I Am Building SLS: Michelle Gonzalez

Space has been a part of my life as long as I can remember. I grew up close to NASA’s Kennedy Space Center in Florida, and I remember running outside to see the space shuttle launches and thinking that one day I wanted to be a part of the action.

After graduating from Florida Institute of Technology in Melbourne, I began working for United Space Alliance on the Space Shuttle Program. Now, I work as the Northrop Grumman program manager for the booster avionics and flight safety system for NASA’s new rocket, the Space Launch System.

My team is working to get the booster avionics hardware for SLS from manufacturers all over the country transported to the Booster Fabrication Facility. At the Booster Fabrication Facility here at Kennedy, the avionics are being integrated into the two boosters that will be used for the first integrated flight of NASA’s Orion spacecraft and the SLS rocket – Exploration Mission-1 (EM-1). The booster avionics, receiving commands from the SLS flight computers in the core stage, provide 80 percent of the control authority for the rocket during the first two minutes of flight. The boosters for the first two launches of SLS will be the world’s largest and most powerful NASA boosters at 177 feet long and 12 feet in diameter with each producing more than 3.6 million pounds of thrust.

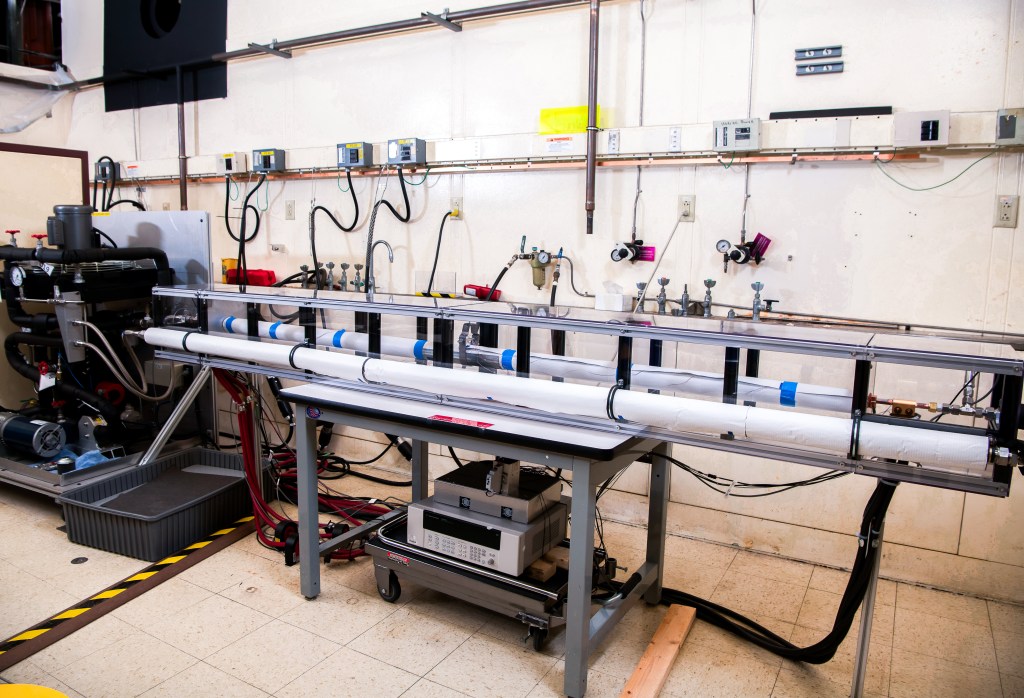

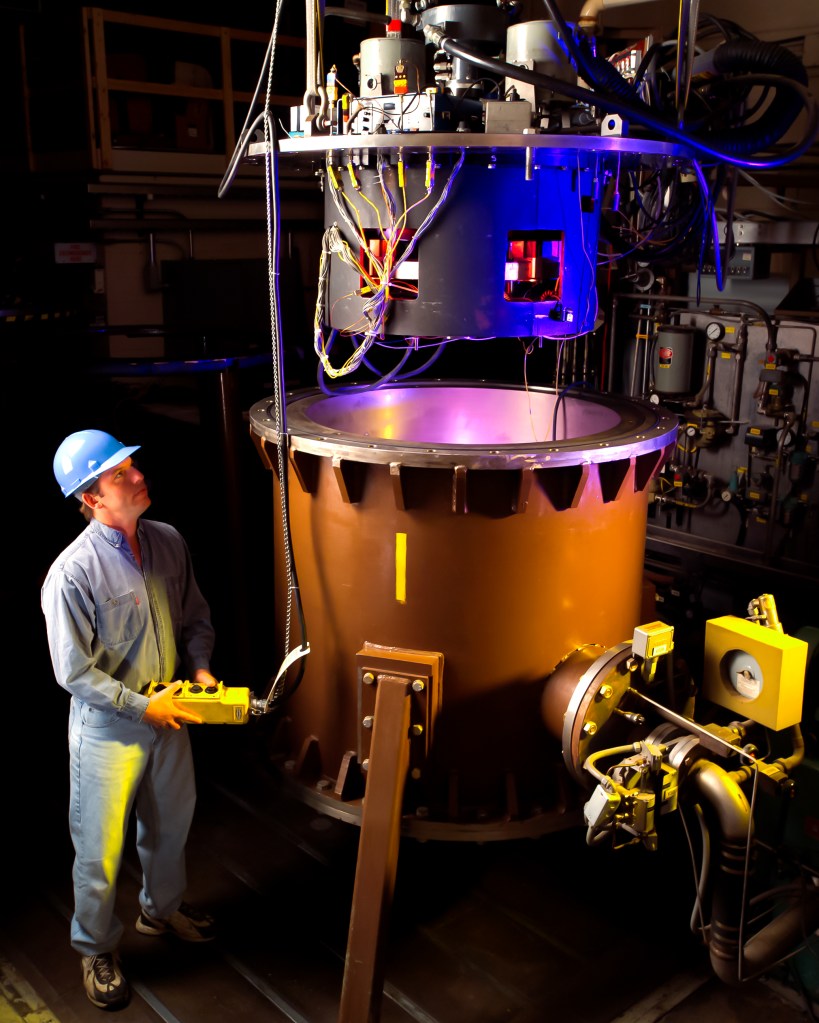

Before launch, the rocket must be certified to show it meets all design requirements before it proceeds to the integrated test, checkout and flight readiness review. Certification happens in a variety of ways. To certify the booster avionics hardware, my team takes test articles – replicas of the flight hardware– and exposes them to extreme conditions to ensure they can withstand the conditions of launch. We expose them to vibration, extreme temperature shifts and electromagnetic interference at levels far beyond what they would experience at launch. If they check out when we are done putting them through the paces, we know they will perform well in flight and keep the astronauts safe.

Our team gets to solve challenging problems through this process. For example, NASA is using batteries from the Space Shuttle Program in the SLS rocket. When we were conducting vibration testing, we learned we needed to beef up the battery so it could handle the heavier loads required for SLS.

When I’m not working on America’s next great rocket, I spend time with my family. I can’t wait to take my two children to the launches of SLS and give them the memories that I had of hearing the roar of the engines and watching history being made when the space shuttle left Earth.