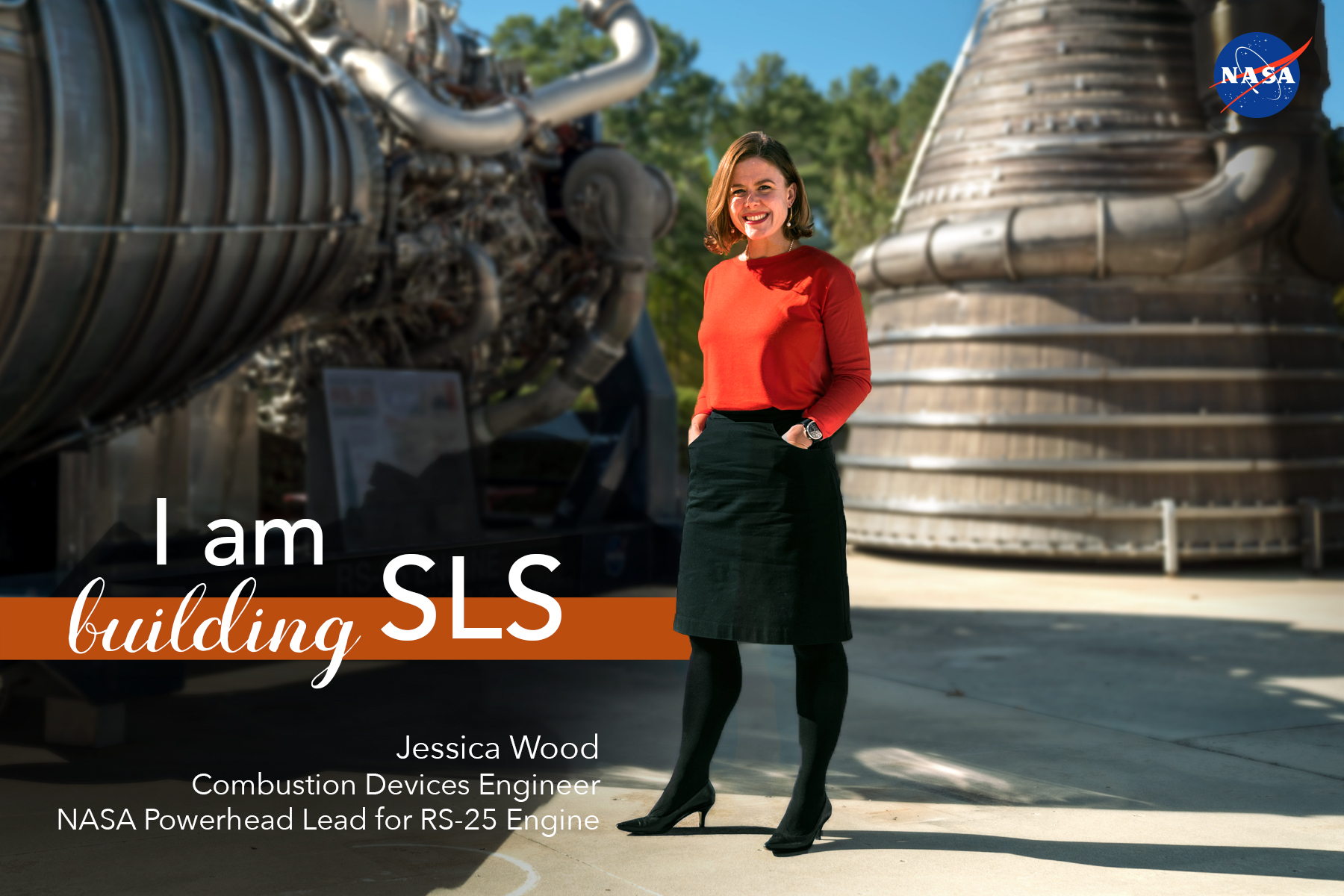

I Am Building SLS: Jessica Wood

SLS Engineer ‘Just Keeps Swimming’

My NASA journey began with my grandmother who worked for the National Advisory Committee for Aeronautics (NACA) in the 1940s before it became NASA. She worked as a computer at Langley Research Center in Hampton, Virginia, for the engineer who became the first flight director for the agency’s Johnson Space Center in Houston. I am continuing her legacy by playing a part in making history with NASA’s Space Launch System (SLS) rocket.

The spirit of exploration runs deep in my work life and personal life. I serve as the NASA combustion devices powerhead lead for the RS-25 engine at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Four RS-25 engines, built by Aerojet Rocketdyne in Canogo Park, California, will power the first flight of the SLS rocket and Orion spacecraft during Exploration Mission-1 (EM-1), as well as future missions.

My passion for exploration spills over from deep space to open-water swimming. I have conquered swims like Lake Tahoe the “long way” and the “Bridge to Bridge” 10K swim from the Golden Gate Bridge to Bay Bridge in San Francisco. Swimming the 21.3 mile length of Lake Tahoe was no easy feat, but I focused on 30 minute increments and ultimately finished in 13 hours, 21 minutes. Building rocket engines is much like a long swim in that you have to take it one step, or stroke, at a time to prevent getting overwhelmed by the big picture.

Aerojet Rocketdyne has started manufacturing brand new engines for SLS, and the powerhead is an integral part of this restart effort. The powerhead is the “backbone” of the engine, housing critical parts such as the hot gas manifold, main injector, heat exchanger, and preburners. Located directly above the main combustion chamber, the powerhead is difficult to see in an assembled RS-25 because it is located at the very center of the engine.

In addition to supporting these production engines, NASA and Aerojet Rocketdyne are currently upgrading the engine design to cut costs by 50 percent and reduce schedule by using advanced manufacturing processes. The team is developing innovative methods to manufacture parts including the powerhead, main combustion chamber and nozzle. This requires a multidisciplinary engineering, analysis and mission support team. Implementing these new designs includes partnership not only between NASA and Aerojet Rocketdyne, but also large and small manufacturers across the United States. The powerhead is a complex piece of hardware made up of thousands of individual pieces, so we look at the big picture to make sure we are both building it as efficiently as possible and ensuring that it will work just as well with parts made a new way.

I attended Georgia Institute of Technology in Atlanta, and received a Bachelor of Science in industrial design. After starting my first job at Marshall, I continued my education by earning a second Bachelor of Science in mechanical engineering from the University of Alabama in Huntsville while working on cryogenic fluid management technology at Marshall.

Whether I am helping build parts of a rocket that will send astronauts to the Moon or completing a long-distance swim — I often visit a quote from Disney’s Finding Nemo: “Just keep swimming.”

I imagine the day SLS launches will feel a lot like the final stroke of a journey in the water. I’ll take a deep breath and smile at what humankind has accomplished by achieving greater things than our minds could ever comprehend.