A facility built during World War II now finds itself on the front lines of NASA’s electrified propulsion renaissance as it looks to further develop green technologies for sustainable commercial aviation and revolutionary vertical lift aircraft.

The Engine Research Building (ERB) at NASA’s Glenn Research Center is a massive test complex, spanning more than 152,000 square feet, and home to more than 60 test rigs. It is being upgraded to meet research demands, both for aeronautics and spaceflight, while also making it an attractive test location for industry customers.

“The ERB has gone through many adaptations over the years, from improving our ability to test aircraft engine components to adding newer test cells that support space research,” said Gwynn Severt, ERB facility manager. “It is a necessary step to ensure we can meet the ever-changing goals of the nation’s aerospace research.”

One upgrade is a full fiber optic network, linking the test cells into a virtual complex that allows several rigs to complete multiple steps of a single test or test different components at the same time. This saves time and money by eliminating the need to swap hardware or locations to complete intricate test campaigns.

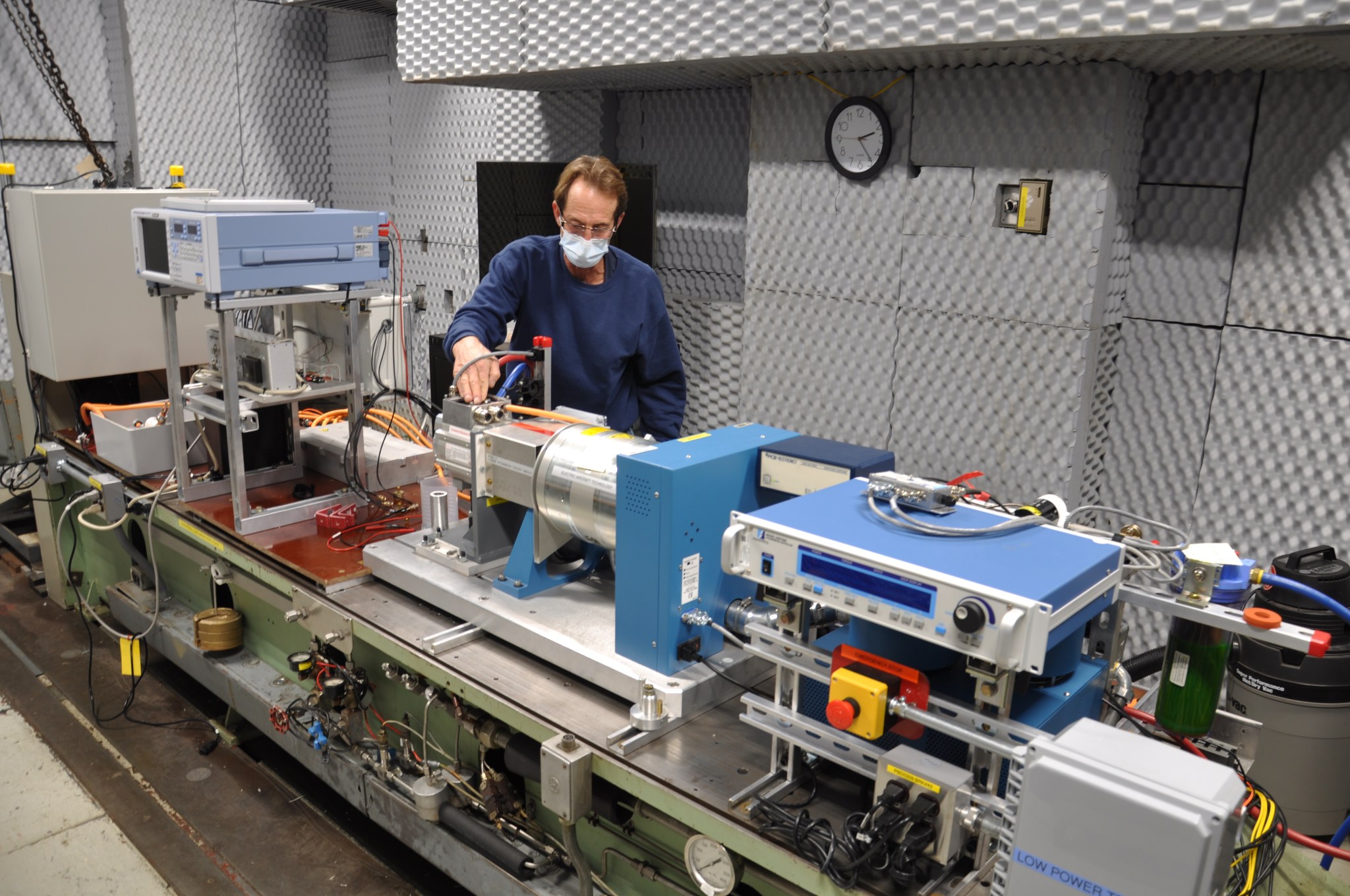

NASA’s focus on electrified aircraft propulsion (EAP) provides an opportunity for the ERB to contribute to the agency’s ambitious flight research goals. Several labs have already been converted to help explore the machines, drives, and subsystems needed for large-scale electric, hybrid-electric, and turboelectric propulsion.

“NASA is examining the possibility of electrifying propulsion systems for vertical lift and fixed-wing vehicles in order to help save energy and fuel, provide cost savings, and increase mobility,” said Amy Jankovsky, EAP technologies project manager at NASA Glenn.

One emerging area under investigation at the ERB is electrified propulsion for vertical takeoff and landing concept vehicles, like those used for advanced air mobility, including everything from small delivery drones to air taxis. There, engineers are developing and testing high-voltage distribution and protection, advanced motors and drives, and novel thermal management concepts.

Beyond vertical lift, NASA is using the ERB to advance flight-weight electric technologies, small core engines, superconducting materials, and other components for potential use in commercial aviation.

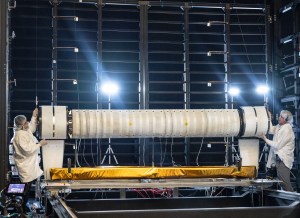

The facility is also now capable of simulating the environmental conditions – temperatures and magnetic fields – these technologies will experience during long-haul flights. This includes the capability to drop temperatures to the boiling point of liquid hydrogen, around 20 degrees Kelvin or -423 degrees Fahrenheit.

Once used to test bomber engines for the Army Air Corps, the renovated ERB is now writing the next chapter of NASA’s groundbreaking research for the future of flight.

Jimi Russell and Doreen Zudell

NASA’s Glenn Research Center