An advanced coating now being tested aboard the International Space Station for use on satellite components could also help NASA solve one of its thorniest challenges: how to keep the Moon’s irregularly shaped, razor-sharp dust grains from adhering to virtually everything they touch, including astronauts’ spacesuits.

Although the coating wasn’t originally conceived for lunar dust busting, “it’s compelling for this application,” said Bill Farrell, a scientist at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, who heads a NASA-sponsored research organization, Dynamic Response of the Environments at Asteroids, the Moon, and moons of Mars, or DREAM2, which studies the lunar and Martian environments. The agency considers lunar dust to be among the top challenges to mitigate as it aims to establish sustainable exploration of the Moon by 2028 under its Artemis Program.

Mitigating Electrical Build-Up

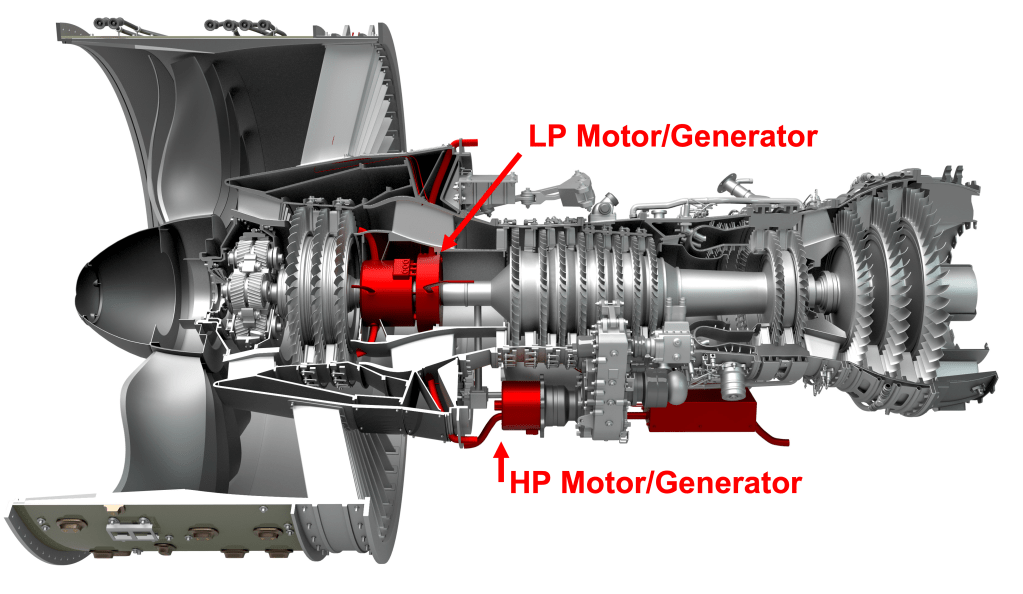

Goddard technologists Vivek Dwivedi and Mark Hasegawa originally created the coating for an equally important job: they wanted to create a coating that would help “bleed off” the build-up of electrical charges that can destroy spacecraft electronics. These potentially mission-ending build-ups occur when spacecraft fly through plasma found within Earth’s magnetosphere. Plasma contains trapped charged particles that conduct electricity, contributing to the build-up.

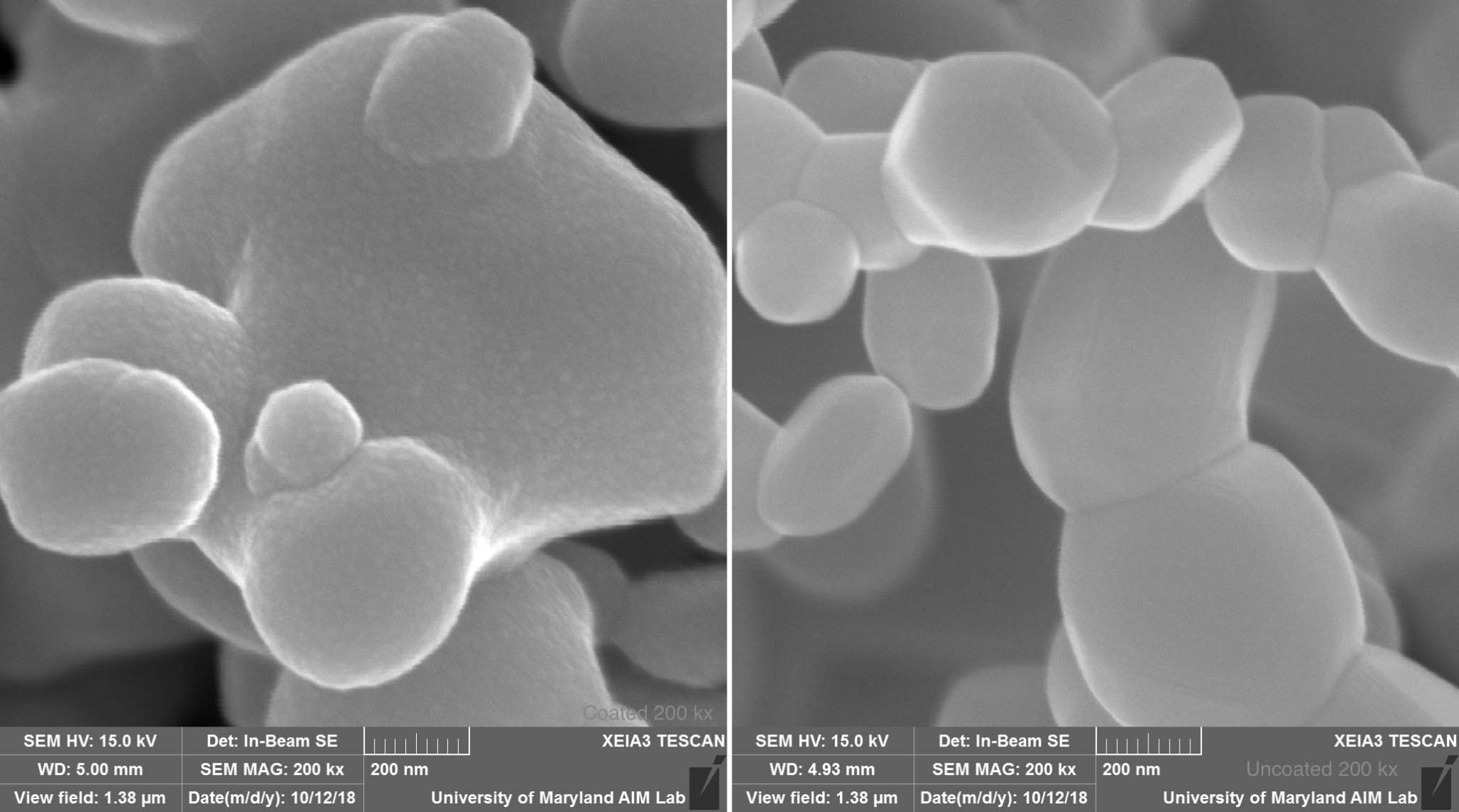

Hasegawa’s idea was to use an advanced technology called atomic layer deposition to apply super-thin films of indium tin oxide — an effective compound for dissipating electrical charges — onto dry pigments of paint. Once mixed, the paint could then be coated on radiators and other spacecraft components to help mitigate the build-up of electrical charges.

Used ubiquitously by industry, atomic layer deposition involves placing a substrate or sample inside a reactor chamber, which is like an oven, and pulsing different types of gases to create an ultra-thin film whose layers are literally no thicker than a single atom. The beauty of this technique is the fact that it can be applied on virtually anything, including three-dimensional objects.

To test the effectiveness of the pigment-treated paint, Dwivedi and his team then prepared a handful of coated coupons or wafers, which are now being exposed to plasma from an experiment pallet aboard the International Space Station. Hasegawa and Dwivedi expect to get their samples later this year for analysis.

“Dust is going to be the environmental problem for future missions, both inside and outside habitats.” — Harrison “Jack” Schmitt, geologist and Apollo 17 astronaut

Same Plasma, Same Trouble

As it turns out, the plasma that can damage electronics as spacecraft fly through Earth’s magnetosphere is also the source of the Moon’s dust problem.

The Moon’s dust is made up of ultra-tiny grains — formed by millions of years of meteorite impacts that repeatedly crushed and melted rocks, creating tiny shards of glass and mineral fragments. Not only can they travel at hurricane-like speeds, but they also cling to all types of surfaces, not only because of their jagged edges, but also because of their electrostatic charge.

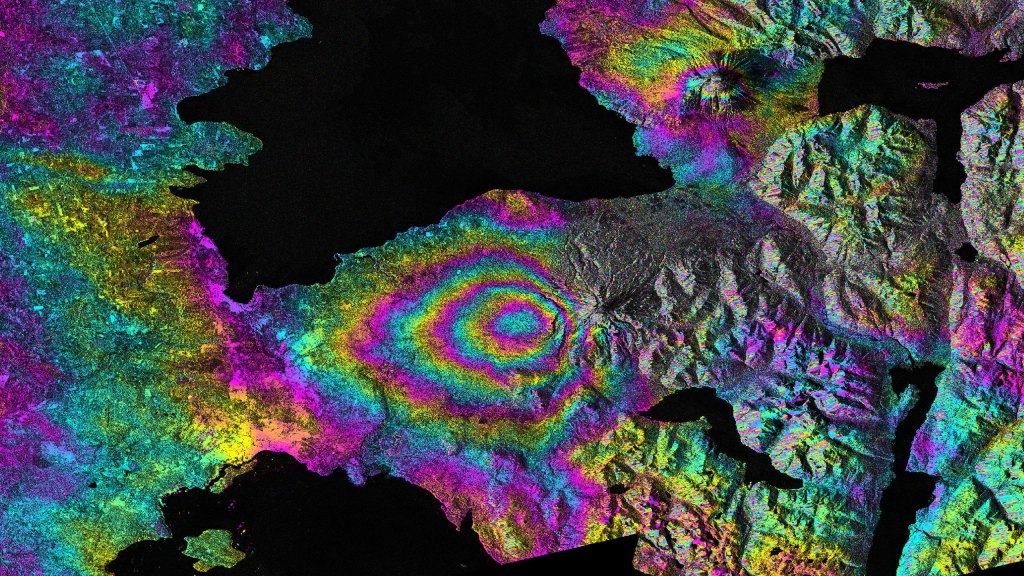

On the day side of the Moon, harsh, unshielded ultraviolet radiation from the Sun kicks electrons off the dust particles in the upper layers of the lunar regolith or soil, giving the surface of each dust particle a net positive charge. On the dark side as well as in the polar regions, the situation is a little different. Plasma flowing out from the Sun also charges the lunar surface, but, in this case, it deposits electrons and creates a net negative charge. It gets more complex at the terminator where the two sides meet and even stronger electric fields develop—all of which could affect humans or technology that land on the Moon.

For astronauts, the situation will be made worse because they carry their own charge and, as the Apollo missions proved, will attract dust as they rove about the Moon. Because NASA has eyed the Moon’s southern pole for possible human habitation, it’s especially important that NASA develop efficient ways to dissipate these charges, Dwivedi said.

That got Dwivedi thinking. Why not apply the coating to Moon rovers and even habitats, or use atomic layer deposition to treat the fibers in spacesuit material?

“We have conducted a number of studies investigating lunar dust. A key finding is to make the outer skin of the spacesuits and other human systems conductive or dissipative,” Farrell said. “We, in fact, have strict conductivity requirements on spacecraft due to plasma. The same ideas apply to spacesuits. A future goal is for the technology to produce conductive skin materials, and this is currently being developed.”

More Research Underway

Working in collaboration with Farrell, Dwivedi and his team, including University of Maryland researcher Raymond Adomaitis, now plan to further enhance their atomic layer deposition capabilities. The team plans to construct a larger reactor, or oven, to increase the yield of the charge-mitigating pigment, which they would then apply to coupons and spacesuit material for testing.

“Constructing a large-volume atomic layer deposition system to create kits that can coat large surface areas, such as rover surfaces, for testing can further benefit technologies for lunar exploration,” Farrell said.

For more Goddard technology news, go to: https://www.nasa.gov/wp-content/uploads/2019/11/fall_2019_final_web_version.pdf?emrc=7fcd63

By Lori Keesey

NASA’s Goddard Space Flight Center