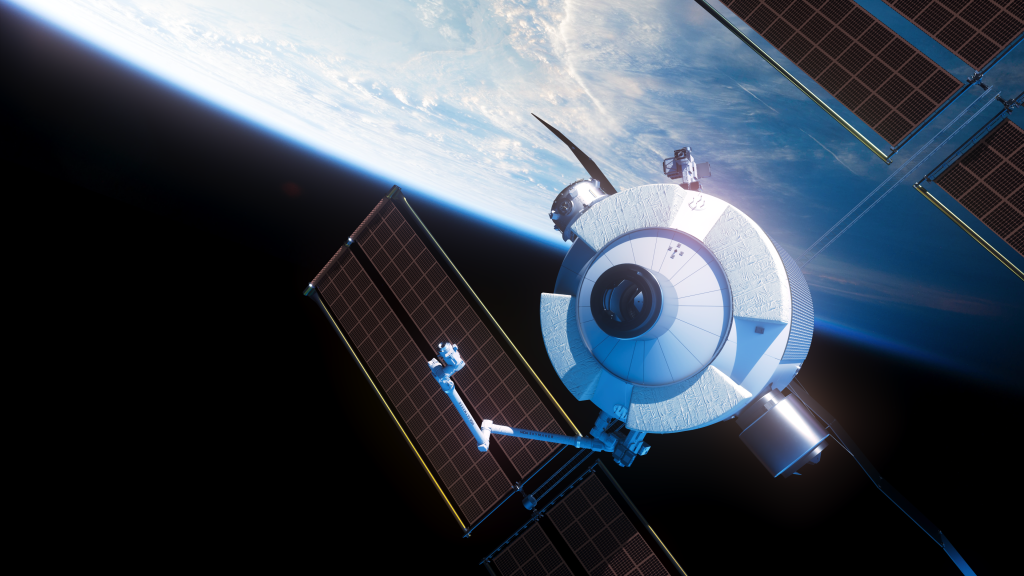

The recently completed Orion spacecraft for Artemis I will head to Ohio for the final stretch of major testing before integration with the Space Launch System rocket for launch.

Slated to begin this fall, a team of engineers and technicians stand ready to test the spacecraft, consisting of the crew and service modules, under simulated extreme in-space conditions in the world’s premier space environments test facility at NASA’s Plum Brook Station in Sandusky, Ohio.

“The tests will confirm the spacecraft’s systems perform as designed, while ensuring safe operation for the crew during future Artemis missions – both on the ground and inflight,” said Nicole Smith, project manager for Orion testing at Plum Brook Station. “We like to say ‘we test like we fly,’ and that is exactly what we are going to accomplish during the upcoming Artemis 1 environmental test.”

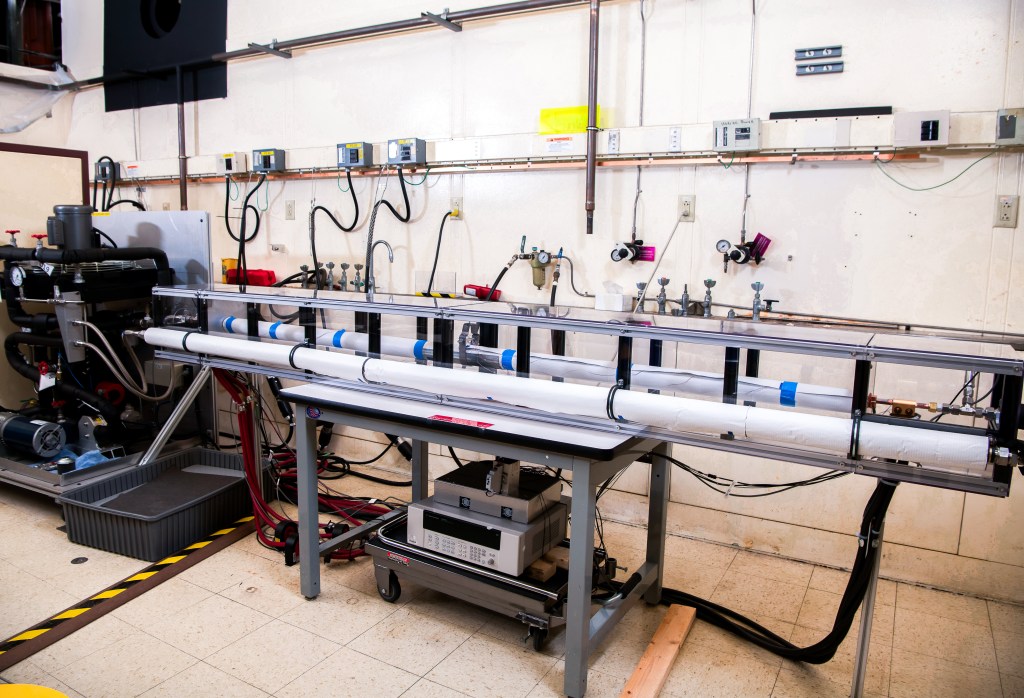

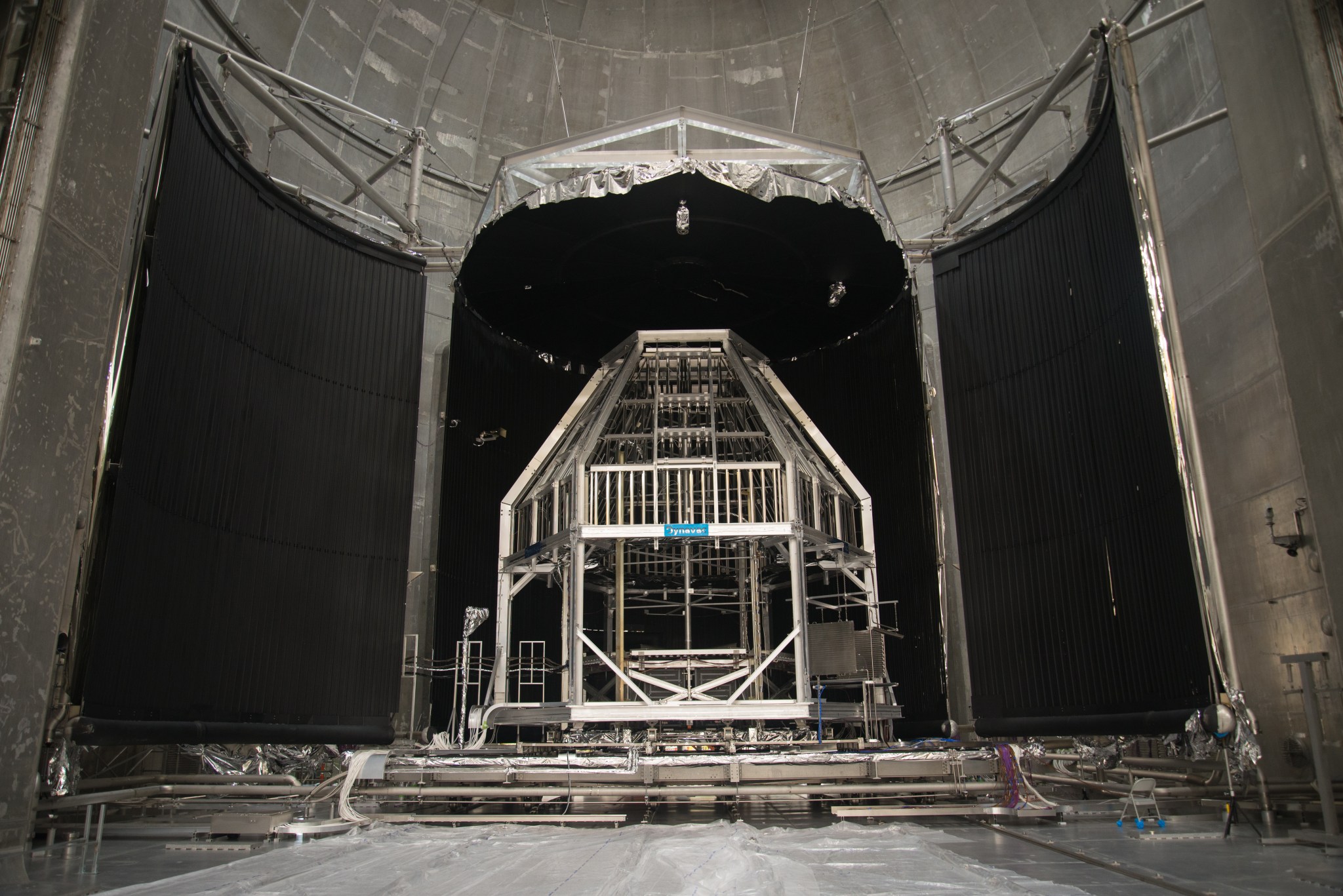

Completed in two phases inside the world’s largest vacuum chamber, testing begins with a thermal test, which will last approximately 60 days, while Orion’s systems are powered-on under vacuum conditions that simulate the space environment.

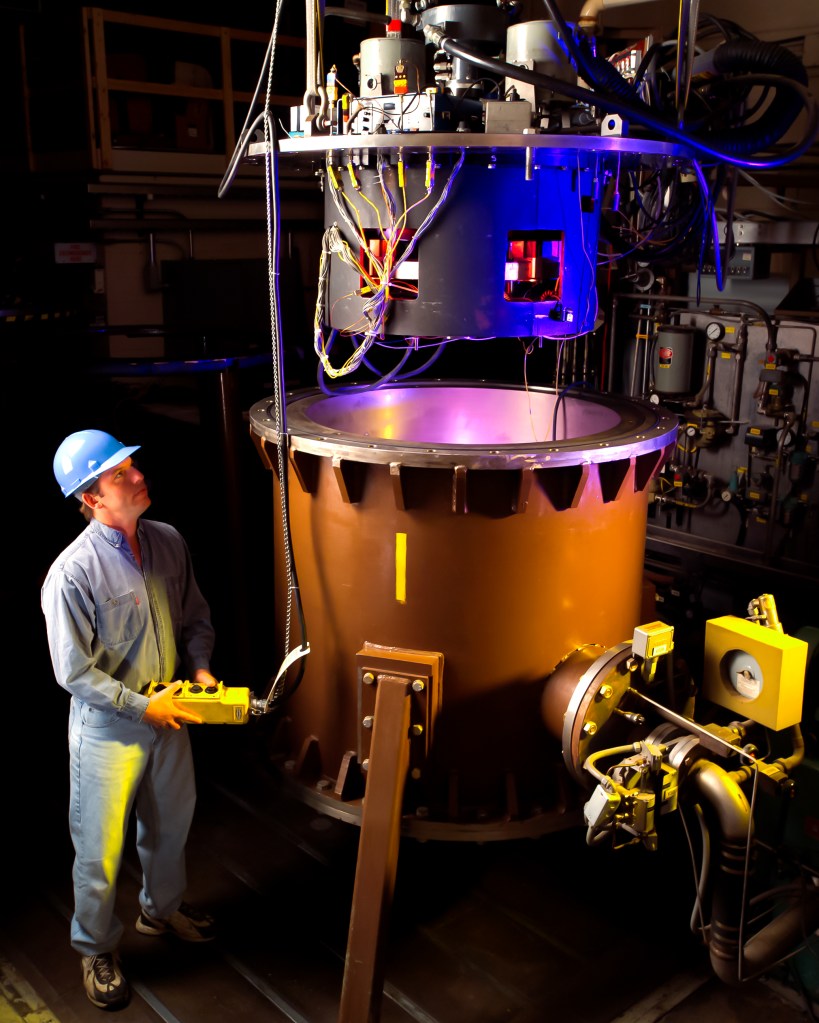

During this phase, the spacecraft will be subjected to extreme temperatures, ranging from -250 to 300-degrees Fahrenheit, to replicate flying in-and-out of sunlight and shadow in space. To simulate these conditions, a specially-designed system, known as the Heat Flux, will be used to heat specific parts of the spacecraft at any given time. It will also be surrounded on all sides by a set of large panels, called a cryogenic-shroud that will provide the cold background temperatures of space.

The second phase is an electromagnetic interference and compatibility test, lasting about 14 days. Every electronic component gives off some type of electromagnetic field that can affect the performance of other electronics nearby. This testing will ensure the spacecraft’s electronics work properly when operated at the same time.

The vacuum chamber at Plum Book is uniquely suited for this testing as it can provide a radio frequency free, or quiet, environment. Having a quiet test facility is important as it prevents external sources from affecting the test. The chamber’s walls are also made of highly reflective aluminum, which allows engineers to bathe the spacecraft in frequencies to simulate outside sources.

“This facility is the only place in the world that can perform these mission-critical tests under one roof,” said Bob Kowalski, SEC’s facility manager. “This one-stop capability reduces risk by eliminating the need to transport a vehicle to multiple locations to test, and the skill of our workforce makes it the best place to evaluate spacecraft.”

After successful completion, the spacecraft will return to NASA’s Kennedy Space Center, where it will begin integration with the powerful Space Launch System (SLS) rocket and other pre-launch preparations in advance of Artemis I.

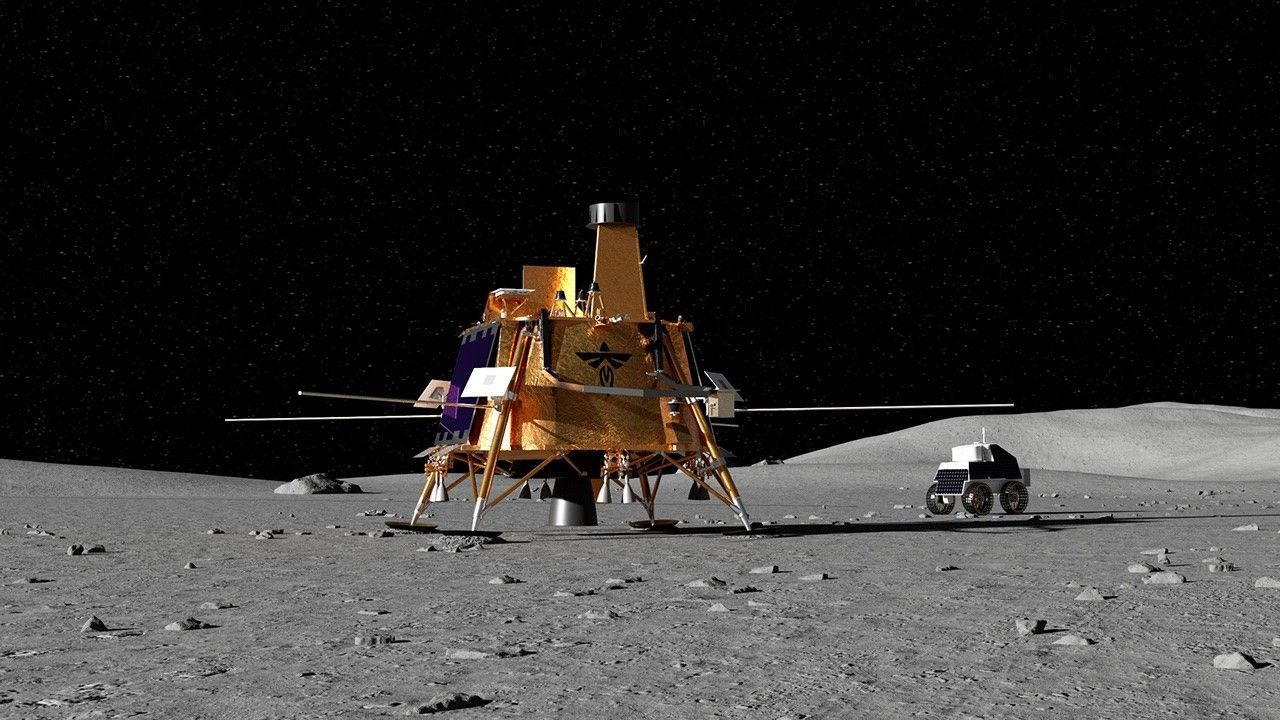

Orion, SLS and the Gateway in lunar orbit will be NASA’s exploration backbone as the agency returns humans to the surface of the Moon by 2024, while building a sustainable, long-term lunar presence by 2028. We then will use what we learn on the Moon to send astronauts to Mars.

Jimi Russell

NASA’s Glenn Research Center