Media are invited to NASA’s rocket factory, the Michoud Assembly Facility in New Orleans, at 7 a.m. CST on Thursday, Feb. 22, to view recently completed test hardware for America’s new deep-space rocket, the Space Launch System.

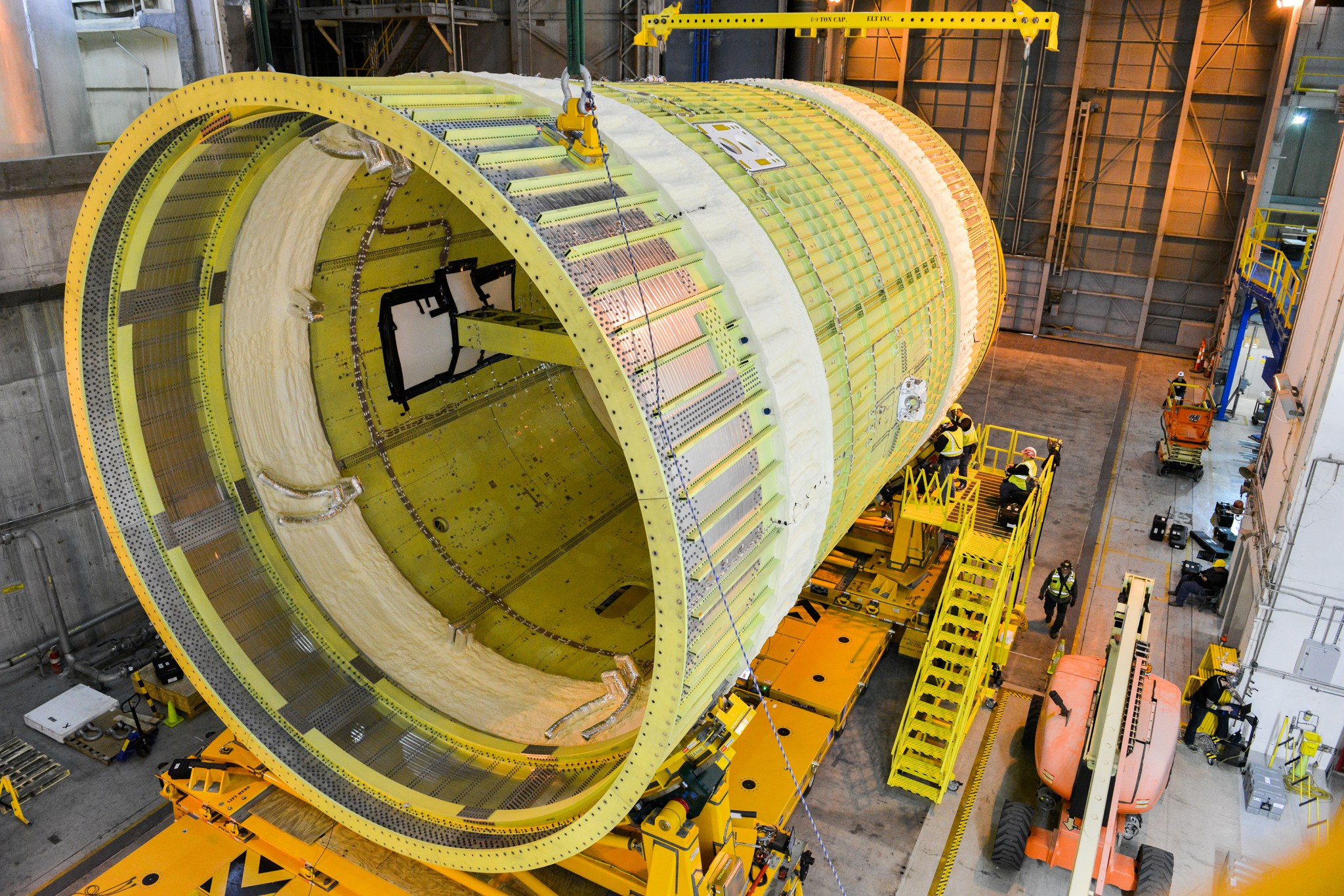

Media will have the opportunity to view a structural test version of the SLS intertank as it is moved for loading onto NASA’s barge Pegasus to be shipped to the Marshall Space Flight Center in Huntsville, Alabama, where it will undergo critical testing. The test article will be moved on new ground support vehicles designed especially for transporting large rocket components. Positioned between the rocket’s two colossal fuel tanks, the intertank is a rigid structure that will connect the solid rocket boosters to the core stage. The intertank also houses much of the avionics computers and electronics that will control the rocket in flight.

Interested media should contact Tracy McMahan at tracy.mcmahan@nasa.gov no later than noon, Wednesday, Feb. 21, and report at 7 a.m., Thursday, Feb. 22, to Michoud’s Building 101 at 13800 Old Gentilly Road. Participating media must be U.S. citizens with valid media credentials and a government-issued photo ID. Long pants and closed-toe shoes with heals smaller than 2 inches are required.

SLS will enable a new era of exploration beyond Earth’s orbit, launching astronauts in NASA’s Orion spacecraft on deep-space exploration missions to the Moon and eventually to Mars. The delivery and subsequent testing of the intertank will mark significant progress toward the rocket’s first flight in 2019.

Media will have the opportunity to view additional SLS hardware and the SLS core stage Pathfinder — a life-size replica of the 212-foot-tall core stage used to practice critical operations without the risk of damaging valuable flight hardware. NASA officials will be available for interviews.

The intertank will be the second major core stage component built at Michoud and delivered to Marshall for testing. The engine section was delivered in May 2017, and Marshall engineers recently completed an extensive test series on the hardware. Delivery is scheduled later this year for the liquid hydrogen and liquid oxygen tanks.

Each test article, which is structurally identical to flight hardware, will undergo extensive structural testing to verify the rocket can withstand the extreme forces expected during launch and flight.

To ferry the test and flight hardware for SLS, NASA modified the barge Pegasus, increasing its length and weight-carrying capacity to carry the entire SLS core stage, which is 50 feet longer and more than 600,000 pounds heavier with support equipment than the space shuttle external tank.

Tracy McMahan

Marshall Space Flight Center

256–682-5326

tracy.mcmahan@nasa.gov