By Alyssa Lee

NASA and its partners across the country are continuing to make progress on the crewed Artemis missions with hardware for NASA’s Space Launch System (SLS) rockets for Artemis II, III, and IV already in various phases of production, assembly, and testing.

SLS proved to be the world’s most powerful rocket, when its two solid rocket boosters and four RS-25 engines produced more than 8.8 million pounds of thrust at liftoff to send NASA’s Orion spacecraft beyond the Moon and back on Artemis I. Data from the first flight of SLS is helping engineers build confidence in the rocket’s systems to safely fly crew on future lunar missions.

“The power that NASA’s Space Launch System rocket provides will enable astronauts to explore farther in our solar system than ever before and discover more about the Moon, Mars, and beyond,” said John Honeycutt, SLS program manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “NASA is on the brink of new age of deep space discovery, and the SLS team and our partners are more focused than ever to manufacture and produce SLS rockets for Artemis missions that will put boots on the Moon for decades to come.”

Like Artemis I, the SLS rockets that will power the Artemis II and III missions to the Moon will use the Block 1 configuration with the interim cryogenic propulsion stage (ICPS). Beginning with Artemis IV, the SLS rocket will evolve into a more powerful configuration called the Block 1B, which replaces the ICPS with the more dynamic Exploration Upper Stage (EUS) for in-space propulsion to send crew and large cargos to the Moon.

NASA and Boeing, lead contractor for the SLS core stage, are manufacturing the 212-foot-tall stages for Artemis II, III, and IV at NASA’s Michoud Assembly Facility in New Orleans. The Artemis II core stage is in final assembly. Once the engine section is joined to the other four elements for the Artemis II core stage at Michoud, teams will uncrate and install each of the four RS-25 engines to the stage and then ready it for delivery to NASA’s Kennedy Space Center in Florida. Technicians are simultaneously preparing for core stage assembly and outfitting activities for the Artemis III Moon rocket – the engine section for Artemis III was delivered to Kennedy in December 2022. In tandem, teams at Michoud are continuing all core stage manufacturing and production activities for the five major elements of the core stage for Artemis III and IV.

“Michoud is humming with activity as teams work on multiple SLS core stages for three different Artemis missions as well as the initial welds for the Exploration Upper Stage (EUS) for the fourth SLS flight,” said Lonnie Dutreix, director of NASA’s Michoud Assembly Facility. “Everywhere you look, you see rocket hardware that will power missions to send the first woman and the first person of color to the Moon.”

In Mississippi, at NASA’s Stennis Space Center near Bay St. Louis, Aerojet Rocketdyne, the RS-25 lead contractor, has completed work on the RS-25 engines for the third SLS flight and is working to complete the four RS-25 engines that will power the fourth flight of the rocket. Aerojet Rocketdyne is also preparing for a series of RS-25 engine tests for engines that will be used beginning with Artemis V.

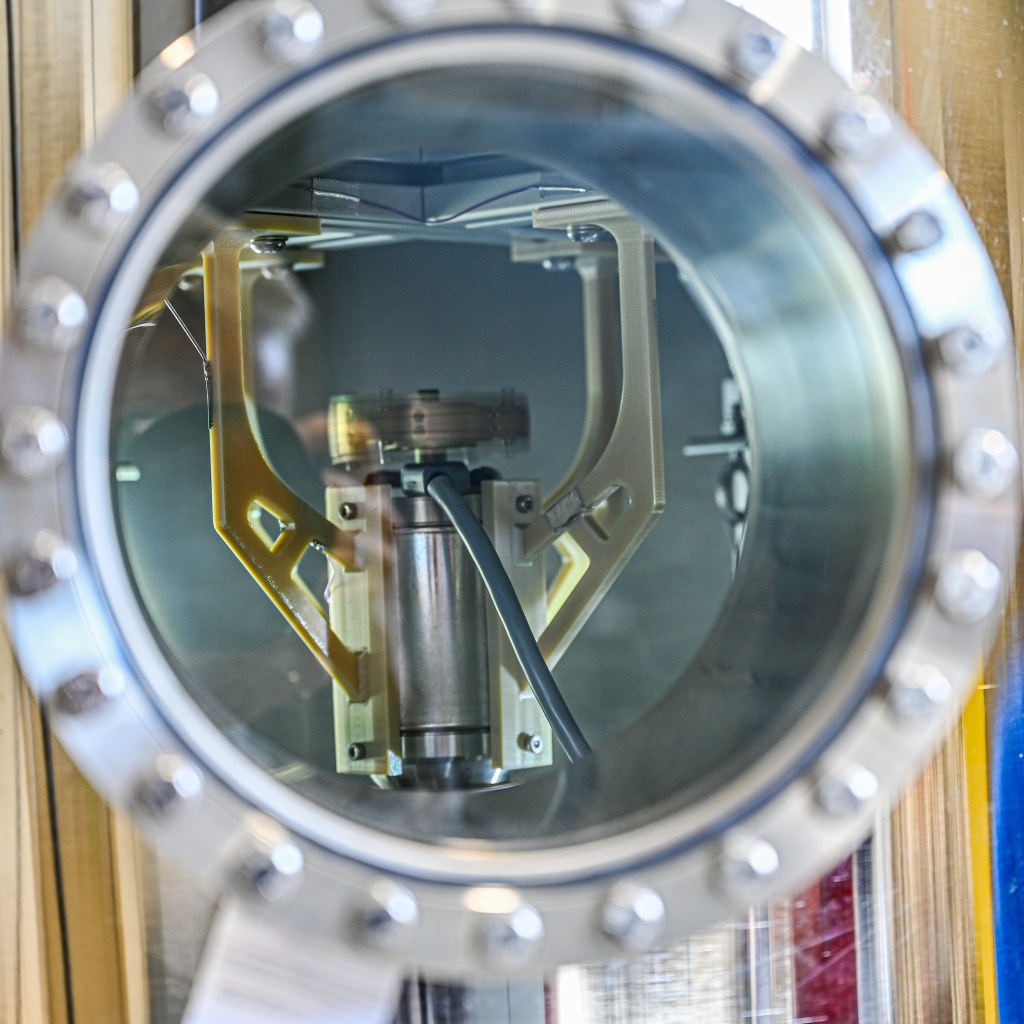

The ICPS, powered by a single RL10 engine, provides in-space propulsion to give Orion the big push it needs to fly beyond the Moon. Currently, the stage for Artemis II is in final assembly in the Horizontal Integration Facility at the contractors Boeing and United Launch Alliance’s (ULA) facilities in Florida. Meanwhile, ULA is wrapping up manufacturing operations on the ICPS for Artemis III in its facility in Decatur, Alabama, where it will undergo a high-pressure test check this spring.

The two five-segment solid rocket boosters provide more than 75% of the thrust at launch for SLS and are produced by lead booster contractor Northrop Grumman. All 10 booster motor segments for both Artemis II and Artemis III are completed and awaiting shipment to Kennedy, where work on the forward and aft assemblies is currently in progress. The booster manufacturing for the Artemis IV mission is underway at the Northrop Grumman facility in Utah.

Both the SLS adapters – the cone-shaped launch vehicle stage adapter (LVSA) and the Orion stage adapter (OSA) – are fully built and produced at Marshall. The adapters serve as vital connection points on the SLS rocket. With the Artemis II LVSA complete, teams are focusing efforts on the LVSA for Artemis III. The OSAs for Artemis II and III have completed painting and are being readied for final hardware installation.

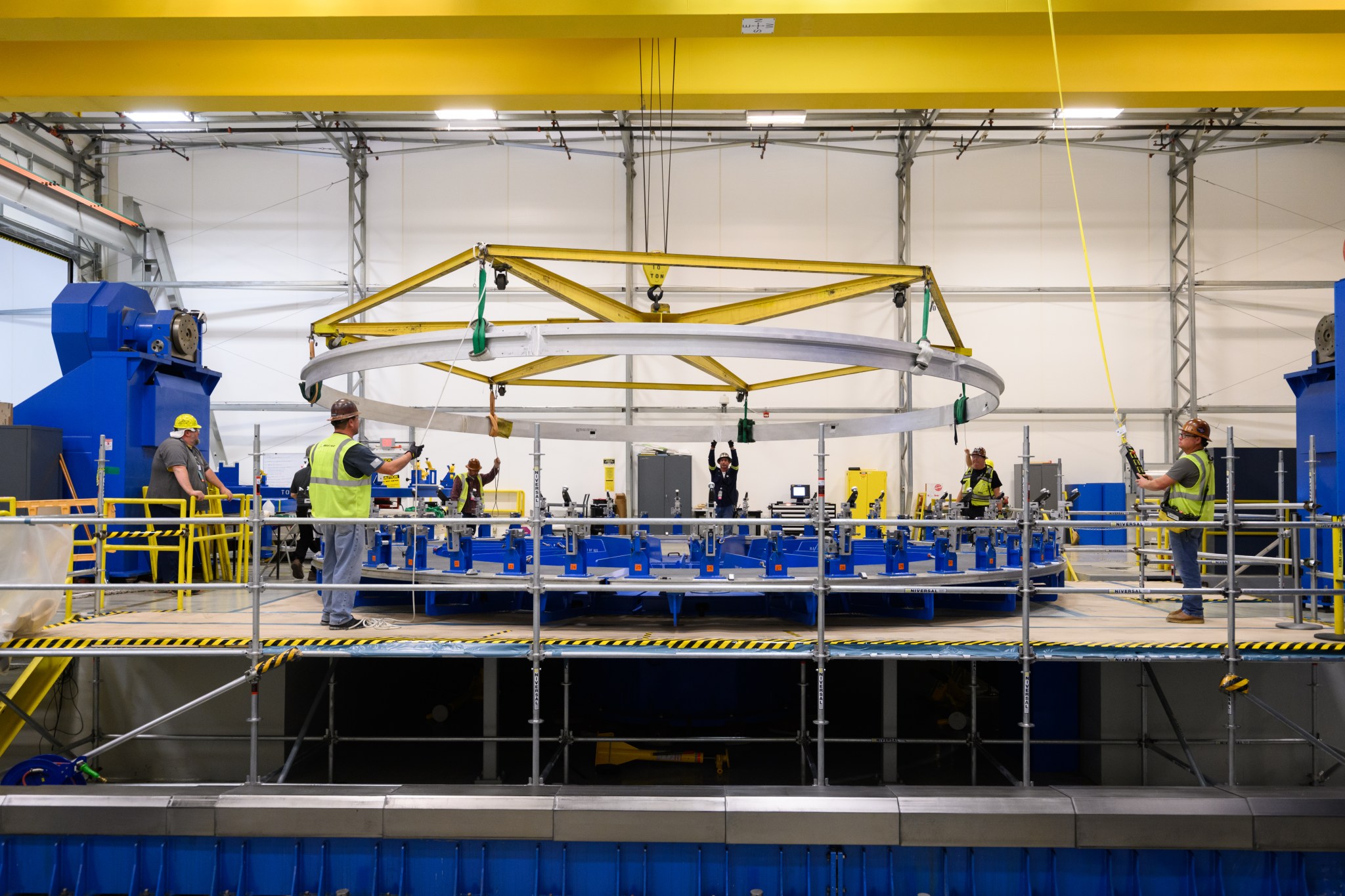

Beginning with the Block 1B configuration, the interim cryogenic propulsion stage, launch vehicle stage adapter, and Orion stage adapter are replaced by the Exploration Upper Stage and interstage, which includes the universal stage adapter (USA). Dynetics and Beyond Gravity, the prime contractors for the adapter, are finalizing a full-scale demonstration test article of the USA at facilities in Decatur, Alabama.

With Artemis, NASA will land the first woman and the first person of color on the lunar surface and establish long-term exploration at the Moon in preparation for human missions to Mars. SLS and NASA’s Orion spacecraft, along with the human landing system and the Gateway in orbit around the Moon, are NASA’s foundation for deep space exploration.

For more on NASA SLS visit:

Corinne Edmiston

Marshall Space Flight Center, Huntsville, Ala.

256.544.0034

corinne.m.edmiston@nasa.gov