SLS (Space Launch System) Booster Fabrication Facility

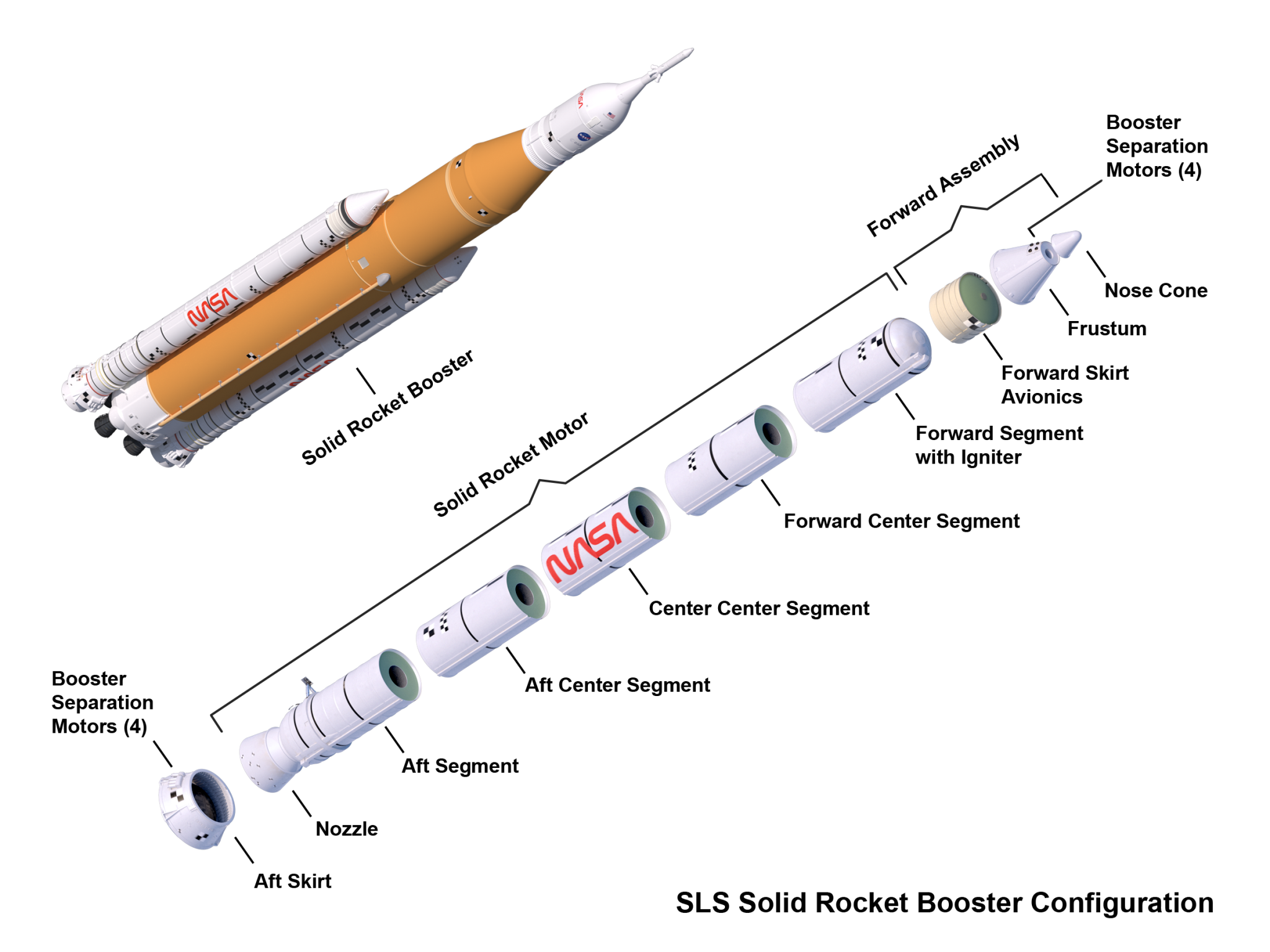

NASA’s Booster Fabrication Facility (BFF) is a 45-acre site managed by NASA’s Marshall Space Flight Center in Huntsville, Alabama, and housed at NASA’s Kennedy Space Center in Florida, located near the spaceport’s Launch Complex 39 area. Northrop Grumman, lead contractor for boosters, and NASA engineers use the facility to refurbish, manufacture, and assemble the aft skirt assembly and forward assembly for the twin solid rocket boosters for the SLS (Space Launch System), the agency’s powerful, deep space rocket for the Artemis campaign.

Refurbishing and Upgrading

The first eight missions of SLS will use upgraded booster hardware from the Space Shuttle Program. Once engineers apply protective coatings and complete evaluations, booster components are transferred to the BFF to continue the processing and upgrades for SLS. The structures are enhanced to better accommodate forces expected during launch and flight. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

The major physical difference between the shuttle and SLS boosters is the addition of a fifth motor segment, compared to the four-segment shuttle booster. Each 17-story-tall booster burns six tons of solid propellant every second (or 1,385,000 pounds in two minutes), producing a max thrust of 3.6 million pounds — more than 75% of the total SLS maximum thrust of 8.8 million pounds at liftoff.

The BFF consists of seven buildings constructed between 1986 and 1992. Formerly known as the Assembly and Refurbishment Facility, it began operation in 1987 to assemble the solid rocket boosters for the space shuttle.

Today’s site includes facilities for the SLS solid rocket booster processing and administrative offices. The buildings that most significantly contribute to booster hardware processing include the Manufacturing Building, the Multi-Purpose Logistics Facility, and the Aft Skirt Test Facility.

Manufacturing Building

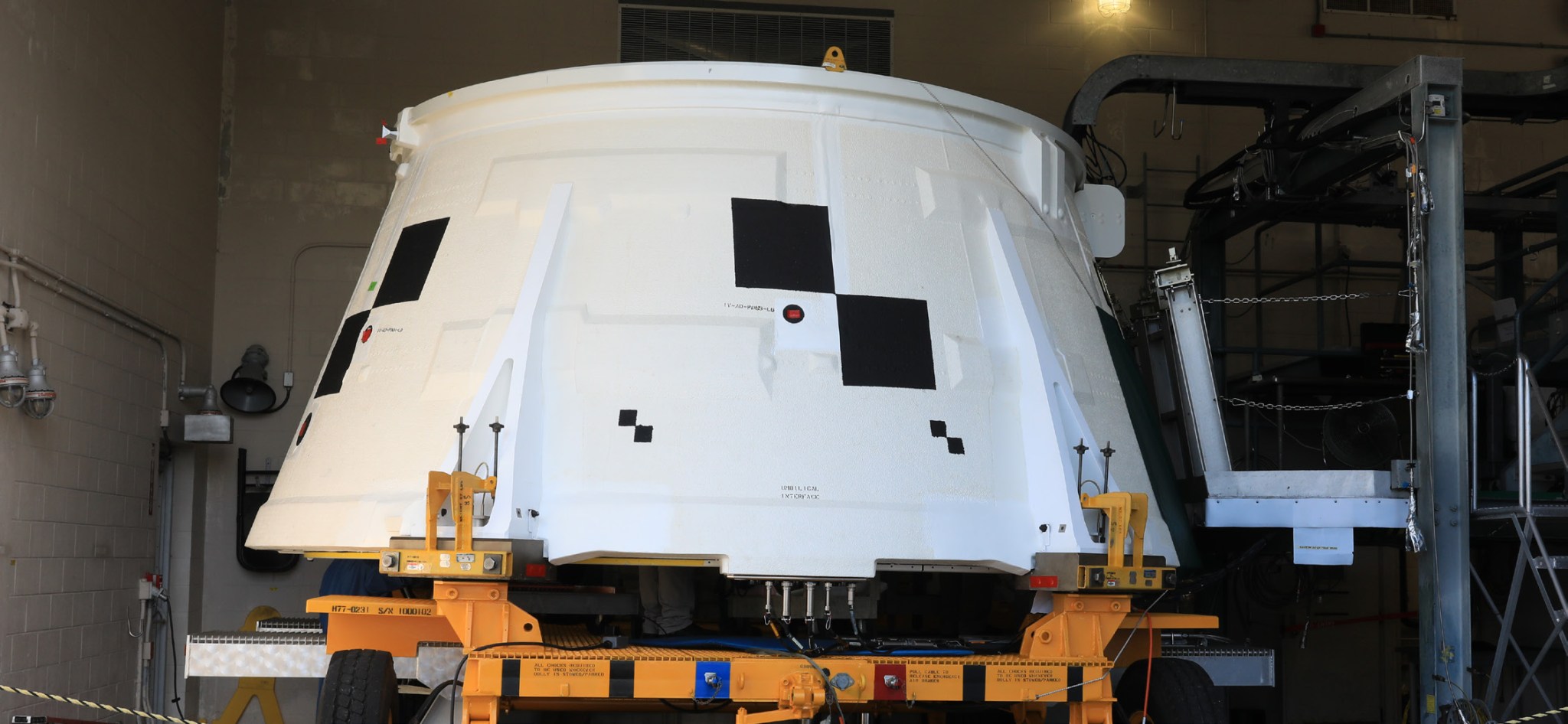

NASA uses the Manufacturing Building for non-propellant booster elements, including assembly of forward and aft skirts, nose caps, and thrust vector control (TVC) components, application of the thermal protection system (TPS), and installation of electronic and guidance systems. The facility is listed with the National Register of Historic Places for its contributions to the Space Shuttle Program.

Multi-Purpose Logistics Facility

The Multi-Purpose Logistics Facility was built in 1988 as an addition to the BFF. Northrop Grumman builds flight hardware components in Utah and delivers them to this facility at Kennedy where they are inspected. It also serves as a climate-controlled storage facility for critical SLS booster flight hardware components.

Aft Skirt Test Facility

The Aft Skirt Test Facility includes two test stands to support booster aft skirt assembly operations. The booster aft skirts house the TVC system, which controls 70% of the steering during SLS booster initial ascent. The system’s actuators are the electromechanical mechanisms that direct the vehicle’s propulsion system and are pressure – and performance – tested at the facility before each flight.

The solid rocket boosters for SLS have three main assemblies: motor segments, forward assemblies, and aft assemblies. The motor segments are produced in Utah by Northrop Grumman then shipped to Kennedy. However, Northrop Grumman produces the forward assemblies and aft skirt at the BFF.

All three booster assemblies come together on the mobile launcher platform in the Vehicle Assembly Building at Kennedy, where they’re mated and stacked before the rocket’s core stage is attached.

Aft Skirt Assembly

The aft skirt assembly contains the aft skirt and the TVC, which moves the nozzle to steer the SLS rocket based on commands from the booster avionics located in the forward skirt assembly. Four booster separation motors (BSM) are installed on each aft skirt to separate the boosters away from the core stage during flight when they are no longer needed. These small solid rocket motors produce 20,000 pounds of thrust during a one-second burn.

During processing, the aft segment is attached to the aft skirt and aft exit cone that covers the nozzle to form the aft skirt assembly.

Forward Skirt Assembly

The forward skirt assembly includes the nose cap and forward skirt of the booster. The forward skirt houses the avionics and serves as a critical connection point that carries most of the booster’s thrust to the SLS during launch. It includes batteries, avionics, and various sensors to monitor booster conditions and transmit flight control data to the avionics in the aft skirt Forward Skirt Assembly, core stage, and forward skirt.

Each forward assembly, like the aft skirt assembly, is outfitted with four BSMs.

For more information about SLS, visit:

http://www.nasa.gov/artemis

https://www.nasa.gov/sls

http://www.twitter.com/NASA_SLS

http://www.facebook.com/NASASLS

https://www.instagram.com/nasaartemis/

National Aeronautics and Space Administration

George C. Marshall Space Flight Center

Huntsville, AL 35812

www.nasa.gov/marshall

www.nasa.gov