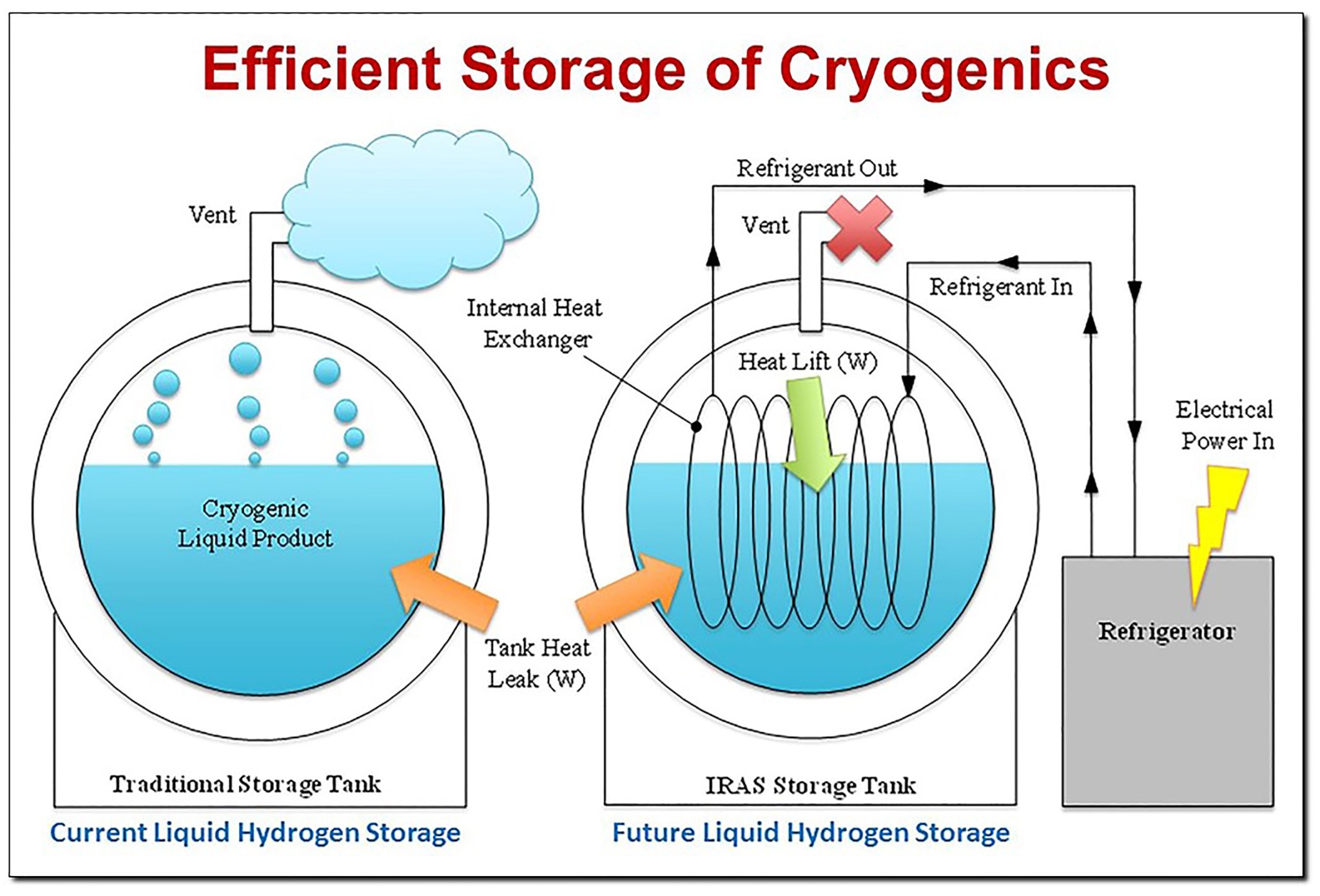

Integrated Refrigeration and Storage, or IRaS, is a refrigeration system allowing control of the fluid inside the storage tanks. This approach provides direct removal of heat energy using an integrated heat exchanger together with a cryogenic refrigeration system. Studies of the new technology began with analysis, modeling and a series of laboratory research tests.

“IRaS is important because it allows unprecedented control in storing cryogenic liquids,” Notardonato said. “The normal evaporation rate or ‘boil off’ can now be a thing of the past.”

The new technology also is being coupled with new glass “bubble” insulation to replace perlite powder. Based on various field demonstration tests completed at Kennedy and NASA’s Stennis Space Center in Mississippi in 2015, with glass bubble insulation, liquid hydrogen losses through boil off can be reduced by as much as 46 percent. If IRaS is employed, boil off can be eliminated altogether. This will be especially important for the new liquid hydrogen tank that will hold 1.25 million gallons.

Comparatively speaking, it’s like going from storing ice in a foam cup to keeping it in a freezer. While insulation in a foam cup will slow melting, it won’t stop it and there is no control. Similarly, cryogenic liquids evaporate when stored in an insulated container, even one with the highest performance vacuum-jacketing.

In a freezer with temperature control, ice can be stored indefinitely. The same is true with liquid hydrogen using IRaS — spending about 15 cents in electricity saves $1 in hydrogen.

To support fueling of NASA’s SLS rocket, Kennedy’s EGS Program soon will begin construction of the new liquid hydrogen storage tank at Pad 39B. The SLS rocket is designed to launch the agency’s Orion spacecraft, sending humans to distant destinations, such as the Moon and Mars. The SLS core stage and in-space stage will require 730,000 gallons of liquid hydrogen and liquid oxygen to fuel the four core stage and single upper stage engine.

“The larger tank will allow us to attempt SLS launches on three consecutive days,” Fesmire said. “In the past, we had to stand down after two attempts so additional liquid hydrogen could be trucked in and loaded into the storage tank.”

Swanger noted that NASA at Kennedy is developing state-of-the-art technologies that not only support agency missions, but commercial companies and partners such as SpaceX and Blue Origin as part of the center’s role as a premier, multi-user spaceport.

“By choosing to implement the new IRaS technologies, EGS is effectively creating the future,” he said. “It’s an innovation that could impact how things are done here and throughout the cryogenic Industry for generations to come.”