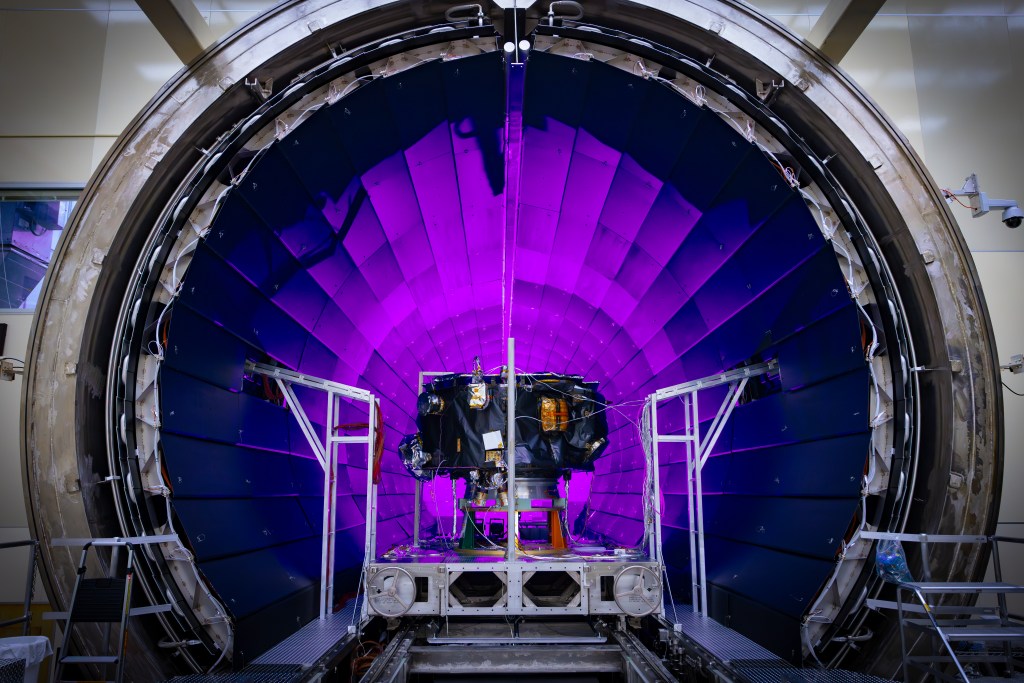

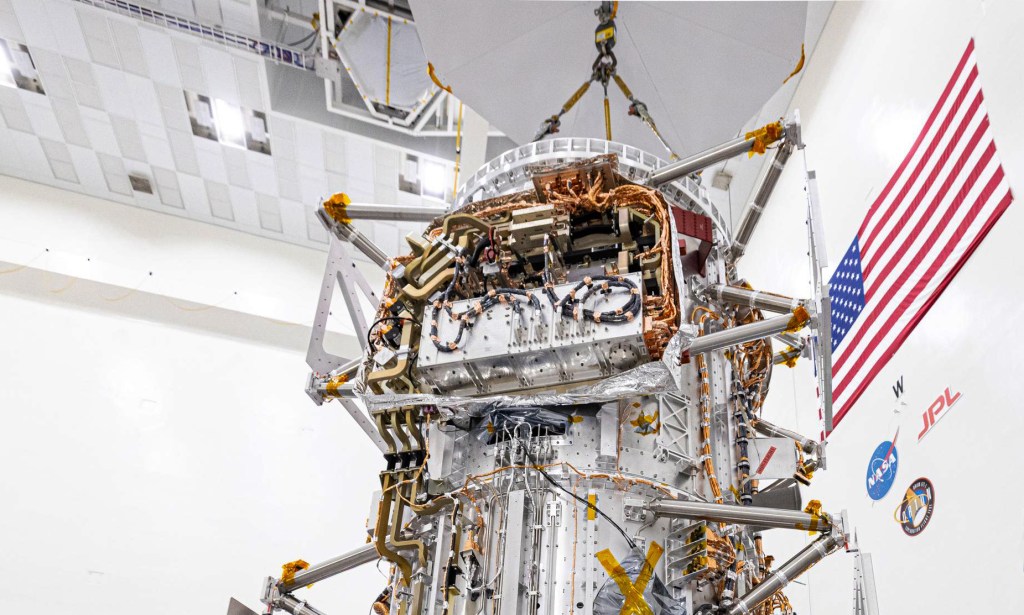

Engineers successfully completed a series of Mars Sample Return (MSR) Earth Entry System (EES) drop tests at the Utah Test and Training Range (UTTR). A Manufacturing Demonstration Unit (MDU) of one potential design for the EES aeroshell was outfitted with sensors and dropped from a helicopter.

Engineers successfully completed a series of Mars Sample Return (MSR) Earth Entry System (EES) drop tests at the Utah Test and Training Range (UTTR). A Manufacturing Demonstration Unit (MDU) of one potential design for the EES aeroshell was outfitted with sensors and dropped from a helicopter.

The drop test series was a follow up to tests conducted last year at UTTR with a .75-meter, less detailed, EES test article. In comparison, the MDU is a full-scale vehicle, 1.25 meters across, with a structure fabricated of materials similar to those that would be used for the EES in the actual mission.

The MSR program being planned by NASA and the European Space Agency proposes to return samples collected by NASA’s Perseverance Mars rover and land them at UTTR inside the EES aeroshell.

During the tests, the MDU was dropped from an altitude of 1,200 feet to provide time to reach the intended landing speed.

“The MDU was very stable during descent – it didn’t wobble around a lot, and it landed successfully, in the sense that there was no structural damage and it survived impact as expected,” said Jim Corliss, MSR EES chief engineer.

It’s important for the aeroshell to land in a particular orientation, Corliss added, and the drop test indicated the full-scale MDU was stable during final descent, landing right on its nose as engineers intended.

This test, along with another series of tests planned for later this year, will help researchers verify predictions of the EES landing performance and complete the characterization of the potential landing area at UTTR.