By Anna Heiney

NASA’s John F. Kennedy Space Center

NASA is gearing up for a test of the system that will help keep astronauts safe when traveling to the Moon aboard agency’s Orion spacecraft. The Ascent Abort-2 (AA-2) flight test will put Orion’s launch abort system (LAS) to work in a high-flying, fast-paced trial without crew aboard.

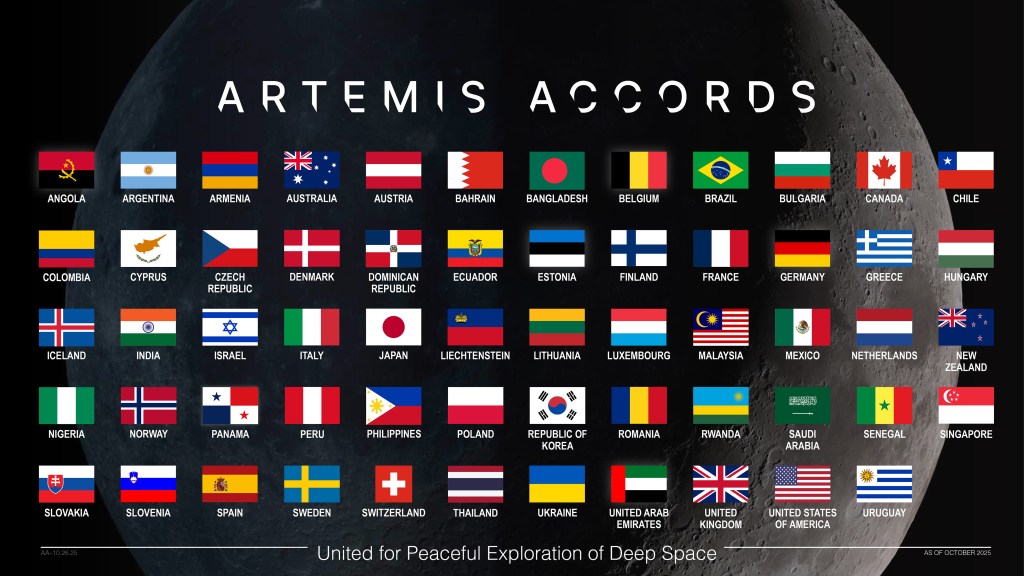

The test paves the way for Artemis 2, the first flight of astronauts aboard Orion and the powerful new Space Launch System (SLS) rocket on a mission to carry humans around the Moon for the first time in half a century. Following Artemis 2, NASA will send the first woman and next man to step foot on the Moon in 2024. For NASA’s Exploration Ground Systems (EGS) and Jacobs Test and Operations Contract (TOSC) teams, preparations for AA-2 also have provided invaluable opportunities to prepare for Artemis 1, the uncrewed first flight of SLS and Orion.

“AA-2 is really a ‘first-flow’ mission,” said Sean Arrieta, NASA EGS element operations manager in the Launch Abort System Facility (LASF), where the Orion crew module flight test article was integrated with the protective payload fairing and launch abort tower. This process marked the first time both elements were prepared using the same sequence and procedures that will be used going forward, providing valuable experience for the team.

The entire test will last about three minutes, but the teamwork and lessons honed during the months leading up to it will benefit Artemis missions for years to come.

Currently slated for July 2, the AA-2 flight test will lift off from Space Launch Complex 46 at Florida’s Cape Canaveral Air Force Station atop an abort test booster provided by Northrop Grumman. The booster will send a test version of the Orion spacecraft with the launch abort system to an altitude of about six miles traveling at more than 1,000 miles per hour. The abort motor will quickly whisk the crew module away from the booster, and the attitude control motor will maneuver the assembly into position to jettison the crew module.

Over the past several months, teams have been working to perfect the many processes, procedures and handoffs the combined team will use for both AA-2 and the first Artemis mission.

“We tried to plan the work as we would for future missions,” said mechanical engineer Alex Mire. She’s led TOSC’s AA-2 operations inside the LASF, determining scheduling, drawing, requirements reviews and more. Mire pointed out that much of the AA-2 hardware is so similar to Artemis 1 or Artemis 2 that there’s only a letter difference in the part numbers. “We’ve made a lot of updates to our procedures, which should help the processing flow go smoothly.”

Several organizations have been involved in getting AA-2 off the ground, and with so many groups handling a variety of elements, one big challenge facing EGS/TOSC was navigating the differences to ensure that hardware and human teams were working well together.

“All these different entities had their own processes and cultures, and many of them had never been to Kennedy,” said Jim Bolton, EGS AA-2 operations lead. “It sounds easy: ‘Here’s a hangar, do your work.’ But it’s not as simple as that.”

Lockheed Martin built the launch abort system inside the LASF, then handed off to the EGS/TOSC team in place at the facility. That team brought the crew module and separation ring to the facility and handled all the integration. The same process will be followed for all future Artemis missions with Orion.

According to Arrieta, this arrangement has allowed EGS to work very closely with contractor teammates.

“It allows for better integration of information,” he said. “It’s good for the health of the combined team and has led to a high level of trust.”

The Orion LAS rolled out of the LASF around 6 p.m. on May 22 for the more than nine-hour trek to the launch pad, and it was later hoisted into position atop the waiting abort test booster. Meanwhile, in the LASF, the processing flow for Artemis 1 can begin.

“AA-2 shows this workforce and the nation that we’re on the precipice of doing what Kennedy Space Center was built to do: processing and launching spaceflight hardware,” Arrieta said. “It’s a foundation, a concrete stepping stone our program can stand on and say, ‘Look at what we’ve accomplished—and where we’re about to go.’”