Lynn Rothschild

NASA Ames Research Center (ARC)

A turtle carries its habitat. While reliable, it costs energy in transporting mass. NASA makes the same trade-off when it transports habitats and other structures off planet “on the back” of its missions. While this approach is reliable, to save upmass and increase mission flexibility, NASA must be more like a bird, low mass, agile and building structures from local resources. We identified a novel biology-based solution to the in situ production of usable structures for space exploration: using fungal mycelial (myco) composites to grow structures off-planet, from habitats to furniture to tableware. As a living material it has the potential to self heal, self replicate, be bioengineered, and enhanced with materials such as metals and melanin. Prior performance: During Phase 1, we raised the TRL to 2 by assessing the growth of fungi on different food substrates and analyzing their use on Mars and Earth. In Phase II we completed TRL 3 for an integrated system of inflatables and myco-material production. We designed prototypes and subsystems. We performed proof-of-concepts analyzing myco-material function before and after exposure to relevant environments in a planetary simulator. Our Phase II report and publications documented analytical and experimental results on fungal and inflatable components of the system validating prediction of key parameters. Phase II developed the Phase I mission concept, with an Artemis-inspired focus towards lunar habitats with a “feed forward to Mars” concept.

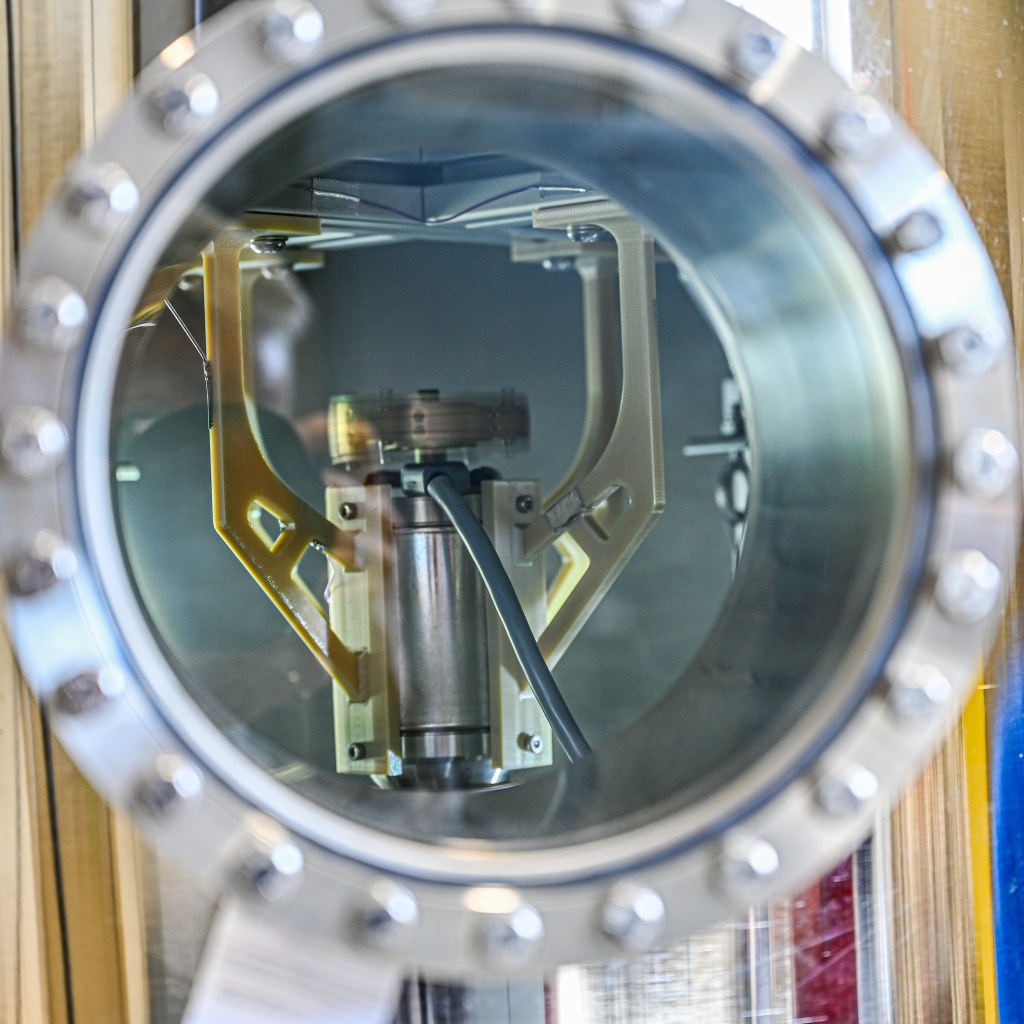

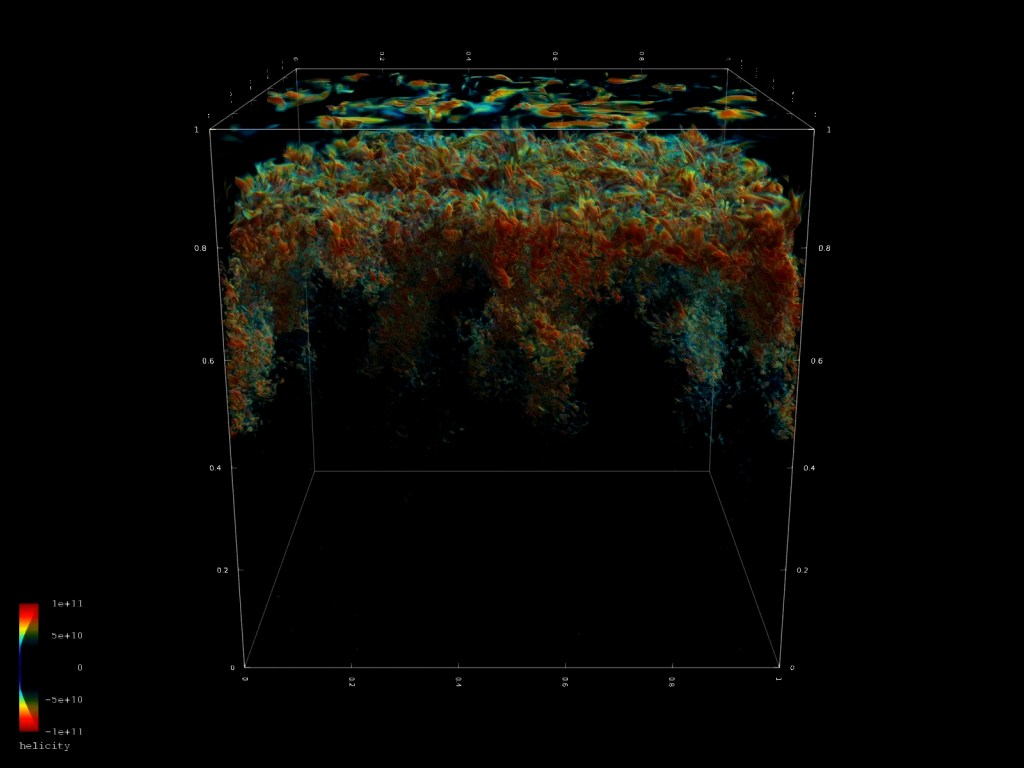

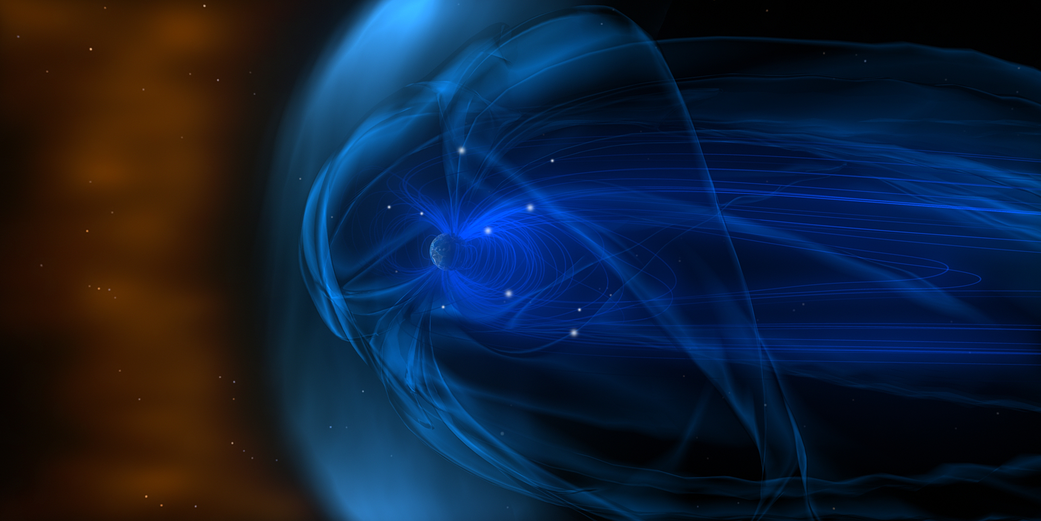

We assessed fungal/algal/bacterial mixtures by testing different combinations at different temperatures with different food sources, and developed a high throughput, reproducible method for producing fungal materials. We tested sand and regolith simulant composites for in situ material construction. We developed prototypes in silicone scale models, and a 4X4 m model of inflatable architecture and grew a mycelium dome on top. We determined the effect of simulated extraterrestrial conditions on materials showing hyphal damage under UV. By tuning different steps of production, we can change the mechanical properties of the mycelium biocomposites as they undergo compression. We incorporated melanin-producing strains into experiments and models for radiation protection. We drafted designs for mycelium-based lunar habitats. We utilized the 500-Day DRM to the Apollo 15 Hadley-Apenine Region to define science objective and infrastructure requirements to support extended exploration missions to the Moon and Mars, identifying critical gaps that can be filled by mycotecture. Archetypes were drafted per this DRM. Terrestrial applications demonstrated the spin-off potential of the NIAC technology from habitats to tableware.

Innovation and Benefits: If we succeed in developing a fungal biocomposite that can grow itself, we will provide NASA with a radically new, cheaper, faster, more flexible, lighter and sustainable material for extended duration Lunar and Mars mission habitats, as well as for furniture and other structures in flight or at destination.

Milestones and Transition Strategy: The mission context of Phase I was Martian habitats. Mindful of the more immediate focus on Artemis, Phase II focused on a lunar implementation, with a DRM for a 500 day mission to the Apollo 15 Hadley-Max region and the south polar region. En route to realizing these visions, we have identified two intermediate opportunities, both of which require NIAC Phase III funding. They are to (1) test mycotecture suitability and growth in LEO by the integration into an orbiting space station, Starlab, and (2) test mycotecture habitat prototypes on the lunar surface through a CLPS mission. To participate in Starlab, we will develop prototypes for this application and then team with Starlab LLC to raise funding to produce flight-ready structures. To be competitive for a CLPS mission, we will use NIAC funding to raise the technology to TRL6 for this lunar demo mission.