When Boeing launches its uncrewed maiden voyage of the CST-100 Starliner to the International Space Station this week, it will mark a critical milestone toward NASA’s return of launching American astronauts to space using American spacecraft from American soil.

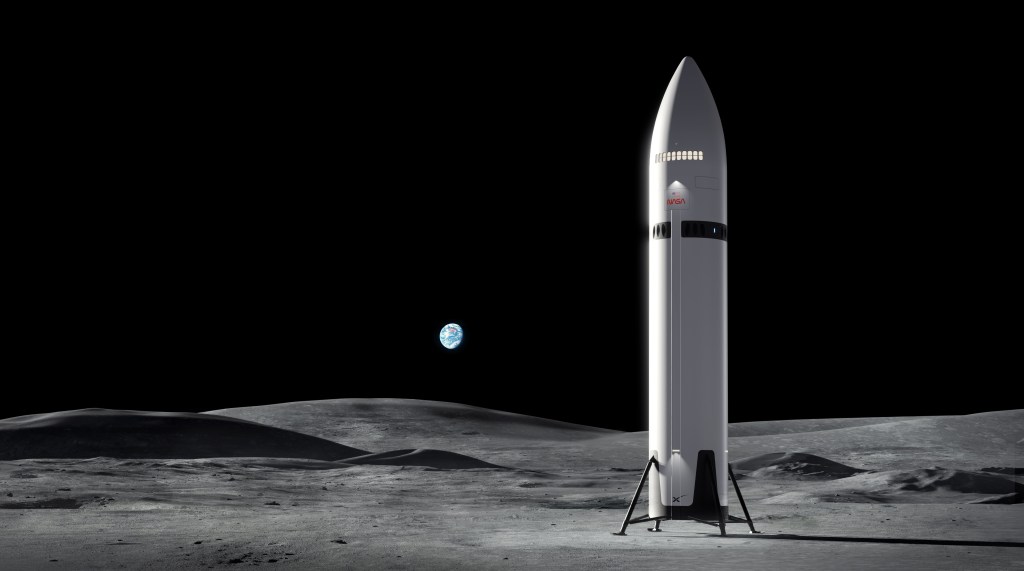

Private companies already play an instrumental role in the U.S. space program by ferrying critical research, supplies and other cargo to the space station through commercial resupply services contracts. In this next phase, commercial crew partners Boeing and SpaceX will carry humans, like a taxi or a city bus shuttling people to their destination and home again. NASA’s goal is to become one customer of many customers in a robust low-Earth orbit economy, enabling the agency to realize the next generation of human space exploration through the Artemis program to the Moon and on to Mars.

Based upon more than 50 years of American experience working in space, these companies build complete spaceflight systems. With essential support from NASA centers across the country, these public-private partnerships are making a new way of accessing space possible. NASA provides the space industry with critical expertise, research and testing to ensure rockets and spacecraft are safe and reliable.

Commercial space partners are already strong in many areas of spacecraft design. NASA identified the core safety requirements and provides insight and feedback for ways to meet those needs, rather than specifying all the elements of design, allowing the companies to create innovative solutions. This process involves feedback to and from the agency and the companies from the initial design approach all the way to the final build.

Getting humans to space and home again safely is a truly niche enterprise. The companies building a commercial space industry often turn to NASA for unique facilities and skill sets they need to do this work.

Some of these facilities focus on how NASA can ensure a spacecraft is safe to fly and return home safely. In wind tunnels at NASA’s Ames Research Center in California’s Silicon Valley and NASA’s Langley Research Center in Hampton Roads, Virginia, teams take models of commercial spacecraft and blast them with air to see how the designs will hold up in flight. This work helped improve the ascent and launch abort systems of these spacecraft using experience gained from the development of NASA’s Orion crew vehicle and Space Launch System rocket, or SLS.

NASA facilities are fundamental to the construction and launch of commercial rockets. The Starliner is the first crew capsule to be completely built on Florida’s Space Coast at Boeing’s Commercial Crew and Cargo Processing Facility located at NASA’s Kennedy Space Center in Florida, retrofitted from a NASA Orbiter Processing Facility used during the Shuttle program.

NASA’s Marshall Space Flight Center in Huntsville, Alabama, works to ensure the safety of NASA astronauts aboard the country’s first commercial crewed space launch vehicles. Engineers at Marshall have propulsion expertise from the Apollo, Shuttle and now Artemis mission programs and, from those experiences, understand launch vehicles and propulsion systems.

NASA’s White Sands Test Facility in Las Cruces, New Mexico, hosted much of the propulsion system testing for the Starliner, including the integrated service module hot fire test. And the end-to-end test of its abort system took place at the adjacent Launch Complex 32 at the U.S. Army’s White Sands Missile Range.

And just as NASA’s very first human spaceflight missions, the Mercury and Gemini programs, did before, the commercial rockets of today launch from either Kennedy or Cape Canaveral’s Air Force Station in Florida. NASA’s operations at these facilities for more than half a century ensure smooth sailing from a spacecraft’s arrival until countdown and launch.

While Starliner is designed to fly autonomously, astronauts are trained to step in for almost any emergency situation. NASA’s Johnson Space Center in Houston is equipped with Starliner simulators and trainers – including the Boeing Mission Simulator, which looks, feels and operates just like the Starliner itself – to ensure the astronauts are prepared for any situation that may arise during their missions.

Flight control teams in NASA’s Christopher C. Kraft Mission Control Center at Johnson will take part in all commercial crew flights from the ground. The International Space Station flight control teams will make sure the space station is ready to welcome Starliner, and just down the hall a new Starliner flight control team including flight directors who have a very long and proud history of flying human-rated spacecraft, will oversee Starliner’s mission.

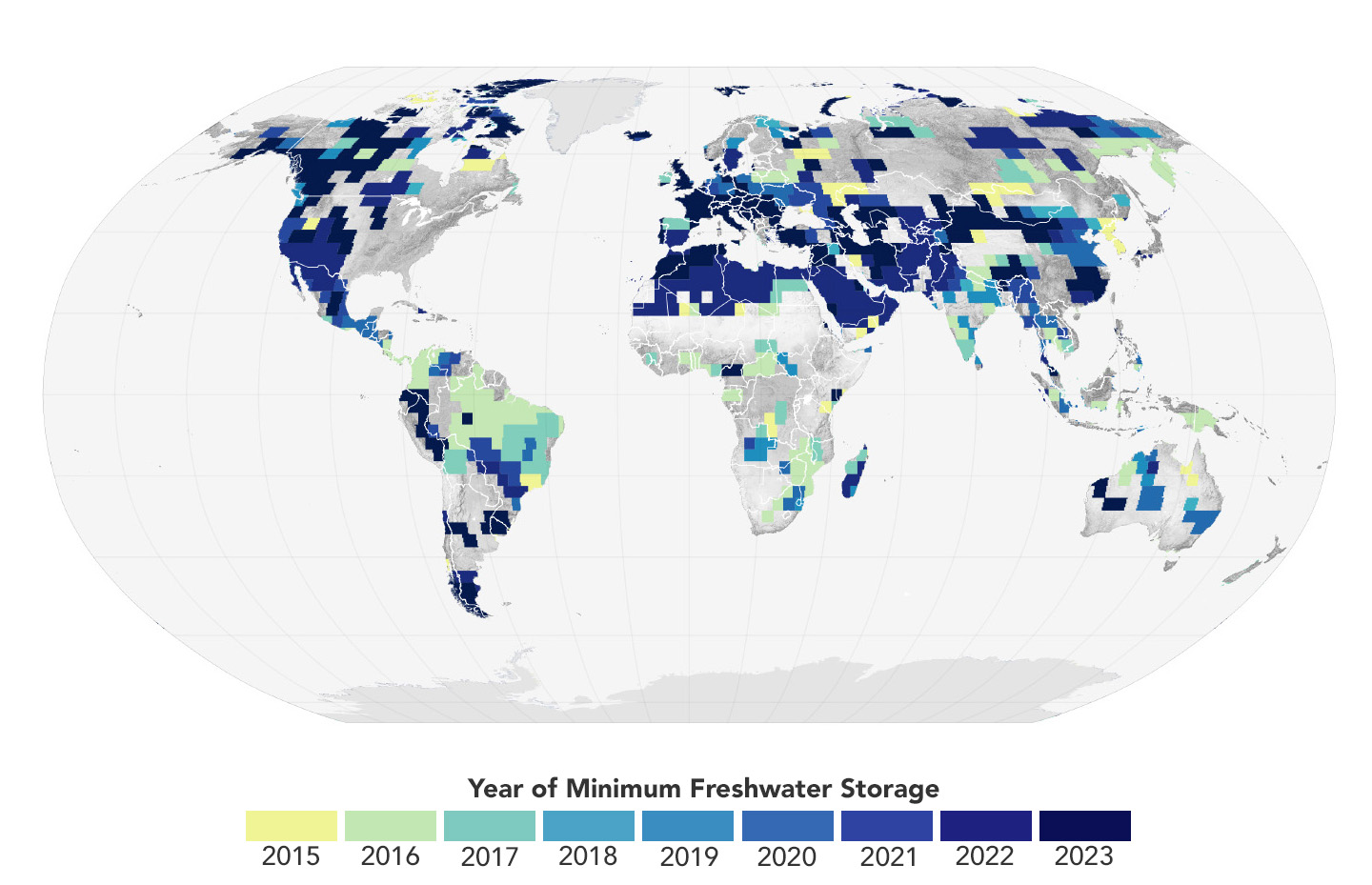

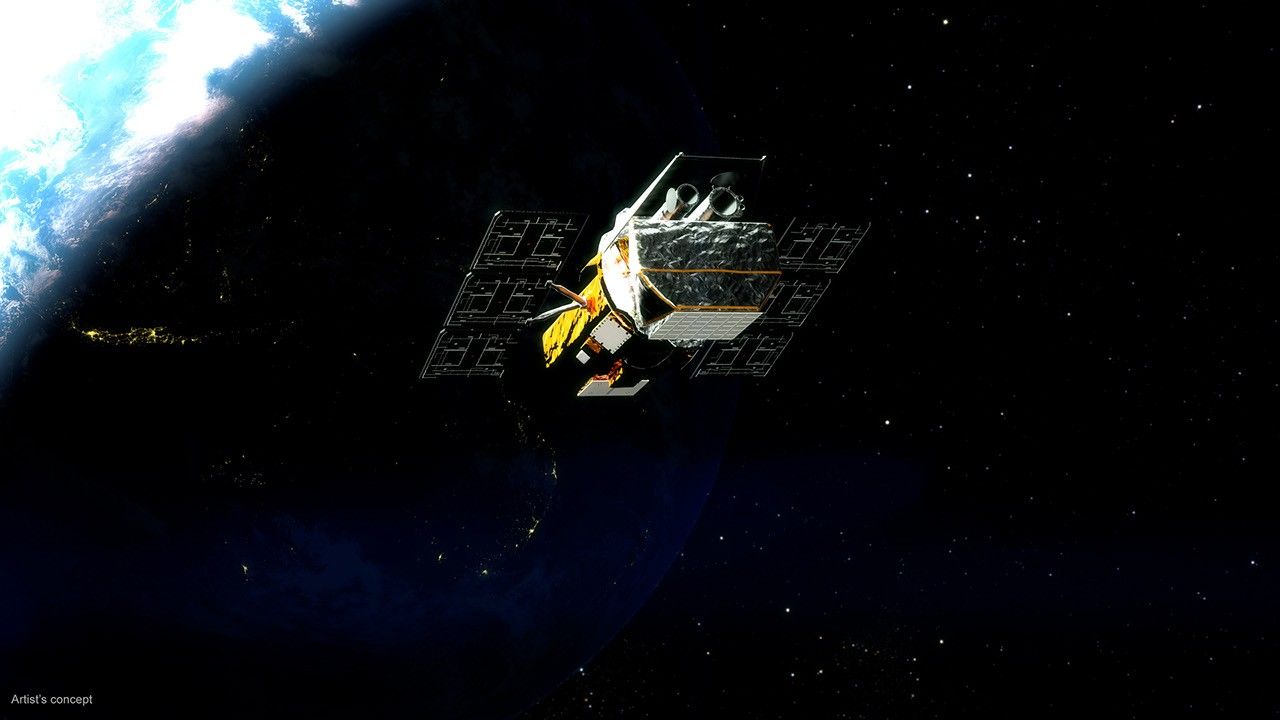

Once the first crewed flights in commercial vehicles are under way, NASA’s networks will ensure astronaut safety through robust and reliable communications services. The Space Network, managed out of NASA’s Goddard Space Flight Center in Greenbelt, Maryland, consists of ground stations and a collection of relay satellites in geosynchronous orbit. It will provide data and voice communications to crew spacecraft during ascent to the space station, docking, undocking, reentry and landing or splashdown.

To ensure spacecraft can return back home, Ames’ Arc Jet Complex can simulate the blazing heat generated while entering Earth’s atmosphere. Whether commercial partners develop their own heatshield materials or use NASA’s designs, testing their performance at temperatures up to 3,000 degrees Fahrenheit ensures they’re up to the task. These tests are supplemented and strengthened by virtual simulations performed on NASA’s supercomputers.

Researchers at Langley worked with Boeing to conduct a series of tests to qualify Starliner’s landing airbag system to ensure astronauts can finish their mission and return safely to Earth for both planned landings on land as well as emergency water landings.

In 2020 alone, both Boeing and SpaceX are preparing to launch humans to the station and return them safely to Earth. Meanwhile, the agency also is preparing for the first uncrewed flight of SLS and Orion – the same rocket and spacecraft that will take astronauts back to the Moon through the Artemis program and one day to Mars.

The work commercial partners are doing couldn’t be done without NASA’s support, but NASA’s future exploration to other worlds wouldn’t be possible without these companies, either. Enabling space exploration markets for many businesses in low-Earth orbit creates an economic engine for the U.S. and a sustainable presence on the Moon with the Artemis program means a wider infrastructure of which our partners are a fundamental part.

For news media:

Members of the news media interested in this topic should reach out to either Joshua Finch, 202-358-1100, at NASA Headquarters or the appropriate center’s contact:

- For NASA’s Ames Research Center, contact the NASA Ames newsroom at 650-604-4789 or by e-mail.

- For NASA’s Marshall Space Flight Center, contact Janet Anderson, 256-544-0034, or the NASA Marshall newsroom.

- For NASA’s Johnson Space Center, contact Dan Huot or Kyle Herring or the NASA Johnson newsroom.

- For NASA’s Goddard Space Flight Center, contact Peter Jacobs or the NASA Goddard newsroom.

- For NASA’s Kennedy Space Center, contact Marie Lewis, Tori McLendon or Jennifer Wolfinger or the NASA Kennedy newsroom.

- For NASA’s Langley Research Center, contact the NASA Langley newsroom.