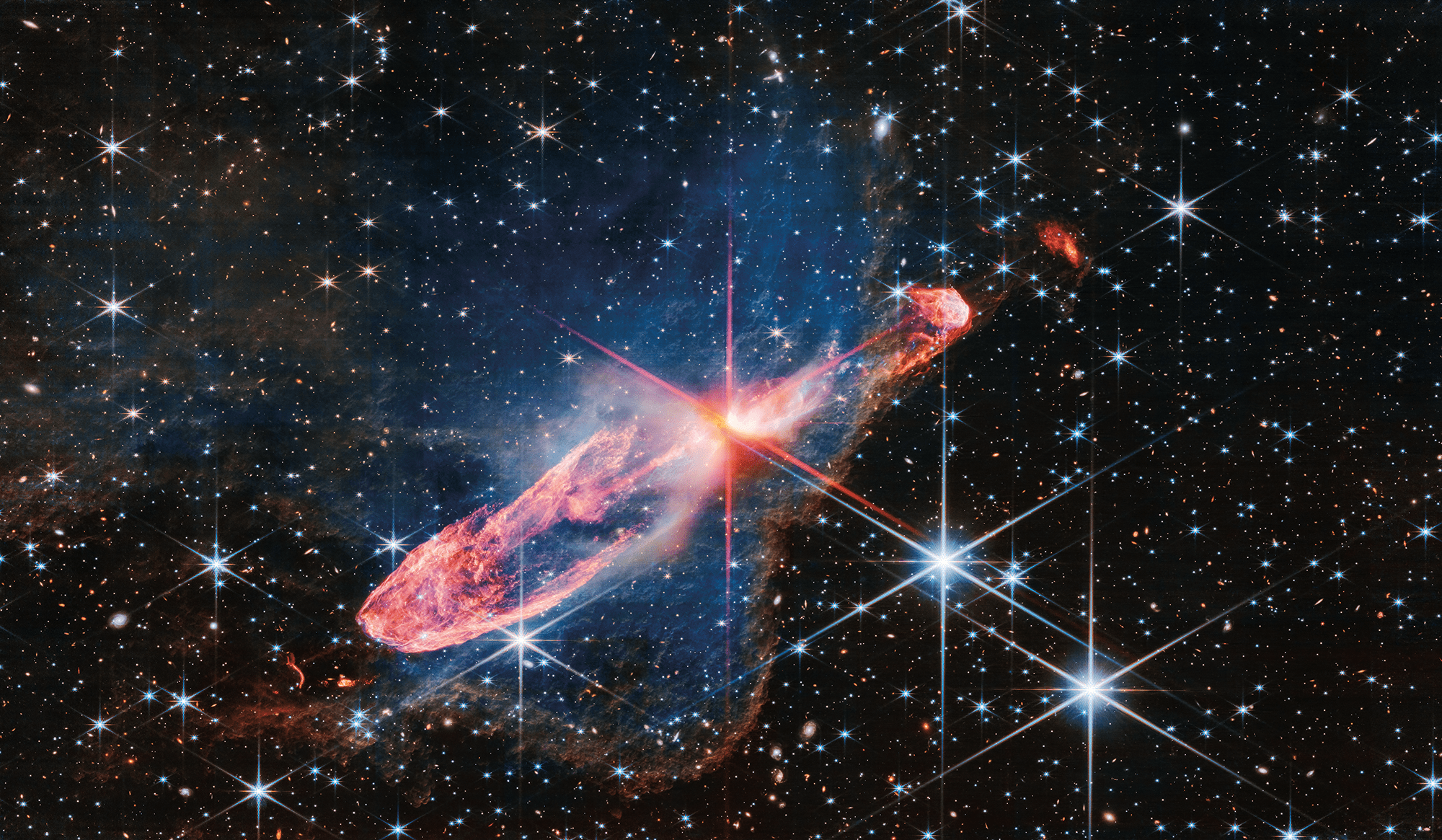

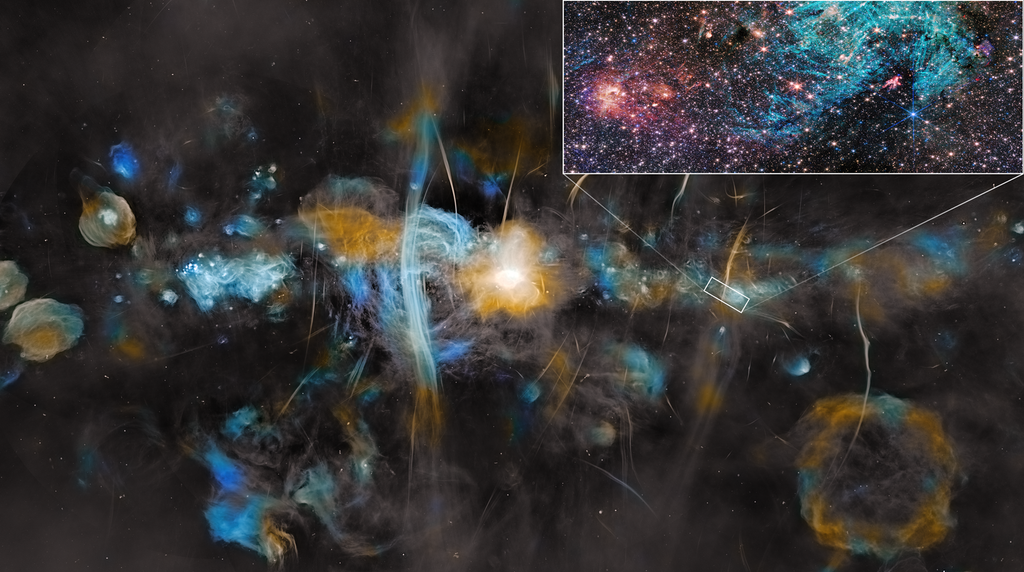

The James Webb Space Telescope truly explores the unknown, displaying stunning images of previously unseen corners of the universe only possible because of the telescope’s 21-foot segmented mirror that unfurled and assembled itself in space.

Decades of testing went into the materials, design, and processes needed to develop the largest telescope in space. However, the whole project was too complex to test on the ground, at scale, at minus 400 degrees Fahrenheit, and in other space-like conditions.

Instead, engineers relied on software simulations to understand how the telescope would behave under different in-space conditions, and that work has helped advance the whole field of integrated computer modeling.

“We pushed everything, all the simulation, just as hard as it would go,” said Erin Elliott, an optical engineer at Ansys, Inc., which makes Ansys Zemax OpticStudio, one of the design software suites used to develop hardware and software for the Webb telescope.

Simulation technology has improved dramatically over the last two decades because of increases in computing power and new ways of accessing offsite computing power as a cloud service. But additional improvements trace back directly to Webb’s development.

.Elliott used OpticStudio to support the Webb telescope while working for NASA contractors, beginning in the early 2000s, before starting work in 2015 for Zemax, which was bought in 2021 by Ansys Inc, which is headquartered in Canonsburg, Pennsylvania.

In the early days, Elliott said, Zemax tweaked its software for the Webb telescope effort. “They made some specific changes for us at the time having to do with handling the coordinate systems of the segments,” she said, referring to the 18 hexagonal segments that make up the telescope’s primary mirror.

Elliott also recalled talking to Zemax leadership numerous times about the need for the software to communicate better with other Microsoft Windows programs. The company introduced an API, or application programming interface, for OpticStudio, which enables the suite to work with other programs and allows for further customization. There were plenty of reasons to add that technology but Webb demands were likely significant among them, Elliott said.

Joseph Howard, an optical engineer at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, where Webb and its science instrument module were assembled, noted that using several modeling packages helped drive innovation in the field. “It’s important to have multiple software companies out there that can help you not only for cross-checking the modeling, but because they make each other better through competition,” he said.

In addition to improvements made to OpticStudio during Webb telescope development, the company in 2021 introduced the Structural, Thermal, Analysis, and Results (STAR) module, which benefited from the knowledge Elliott gained working on the NASA project.

When a mirror or lens changes shape due to temperature swings, the optics move. Much of the OpticStudio modeling was completed in smaller pieces — engineers would run a thermal simulation independently and add that data to the next optical model, generating more data for the next run.

The STAR module incorporates analyses from other simulation software directly into OpticStudio optical models — an efficiency applicable to telescope and aerospace designs. This feature is also increasingly important for autonomous vehicles, cell phone lenses, and other optics working in tough environments.

Future telescopes and other spacecraft are likely to involve elements of the Webb design. More will travel in segments that must self-assemble in space, and the development of the increasingly complicated robotics and optics will rely on improved modeling software.

“When we built Webb, we knew we couldn’t fully test it on the ground prior to flight, so we depended a whole lot upon modeling and doing analysis to get ready for flight,” Howard said. “The next great observatory will be even more dependent on modeling software.”

Meanwhile, designers of more earthly technologies are already seeing the benefits of an improved OpticStudio, using it to design precision endoscopes, a thermal imager to detect COVID-19 exposures in a crowd, augmented reality displays and headsets, a laser thruster technology for nanosatellites, and, of course, more telescopes.

Elliott also noted that the Webb telescope project trained the next cohort of telescope and optical device builders – those designing and using the telescope’s technological spinoffs.

“The people who built the Hubble Space Telescope were leading the Webb Telescope,” she said. “And now the younger engineers who cut our teeth on this project and learned from it are becoming the group of people who will build the next structures.”

Elliott maintains that the project “was worth it alone for training this huge cohort of young engineers and releasing them into high-tech fields.”

NASA has a long history of transferring technology to the private sector. The agency’s Spinoff publication profiles NASA technologies that have transformed into commercial products and services, demonstrating the broader benefits of America’s investment in its space program. Spinoff is a publication of the Technology Transfer program in NASA’s Space Technology Mission Directorate (STMD).

For more information on how NASA brings space technology down to Earth, visit:

/quantum_physics_bose_einstein_condensate.jpg?w=1024)