“I believe that this nation should commit itself to achieving the goal, before this decade is out, of landing a man on the Moon and returning him safely to the Earth.”

When President John F. Kennedy declared this to Congress in May 1961, humans had barely brushed past the outer edge of Earth’s atmosphere.

Only a month earlier, the Soviet Union sent the first human to space, while America’s furthest foray at that time was Alan Shephard’s 15-minute flight that fell short of entering Earth’s orbit. Between that history-making speech and Neil Armstrong’s first step on the lunar surface in 1969 is the story of how NASA ensured our voyage to the Moon had a way to get back home.

There were almost an infinite number of ways for it all to go wrong, especially during the most dangerous part of the mission – reentering Earth’s atmosphere. The hypersonic speeds and intense heat of reentry were extreme and largely unfamiliar conditions. NASA had to develop entirely new vehicles and areas of research to protect the vulnerable astronauts within.

NASA continues to build on these innovations in spaceflight that first led us to the Moon, now solving new problems with our commercial partners as the agency moves forward to the Moon and even further to Mars.

But before all that, we had to find a way to safely bring astronauts to the Moon and back again. That journey begins with the design of a spaceship.

A Visionary Engineer for a New Challenge

Picture a child’s drawing of a spaceship: wide on the bottom with fins and a fiery blaster, and a pointed tip to slice through the atmosphere at high speeds. At the dawn of the Space Age, this was humanity’s conception of what a spaceship should look like. The problem: a pointy-tipped spacecraft would melt on reentry from space. Aerospace engineer “Harvey” Julian Allen took up this problem and in solving it opened up the possibility of human spaceflight.

Allen’s work began during World War II as he helped design war planes and missiles with pointy tips that provided the aerodynamic precision needed for Allied victory. In 1940, he made his way to California and Ames Aeronautical Laboratory.

Strategically positioned on the West Coast in what has become the heart of Silicon Valley, today’s Ames Research Center was founded at the start of the war in 1939 to boost America’s aeronautical prowess. It became the second laboratory for aerodynamics research under the National Advisory Committee for Aeronautics, or NACA.

At this precursor agency to NASA, Allen understood the “normal” conditions of aviation would simply not work for extreme travel. An eccentric and deeply curious engineer, he rose through the ranks and created a work culture that fostered collaboration and creativity. Under Allen’s leadership, his new research lab was poised to tackle the problems of reentering Earth’s atmosphere.

A Solution Takes Shape

The gaseous layers of Earth’s atmosphere create a kind of barrier around our planet, shielding us from some of the dangerous radiation from the Sun. In our everyday experience, we only move through the lowest layer of the atmosphere. But even here, we can get a sense of how strong the resistance of air molecules can be. Just stick a hand out of a car traveling on the highway at 60 miles per hour.

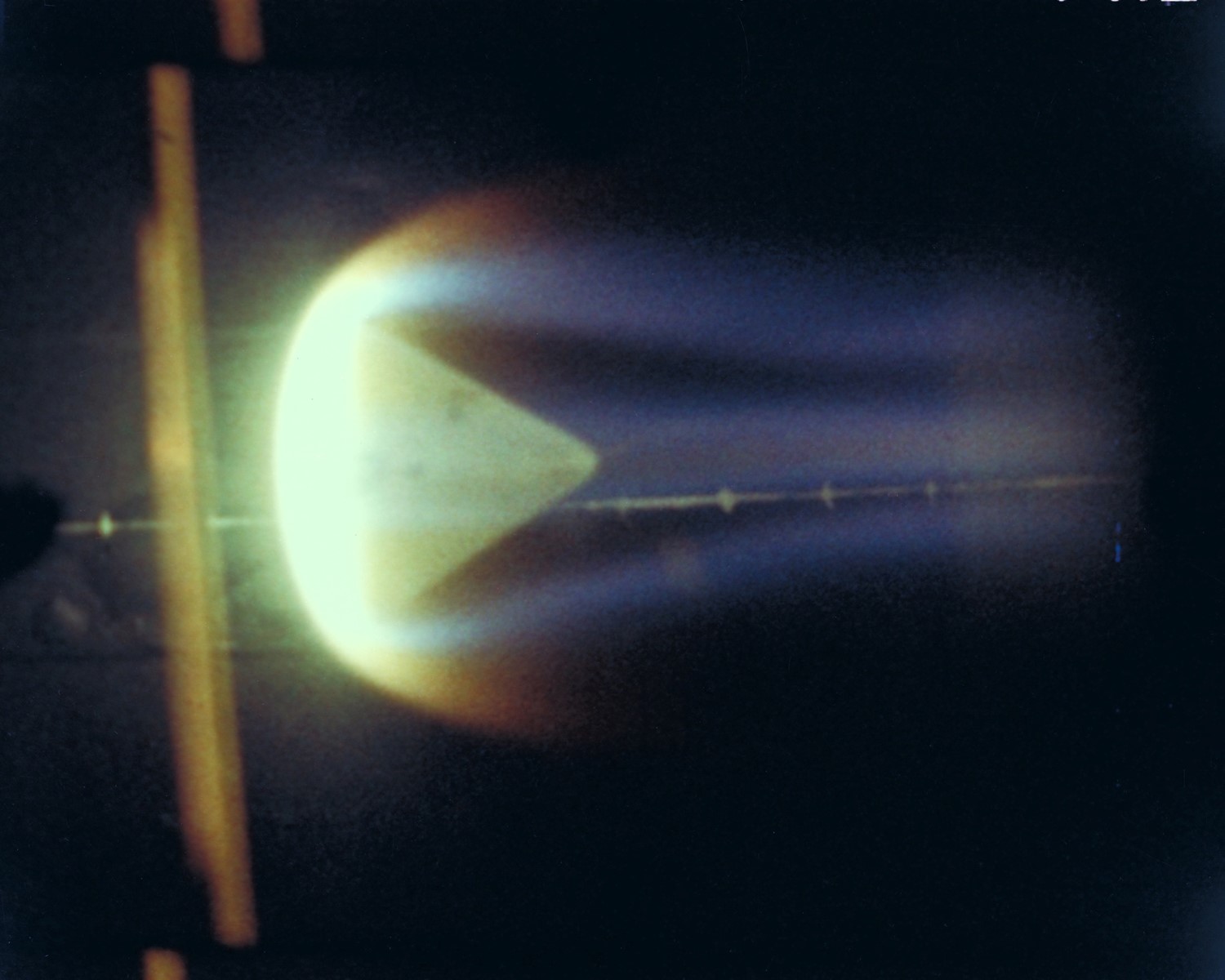

Now picture traveling at 24,600 miles per hour – the speed of the Apollo 11 space capsule on its return trip from the Moon. That speed is hypersonic, meaning many times faster than the speed of sound. At speeds this fast, an incredible amount of heat is generated in part by the friction between the spacecraft and air molecules, but mainly from the compression of air in the form of a shockwave created by the spacecraft careening through the atmosphere. Plasma, the substance of stars, forms between the shockwave and the vehicle at peak heating conditions.

Tasked with solving the reentry problem for long-range ballistic missiles, Allen in 1951 developed a theory that would go on to become the foundation for rocket design for the Space Age continuing to this day. His solution: instead of a pointy tip to a spacecraft, make it blunt. Blunted shapes still create shockwaves, but further away from the body so that more of the heat flows around the spacecraft instead of into its surface. With most of the heat of reentry flowing away from the spacecraft, the crew or cargo inside can be more easily protected.

Turning Up the Heat

Allen’s “blunt-body theory” became instrumental when NASA was founded in 1958 as America’s space agency, with its first major task to put an astronaut into orbit under Project Mercury. Kennedy’s 1961 directive to put humans on the Moon propelled the research into a full-blown science and engineering endeavor into the design of protective caps placed on the nose of space capsules, known as heat shields.

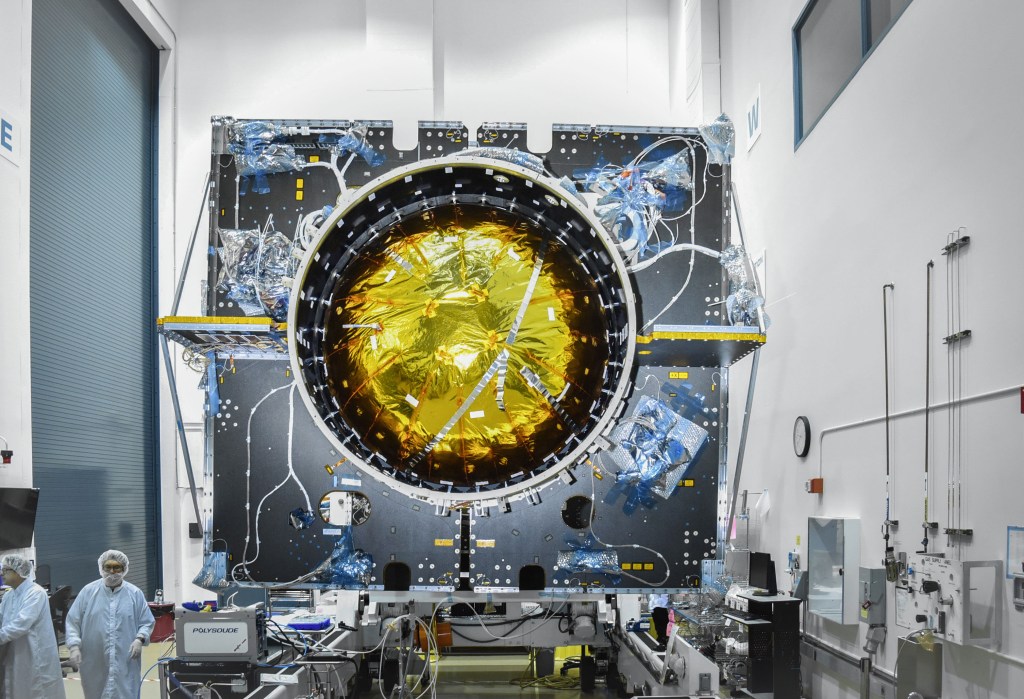

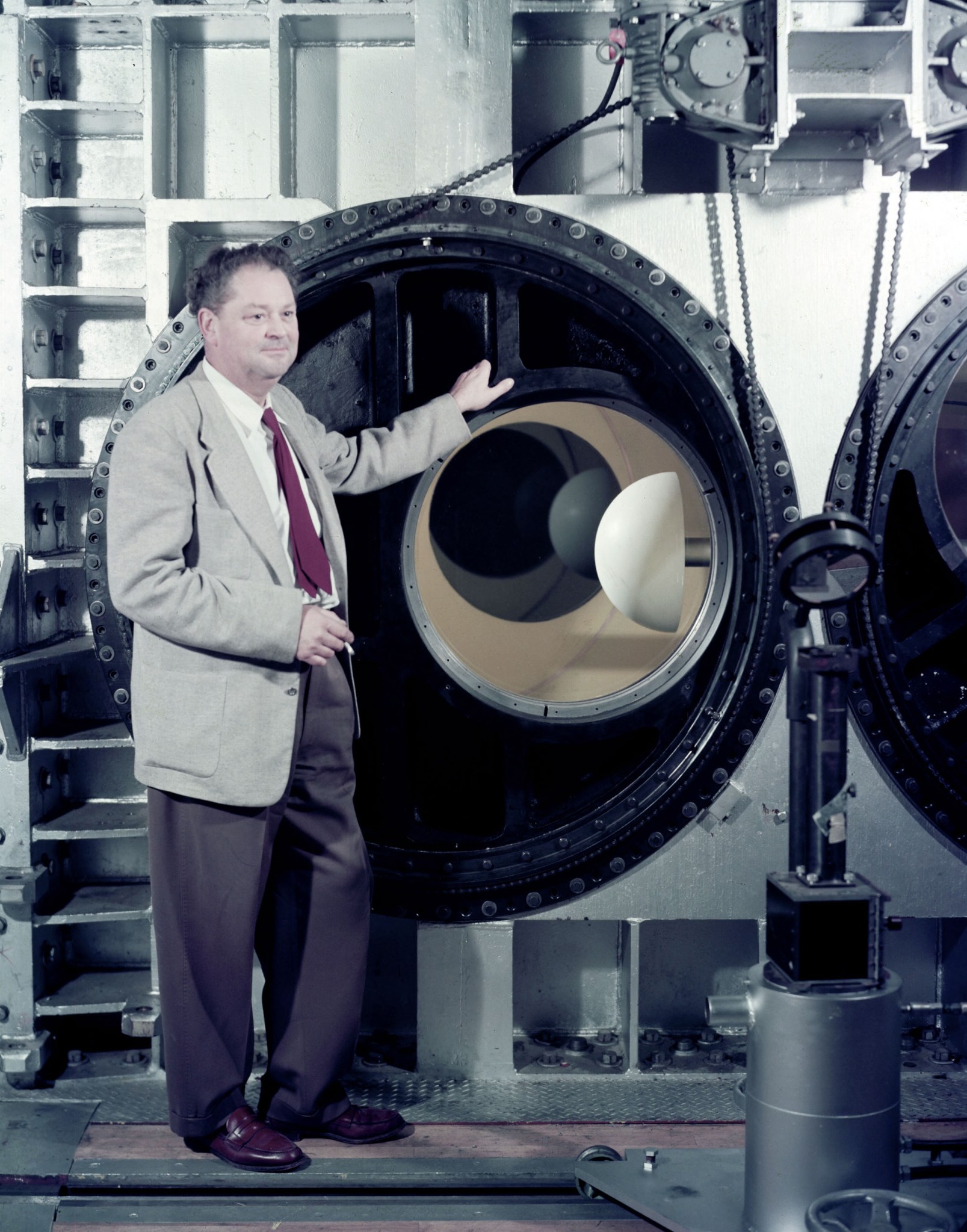

A facility known as the Arc Jet Complex was built to test heat shield materials and design. A chamber simulated reentry conditions by artificially creating plasma at temperatures of about 3,000 degrees Fahrenheit and blasting it at high speeds against the heat shield test models to see how they performed. The Ames facility helped develop the shape and material composition of heat shields that would be integrated onto the Apollo capsules.

Meanwhile, Allen stepped into the role of center director for Ames from 1965 to 1969. Under his direction, the center became a construction site for new facilities that would test out every stage of the journey to the Moon. Ames facilities were used to simulate aerodynamics at the extreme speeds encountered upon returning from the Moon.

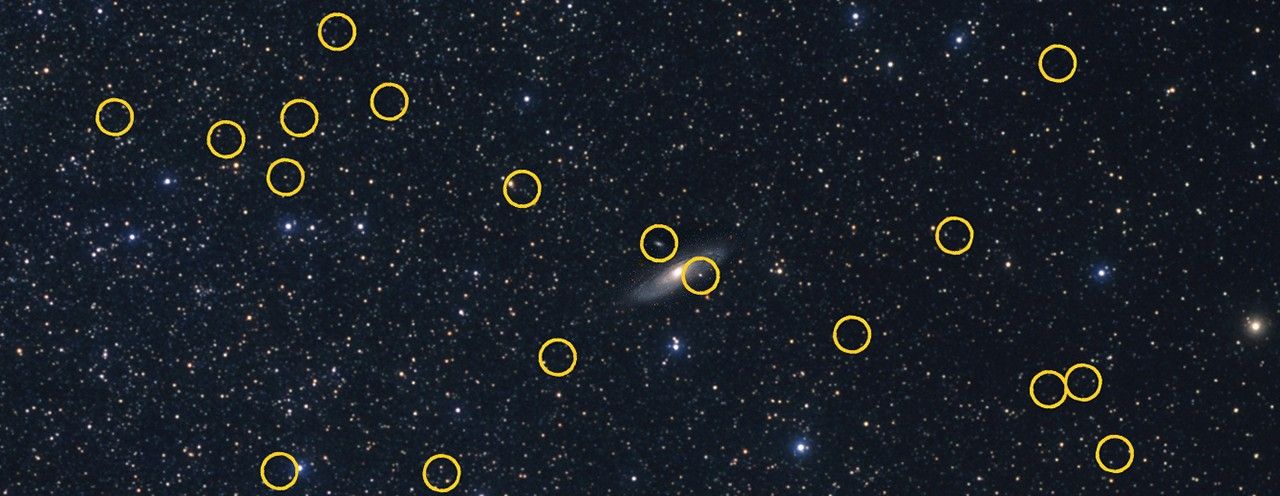

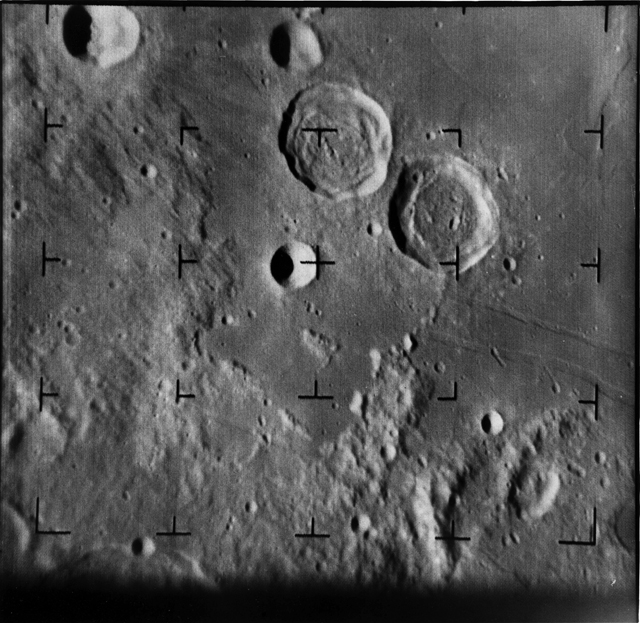

From NASA facilities came solutions to obstacles that just a few years before seemed insurmountable. Models for the now famous Saturn V rocket and Apollo lunar landers were tested and iterated upon to create the most aerodynamically efficient designs for launch. Simulators allowed astronauts to practice their journey to the Moon and descent to its surface until it became muscle memory. And to safely reenter through the atmosphere, heatshields built from Allen’s blunt body designs used ablative materials to withstand the extreme environments of atmospheric entry. The iconic three-parachute system – tested to ensure it could slow the crew capsule’s fall – could then safely bring the crew to the Pacific Ocean’s surface.

From launch until landing, the Apollo astronauts would be covered.

And then, on one otherwise ordinary summer evening in 1969, all that preparation, research and testing coalesced into a single moment as the first human footprint was placed on the Moon.

President Kennedy’s dream of taking humans to the lunar surface and back again became a reality, less than a decade after those words left his lips. Meanwhile, Harvey Allen retired and, ever the dabbler, began investigating personal curiosities, such as the aerodynamics of owls and their silent flight.

NASA’s mission continued as the innovators and explorers who were brought together in service of that singular accomplishment looked towards the next journeys beyond Earth.

Forward to the Moon and Beyond

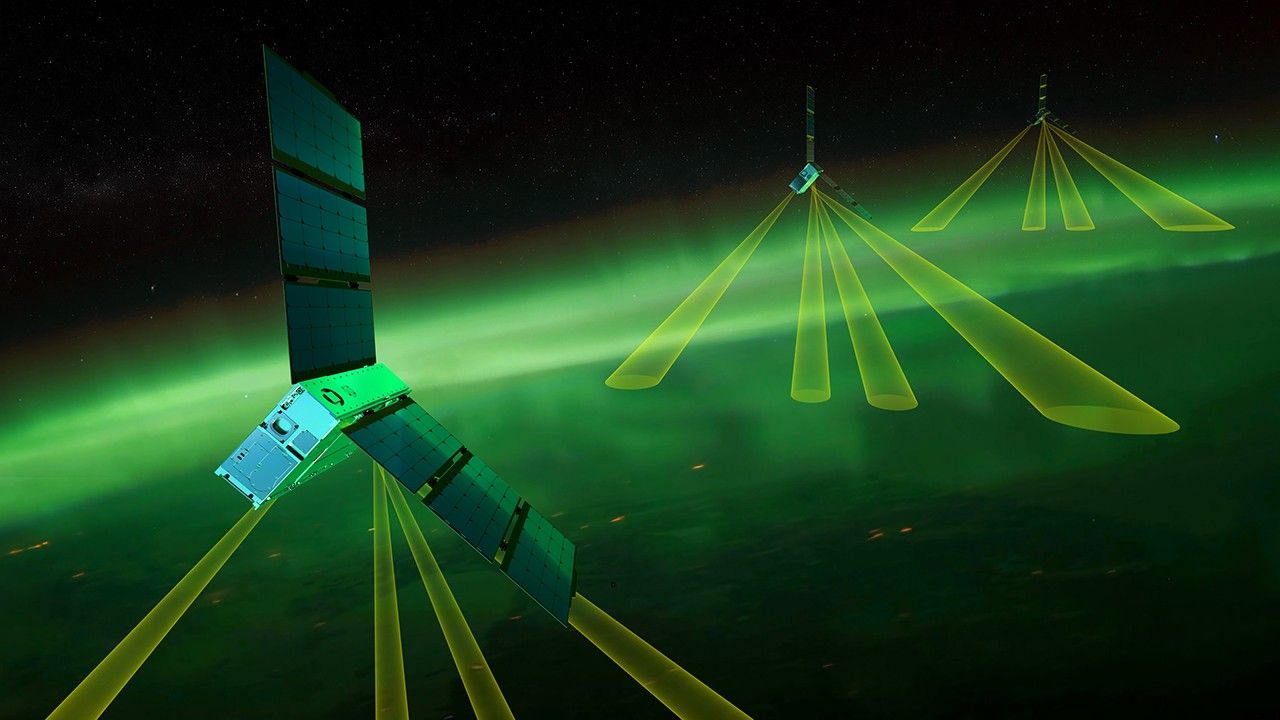

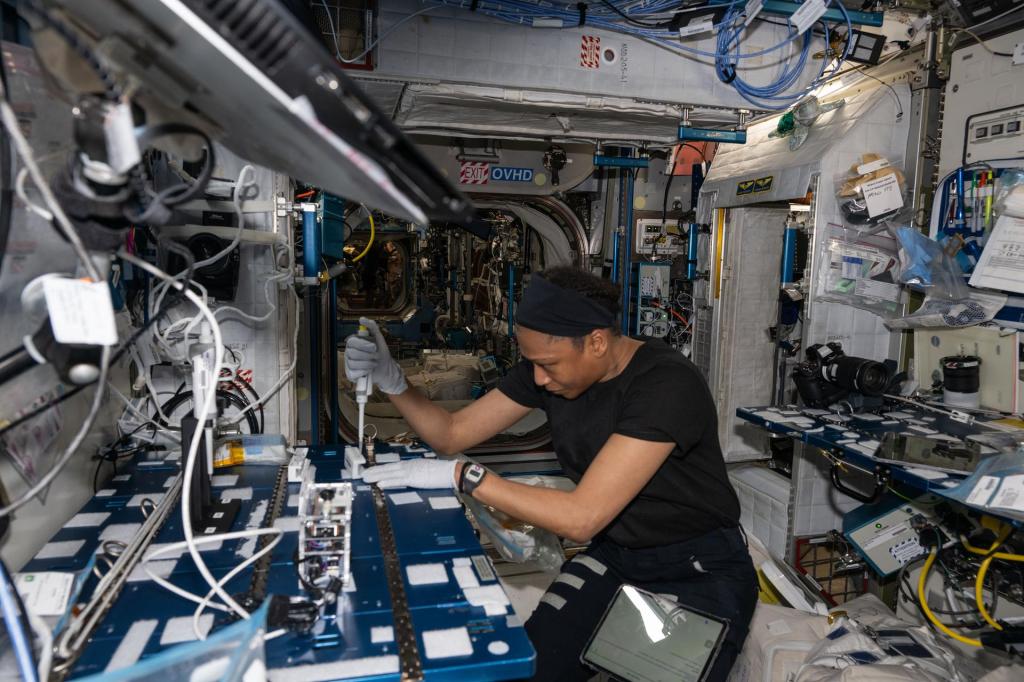

Today, NASA’s center in Silicon Valley is doing the same work for the Artemis program, the agency’s new lunar exploration program. Under Artemis, NASA will send the first woman and next man to the Moon by 2024, and establish sustainable exploration by 2028. Using our new deep space transportation system in development, the Space Launch System rocket will send crew aboard the Orion spacecraft to the Gateway in lunar orbit. From the Gateway, crew will travel to the surface of the Moon and back to the Gateway in a new integrated human landing system.

Future exploration requires a new generation of heatshields and tools for testing.

Our modern rocket testing begins with tools that allow us to be more precise, even when using the same wind tunnels from 50 years ago. Pressure sensitive paint can reveal every slight effect of intense speeds on a model. New facilities such as our supercomputers allow us to simulate launch and digitally test for every possible scenario, adjusting and iterating until every variable is accounted for.

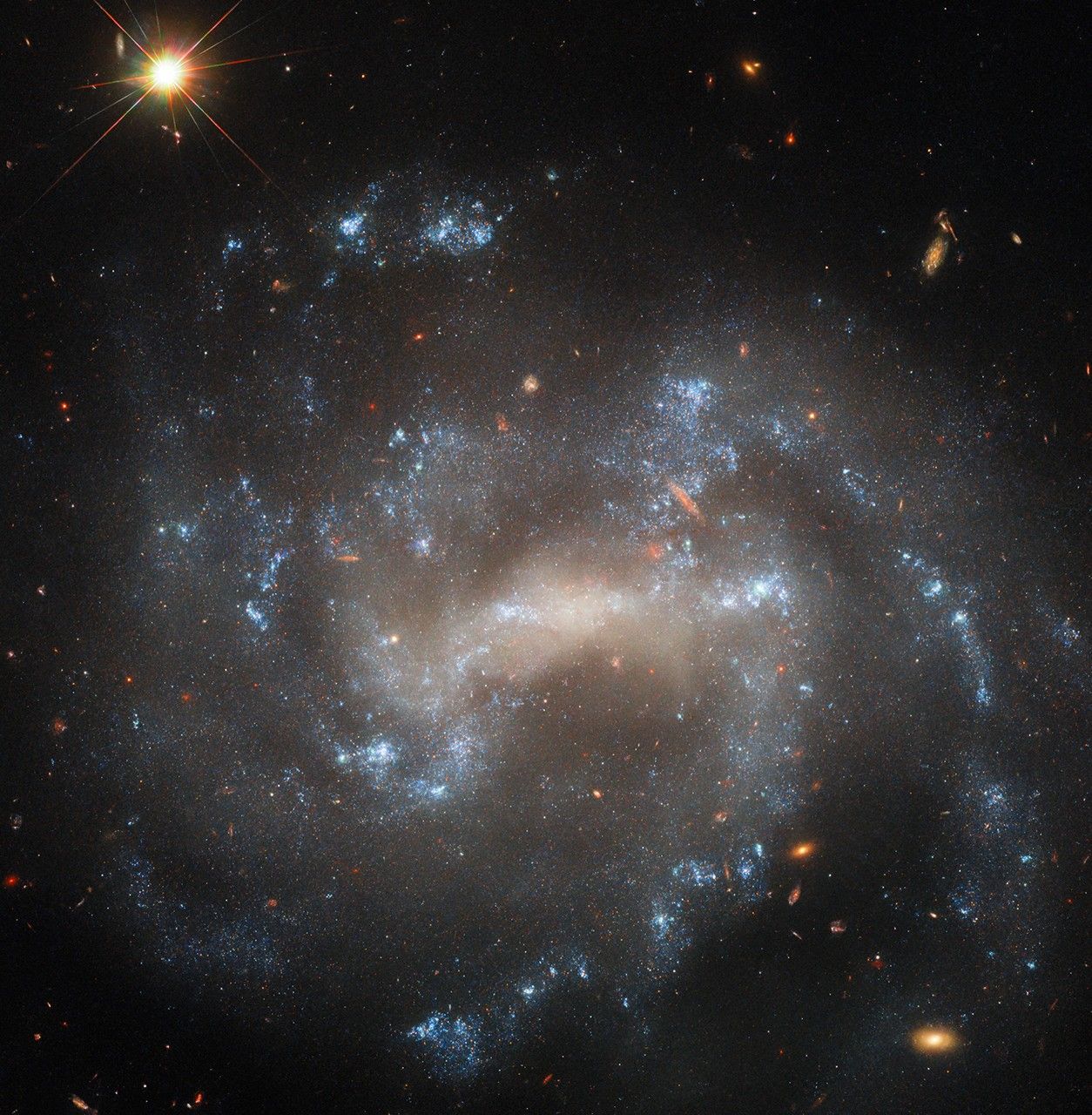

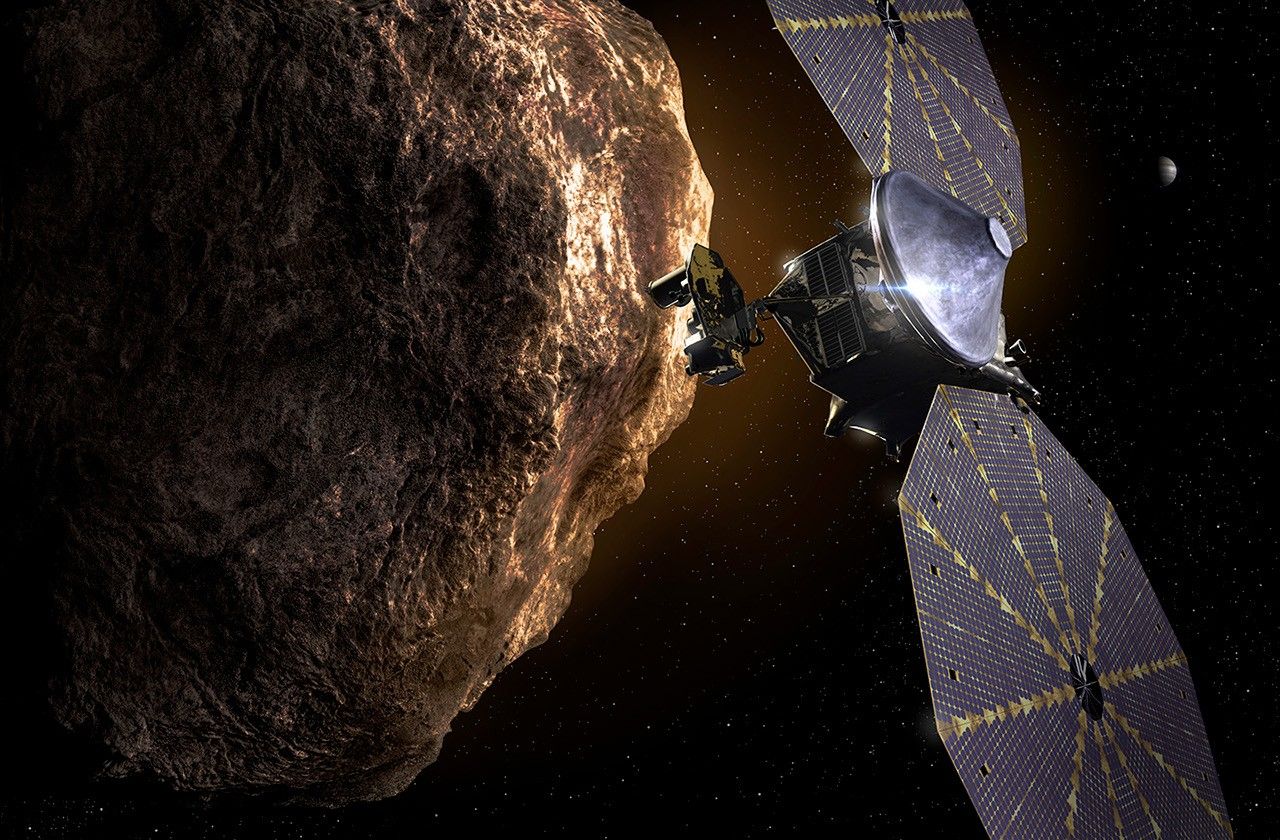

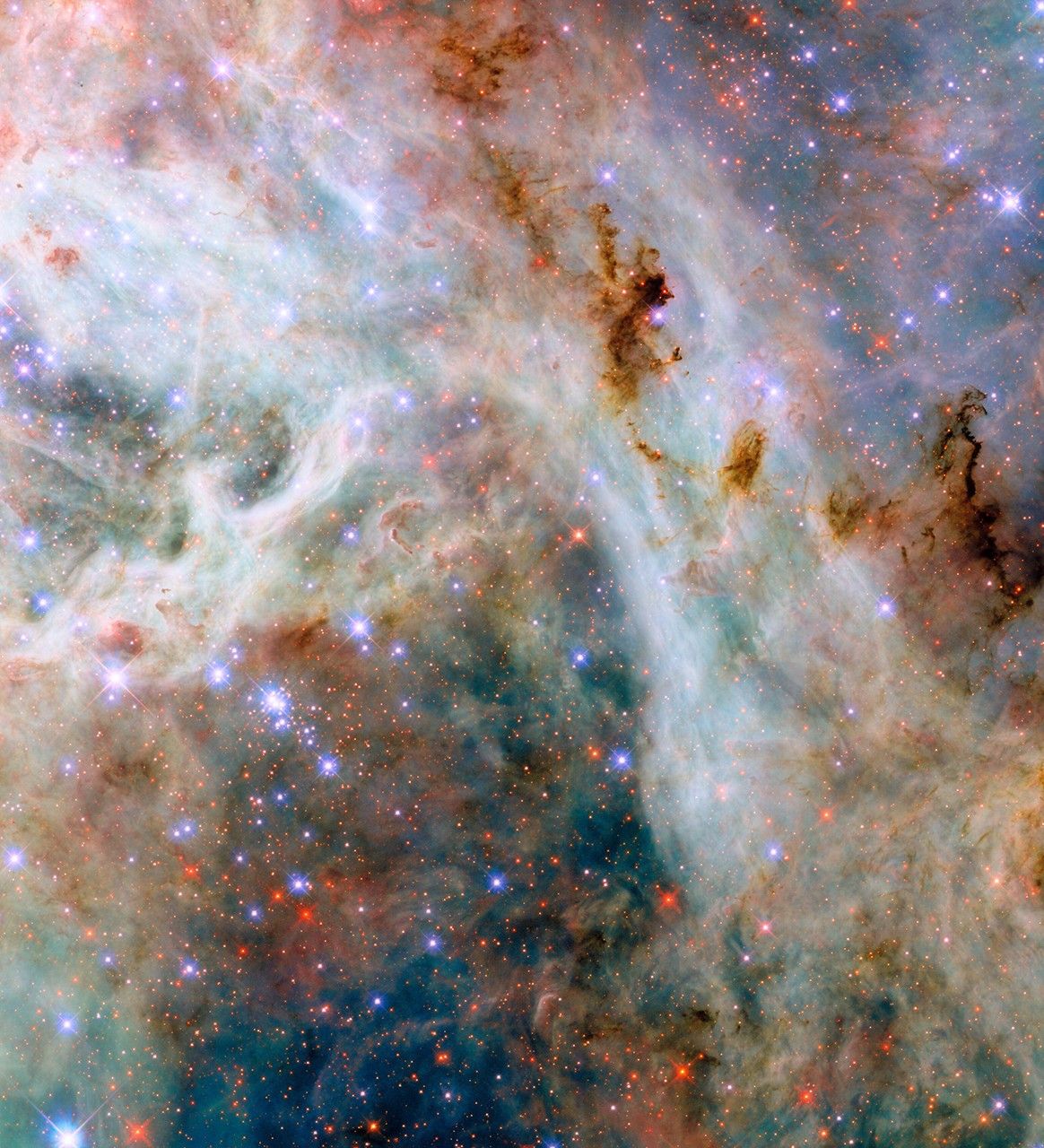

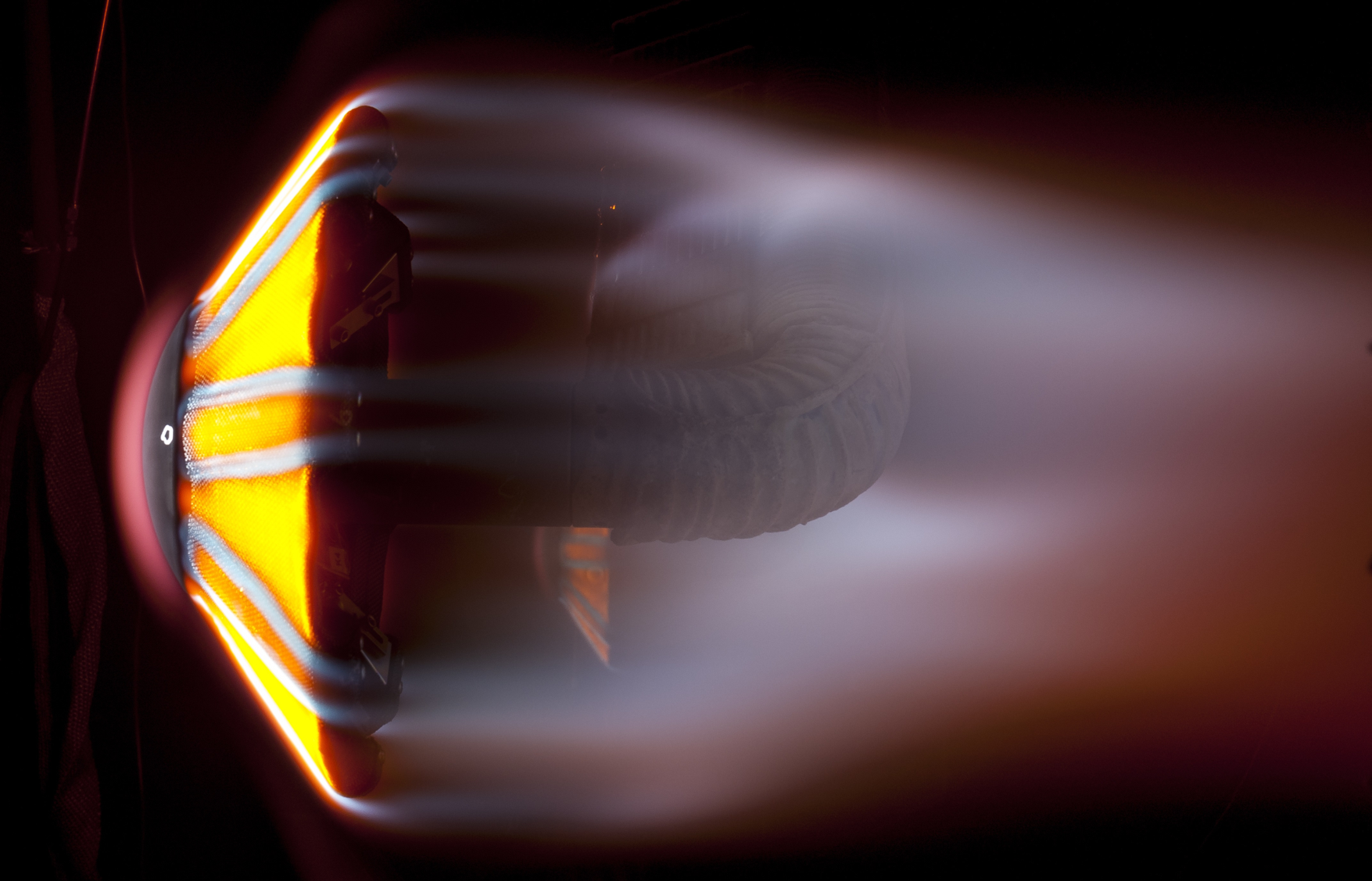

The Moon is our stepping-stone for Mars, and even as we work to ensure our systems can safely take us there and back, we’re also looking ahead to what could someday become future destinations. Modern heat shields will be able to protect robotic explorers as well, withstanding the even more intense temperatures of places like Venus. They will even be flexible enough to adapt to the diverse environments on the moons of Jupiter and Saturn. ADEPT – the Adaptable, Deployable Entry Placement Technology – can open and close like an umbrella. When it needs to be small, the heat shield can be tightly packed up to fit into a confined rocket, but can protect larger spacecraft once deployed. It’ll allow us to take larger robotics and more materials on longer voyages to Mars and to worlds in the outer solar system, and one day, safely bring samples from those worlds back to Earth.

The shielding itself is getting an upgrade, too. The Heatshield for Extreme Entry Environment Technology project, known as HEEET, uses an all-carbon layer 3D weave with an insulating layer of carbon and synthetic yarns to create an interlocking and versatile protective material.

Just like Allen’s blunt body was needed to safely pass through the then-unfamiliar environment of our upper atmosphere, these new technologies will ensure our spacecraft can survive the future unexplored atmospheres of the solar system’s many destinations. No matter how far we journey into the stars, we’re developing the technology to safely get back home.

Author: Frank Tavares, NASA’s Ames Research Center