In March, the Relativity Space Terran 1 rocket lit up the night sky as it launched from Cape Canaveral Space Force Station in Florida. This was the first launch of a test rocket made entirely from 3D-printed parts, measuring 100 feet tall and 7.5 feet wide. A form of additive manufacturing, 3D printing is a key technology for enhancing capabilities and reducing cost. Terran 1 included nine additively manufactured engines made of an innovative copper alloy, which experienced temperatures approaching 6,000 degrees Fahrenheit.

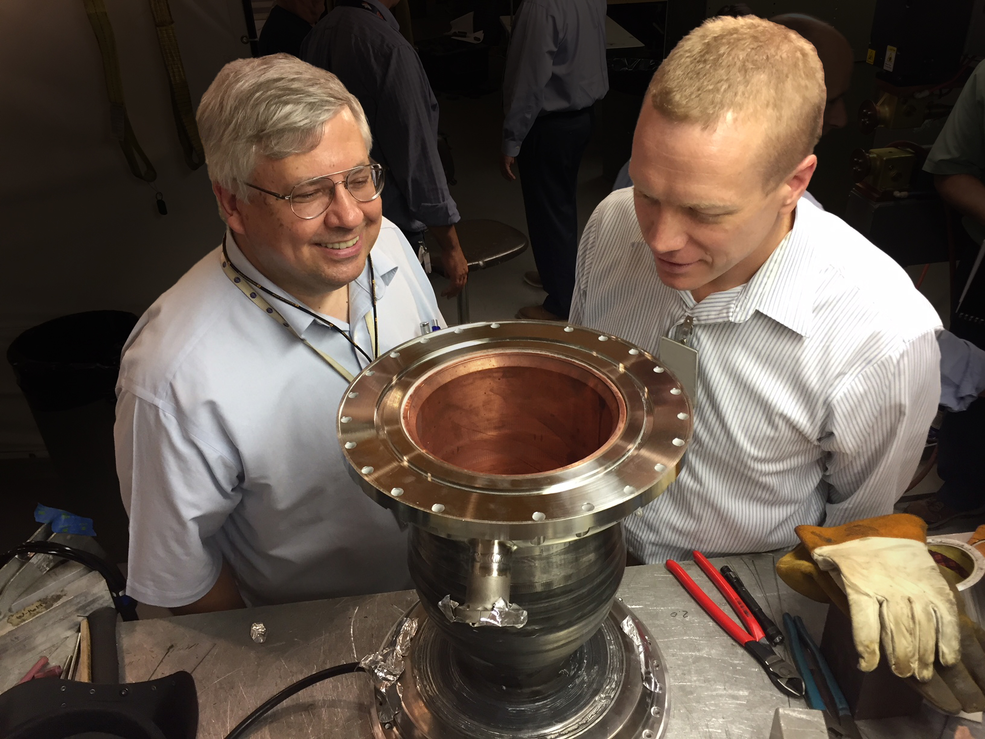

Created at NASA’s Glenn Research Center in Cleveland under the agency’s Game Changing Development program, this family of copper-based alloys known as Glenn Research Copper, or GRCop, are designed for use in combustion chambers of high performance rocket engines. A combination of copper, chromium, and niobium, GRCop is optimized for high strength, high thermal conductivity, high creep resistance – which allows more stress and strain in high temperature applications – and good low cycle fatigue – which prevents material failures –above 900 degrees Farenheit. They tolerate temperatures up to 40% higher than traditional copper alloys, which leads to higher performance components and reusability.

In the late 1980s, NASA wanted to develop an engine for manuvering spacecraft in low-Earth orbit that could withstand multiple firings. Rocket engines encounter complex challenges in design and environments in which they operate, including multiple startups and shutdowns that create a cycle of wear and tear on critical components.

Dr. David Ellis developed the GRCop family of alloys as a NASA-supported graduate student during the space shuttle era. He continued to mature the alloys and their applications throughout his career.

“At the time, Space Shuttle Main Engine combustion chamber liners were typically replaced after one to five missions,” explained Ellis. “Our research was able to show that GRCop-84 would easily meet the goal of 100 missions between maintenance service and 500 missions of engine life.”

Throughout years of alloy development, Ellis and his team worked with multiple projects and programs, like NASA’s Rapid Analysis and Manufacturing Propulsion Technology (RAMPT), to advance different versions of GRCop alloys. The most recent iteration, named GRCop-42, uses a variety of additive manufacturing methods to create single-piece and multi-material combustion chambers and thrust chamber assemblies for rocket engines. These processes improved the performance, while significantly reducing weight and costs of thrust chamber components.

NASA found that the GRCop alloys pair very well with the latest additive manufacturing methods. Modern manufacturing methods such as laser powder bed fusion and directed energy deposition are two approaches that can be used to build GRCop parts for many aerospace applications, such as the Terran 1 rocket engines.

In laser powder bed fusion, a 3D computer model is sliced into thin layers digitally. Then, a powder bed machine, which acts like a printer, begins a process of spreading and fusing thin layers of powder atop one another, thousands of times over to form a complete part. This process of bonding layers together results in materials strength that is comparable to forged metal. The advantage of this method is that finely detailed parts can be created, such as nozzles and cooling channels used for combustion chambers and nozzles.

The directed energy deposition (DED) process uses a laser to create a melt pool. Powder is then blown into the melt pool and cools creating solid material. The 3D motion of a robot directs the building process to create the entire part with the laser and blown powder. The DED process produces larger shapes and components compared to laser powder bed fusion, but with fewer fine details.

“Development projects, like RAMPT, allow advancement of new alloys and processes for use by commercial space, industry, and academia,” said Paul Gradl, principal engineer at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “NASA takes on the development risk and matures the process from early material and process concepts through certification. This infusion of GRCop-42 alloys into commercial space is another great example of how NASA-led innovations advance industry capabilities and contribute to America’s growing space economy.”

Under a reimbursable Space Act Agreement, NASA provided technical expertise to Relativity Space that moved GRCop-42 from development into a flight-ready product used to launch the Terran 1 rocket. Relativity Space has shown these higher performing rocket engine components, produced by additive manufacturing with GRCop alloys, could be used in future missions to the Moon, Mars, and beyond.

Game Changing Development is part of NASA’s Space Technology Mission Directorate, which develops new cross-cutting technologies and capabilities for NASA’s current and future missions.

Nancy Smith Kilkenny

NASA’s Glenn Research Center